Northisle Announces Near Surface Intercepts and Higher-Grade Intercepts at Depth at West Goodspeed on its North Island Project

Highlights:

- Recent drilling at West Goodspeed supports the presence of wide intervals of copper-gold-molybdenum-rhenium mineralization within previously untested portions of the West Goodspeed mineralization outline.

- Selected copper equivalent assay intercepts (based on Cu, Au, Mo and Re assays) include:

- GS25-17: 47.5m grading 0.70% Cu Eq. from 155m, within 70m grading 0.58% Cu Eq. from 145m plus 34m grading 0.48% Cu Eq. from 71m within 82m grading 0.40% Cu Eq. from 59m

- GS25-18: 19m grading 0.96% Cu Eq. from 303.5m, within 72.5m of 0.54% Cu Eq. from 282.5m, which also included 15m grading 0.59% Cu Eq. from 340m.

- This hole also intersected 20m grading 0.42% Cu Eq. from 260m, within 35m grading 0.35% Cu Eq. from 245m, and 10m grading 0.36% Cu Eq. from 215m

- GS25-19: 10m grading 0.42% Cu Eq. from 220m

- GS25-20: 45m grading 0.59% Cu Eq. from 237m, within 81m grading 0.47% Cu Eq. from 204m plus 36m grading 0.32% Cu Eq. from 90m and 15m grading 0.33% Cu Eq. from 294m

- As of June 26, 2025, Northisle has now completed a total of 5,126 metres of drilling including 3,550 metres in the West Goodspeed and Red Dog area, and an additional 1,515 metres at the Cougar target, located approximately 1.5 kilometres northeast of the Northwest Expo deposit.

Northisle Copper and Gold Inc. (TSX-V: NCX) (OTCQX: NTCPF) is pleased to announce initial results from its 2025 exploration campaign, with four drill holes at the West Goodspeed target and the successful mobilization of a Scan by Veracio mobile XRF scanning system to the North Island Project. The results, and the addition of the scanning system, represent key steps in Northisle’s 2025 exploration strategy, focused on increasing higher-margin resources in the Northwest Corridor and accelerating target generation across the 35-kilometre North Island Project porphyry belt.

Sam Lee, President and CEO stated “Drilling at West Goodspeed continues to reinforce the potential for near-surface deposits in the Northwest Corridor. We are encouraged by the continuity of mineralization, including in the higher-grade zones at depth. The intercepts observed in multiple holes underscore the strength of the system outlined at West Goodspeed during the 2023 and 2024 campaigns and the growing understanding of the mineralized system in this area.”

Discussion of Drill Results

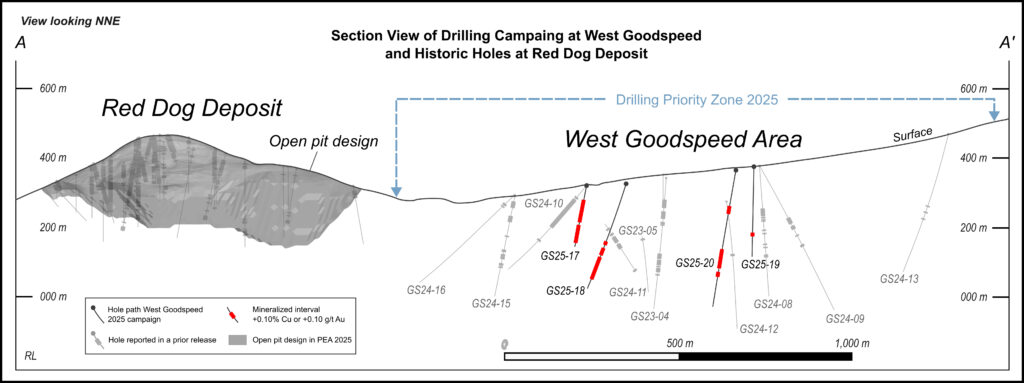

Initial results from the current drilling campaign at West Goodspeed confirm the presence of copper-gold mineralization extending from shallow levels to depths of approximately 250 metres below the surface. Preliminary interpretation suggests that mineralized intervals are wider in the northwest sector compared to the eastern portion of the target area, consistent with 2024 drilling results. Notably, hole GS24‑10 intersected 210 metres of consistent mineralization from near surface, including a 68 metres interval of higher-grade material (see news release dated August 19, 2024). These results show above average length-grade profiles for both copper and gold compared to the drilling results obtained in 2024 at West Goodspeed.

While the geometry of the mineralized zone remains under evaluation, the drilling core seems to indicate a structurally controlled system bounded by two NW-SE–oriented faults spaced approximately 250 metres apart. Copper and gold grades appear to be concentrated within this corridor. All four reported holes show evidence of internal dynamic fabric and brittle deformation textures, suggesting that the mineralization was influenced by post-mineralization fault activity. In several cases, post-mineralization dykes were observed cross-cutting the mineralized zones, potentially affecting local continuity within the fault-bounded system.

Selected intervals from holes GS25-17 through GS25-20 are summarized in Table 1 below.

| Table 1: West Goodspeed 2025 Significant Intercepts | |||||||||||

| Hole ID | From

(m) |

To

(m) |

Interval

(m) |

Cu Grade

(%) |

Au Grade

(g/t) |

Mo Grade

(ppm) |

Re Grade

(g/t) |

Cu Eq.

Grade (%) |

Au Eq.

Grade (g/t) |

||

| GS25-17 | 59.0 | 141.0 | 82.0 | 0.20 | 0.20 | 84.96 | 0.60 | 0.40 | 0.54 | ||

| Including | 71.0 | 105.0 | 34.0 | 0.25 | 0.24 | 84.22 | 0.55 | 0.48 | 0.64 | ||

| And | 145.0 | 215.0 | 70.0 | 0.25 | 0.35 | 97.83 | 0.62 | 0.58 | 0.77 | ||

| Including | 155.0 | 202.5 | 47.5 | 0.30 | 0.47 | 74.15 | 0.50 | 0.70 | 0.94 | ||

| GS25-18 | 215.0 | 225.0 | 10.0 | 0.25 | 0.14 | 19.62 | 0.12 | 0.36 | 0.49 | ||

| And | 245.0 | 280.0 | 35.0 | 0.22 | 0.16 | 24.38 | 0.13 | 0.35 | 0.47 | ||

| Including | 260.0 | 280.0 | 20.0 | 0.26 | 0.19 | 30.90 | 0.18 | 0.42 | 0.57 | ||

| And | 282.5 | 355.0 | 72.5 | 0.32 | 0.20 | 119.87 | 0.53 | 0.54 | 0.73 | ||

| Including | 303.5 | 322.5 | 19.0 | 0.49 | 0.45 | 207.65 | 1.09 | 0.96 | 1.29 | ||

| Also including | 340.0 | 355.0 | 15.0 | 0.45 | 0.13 | 82.86 | 0.24 | 0.59 | 0.79 | ||

| GS25-19 | 220.0 | 230.0 | 10.0 | 0.18 | 0.15 | 165.29 | 1.71 | 0.42 | 0.56 | ||

| GS25-20 | 90.0 | 126.0 | 36.0 | 0.13 | 0.19 | 73.81 | 0.49 | 0.32 | 0.43 | ||

| And | 204.0 | 285.0 | 81.0 | 0.23 | 0.21 | 104.63 | 0.94 | 0.47 | 0.62 | ||

| Including | 237.0 | 282.0 | 45.0 | 0.30 | 0.26 | 146.09 | 1.29 | 0.59 | 0.80 | ||

| And | 294.0 | 309.0 | 15.0 | 0.17 | 0.13 | 100.94 | 0.62 | 0.33 | 0.44 | ||

Note on equivalent calculation for West Goodspeed:

Copper equivalent grade is determined by calculating total contained metal value per tonne, adjusted for recoveries, if known, dividing by the copper price, and then dividing the resultant number of pounds of copper by 2204.6. Gold equivalent grade is determined by calculating total contained metal value/tonne, adjusted for recoveries, if known, dividing by the gold price, and then multiplying the resultant number of troy ounces of gold by 31.103. Analyzed metal equivalent calculations are reported for illustrative purposes only and assume 100% recoveries as metallurgical testing has not yet been completed on material from the West Goodspeed target.

Copper and gold equivalent calculations based on the following metal prices which were used in the Company’s 2025 Preliminary Economic Assessment for North Island: Cu = US$4.20/lb, Au = US$2,150/oz, Mo = US$21/lb, Re = US$1,950/kg. Intervals were selected based on continuous intercepts with a copper grade above 0.1% Cu or a gold grade above 0.1g/t Au. Totals may not add due to rounding.

Intervals are drill intersections and not necessarily true widths. True widths cannot be provided at this time due to the uncertainty in the geometry of the mineralization. Drill intersections have been selected and composites calculated independently by Northisle. The locations and distances highlighted on all maps in this news release are approximate.

Collar locations for the drill holes are detailed in Table 2. There are no material drilling, sampling, recovery, or other factors known that could materially affect the accuracy or reliability of the assay data.

| Table 2: West Goodspeed 2025 Drill Hole Collar Locations | ||||||||

| Hole ID | Length

(m) |

UTM

East |

UTM

North |

UTM

Elevation |

Azimuth

(deg) |

Dip

(deg) |

||

| NW25-17 | 231 | 573462 | 5617614 | 324.11 | 210 | -49.3 | ||

| NW25-18 | 393 | 573619 | 5617731 | 323.39 | 220 | -49.5 | ||

| NW25-19 | 300 | 573887 | 5617367 | 376.71 | 200 | -59.9 | ||

| NW25-20 | 399 | 573825 | 5617349 | 364.43 | 280 | -80.0 | ||

| Coordinates are reported in UTM Zone 9 North (WGS 84 datum, EPSG:32609), with units in metres | ||||||||

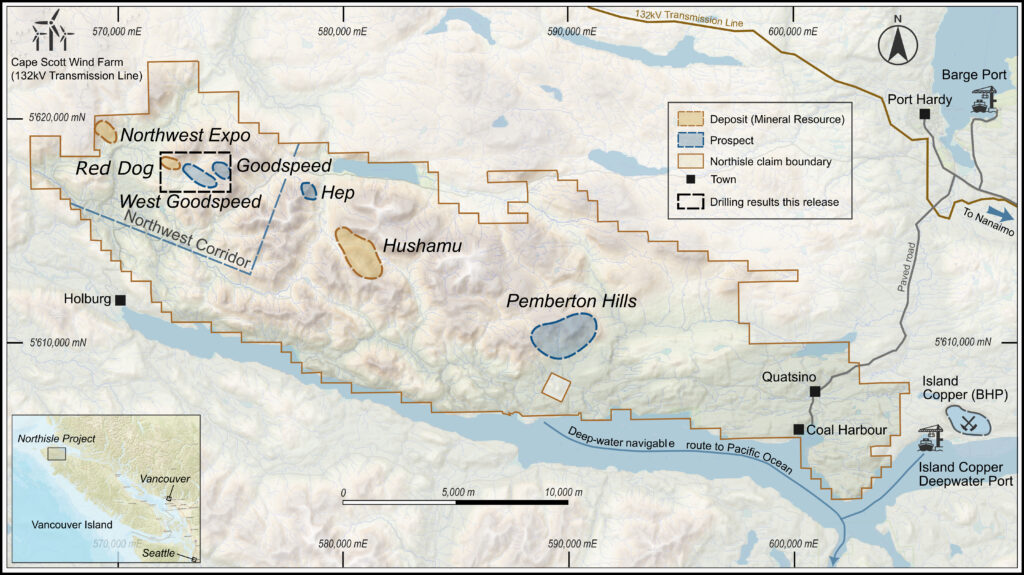

Figure 1 shows a map of the overall North Island Project including existing deposits and key prospects.

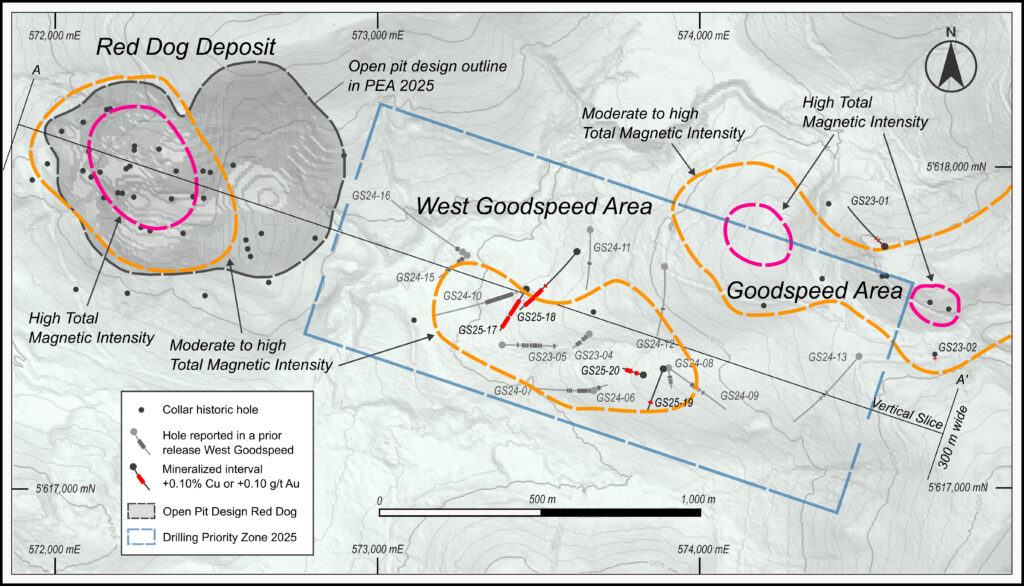

Figure 2 shows the location of the drill holes announced in this press release in context with other drilling in the West Goodspeed area, while Figure 3 shows the drilling on a longitudinal section through Red Dog and West Goodspeed.

2025 Exploration Program Advancing Rapidly

The drill results described above, and the mobilization of the Scan by Veracio system described below are part of the Company’s broader 2025 exploration program which builds on the successful 2025 Preliminary Economic Assessment on the North Island Project which demonstrated an after-tax 29% IRR, $2 billion NPV and 1.9-year payback for a C$1.1 billion capex1. The 2025 program includes:

- Advanced geophysical interpretation and soil geochemistry across the Northwest Corridor

- Expansion drilling at West Goodspeed and Northwest Expo areas

- Regional stream sediment surveys and regional geophysical integration to define new potential areas of interest aiming to discover new porphyry mineralization centers over the full belt

As of June 26, 2025, Northisle has completed a total of 5,126 metres of drilling at the North Island Project. This includes twelve drill holes totaling 3,554 metres at West Goodspeed, three holes totaling 1,315 metres at the Cougar target in the Northwest Expo area, one 342-metre hole at the Goodspeed prospect, and one 257-metre hole at Red Dog testing the potential northwest extension of West Goodspeed towards the northwest.

Expected Key exploration milestones include the following:

- COMPLETED – Updated Preliminary Economic Assessment on North Island Project

- COMPLETED – 2025 Exploration Program Commenced

- COMPLETED – Initial results from drilling program at West Goodspeed

- Q3 2025 – Results of belt-wide geophysical data integration for the North Island Project

- Q3 2025 – Initial results from Northwest Expo Area drilling aimed at discovering extensions of the high-grade gold mineralization at the Northwest Expo deposit

- Q3 2025 – Results from regional stream sediment survey to identify additional porphyry centres in the belt

- Q3 2025 – Results from the Northwest Corridor soil geochemistry program to refine target definition in this segment of the belt

- Q3 2025 – Commencement of Phase V exploration program

- Ongoing – Continued positive engagement with indigenous rightsholders and local stakeholders

Additional details on development milestones will be shared later in 2025.

Scan by Veracio Unit Mobilized to Enhance Real-Time Decision Making

A Scan by Veracio mobile scanning system has been mobilized to the North Island Project. This unique, patented technology delivers rapid, high-resolution scanning and multi-element geochemistry of drill core in near-real time. By providing timely access to verifiable geological and geochemical data, Scan by Veracio enables the Northisle team to make timely, informed decisions during active drilling. This includes refining drill targeting, adjusting hole orientations, and reallocating meterage based on live results, ultimately increasing the efficiency of the program while reducing delays and operational costs.

Pablo Mejia, Vice President Exploration stated “The addition of the Scan by Veracio mobile XRF device is anticipated to support Northisle’s ongoing exploration program by improving our real-time decision making through near-instantaneous feedback on drill core. In addition, we will be scanning previously drilled core from the 2025 program as well as previous years to gain a better understanding of the mineral composition. XRF scanning has been a valuable tool at the North Island Project, and we look forward to leveraging this technology to further enhance our efforts.”

The Scan by Veracio unit, which is about the size of a cargo van, contains sophisticated software and XRF scanning equipment that analyzes drill core to detect and measure copper, molybdenum and other associated elements. Each element present in a sample produces a set of characteristic fluorescent X-rays (a fingerprint) that is unique to that specific element.

Additional Technical Details

Logging, Sampling and Assaying Procedures and QA/QC

The diamond drill core logging and sampling program was carried out under a rigorous quality assurance / quality control program. Drill intersections in this release are typically HQ to 150 metres and NQ thereafter to the end of holes. After drilling, core was logged for geology, structure, and geotechnical characteristics utilizing MX Deposit —core logging software, then marked for sampling and photographed on site. The cores for analyses were marked for sampling based on geological intervals with individual samples of 3-metre length or less. Drill core was cut lengthwise in half with a core saw. Half-core was sent for assays reported in this news release. Prior to cutting core for assay bulk density was also determined on site by taking 15 to 20-centimetre (cm) length of whole core of each lithology at 10-metre intervals. The ends of these were then cut at right angle to the core axis, retaining all pieces to be returned to the core box for later sample cutting and analysis. The diameter of each core sampled for bulk density was measured at each end with digital calipers to 3 decimal places and recorded. The length of the core was measured on four sides at 90 degrees to each other, to 2 decimal places and recorded. The software averaged the lengths and diameters. The mass of the dry core was measured twice on an Ohaus© balance to 2 decimal places. If no discrepancy occurred, the measurement was recorded. If there was a discrepancy the measuring was repeated until no discrepancy between 2 measurements occurred. The density was calculated using the formula Bulk Density = π times r² times h (where r is radius of core and h is length of core). Certified standard masses are used to calibrate the scale balance used for bulk density determinations. The balance in the core logging area was levelled on a large concrete block to avoid vibration, and surrounded by a wooden partition to avoid wind affecting the balance. The measurements were recorded in MX Deposit and Bulk Density calculated to 2 decimal places.

A total of +7% assay standards or blanks and +3% core duplicates are included in the sample stream as a quality control measure and are reviewed after analyses are received. Standards and Blanks were obtained from CDN Resource Laboratories, Langley, British Columbia. Blanks were obtained from unmineralized course bagged limestone landscaping rock. Standards and blanks in 2025 drill results to date have been approved as acceptable. Duplicate data add to the long-term estimates of precision for assay data on the project and precision for drill results reported is deemed to be within acceptable levels. Samples were sent to the MSALABS in Langley, British Columbia, where the samples were dried, then crushed, split and a 250-gram (g) split was pulverized to 85% passing -200 mesh (-75 micrometres (µm)) size pulps. Clean crush material was passed through the crusher, and clean silica was pulverized between each sample. The pulps were analyzed for gold by fire assay fusion of 50 g of the 250 g split. Total gold content was determined by digesting the silver doré bead from the fusion and then analysing by AA (MSA Code FAS-121). All samples were also analyzed for multiple elements by taking a 0.25 g of the 250 g split which was heated in HNO3, HClO4 and HF to fuming and taken to dryness. The residue was dissolved in HCl and then analyzed utilizing ICP-MS (MSA Code IMS-230). Any sulphur analysis from this latter analysis with a value greater than 10% was reanalyzed utilizing a Leco sulfur analyzer. Iron and Tungsten accelerators are added to the sample and a stream of oxygen is passed over the sample in the induction furnace. As the sample is heated, sulfur dioxide released from the sample is measured by an IR detection system and the Total Sulphur content is determined. (MSA Code SPM-210). MSALABS (Langley) is an independent, international ISO/IEC 17025:2005 accredited laboratory.

Pulps and rejects of holes with significant assay intervals are stored at Western Mineral Storage. The remaining split core is indexed and stored at the Company’s logging and office facility in Port Hardy, BC.

Drill Results in this news release are length weighted averages.

Qualified Persons and Data Verification

Dr. Pablo Mejia Herrera, P.Geo., Vice President Exploration of Northisle and a Qualified Person as defined by National Instrument 43-101 – Standards of Disclosure for Mineral Projects, has reviewed and approved the scientific and technical information contained in this news release. Dr. Mejia Herrera has verified the underlying data, including through multiple visits to drill sites, oversight of sample preparation protocols, and review of the QA/QC procedures applied to analytical results received from MSALABS.

About Northisle

Northisle Copper and Gold Inc. is a Vancouver-based company whose mission is to become Canada’s leading sustainable mineral resource company for the future. Northisle, through its 100% owned subsidiary North Island Mining Corp., owns the North Island Project, which is one of the most promising copper and gold porphyry projects in Canada. The North Island Project is located near Port Hardy, British Columbia on a more than 34,000-hectare block of mineral titles 100% owned by Northisle on a belt stretching 50 kilometres northwest from the now closed Island Copper Mine operated by BHP Billiton. Since 2021, the Company has discovered two significant deposits, expanded resources, demonstrated the economic potential of the project, and is now focused on accelerating the advancement of this compelling project while exploring within this highly prospective land package.

Figure 1: North Island Property Showing Location of Deposits and Prospects

Figure 2: West Goodspeed Area Drilling with Magnetic Anomalies

Figure 3: Section View of Red Dog and West Goodspeed

MORE or "UNCATEGORIZED"

Helius Minerals Announces Closing of C$40 Million Private Placement

Helius Minerals Limited (TSX-V: HHH) is pleased to announce the... READ MORE

Aldebaran Announces Closing of $40 Million Bought Deal Offering

Aldebaran Resources Inc. (TSX-V: ALDE) (OTCQX: ADBRF) is please... READ MORE

Erdene Announces Closing of $25 Million Bought Deal Private Placement

Erdene Resource Development Corp. (TSX:ERD) (MSE:ERDN) (OTCQX: ER... READ MORE

NOVAGOLD Announces Closing of Upsized Bought Deal for Gross Proceeds of US$310 Million

NOVAGOLD RESOURCES INC. (NYSE: NG) (TSX: NG) is pleased to report... READ MORE

Guanajuato Silver Sees Significant Growth in Resources at Valenciana

~ Inferred Mineral Resources Increased by 630% to 20.3M AgEq Ounc... READ MORE