TinOne Drills 14 Metres of 1.03% Tin Within a Near-Surface Intercept of 29 Metres of 0.71% at Its Great Pyramid Project, Tasmania

TinOne Resources Inc. (TSX-V: TORC) (OTCQB: TORCF) is pleased to announce it has completed the confirmatory RC drill program at its Great Pyramid Tin Project located in the tier one mining jurisdiction of Tasmania, Australia.

The focussed 7-hole drill program was successful in demonstrating that significant tin mineralization occurs from surface and that previous drilling and modeling may be understated. The recent modern Reverse Circulation drilling has returned higher tin grades than the historical open hole percussion drilling.

Highlights

- High-grade, near-surface tin mineralization intersected in multiple holes:

- 29 metres of 0.71% tin from 2 metres depth, including 14 metres of 1.03% tin from 14 metres depth, drill hole 24GPRC026

- 37 metres of 0.56% tin from surface, including 7 metres of 0.91% tin from surface, drill hole 24GPRC028

- A total of 16 one metre intervals returned >1% tin mineralization across all new drilling

- Multiple holes bottomed in mineralization

- Potential grade increase in near-surface mineralized domains: New RC holes adjacent to historic open hole percussion drill holes returned significantly higher grades

“We are very pleased to have completed our Great Pyramid confirmatory drill program,” commented Chris Donaldson, Executive Chairman. “The results of the program delivered numerous high-grade intercepts and demonstrated the presence of higher-grade tin mineralization from within an area previously tested by open hole percussion drilling. These results indicate the potential for the Great Pyramid system to provide higher tin values than previously understood and historically reported.”

Drill Program

A seven hole RC drill program was recently carried out at the Great Pyramid tin project with two primary objectives:

- Confirmatory drilling

A line of five vertical RC holes was drilled in an area that was previously drilled in 1970 using the open hole percussion method. The RC holes were designed to test and verify the tenor of mineralization returned from the 1970 percussion holes (Figure 1). The line of historic holes was chosen to be representative of the deposit with a range from high grade to lower grade mineralization. The RC holes were initially designed to be sited between the older drill holes but due to site restrictions, two of the current holes were effectively twins, being approximately 1-2 metres from the original drilling. These two holes, 24GPRC027 and 24GPRC028, returned, approximately 70% and 21% higher tin grades, over the same depth intervals as the original drill holes (H052 and H051).

Table 1: TinOne Resources Great Pyramid 2024 RC results.

| Hole | From (m) |

To (m) |

Intersection (m) |

Sn (%) |

Comments |

| 24GPRC025 | 7.0 | 31.0 | 24.0 | 0.29 | Bottoms in mineralization |

| incl | 8.0 | 14.0 | 6.0 | 0.50 | |

| incl | 28.0 | 31.0 | 3.0 | 0.59 | |

| 24GPRC026 | 2.0 | 31.0 | 29.0 | 0.71 | Bottoms in mineralization |

| incl | 14.0 | 28.0 | 14.0 | 1.03 | |

| 24GPRC027 | 0.0 | 28.0 | 28.0 | 0.52 | |

| incl | 0.0 | 4.0 | 4.0 | 0.95 | |

| 24GPRC028 | 0.0 | 37.0 | 37.0 | 0.56 | Bottoms in mineralization |

| incl | 0.0 | 7.0 | 7.0 | 0.91 | |

| incl | 19.0 | 23.0 | 4.0 | 1.57 | |

| 24GPRC029 | 0.0 | 36.0 | 36.0 | 0.25 | |

| 0.0 | 3.0 | 3.0 | 0.51 | ||

| 8.0 | 13.0 | 5.0 | 0.50 | ||

| 24GPRC030A | 14.0 | 23.0 | 9.0 | 0.25 | Targeting the Pyramid Hill Fault |

| 31.0 | 41.0 | 10.0 | 0.12 | ||

| 67.0 | 78.0 | 11.0 | 0.12 | ||

| 243.0 | 251.0 | 8.0 | 0.15 | ||

| 24GPRC031 | na | na | na | na | No significant mineralisation. |

|

NOTES: All intersections are calculated with a cut-off grade of 0.1% Sn with maximum consecutive internal waste of 4 metres. |

|||||

Each of the other three holes drilled were strongly mineralised and returned grades higher that the current resource grade through mineralized intervals. 24GPRC026 returned 29 metres at 0.71% (Table 1) and 24GPRC028 was mineralized from surface to the end of hole and returned 37 metres at 0.56% tin (Table 1). 24GPRC025 was the only hole that returned lower grade than its nearest historical neighbour.

A statistical analysis of the new RC data and comparison with the historical Paringa-Aberfoyle percussion drilling data was carried out by Mining Associates, the independent consultants who prepared the current Mineral Resource Estimate (Table 3).

Table 2: Statistical comparison – current and historical drilling.

| Statistic | H holes (PA) | TinOne Holes | ||

| Length | 146.3 | 150 | ||

| Samples | 96 | 150 | ||

| Average Sn grade | 3233 | 3731 | ||

| Min Sn Grade | 200 | 20 | ||

| Max Sn Grade | 19600 | 29200 | ||

| standard deviation | 2980 | 3801 | ||

| 95 confidence interval | 596 | 608 | ||

| Min Expected | 2637 | 3123 | ||

| Max Expected | 3830 | 4339 |

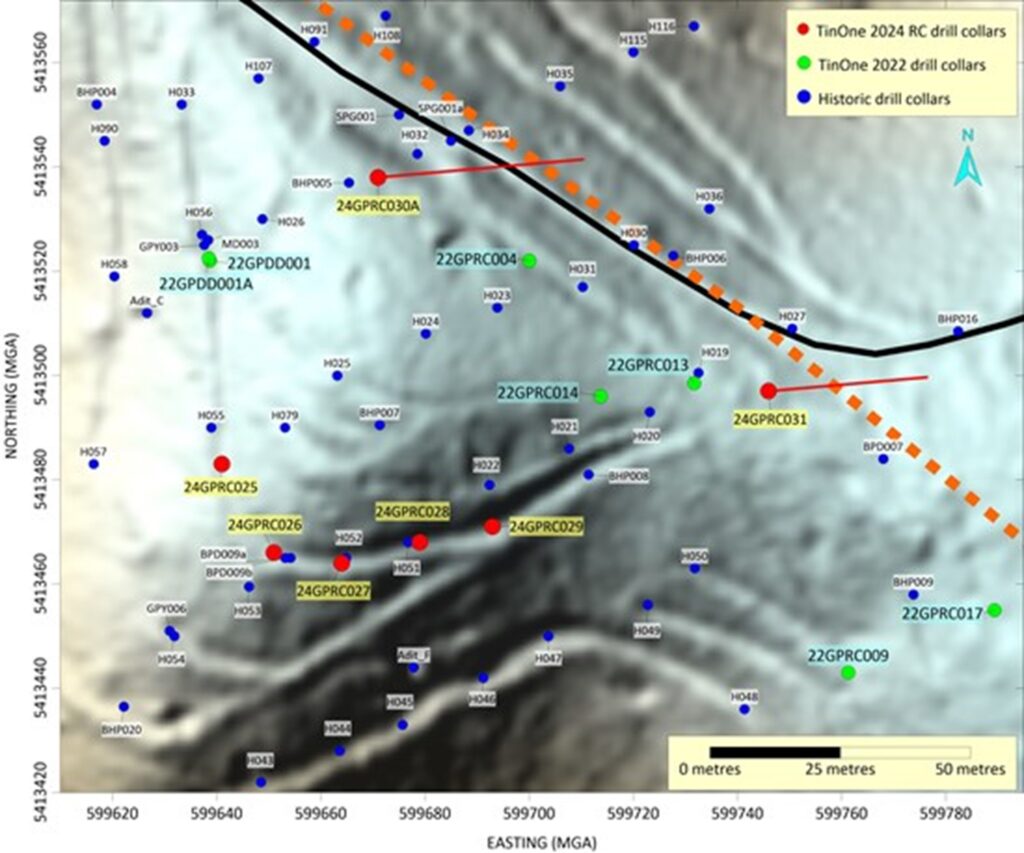

Figure 1: Drill section 2024 and Paringa-Aberfoyle drilling.

QQ plots were created to compare the distribution of grades from the two drill programmes (raw and composited samples were considered) with a significant increase in samples returning over 2500 ppm tin. Both plots confirm higher value samples were returned from the TinOne drill program. The mean grade and confidence intervals show the drill holes represent the same population but not confidently. The mean grade of the PA holes is near the lower end of expected mean of the TinOne holes. The mean grade of the TinOne holes is near the upper end of the expected mean of the Paringa-Aberfoyle holes.

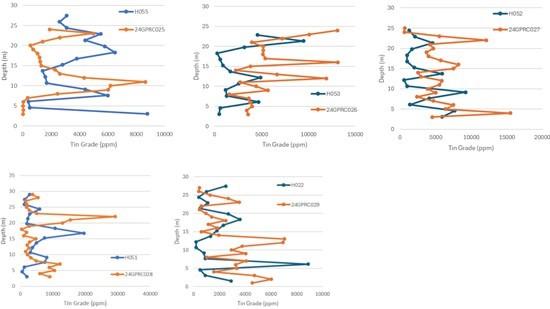

Figure 2: Downhole tin grade plots.

- High grade targeting

Two holes for a total of 140 metres were also drilled to test for the presence of high-grade, fault-related tin mineralization associated with the project-scale Pyramid Hill Fault. The fault dips steeply to the southwest and transects the project through at least 400 metres of favorable sandstone host. Very few historical holes have drilled through the Pyramid Hill Fault as it trends orthogonal (at right angles) to the strike of the mineralized joints and veinlets. Most previous drilling at Great Pyramid was therefore parallel to the fault rather than across it. The Company interprets that the very high tin grades in 22GPRC012 (78m @ 0.51% Sn incl. 23m @ 1.09% Sn, see September 22, 2022 news release) are hosted in the Pyramid Hill Fault, which was intersected at a relatively shallow angle. No past explorers have targeted high-grade tin mineralisation at Great Pyramid. Results from 24GPRC030A indicate that the fault may have been intercepted at shallower depth than anticipated with a discrete nine metre zone of mineralization occurring from 14 metres. If this is the case the lack of significant mineralization in 24GPRC031 could be interpreted as resulting from the hole being collared on the eastern side of the west-dipping fault.

Figure 3: Plan showing collar locations of 2024 and previous drilling on LiDAR- generated hill shade. Main access track – black line. Pyramid Hill Fault (interpreted position) – orange dashed line.

Based on the results from this phase of confirmation RC drilling, additional, tight-spaced drilling is warranted across the deposit area. This next phase of drilling will be informed by ongoing geological and domain modelling and results will be used to update the mineral resource estimate.

Geological Interpretation and Mineral Resources

The Great Pyramid tin deposit is located around a topographical feature known as Pyramid Hill and is hosted by Silurian to Devonian Mathinna Supergroup sandstones. Tin mineralisation occurs in veinlets developed along close spaced joints predominantly 1 to 5 mm in width. The joints strike at about 070° and dip at 60° to 70° to the northwest. Tin is present as cassiterite (SnO₂), generally with two or more of the following minerals: quartz, muscovite, fluorite, siderite, sulphides (arsenopyrite, pyrite, sphalerite, galena, chalcopyrite and/or their decomposition products scorodite and goethite), tourmaline and wolframite (at depth). Mineralization is associated with strong silicification.

The Great Pyramid mineralization is currently known over a strike length of more than 500 metres with an average width of approximately 150 metres. The few deeper drill holes at Great Pyramid have encountered tin mineralization, with a similar tenor to near surface mineralisation, at depths of approximately 300 metres below surface. The deposit style and regional comparisons suggest that a tin-fertile granite may exist at depth below the deposit, however this has not been encountered in drilling and the deposit is open at depth. Geological interpretation indicates that certain sedimentary units within the folded Mathinna Supergroup sediments are more favourable hosts and recent RC drilling combined with numerical modelling, will assist in developing a deeper understanding of controls on grade for follow-up drilling.

In 2023, a mineral resource estimate (MRE) was prepared in accordance with Canadian Institute of Mining, Metallurgy and Petroleum Definition Standards for Mineral Resources and Mineral Reserves adopted May 19, 2014, and in accordance with National Instrument 43-101 Standards of Disclosure for Mineral Projects.

Table 3: Great Pyramid tin deposit inferred Mineral Resource1,2,3,4,5

| Cut Off (Sn %) | Tonnes (Mt) | Grade (Sn %) | Metal (Sn kt) | Classification |

| > 0.10 | 8.39 | 0.17 | 14.40 | Inferred |

- Near surface mineral resources are reported at a Sn cut-off grade of 0.10% inside a domain based on geology and grade and considering an Sn price of US$24,978t and 80% recovery for tin.

- Mineral resources are reported within a conceptual pit shell.

- Mineral resources are not mineral reserves and do not have demonstrated economic viability.

- All numbers have been rounded to reflect the relative accuracy of the estimate.

- Discrepancies may occur due to rounding of values.

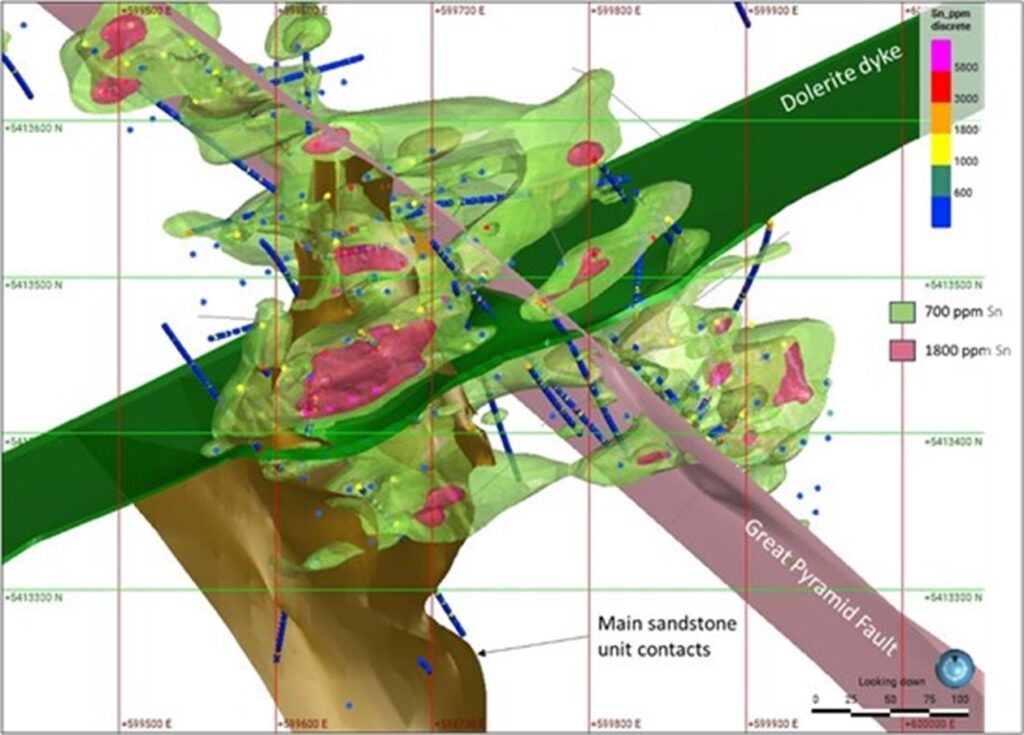

Figure 4: Plan View of Geological-Mineralization Model.

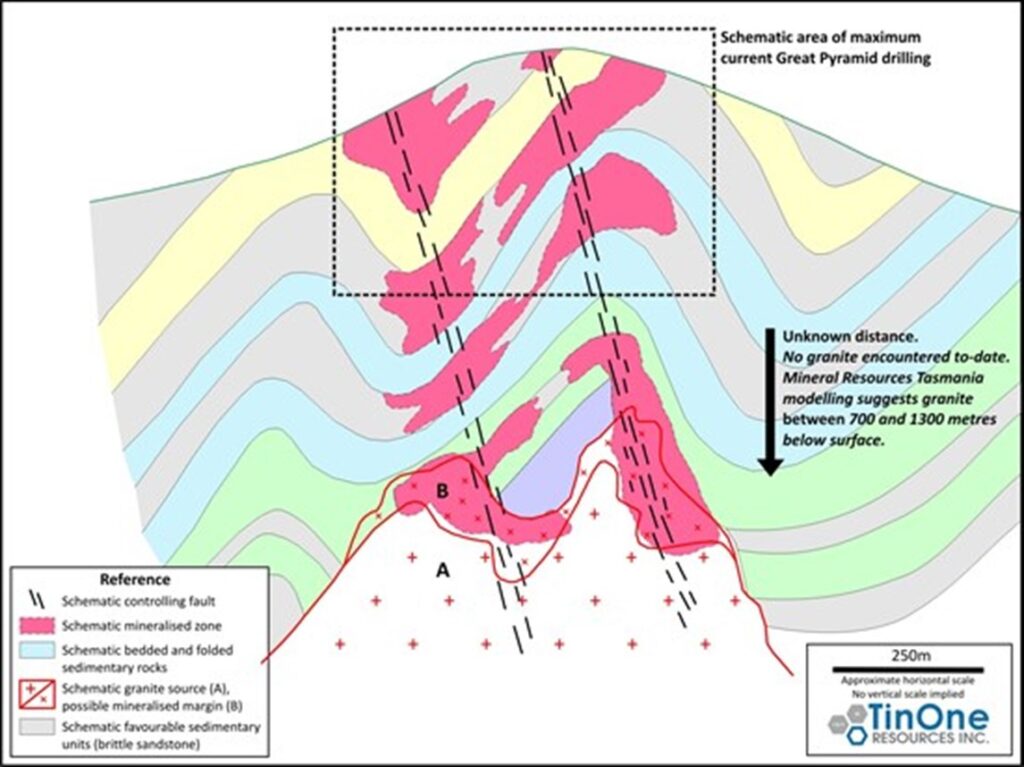

Figure 5: Great Pyramid conceptual model, showing the interaction of the two principal local controls on mineralization (i.e. favourable sedimentary units and feeder fault structures). Detailed work is underway to define these controls in detail to guide further drilling and resource estimation.

Next Steps

With the successful completion of the Phase 1 drill program, the TinOne technical team has significantly advanced its understanding of the Great Pyramid system and focus has now shifted to interpretation and integration of the various data sets. This interpretation and modelling phase will develop an understanding of the inter-related controls discussed above and guide more efficient targeting of additional drilling and future resource estimation.

Quality Assurance / Quality Control

RC samples were shipped to ALS Limited in Burnie, Australia for sample preparation. Analytical work was carried out at the ALS Brisbane facilities, which are ISO 9001 and ISO/IEC 17025 certified. Tin and tungsten are analysed by ICP-MS following lithium borate fusion (ALS method ME-MS85), overlimit results are reanalysed by XRF (ALS method XRF15b). Thirty-four element analyses are conducted by ICP-AES after HF-HNO3-HClO4 acid digestion and HCl leach (ALS method ME-ICP61).

Control samples comprising certified reference samples, duplicates and blank samples were systematically inserted into the sample stream and analyzed as part of the Company’s quality assurance / quality control protocol.

About TinOne

TinOne is a TSX Venture Exchange listed Canadian public company with a high-quality portfolio of tin projects in the Tier 1 mining jurisdictions of Tasmania and New South Wales, Australia. The Company is focussed on advancing its highly prospective portfolio while also evaluating additional tin opportunities.

Figure 6: Location of the Company’s projects in the mining friendly jurisdiction of Tasmania

Qualified Person

The Company’s disclosure of technical or scientific information in this press release has been reviewed and approved by Russell Fulton (MAIG), VP Exploration for TinOne. Mr. Fulton is a Qualified Person as defined under the terms of National Instrument 43-101.

MORE or "UNCATEGORIZED"

Hudbay Delivers Record Fourth Quarter and Full Year 2025 Results; Achieves 2025 Consolidated Copper and Gold Production and Cost Guidance

Hudbay Minerals Inc. (TSX:HBM) (NYSE: HBM) released its fourth ... READ MORE

Argo to Acquire the Hurdman Silver-Zinc Project

Argo Gold Inc. (CSE: ARQ) (OTC: ARBTF) entered into an agreement ... READ MORE

Centerra Gold Announces 2025 Year-End Mineral Reserves and Resources and Provides Exploration Update; Gold and Copper Reserves Increased 58% and 49%

Centerra Gold Inc. (TSX: CG) (NYSE: CGAU) announces its 2025 year... READ MORE

Eldorado Gold Delivers Strong 2025 Full Year and Fourth Quarter Financial and Operational Results; Significant Free Cash Flow Excluding Skouries and Increased Cash Generated From Operating Activities

Eldorado Gold Corporation (TSX: ELD) (NYSE: EGO) reports the Comp... READ MORE

Centerra Gold Reports Fourth Quarter and Full Year 2025 Results; Delivered Robust Annual Production and Beat Cost Guidance; 2026 Outlook Remains Strong as Centerra Executes its Self-Funded Growth Strategy

Centerra Gold Inc. (TSX: CG) (NYSE: CGAU) reported its fourth qua... READ MORE