Titan Mining Announces Significant Graphite Discovery at Empire State Mines in Upstate New York, USA

Titan Mining Corporation (TSX:TI) is pleased to announce the discovery of the Kilbourne graphite trend, an extensively drill tested graphite-bearing trend located on the permitted lands hosting Titan’s currently operating Empire State Mine in upstate New York.

Highlights

- At or near surface targets with geological potential totaling between 210 and 1,050 million tons grading between 2.0% and 4.5% graphitic carbon

- Flake graphite is a key input to the auto industry battery supply chain and designated as a Critical Material by the United States Department of Energy

- There is no domestic source of flake graphite production; China, which accounts for more than half of global production, has recently announced export restrictions that may threaten the market

- ESM lands hosting the Kilbourne graphite trend are fully permitted for drilling with some portions of these lands also currently permitted for mining

- Aggressive plan to fast-track exploration and development with goal of being first domestic supplier of materials to the auto industry battery market

Donald Taylor, President and CEO of the Company, commented, “Natural flake graphite is a critical material in the production of lithium-ion batteries with significant and increasing demand. The confirmation of a global scale flake graphite target on the Company’s land package is an especially significant development in the history of the Company.”

Titan Director and Former Speaker of the United States House of Representatives John Boehner said, “This could be extremely attractive and strategically important for America to secure a domestic supply of graphite which is the biggest component of the growing electric vehicle battery industry.”

The Company believes that the Kilbourne target has the potential to host between 3.36 Mt and 26.25 Mt of Cg, contained within 210 to 1,050 Mt grading 2.0% to 4.5% Cg. The potential tonnages and grades are conceptual in nature and have been estimated using the available drill data, with extents restricted to areas of accessibility and probability of extraction. There has been insufficient exploration to define a current mineral resource and the Company cautions that there is a risk further exploration will not result in the delineation of a current mineral resource.

The Kilbourne target was generated through the review of historic geologic data, recent drilling and assays within the known stratigraphic sequence that hosts Empire State Mines’ zinc ore bodies. The high metamorphic grade of the host rocks has increased the size and morphology of the contained graphite to flake sizes.

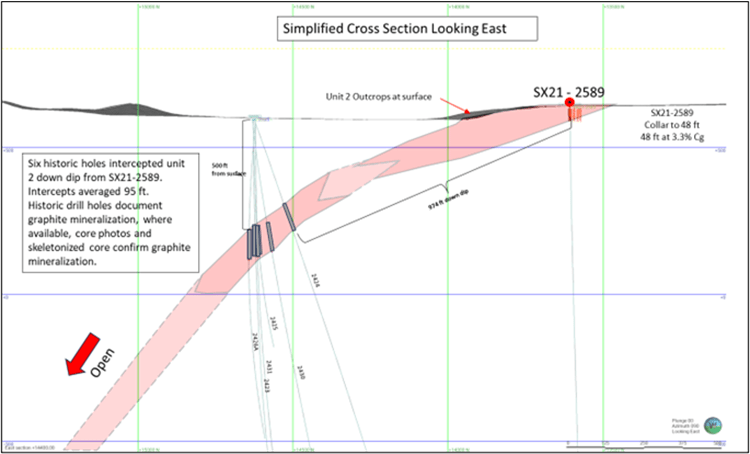

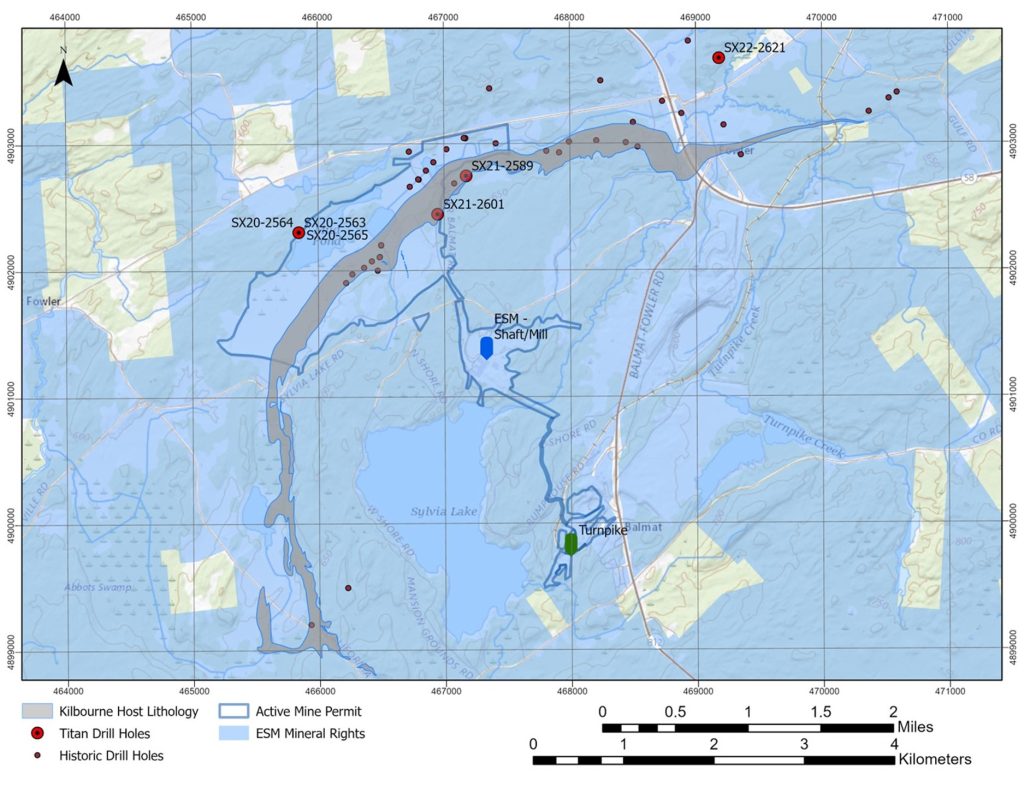

Fifty-three drill holes have tested the Kilbourne target. All 53 drill holes contain graphite however, to date only six of the holes have been assayed for Cg (Table 1/Figure 1 and 2). Based on the grades of the initial samples and large volumes of the potentially mineralized areas, the Company has retained an independent laboratory for continued testing and evaluation to determine the quality and character of the concentrated graphite product.

The presence of graphite mineralization in the district is well documented, with historic exploration and very limited production occurring in the first half of the 20th century. The Company currently holds over 80,000 acres of mineral rights within St. Lawrence County, NY and will continue to evaluate historic occurrences, prospective lithologies, and geophysical data to aid in identifying additional graphite exploration targets within the district.

Figure 1: Cross section looking east highlighting the downdip continuity of the #2 geologic unit which host the Kilbourne mineralization.

Table 1: Kilbourne Drilling Intercepts

| 2020-2022 Kilbourne Drilling | |||||||

| Hole ID | From (ft) | To (ft) | Interval (ft) | From (m) | To (m) | Interval (m) | Cg% |

| SX20-2563 | 632.3 | 665.6 | 33.3 | 192.7 | 202.9 | 10.1 | 3.1 |

| 673.9 | 697.0 | 23.1 | 205.4 | 212.4 | 7.0 | 1.5 | |

| 723.1 | 760.8 | 37.7 | 220.4 | 231.9 | 11.5 | 2.3 | |

| SX20-2564 | 652.0 | 742.5 | 90.5 | 198.7 | 226.3 | 27.6 | 2.3 |

| SX20-2565 | 612.0 | 642.0 | 30.0 | 186.5 | 195.7 | 9.1 | 3.1 |

| 742.0 | 768.1 | 26.1 | 226.2 | 234.1 | 8.0 | 1.9 | |

| SX21-2589 | 0.0 | 47.9 | 47.9 | 0.0 | 14.6 | 14.6 | 3.3 |

| SX21-2601 | 70.0 | 101.2 | 31.2 | 21.3 | 30.8 | 9.5 | 2.1 |

| SX22-2621 | 1,031.9 | 1,140.0 | 108.1 | 314.5 | 347.5 | 32.9 | 2.6 |

| 1,243.9 | 1,255.0 | 11.1 | 379.1 | 382.5 | 3.4 | 1.9 | |

| 1,310.0 | 1,350.0 | 40.0 | 399.3 | 411.5 | 12.2 | 3.1 | |

| 1,375.0 | 1,400.0 | 25.0 | 419.1 | 426.7 | 7.6 | 2.1 | |

| 1,465.0 | 1,831.0 | 366.0 | 446.5 | 558.1 | 111.6 | 2.2 | |

| Including | 1,495.0 | 1,510.0 | 15.0 | 455.7 | 460.2 | 4.6 | 3.3 |

| and | 1,530.0 | 1,560.0 | 30.0 | 466.3 | 475.5 | 9.1 | 3.5 |

| and | 1,695.0 | 1,831.0 | 136.0 | 516.6 | 558.1 | 41.5 | 3.1 |

Figure 2: Relative location of Kilbourne drilling and ESM’s #4 Mine and the Turnpike project. The mineralized horizon has a mapped surface expression over 27,000 ft in length. The Blue shading represents Titan held mineral rights and the grey shading represents the Kilbourne host lithology.

Table 2: Kilbourne Collar Information (NAD 1983 UTM Zone 18N)

| Collars | ||||||

| Hole ID | Length (ft) | Easting (m) | Northing (m) | Elevation (m) | Azimuth | Dip |

| SX20-2563 | 3153 | 465846 | 4902302 | 186.010 | 120 | -55 |

| SX20-2564 | 3487 | 465846 | 4902302 | 186.010 | 125 | -63 |

| SX20-2565 | 3407 | 465846 | 4902302 | 186.100 | 125 | -50 |

| SX21-2589 | 2287 | 467176 | 4902744 | 186.000 | 0 | -90 |

| SX21-2601 | 1877 | 466948 | 4902442 | 193.000 | 0 | -90 |

| SX22-2621 | 3487 | 469184 | 4903668 | 182.837 | 150 | -70 |

Graphite Overview

Graphite is a form of pure carbon that occurs naturally as black crystal flakes and masses. It is chemically inert, thermally stable, has a high electrical conductivity, and is a natural lubricant. These properties make graphite suitable for both industrial (refractories, foundries, lubricants) and energy (batteries, fuel cells, and nuclear reactors) applications. Graphite occurs naturally or may be synthetically produced from hydrocarbon precursor materials. Naturally occurring graphite is classified into three categories, amorphous, flake, and lump. Of these, flake graphite is used in the production of lithium-ion batteries (LIBs). The mineralization intercepted by Titan is dominated by crystalline flakes of graphite and may be suitable for use in battery production.

Currently there are no domestic sources for natural flake graphite in the United States, while China produces in excess of 60% of the world’s graphite supply. The United States Department of Energy projects that demand for graphite will exceed production by 79% in 2025. By the year 2035 that gap between production and demand is projected to range from 34% up to 822%. Even with developments elsewhere in world, China is expected to maintain their global dominance.

Graphite is the primary anode material, regardless of battery chemistry, for LIBs. Representing nearly 50% by weight of the contained material in an LIB. Both synthetic graphite and natural graphite may be used in the production of LIBs. Synthetic graphite is manufactured from hydrocarbon sources using high-temperature heat treatment, this is called graphitization, it requires large amounts of energy and is more expensive to produce than natural graphite. The projected upward trends of demand and production cost of synthetic graphite are expected to lead to increased use of natural flake graphite in battery applications.

The lack of domestic source, concerns with supply security, and projected demand have earned graphite a place on the United States Department of Energy’s critical materials list. Currently the US is seeing a boom in the construction of battery plants and Electric Vehicle (EV) manufacturing facilities, adding urgency to developing a domestic graphite supply chain. The high costs of synthetic graphite, financially and environmentally, point to natural graphite as an increasing source in the production of EVs and LIBs. This may prove particularly true as ESG concerns tied the sourcing of critical materials continues to grow.

The US currently only has 2 graphite deposits at pre-feasibility stage or beyond. These are the Graphite Creek Deposit in Alaska and the Coosa Graphite project in Alabama.

Qualified Person

The scientific and technical information contained in this news release relating to the Kilbourne target and the sampling, analytical and test data underlying the scientific and technical information has been reviewed, verified and approved by Donald R. Taylor, MSc., PG, President and Chief Executive Officer of the Company, a qualified person for the purposes of NI 43-101. Mr. Taylor has more than 25 years of mineral exploration and mining experience and is a Registered Professional Geologist through the SME (registered member #4029597). The data was verified using data validation and quality assurance procedures under high industry standards.

Assays and Quality Assurance/Quality Control

To ensure reliable sample results, the Company has a rigorous QA/QC program in place that monitors the chain-of-custody of samples and includes the insertion of blanks and certified reference standards at statistically derived intervals within each batch of samples. Core is photographed and split in half with one-half retained in a secured facility for verification purposes.

Analysis has been performed as SGS Canada Inc. an independent ISO/IEC accredited lab. Sample preparation (crushing and pulverizing) and total graphitic carbon analysis has been completed at SGS Lakefield, Ontario, Canada. SGS prepares a pulp of all samples and sends the pulps to their analytical laboratory in Burnaby, B.C., Canada for multielement analysis. SGS analyzes the pulp sample by leach and IR combustion for total graphitic carbon (GC_CSA05V) and aqua regia digestion (GE-ICP21B20 for 34 elements) with an ICP – OES finish including Cu (copper), Pb (lead), and Zn (zinc). All samples in which Cu (copper), Pb (lead), or Zn (zinc) are greater than 10,000 ppm are re-run using aqua regia digestion (GO_ICP21B100) with the elements reported in percentage (%).

Additional sample preparation (crushing and pulverizing) has been performed at ALS Geochemistry, an independent ISO/IEC accredited lab located in Sudbury, Ontario, Canada. ALS prepares a pulp of all samples and sends the pulps to their analytical laboratory in Vancouver, B.C., Canada, for analysis. ALS analyzes the pulp sample by an aqua regia digestion (ME-ICP41 for 35 elements) with an ICP – AES finish including Cu (copper), Pb (lead), and Zn (zinc). All samples in which Cu (copper), Pb (lead), or Zn (zinc) are greater than 10,000 ppm are re-run using aqua regia digestion (Cu-OG46; Pb-OG46; and Zn-OG46) with the elements reported in percentage (%). Silver values are determined by an aqua regia digestion with an ICP-AES finish (ME-ICP41) with all samples with silver values greater than 100 ppm repeated using an aqua regia digestion overlimit method (Ag-OG46) calibrated for higher levels of silver contained. Gold values are determined by a 30 g fire assay with an ICP-AES finish (Au-ICP21). Graphite values are determined by leach and induction furnace/IR (C-IR18).

The Company has not identified any drilling, sampling, recovery, or other factors that could materially affect the accuracy or reliability of the data set out in this news release. True widths of the mineralized zones described in this news release are not presently known.

About Titan Mining Corporation

Titan is an Augusta Group company which produces zinc concentrate at its 100%-owned Empire State Mine located in New York state. Titan is built for growth, focused on value and committed to excellence.

MORE or "UNCATEGORIZED"

Eloro Resources Announces Closing of Bought Deal LIFE Private Placement for Gross Proceeds of C$17 Million

Eloro Resources Ltd. (TSX: ELO) (FSE: P2QM) is pleased to announce the closing of its previously an... READ MORE

Minera Alamos Updates Resources and Reserves for the Pan Gold Mine in Nevada

Minera Alamos Inc. (TSX-V: MAI) (OTCQX: MAIFF) is pleased to announce updated Mineral Resource and M... READ MORE

Ero Copper Reports Fourth Quarter and Full Year 2025 Operating and Financial Results

Ero Copper Corp. (TSX: ERO) (NYSE: ERO) is pleased to announce its operating and financial results f... READ MORE

Rare Element Resources Announces Results of Oversubscribed Rights Offering of Common Shares

Rare Element Resources Ltd. (OTCQB: REEMF) is pleased to report that its previously announced... READ MORE

TRX Gold Reports Record Q2 2026 Production and Company Update

TRX Gold Corporation (TSX: TRX) (NYSE American: TRX) is pleased to announce preliminary resu... READ MORE