Ero Copper Announces Update on Nickel Sulphide Exploration Program — Intercepts 11.2 Meters Grading 1.86% Nickel, including 5.0 Meters Grading 3.71% Nickel

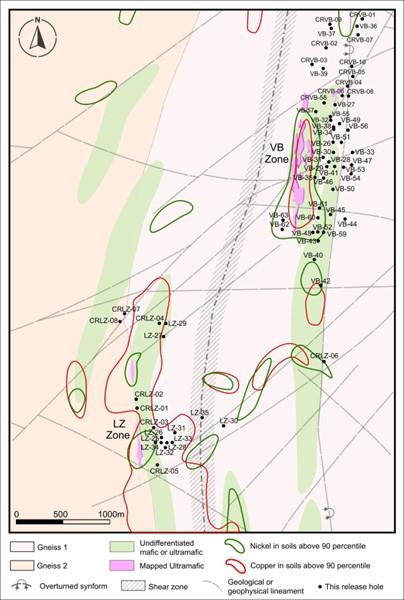

Ero Copper Corp. (TSX: ERO) (NYSE: ERO) is pleased to provide an update on its ongoing regional nickel sulphide exploration program within the Curaçá Valley. Drilling activity over the last several months has focused on delineating the Umburana System, which has a current strike length of approximately five kilometers. Mineralization, which outcrops at surface, remains open to depth, to the north and between the VB and Lazaro Zones.

To date, the Company has received assays on 97 diamond drill holes across the Umburana System, including 63 diamond drill holes within the VB Zone and 34 within the LZ Zone. New results from drilling conducted since September 2022 are highlighted by:

- VB Zone

- VB-41: 11.2 meters at 1.86% Ni, 0.26% Cu and 0.05% Co (2.08% NiEq), including 5.0 meters at 3.71% Ni, 0.13% Cu and 0.09% Co (4.00% NiEq)

- Interval includes 1.9 meters of massive-sulphide textures grading 7.09% Ni, 0.18% Cu and 0.18% Co (7.61% NiEq)

- VB-52: 25.9 meters at 0.69% Ni, 0.18% Cu and 0.02% Co (0.80% NiEq), including 15.5 meters at 1.01% Ni, 0.25% Cu and 0.03% Co (1.17% NiEq)

- VB-59: 18.7 meters at 0.79% Ni, 0.14% Cu and 0.02% Co (0.90% NiEq), including 6.8 meters at 1.49% Ni, 0.22% Cu and 0.04% Co (1.68% NiEq)

- VB-41: 11.2 meters at 1.86% Ni, 0.26% Cu and 0.05% Co (2.08% NiEq), including 5.0 meters at 3.71% Ni, 0.13% Cu and 0.09% Co (4.00% NiEq)

- LZ Zone

- LZ-25: 46.1 meters at 0.20% Ni, 0.04% Cu and 0.03% Co (0.28% NiEq), including 2.6 meters at 0.75% Ni, 0.18% Cu and 0.06% Co (0.96% NiEq)

- LZ-32: 11.3 meters at 0.43% Ni, 0.10% Cu and 0.02% Co (0.51% NiEq), including 7.0 meters at 0.61% Ni, 0.14% Cu and 0.03% Co (0.73% NiEq)

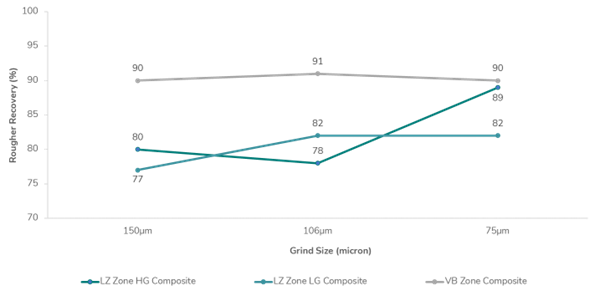

In addition to new drill results, the Company has commenced metallurgical test work on the Umburana System. While the program remains ongoing, initial metallurgical tests, completed on three composite samples of varying grades, demonstrates nickel recoveries through the rougher circuit ranging from 77% to 91% across a range of grind sizes, suggesting that the vast majority of nickel within the Umburana System is contained within sulphide minerals with very little nickel encapsulated within silicate minerals that would render the nickel unrecoverable.

Commenting on the update, David Strang, Chief Executive Officer, said “We are excited by the continuity and growth we are seeing with the Umburana System, which we believe demonstrates the Curaçá Valley’s potential to be a globally significant magmatic sulphide district for both copper and nickel. Notably, the VB Zone has increased from one distinct zone of mineralization to three, with massive-sulphide nickel mineralization extending to a depth of approximately 325 meters and remaining open to depth and along strike. Furthermore, our exploration team has identified several new and distinct nickel targets within the Curaçá Valley with similar geological signatures to the Umburana System, which we are currently drilling or plan on drilling later this year.”

TECHNICAL DISCUSSION

Detailed geologic mapping, comprehensive multi-element soil geochemistry and re- interpretation of the Company’s available geophysical datasets throughout 2021 and the first half of 2022 resulted in the discovery of a new nickel system, announced in September 2022, featuring favourable geology with coincident geochemical and geophysical anomalies. To date, detailed exploration has focused primarily on two target areas located at the interpreted northeast and southwest boundary of a five-kilometer system, each characterized by multiple expressions of outcropping nickel mineralization in the form of gossans, geochemical and geophysical anomalies – all associated with mafic-ultramafic intrusions. Please refer to Figure 5 for a plan view map of the Umburana System.

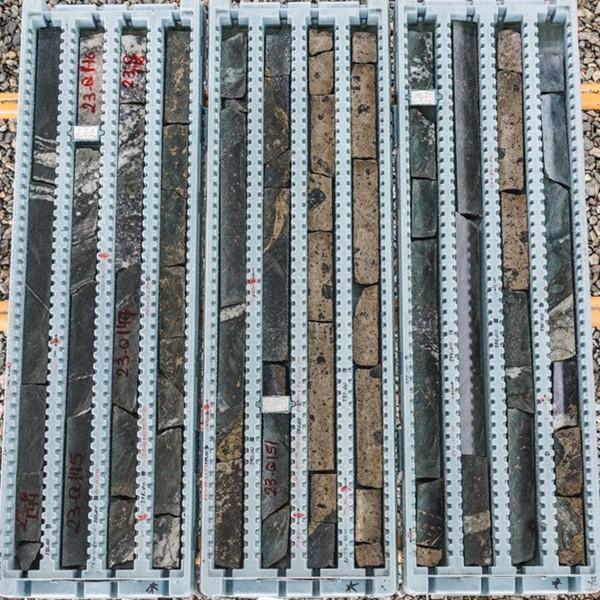

Initial drill-testing at the northeast and southwest boundaries of the currently known system has identified nickel sulphide mineralization ranging from disseminated and interstitial nickel sulphides (containing less than 10% sulphides) extending over 50 meters in thickness to patchy net-textured sulphides (containing approximately 10% to 30% sulphides) with localized centimeter up to 1.9 meter thick massive-sulphide lenses (containing approximately 60% to 80% sulphides) grading up to 7.09% nickel (7.61% NiEq). Mineralization within these zones is hosted by pyroxenite and websterite ultramafic rocks. Sulphide minerals are mainly pyrrhotite, pentlandite (loop-textured where massive sulphide, see Figure 2) with lesser pyrite and chalcopyrite. Loop-textured pentlandite is an important geologic indicator commonly observed in magmatic nickel sulphide deposits. The full extent of the system remains unknown at this time with mineralization open to depth and along strike both between the VB and LZ Zones and to the north of the Umburana System.

Based upon the exploration techniques used to identify the Umburana System, the Company has identified several geographically distinct nickel targets, two of which are currently being drilled. Surface field work and data interpretation is also underway to identify additional targets.

The Company has begun evaluating the metallurgical characteristics, recoveries and concentrates grade to determine whether a saleable nickel concentrate is achievable from the Umburana System. While the program is comprehensive and remains ongoing, initial rougher stage flotation tests demonstrate a range of recoveries of between 77% and 91% depending on grind size (75 to 150 microns). The results of this test work, combined with ongoing mineralogy studies, suggests that nickel within the Umburana System is associated primarily with sulphide minerals with very little nickel encapsulated in silicate minerals. Further test work remains ongoing to determine whether saleable concentrate grades are achievable, and if so, overall nickel recoveries.

Figure 1: Rougher stage nickel recovery versus grind size.

Composite samples were prepared based on nickel grades within each zone, and are summarized as follows:

- LZ Zone HG Composite = 0.90% Ni

- LZ Zone LG Composite = 0.45% Ni

- VB Zone Composite = 0.92% Ni

Where applicable, nickel equivalent (“NiEq”) in this press release has been calculated using the following formula: NiEq = Ni + (Cu x $3.50/$9.80) + (Co x $25.50/$9.80). No adjustment for metallurgical recoveries has been made when calculating NiEq.

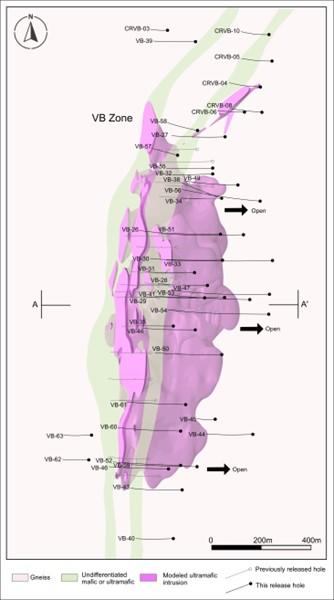

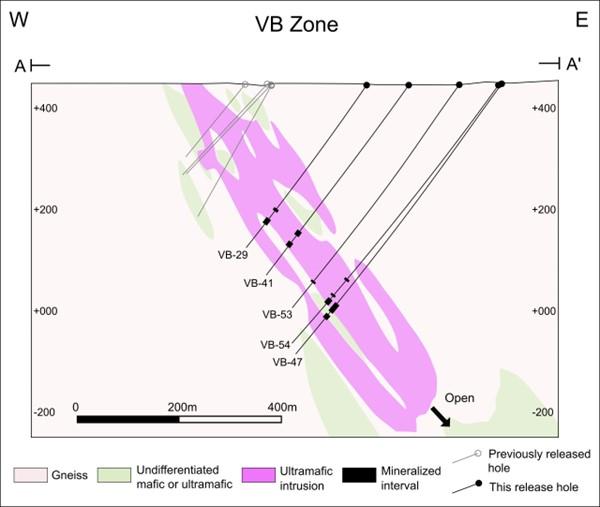

VB Zone

At the northeast extent of the Umburana System nickel-bearing ultramafic rocks have been identified over 1.4 kilometers north-south and up to 200 meters east-west using surface mapping supported by soil geochemistry and 30 trenches. To date, 63 diamond drill holes with assay results have been received with nickel mineralization identified starting at surface and to a depth of approximately 450 meters from surface. Mineralization remains open to depth as the majority of holes drilled to date have focused on delineating near surface open pit-able mineral resources, and remains open to the south trending towards the LZ Zone.

Mineralization within the VB Zone is characterized by disseminated and patchy net-textured nickel sulphides with three distinct high-grade (north, central and south) zones of massive sulphides featuring localized thickening of up to 1.9 meters grading up to 7.09% nickel (7.61% NiEq). Within the VB Zone, higher-grade mineralization continues to be focused at the base of a pyroxenite intrusion. Mineralization occurs predominantly within orthopyroxenites ranging from isotropic to locally banded.

Within the northern high-grade portion of the VB Zone, results are highlighted by holes VB-38 and VB-56, both located on the same section, which intercepted small intervals of disseminated, interstitial and patchy net-texture nickel sulphides ranging between approximately 3 and 9 meters grading between 0.63% NiEq to 1.69% NiEq.

Results within the central high-grade zone are highlighted by hole VB-41, which intercepted high-grade massive sulphide of 1.9 meters grading 7.61% NiEq within a broader mineralized interval of 11.2 meters grading 2.08% NiEq. Please see Figure 2 and Figure 3 for photos showing high-grade massive sulphides within hole VB-41. Please see “VB Zone Intercepts” table below for complete results.

High-grade mineralization in the southern zone are highlighted by holes VB-52 and VB-59, both located on the same section, which intercepted large intervals of disseminated and interstitial nickel sulphides ranging between approximately 18 and 26 meters grading between 0.80% NiEq to 0.90% NiEq.

The deepest drilling to date within the VB Zone, is highlighted by hole VB-47 that intercepted two intervals of disseminated nickel sulphide mineralization, 20.7 meters grading 0.47% NiEq and 9.8 meters grading 0.53% NiEq, the latter of which is approximately 450 meters below surface.

There is currently one drill rig active within the VB Zone, focused on expanding the current limits of mineralization along strike and two additional drill rigs testing regional nickel targets. Please see Figures 6 and 7 for details on drill hole locations and intercepts within the VB Zone.

VB Zone Intercepts

| Hole ID | From (m) | To (m) | Length (m) | Ni (%) | Cu (%) | Co (%) |

| VB-26 | NSI | NSI | NSI | NSI | NSI | NSI |

| VB-27 | NSI | NSI | NSI | NSI | NSI | NSI |

| VB-28 | 326.6 | 329.3 | 2.7 | 0.50 | 0.36 | 0.02 |

| and | 334.7 | 338.4 | 3.7 | 0.25 | 0.05 | 0.01 |

| including | 337.3 | 338.4 | 1.1 | 0.60 | 0.15 | 0.02 |

| and | 347.0 | 368.0 | 21.1 | 0.28 | 0.06 | 0.02 |

| including | 347.0 | 347.5 | 0.5 | 0.87 | 0.13 | 0.03 |

| including | 352.1 | 352.7 | 0.6 | 1.10 | 0.20 | 0.03 |

| including | 361.7 | 368.0 | 6.4 | 0.50 | 0.22 | 0.02 |

| including | 362.5 | 364.2 | 1.6 | 0.95 | 0.33 | 0.03 |

| VB-29 | 301.0 | 304.0 | 3.0 | 0.27 | 0.08 | 0.01 |

| and | 325.6 | 337.5 | 11.9 | 0.26 | 0.08 | 0.01 |

| including | 332.5 | 337.5 | 5.0 | 0.36 | 0.12 | 0.01 |

| VB-30 | NSI | NSI | NSI | NSI | NSI | NSI |

| VB-31 | 283.7 | 308.0 | 24.3 | 0.27 | 0.08 | 0.01 |

| including | 287.8 | 288.3 | 0.5 | 0.93 | 0.09 | 0.03 |

| including | 289.1 | 289.8 | 0.7 | 0.76 | 0.29 | 0.03 |

| VB-32 | 243.6 | 249.1 | 5.5 | 0.36 | 0.28 | 0.02 |

| including | 243.6 | 244.6 | 1.0 | 1.06 | 0.29 | 0.05 |

| VB-33 | NSI | NSI | NSI | NSI | NSI | NSI |

| VB-34 | NSI | NSI | NSI | NSI | NSI | NSI |

| VB-35 | 210.8 | 237.7 | 26.9 | 0.21 | 0.10 | 0.01 |

| including | 237.2 | 237.7 | 0.5 | 0.69 | 0.64 | 0.02 |

| VB-36 | NSI | NSI | NSI | NSI | NSI | NSI |

| VB-37 | NSI | NSI | NSI | NSI | NSI | NSI |

| VB-38 | 327.8 | 337.1 | 9.3 | 0.51 | 0.16 | 0.02 |

| including | 330.2 | 332.0 | 1.9 | 1.08 | 0.22 | 0.05 |

| including | 330.2 | 330.8 | 0.6 | 2.22 | 0.26 | 0.09 |

| including | 333.0 | 337.1 | 4.1 | 0.54 | 0.13 | 0.03 |

| including | 334.0 | 334.8 | 0.8 | 1.70 | 0.31 | 0.07 |

| VB-39 | NSI | NSI | NSI | NSI | NSI | NSI |

| VB-40 | NSI | NSI | NSI | NSI | NSI | NSI |

| VB-41 | 359.5 | 370.2 | 10.7 | 0.29 | 0.08 | 0.01 |

| and | 386.9 | 398.1 | 11.2 | 1.86 | 0.26 | 0.05 |

| including | 390.8 | 395.8 | 5.0 | 3.71 | 0.13 | 0.09 |

| including* | 390.8 | 392.7 | 1.9 | 7.09 | 0.18 | 0.18 |

| including* | 395.1 | 395.8 | 0.8 | 6.22 | 0.20 | 0.16 |

| VB-42 | NSI | NSI | NSI | NSI | NSI | NSI |

| VB-43 | NSI | NSI | NSI | NSI | NSI | NSI |

| VB-44 | NSI | NSI | NSI | NSI | NSI | NSI |

| VB-45 | NSI | NSI | NSI | NSI | NSI | NSI |

| VB-46 | 284.75 | 290.75 | 6.0 | 0.25 | 0.21 | 0.01 |

| including | 285.8 | 286.8 | 1.0 | 0.47 | 0.16 | 0.03 |

| VB-47 | 537.4 | 558.1 | 20.7 | 0.39 | 0.15 | 0.01 |

| including | 537.4 | 549.7 | 12.3 | 0.39 | 0.15 | 0.01 |

| including | 540.4 | 548.5 | 8.1 | 0.56 | 0.11 | 0.01 |

| and | 565.6 | 575.4 | 9.8 | 0.44 | 0.13 | 0.02 |

| VB-48 | 262.8 | 278.2 | 15.4 | 0.25 | 0.08 | 0.01 |

| VB-49 | NSI | NSI | NSI | NSI | NSI | NSI |

| VB-50 | 411.0 | 415.0 | 3.9 | 0.23 | 0.08 | 0.01 |

| VB-51 | NSI | NSI | NSI | NSI | NSI | NSI |

| VB-52 | 210.0 | 235.9 | 25.9 | 0.69 | 0.18 | 0.02 |

| including | 210.0 | 225.5 | 15.5 | 1.01 | 0.25 | 0.03 |

| including | 211.0 | 219.0 | 8.0 | 1.62 | 0.35 | 0.05 |

| and | 316.9 | 333.2 | 16.3 | 0.21 | 0.06 | 0.01 |

| including | 320.1 | 323.1 | 3.1 | 0.43 | 0.12 | 0.02 |

| VB-53 | 482.1 | 485.4 | 3.3 | 1.43 | 0.15 | 0.04 |

| including | 483.8 | 484.9 | 1.1 | 3.92 | 0.15 | 0.11 |

| including* | 483.8 | 484.3 | 0.5 | 6.63 | 0.12 | 0.18 |

| including | 484.3 | 484.9 | 0.6 | 1.46 | 0.19 | 0.04 |

| VB-54 | 484.2 | 487.2 | 3.0 | 0.31 | 0.04 | 0.01 |

| including | 484.2 | 485.2 | 1.0 | 0.62 | 0.06 | 0.02 |

| and | 523.4 | 528.0 | 4.6 | 1.01 | 0.17 | 0.06 |

| including | 523.4 | 523.9 | 0.5 | 3.52 | 0.40 | 0.09 |

| including | 527.5 | 528.0 | 0.5 | 4.86 | 0.35 | 0.25 |

| and | 534.5 | 548.1 | 13.6 | 0.50 | 0.15 | 0.02 |

| including | 534.5 | 538.1 | 3.6 | 1.33 | 0.29 | 0.07 |

| including | 537.6 | 538.1 | 0.5 | 5.58 | 0.20 | 0.18 |

| VB-55 | 229.0 | 243.6 | 14.6 | 0.61 | 0.24 | 0.03 |

| including | 232.6 | 243.6 | 11.0 | 0.77 | 0.29 | 0.04 |

| including | 236.8 | 237.8 | 1.0 | 1.24 | 0.28 | 0.06 |

| including | 238.8 | 240.3 | 1.4 | 1.65 | 0.24 | 0.08 |

| including | 242.4 | 243.6 | 1.2 | 1.44 | 0.21 | 0.10 |

| VB-56 | 439.8 | 442.9 | 3.1 | 0.51 | 0.14 | 0.02 |

| and | 453.9 | 459.9 | 6.0 | 0.20 | 0.10 | 0.01 |

| and | 464.3 | 467.6 | 3.3 | 1.43 | 0.30 | 0.06 |

| including | 465.3 | 467.6 | 2.3 | 1.82 | 0.29 | 0.07 |

| including | 466.3 | 467.0 | 0.7 | 3.67 | 0.10 | 0.14 |

| VB-57 | 90.2 | 109.2 | 19.0 | 0.37 | 0.16 | 0.02 |

| including | 104.4 | 109.2 | 4.8 | 0.56 | 0.25 | 0.03 |

| including | 104.4 | 105.4 | 1.0 | 1.13 | 0.22 | 0.05 |

| including | 108.7 | 109.2 | 0.5 | 0.98 | 0.34 | 0.04 |

| VB-58 | NSI | NSI | NSI | NSI | NSI | NSI |

| VB-59 | 281.1 | 299.7 | 18.7 | 0.79 | 0.14 | 0.02 |

| including | 282.1 | 288.9 | 6.8 | 1.49 | 0.22 | 0.04 |

| and | 304.3 | 311.4 | 7.1 | 0.33 | 0.10 | 0.01 |

| and | 392.5 | 402.2 | 9.7 | 0.33 | 0.08 | 0.02 |

| including | 400.6 | 401.1 | 0.6 | 1.10 | 0.14 | 0.06 |

| VB-60 | NSI | NSI | NSI | NSI | NSI | NSI |

| VB-61 | 226.4 | 240.9 | 14.5 | 0.37 | 0.07 | 0.01 |

| including | 238.6 | 239.1 | 0.5 | 1.48 | 0.10 | 0.05 |

| including | 239.8 | 240.9 | 1.1 | 1.20 | 0.20 | 0.04 |

| VB-62 | 96.15 | 98.38 | 2.23 | 0.34 | 0.10 | 0.01 |

| and | 103.5 | 112.2 | 8.8 | 0.45 | 0.12 | 0.01 |

| VB-63 | NSI | NSI | NSI | NSI | NSI | NSI |

| CRVB-01 | NSI | NSI | NSI | NSI | NSI | NSI |

| CRVB-02 | NSI | NSI | NSI | NSI | NSI | NSI |

| CRVB-03 | NSI | NSI | NSI | NSI | NSI | NSI |

| CRVB-04 | NSI | NSI | NSI | NSI | NSI | NSI |

| CRVB-05 | NSI | NSI | NSI | NSI | NSI | NSI |

| CRVB-06 | NSI | NSI | NSI | NSI | NSI | NSI |

| CRVB-07 | 98.0 | 102.0 | 4.0 | 0.23 | 0.05 | 0.01 |

| CRVB-08 | NSI | NSI | NSI | NSI | NSI | NSI |

| CRVB-09 | NSI | NSI | NSI | NSI | NSI | NSI |

| CRVB-10 | NSI | NSI | NSI | NSI | NSI | NSI |

NSI denotes no significant intercept grading above 0.10% Ni. Drill holes were drilled from surface. Holes not included are either pending assay results or have been included in a different section of this press release. The length of intercept may not represent the true width of mineralization. Values may not add up due to rounding. From, To and Length are rounded to the nearest tenth of a meter.

(*) denotes interval of massive sulphide within larger reported intercept.

Figure 2: Drill core from the VB Zone (hole VB-41 at 392.4 meters) highlighting loop textured pentlandite.

Figure 3: Drill core from the VB Zone (hole VB-41) highlighting high-grade massive sulphide within the zone from 385.0 to 396.5 meters.

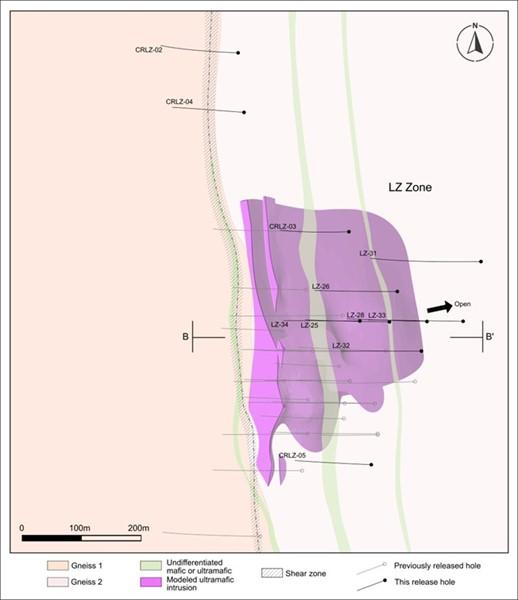

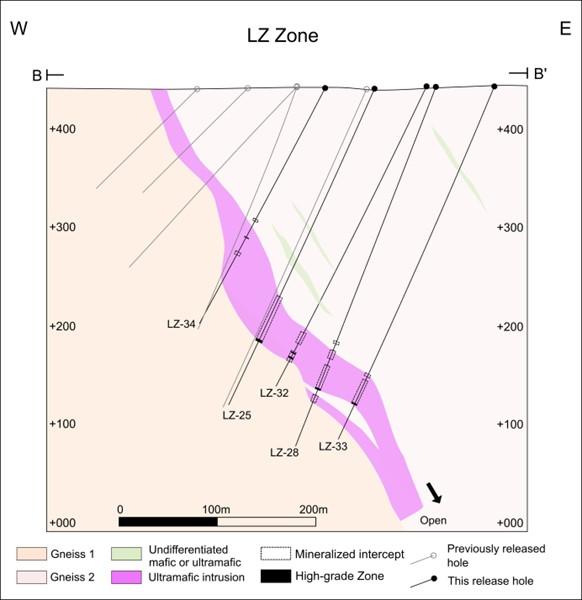

LZ Zone

At the southwest extent of the Umburana System, located approximately 20 kilometers from the Company’s Caraíba milling operations and approximately 3.2 kilometers southwest of the VB Zone, nickel-bearing ultramafic rocks have been identified over 500 meters in strike- length and approximately 50 meters in apparent thickness using surface mapping supported by geochemistry, airborne electromagnetic response and eight trenches and has been traced from surface to a depth of 315 meters down-dip. Drilling has primarily focused to date on delineating near surface, open pit-able mineral resources. Mineralization remains open to depth and to the north. To date, 34 diamond drill holes with assay results have been received.

Mineralization within the LZ Zone is primarily comprised of disseminated nickel sulphide mineralization with intercalated intervals of interstitial and patchy net-textured sulphides (see Figure 4). Within the 500-meter identified strike length, a zone of higher-grade mineralization has been identified within the footwall of the mafic-ultramafic intrusion associated with a websterite layer.

Results within the footwall are highlighted by hole LZ-25 that intercepted a broad interval of mineralization covering 46.1 meters grading 0.28% NiEq from approximately 230 meters downhole. Hole LZ-32 intercepted 11.3 meters grading 0.51% NiEq from approximately 295 meters downhole. Together, these intercepts demonstrate continuity of nickel sulphide mineralization down-dip. Please see “LZ Zone Intercepts” table below for complete results.

The deepest drilling to date is highlighted by hole LZ-33 that intercepted disseminated nickel mineralization over 2.6 meters grading 0.70% NiEq, from approximately 350 meters downhole. At the bottom of this mineralized intercept, an extension of the high-grade websterite layer of the footwall zone, approximately 320 meters below surface, was intercepted over 1.6 meters grading 1.03% NiEq, indicating continuity, albeit thinner, to depth. There are no drill rigs currently working within the LZ Zone, as exploration efforts are focused on the VB Zone and other regional nickel targets within the Curaçá Valley identified using systematic geological mapping, soil geochemistry, trenching and ground electromagnetic (“EM”) surveys.

Please see Figure 8 and 9 for additional details on drill hole locations and intercepts within the LZ Zone.

LZ Zone Intercepts

| Hole ID | From (m) | To (m) | Length (m) | Ni (%) | Cu (%) | Co (%) |

| LZ-25 | 236.6 | 282.8 | 46.1 | 0.20 | 0.04 | 0.03 |

| including | 280.2 | 282.8 | 2.6 | 0.75 | 0.18 | 0.06 |

| including | 280.2 | 281.2 | 1.0 | 1.16 | 0.25 | 0.05 |

| including | 282.2 | 282.8 | 0.6 | 0.90 | 0.32 | 0.09 |

| LZ-26 | 244.4 | 259.5 | 15.1 | 0.20 | 0.06 | 0.01 |

| including | 253.4 | 256.4 | 3.0 | 0.36 | 0.10 | 0.02 |

| and | 272.4 | 275.1 | 2.7 | 0.46 | 0.12 | 0.03 |

| including | 274.4 | 275.1 | 0.7 | 0.78 | 0.21 | 0.04 |

| LZ-27 | NSI | NSI | NSI | NSI | NSI | NSI |

| LZ-28 | 279.4 | 281.4 | 2.0 | 0.29 | 0.07 | 0.02 |

| and | 328.8 | 331.3 | 2.6 | 0.65 | 0.16 | 0.03 |

| including | 329.7 | 331.3 | 1.6 | 0.91 | 0.22 | 0.04 |

| LZ-29 | NSI | NSI | NSI | NSI | NSI | NSI |

| LZ-30 | NSI | NSI | NSI | NSI | NSI | NSI |

| LZ-31 | NSI | NSI | NSI | NSI | NSI | NSI |

| LZ-32 | 296.9 | 308.2 | 11.3 | 0.43 | 0.10 | 0.02 |

| including | 300.3 | 307.3 | 7.0 | 0.61 | 0.14 | 0.03 |

| including | 300.3 | 301.4 | 1.1 | 1.35 | 0.29 | 0.05 |

| including | 305.4 | 306.0 | 0.6 | 0.87 | 0.20 | 0.04 |

| including | 306.7 | 307.3 | 0.7 | 1.44 | 0.25 | 0.06 |

| LZ-33 | 320.9 | 324.0 | 3.1 | 0.31 | 0.10 | 0.02 |

| and | 352.1 | 354.7 | 2.6 | 0.57 | 0.17 | 0.03 |

| including | 353.1 | 354.7 | 1.6 | 0.84 | 0.24 | 0.04 |

| LZ-34 | 148.3 | 150.3 | 2.0 | 0.21 | 0.08 | 0.01 |

| and | 151.3 | 153.5 | 2.2 | 0.28 | 0.08 | 0.02 |

| and | 169.8 | 172.9 | 3.0 | 0.39 | 0.08 | 0.02 |

| including | 172.0 | 172.9 | 0.9 | 1.05 | 0.24 | 0.05 |

| and | 189.3 | 193.1 | 3.8 | 0.30 | 0.06 | 0.01 |

| CRLZ-01 | NSI | NSI | NSI | NSI | NSI | NSI |

| CRLZ-02 | NSI | NSI | NSI | NSI | NSI | NSI |

| CRLZ-03 | NSI | NSI | NSI | NSI | NSI | NSI |

| CRLZ-04 | NSI | NSI | NSI | NSI | NSI | NSI |

| CRLZ-05 | NSI | NSI | NSI | NSI | NSI | NSI |

| CRLZ-06 | NSI | NSI | NSI | NSI | NSI | NSI |

| CRLZ-07 | NSI | NSI | NSI | NSI | NSI | NSI |

NSI denotes no significant intercept grading above 0.10% Ni. Drill holes were drilled from surface. Holes not included are either pending assay results or have been included in a different section of this press release. The length of intercept may not represent the true width of mineralization. Values may not add up due to rounding. From, To and Length are rounded to the nearest tenth of a meter.

Figure 4: Brecciated and patchy net-textured sulphides shown in detail for hole LZ-32 (~300 meters downhole) showing both pentlandite and pyrrhotite

NOTE ON NI 43-101 COMPLIANT TECHNICAL REPORT(S)

The conversion of drill results presented in this press release into NI 43-101 compliant mineral resources and mineral reserves all require additional work and analysis that remains ongoing. To date, there has been insufficient exploration and accompanying analysis to define a mineral resource and it is uncertain if further exploration will result in this nickel system being delineated as a mineral resource. Accordingly, the results herein may not be included in future NI 43-101 compliant mineral resources or mineral reserves depending on the results of this additional work and analysis, and other technical and/or economic reasons.

QUALITY ASSURANCE & QUALITY CONTROL

In support of its ongoing Umburana System exploration program, the Company is currently drilling on surface using third-party contracted core drill rigs. During the period from September 2022 through May 2023, third-party drill rigs were operated by Major Drilling do Brasil Ltda., DrillGeo Geologia e Sondagem Ltda. and Layne Christensen Co., all of whom are independent of the Company. Drill core is logged, photographed and split in half using a diamond core saw at the secure core logging and storage facilities of Mineração Caraíba S.A. (“MCSA”). Half of the drill core is retained on site and the other half core is used for analysis, with samples collected on one-meter sample intervals unless an interval crosses a geological contact. All sample preparation is performed in MCSA’s secure on-site laboratory. Total nickel and copper is determined using a nitric-hydrochloric acid digestion and Atomic Absorption Spectrometry and/or Titration at the on-site laboratory. All sample results during the period have been monitored through a QA/QC program that includes the insertion of certified standards, blanks, and pulp and reject duplicate samples. Check-assays for nickel and copper were submitted to ALS Brasil Ltda’s facility located in Vespasiano, Minas Gerais, Brazil, at a rate of approximately 5%. ALS Brasil Ltda is a subsidiary of ALS Limited and is independent of the Company.

Mr. Cid Gonçalves Monteiro Filho, SME RM (04317974), MAIG (No. 8444), MAusIMM (No. 3219148) and Resource Manager of the Company, who is a “qualified person” within the meanings of NI 43-101, has reviewed and approved the disclosure of technical information, including verification of the sampling, analytical and testing data in this press release. Quarterly reviews entail sampling and laboratory procedure review as well as verification of original assay certificates associated with a selection of samples from Company’s internal database included in this press release.

ABOUT ERO COPPER CORP

Ero is a high-margin, high-growth, clean copper producer with operations in Brazil and corporate headquarters in Vancouver, B.C. The Company’s primary asset is a 99.6% interest in the Brazilian copper mining company, MCSA, 100% owner of the Company’s Caraíba Operations (formerly known as the MCSA Mining Complex), which are located in the Curaçá Valley, Bahia State, Brazil and include the Pilar and Vermelhos underground mines and the Surubim open pit mine, and the Tucumã Project (formerly known as Boa Esperança), an IOCG-type copper project located in Pará, Brazil. The Company also owns 97.6% of NX Gold

S.A. which owns the Xavantina Operations (formerly known as the NX Gold Mine), comprised of an operating gold and silver mine located in Mato Grosso, Brazil. Additional information on the Company and its operations, including technical reports on the Caraíba Operations, Xavantina Operations and Tucumã Project, can be found on the Company’s website (www.erocopper.com), on SEDAR (www.sedar.com), and on EDGAR (www.sec.gov).

Figure 5 Umburana System – Plan Map

Figure 6

VB Zone – Plan Map

Figure 7

VB Zone – East-West Composite Section

Figure 8

LZ Zone – Plan Map

Figure 9

LZ Zone – East-West Composite Section

MORE or "UNCATEGORIZED"

Eloro Resources Announces Closing of Bought Deal LIFE Private Placement for Gross Proceeds of C$17 Million

Eloro Resources Ltd. (TSX: ELO) (FSE: P2QM) is pleased to announce the closing of its previously an... READ MORE

Minera Alamos Updates Resources and Reserves for the Pan Gold Mine in Nevada

Minera Alamos Inc. (TSX-V: MAI) (OTCQX: MAIFF) is pleased to announce updated Mineral Resource and M... READ MORE

Ero Copper Reports Fourth Quarter and Full Year 2025 Operating and Financial Results

Ero Copper Corp. (TSX: ERO) (NYSE: ERO) is pleased to announce its operating and financial results f... READ MORE

Rare Element Resources Announces Results of Oversubscribed Rights Offering of Common Shares

Rare Element Resources Ltd. (OTCQB: REEMF) is pleased to report that its previously announced... READ MORE

TRX Gold Reports Record Q2 2026 Production and Company Update

TRX Gold Corporation (TSX: TRX) (NYSE American: TRX) is pleased to announce preliminary resu... READ MORE