Hudbay De-risks Copper World Phase I with Enhanced Pre-Feasibility Study

- Phase I, which is a standalone operation requiring only state and local permits for an extended 20-year mine life, has an after-tax net present value (8%) of $1.1 billion and generates a 19% internal rate of return at a copper price of $3.75 per pound.

- Average annual copper production over the first ten years of approximately 92,000 tonnes at cash costs and sustaining cash costs of $1.53 and $1.95 per pound of copperi, respectively.

- Extended Phase I mine life to 20 years, with the potential for further expansion, compared to 16 years in the previous study with an 18% increase to total copper production and higher mill head grades.

- Lowered initial capital cost estimate to approximately $1.3 billion ($1.1 billion net of existing stream agreement), compared to $1.9 billion in the previous preliminary economic assessment, due to the deferral of the construction of a concentrate leach facility to year 4 with the potential to be fully funded from operating cash flows or benefit from future government incentives for critical minerals processing.

- Simplified project flow sheet includes a 60,000 ton per day sulfide concentrator that will produce copper concentrate as a final product until the addition of a concentrate leach facility and a solvent extraction and electrowinning plant in year 5 that will allow the project to produce copper cathodes. The production of copper cathodes will reduce the project’s carbon footprint, make Copper World the third largest domestic copper cathode producer in the United Statesii and bolster the country’s green energy independence with “Made in America” copper.

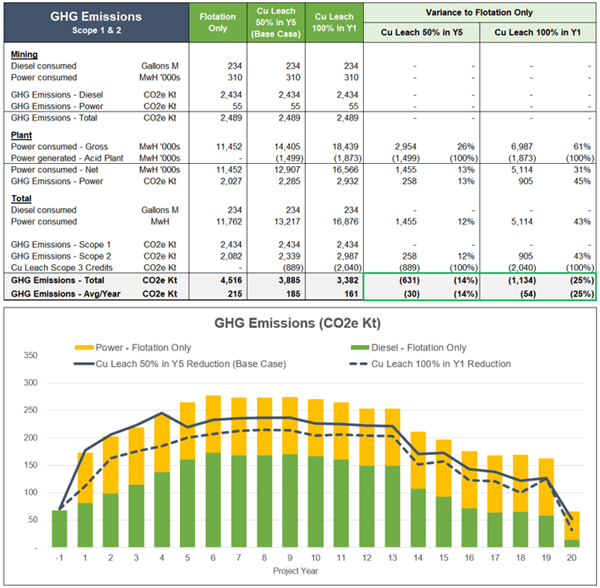

- Total GHG emissions are expected to be 14% lower compared to an operation that only produces copper concentrate.

- Significant benefits for the community and local economy in Arizona through payment of more than $850 million in U.S. federal and state taxes and the creation of an estimated 400 direct and 3,000 indirect jobs.

- Copper World is one of the highest-grade open pit copper projects in the Americasiii with proven and probable mineral reserves of 385 million tonnes at 0.54% copper.

- Together with the pre-feasibility study, Hudbay has updated the mineral resource estimates for the project, which increases the global measured and indicated mineral resources (inclusive of mineral reserves) to 1.2 billion tonnes at 0.42% copper, representing a 4% increase in total in-situ copper. This confirms significant upside at Copper World with an intended Phase II expansion of mining activities onto federal land to further enhance the project economics and extend the mine life well beyond 20 years.

Hudbay Minerals Inc. (TSX:HBM) (NYSE: HBM) announced the results of the enhanced pre-feasibility study for Phase I of its 100%-owned Copper World project in Arizona. All dollar amounts are in US dollars, unless otherwise noted. “Tonnes” refer to metric tonnes and “tons” refer to imperial or U.S. short tons.

“The PFS for Phase I of Copper World significantly enhances the economics and de-risks the project through higher levels of engineering, a simplified project design, lower upfront capex and a longer mine life,” said Peter Kukielski, Hudbay’s President and Chief Executive Officer. “Copper World is an attractive copper growth project for Hudbay and our stakeholders, generating strong project returns and bringing many benefits to the community and local economy in Arizona. We will continue to be prudent with our financing plans for Copper World as we remain focused on meeting all of the prerequisites for project sanctioning as laid out in our 3-P plan in October 2022.”

2023 PFS Summary

The PFS reflects the results of the company’s further technical work on the first phase of the Copper World project. Phase I is a standalone operation requiring state and local permits only. Phase I has a mine life of 20 years, which is four years longer than the Phase I mine life that was presented in the preliminary economic assessment published in June 2022 due to an increase in the capacity for tailings and waste deposition as a result of optimizing the site layout. The second phase of the project is expected to involve an expansion onto federal lands with an extended mine life and enhanced project economics. Phase II would be subject to the federal permitting process and has not been included in the PFS results.

Phase I contemplates average annual copper production of 85,000 tonnes over a 20-year mine life, at average cash costs and sustaining cash costs of $1.47 and $1.81 per pound of copperi, respectively. A variable cut-off grade strategy allows for higher mill head grades in the first ten years, which increases annual production to approximately 92,000 tonnes of copper at average cash costs and sustaining cash costs of $1.53 and $1.95 per pound of copperi, respectively.

At a copper price of $3.75 per pound, the after-tax net present value of Phase I using an 8% discount rate is $1.1 billion and the internal rate of return is 19%. The valuation metrics are leveraged to higher copper prices and at a price of $4.25 per pound, the after-tax NPV (8%) of Phase I increases to $1.7 billion, and the IRR increases to 25.5%. In the flotation only scenario, the project has an after-tax NPV (8%) of $863 million, an after-tax IRR of 18.7% and a payback period of 5.3 years at $3.75 per pound copper. At a copper price of $4.25 per pound, the flotation only NPV (8%) increases to $1.5 billion and the IRR increases to 25.7%. These economics demonstrate the project is robust even without the concentrate leach facility, providing Hudbay with flexibility to optimize the project in the future through funding the addition of the concentrate leach facility with operating cash flows or potential government incentives for critical minerals processing.

A summary of key valuation, production and cost details from the PFS can be found below. For further details, including operating and cash flow metrics provided on an annual basis, please refer to Exhibit 1 at the end of this news release.

| Summary of Key Metrics (at $3.75/lb Cu) | ||||

| Valuation Metrics (Unlevered)1 | Unit | Phase I | ||

| Net present value @ 8% (after-tax) | $ millions | $1,100 | ||

| Net present value @ 10% (after-tax) | $ millions | $771 | ||

| Internal rate of return (after-tax) | % | 19.2% | ||

| Payback period | # years | 5.9 | ||

| Project Metrics | Unit | Phase I | ||

| Growth capital – initial | $ millions | $1,323 | ||

| Construction length – conc process plant | # years | 2.5 | ||

| Growth capital – conc leach facility (yr 4) | $ millions | $367 | ||

| Construction length – conc leach facility | # years | 1.0 | ||

| Operating Metrics | Unit | Year 1-10 | Year 11-20 | Phase I |

| Copper production (annual avg.)2 | 000 tonnes | 92.3 | 77.5 | 85.3 |

| EBITDA (annual avg.)3 | $ millions | $404 | 339 | $372 |

| Sustaining capital (annual avg.)4 | $ millions | $33.9 | 19.4 | $27.1 |

| Cash cost5 | $/lb Cu | $1.53 | 1.39 | $1.47 |

| Sustaining cash cost5 | $/lb Cu | $1.95 | 1.62 | $1.81 |

1 Calculated assuming the following commodity prices: copper price of $3.75 per pound, copper cathode premium of $0.02 per pound (net of cathode freight charges), gold stream price of $450 per ounce, silver stream price of $3.90 per ounce and molybdenum price of $12.00 per pound. Reflects the terms of the existing Wheaton Precious Metals stream, including an upfront deposit of $230 million in the first year of Phase I construction in exchange for the delivery of 100% of gold and silver produced.

2 Copper production includes copper contained in concentrate sold and copper cathode produced from the concentrate leach facility. Average annual copper production excludes partial year of production in year 20.

3 EBITDA is a non-IFRS financial performance measure with no standardized definition under IFRS. For further information, please refer to the company’s Management’s Discussion and Analysis for the three and six months ended June 30, 2023.

4 Sustaining capital expenditures include the benefit of capital leasing of mobile equipment.

5 Cash cost and sustaining cash cost exclude the cost of purchasing external concentrate, which may vary in price and or potentially be replaced with additional internal feed. By-product credits calculated using amortization of deferred revenue for gold and silver stream sales as per the company’s approach in its quarterly financial reporting. By-product credits also include the revenue from the sale of excess acid produced at a price of $145 per tonne. Sustaining cash cost includes sustaining capital expenditures and royalties. Cash cost and sustaining cash cost are non-IFRS financial performance measures with no standardized definition under IFRS. For further details on why Hudbay believes cash costs are a useful performance indicator, please refer to the company’s Management’s Discussion and Analysis for the three and six months ended June 30, 2023.

| Sensitivity Analysis | |||||||

| Copper Price | Unit | $3.25/lb | $3.50/lb | $3.75/lb | $4.00/lb | $4.25/lb | $4.50/lb |

| Net present value1 @ 8% | $ millions | $463 | $786 | $1,100 | $1,409 | $1,710 | $2,006 |

| Net present value1 @ 10% | $ millions | $227 | $503 | $771 | $1,033 | $1,289 | $1,540 |

| Internal rate of return1 | % | 12.70% | 16.00% | 19.20% | 22.40% | 25.50% | 28.50% |

| Payback period | # years | 7.9 | 6.7 | 5.9 | 5.4 | 5 | 4.4 |

| EBITDA (annual avg.)2 | $ millions | 288 | 330 | $372 | 413 | 455 | 497 |

| Concentrate Leach Facility (at $3.75/lb Cu) | Unit | No Conc Leach (Flotation Only) | 50% Capacity in Year 5 (Base Case) | 50% Capacity in Year 1 | 100% Capacity in Year 5 | 100% Capacity in Year 1 | |

| Net present value1 @ 8% | $ millions | $863 | $1,100 | $1,222 | $1,302 | $1,523 | |

| Net present value1 @ 10% | $ millions | $605 | $771 | $869 | $922 | $1,105 | |

| Internal rate of return1 | % | 18.70% | 19.20% | 19.60% | 20.00% | 21.00% | |

| Payback period | # years | 5.3 | 5.9 | 5.1 | 6 | 4.8 | |

| EBITDA (annual avg.) 2 | $ millions | $296 | $372 | $389 | $413 | $441 | |

| Copper production (annual avg.)3 | 000 tonnes | 85.8 | 85.3 | 85.1 | 118 | 124.5 | |

| Cash cost4 | $/lb Cu | $1.81 | $1.47 | $1.39 | $1.43 | $1.34 | |

| Sustaining cash cost4 | $/lb Cu | $2.15 | $1.81 | $1.73 | $1.77 | $1.69 | |

1 Net present value and internal rate of return are shown on an after-tax basis.

2 EBITDA is a non-IFRS financial performance measure with no standardized definition under IFRS. For further information, please refer to the company’s Management’s Discussion and Analysis for the three and six months ended June 30, 2023.

3 Copper production includes copper contained in concentrate sold and copper cathode produced from the concentrate leach facility. In the 100% Albion scenarios, the production facilities are assumed to have an increased annual capacity of 140,000 tonnes of copper cathode, providing the opportunity to purchase third party concentrate to maximize the utilization of the SX/EW facility. Average annual copper production excludes partial year of production in year 20.

4 Cash cost and sustaining cash cost exclude the cost of purchasing external concentrate, which may vary in price and or potentially be replaced with additional internal feed. By-product credits calculated using amortization of deferred revenue for gold and silver stream sales as per the company’s approach in its quarterly financial reporting. By-product credits also include the revenue from the sale of excess acid produced at a price of $145 per tonne. Sustaining cash cost includes sustaining capital expenditures and royalties. Cash cost and sustaining cash cost are non-IFRS financial performance measures with no standardized definition under IFRS. For further details on why Hudbay believes cash costs are a useful performance indicator, please refer to the company’s Management’s Discussion and Analysis for the three and six months ended June 30, 2023.

Simplified Project Design

Copper World is planned to be a traditional open pit shovel and truck operation with a conventional flotation concentrator producing copper concentrate and molybdenum concentrate, with an expansion of the processing facility to include a copper concentrate leach facility in year 5, producing copper cathode and silver/gold doré.

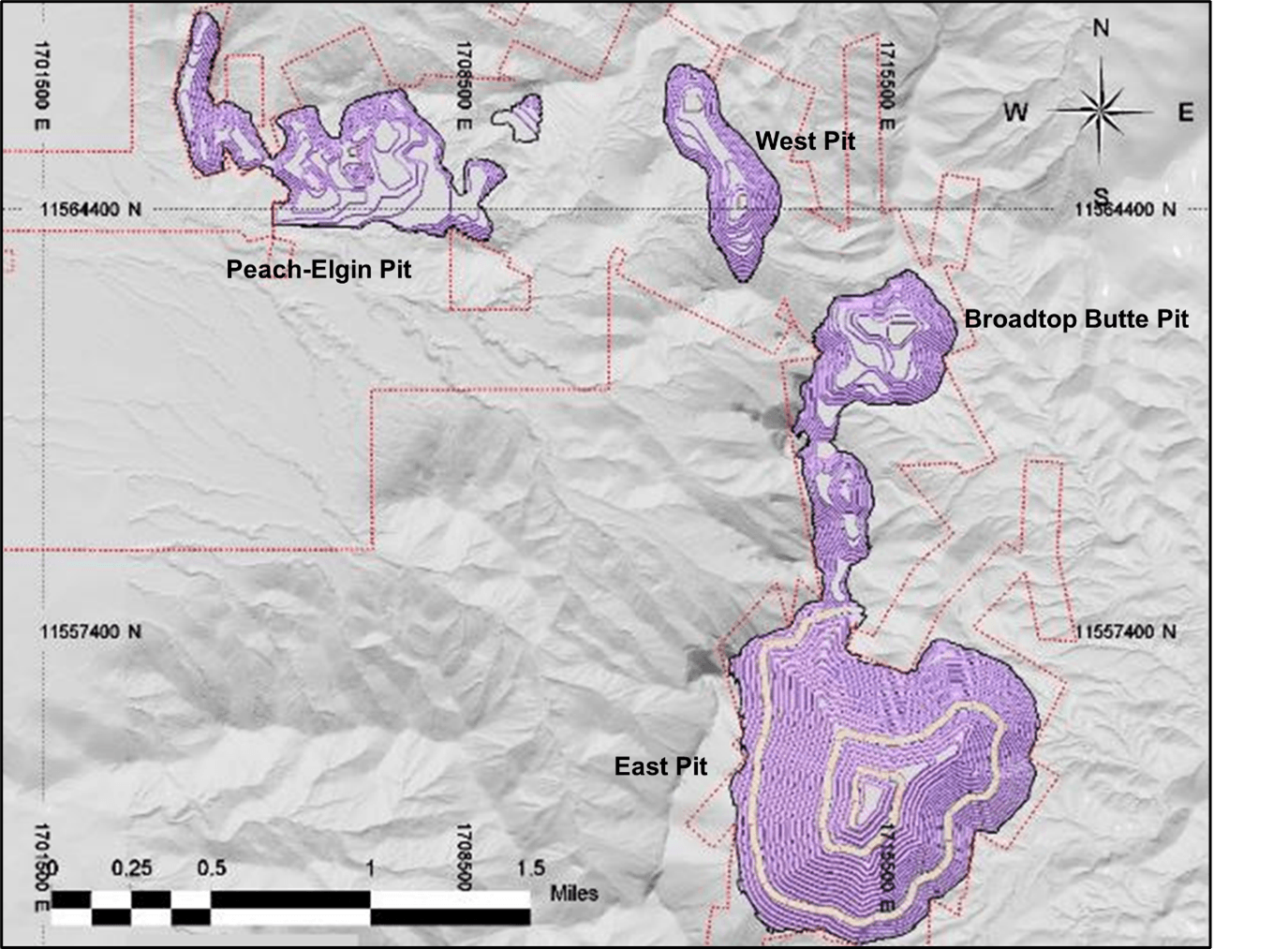

The overall mining operation is expected to consist of four open pits in Phase I, as shown in Figure 1, with similar processing infrastructure as contemplated in the 2022 PEA. The mine plan for Phase I is now optimized solely on the flotation of both copper sulfides and oxides.

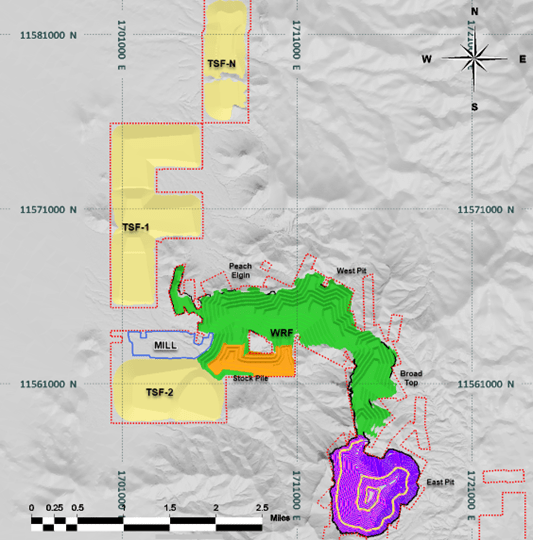

The concentrator during Phase I will have an installed capacity of 60,000 tons per day with conventional crushing, grinding, flotation, molybdenum separation, concentrate dewatering and tailings thickening. For the first 4 years, the final product is a copper concentrate sold to market. The processing plant is expected to be expanded by year 5 with the construction of a concentrate leach facility in year 4, which will produce copper cathodes and silver/gold doré. The concentrate leach facility will also include sulfur flotation, an acid plant, an SX/EW plant and a Merrill Crowe circuit for precious metals. Please refer to Figure 2 for an overview of the plant layout. The concentrate leach facility will also produce sulfur which will be processed into sulfuric acid at the acid plant. When sulfur production from the concentrate leach process is insufficient to fill the sulfuric acid plant capacity, sulfur will be purchased at local market price. When sulfuric acid production exceeds the concentrate leach requirements, the excess will be sold.

As part of the PFS, detailed test work was completed on the different concentrate leach technologies, including Glencore Technology’s Albion Process (“Albion”) as well as low and high temperature pressure oxidation. The tests indicate Albion and high temperature pressure oxidation yield the highest copper extraction rates in the range of 97% to 99% for all samples. Albion was selected as the preferred concentrate leach technology because it is simpler to operate, is modular and offers flexibility to scale the plant and has significantly lower acid neutralization requirements when compared to high temperature pressure oxidation.

The concentrate leach facility is sized at 70,000 tonnes of copper cathode during Phase I, which represents 50% of the maximum 140,000-tonne design capacity. In the PFS, there remains the opportunity to process third party feed during the last two years of the mine life to maximize the utilization of the SX/EW facility. Given the modular nature of the Albion technology, there also remains the opportunity to increase the scale of the concentrate leach facility up to the maximum design capacity, which will allow for the processing of additional internal concentrates or third party feed and further increase the NPV and IRR as shown in the sensitivity analysis table on the previous page.

The PFS contemplates the construction of three tailings storage facilities for Phase I and provides storage for 385 million tonnes, sufficient for 20 years of mine life on land requiring state and local permits only. Please refer to Figure 3 for a layout of the tailings storage facilities.

Total initial capital costs are estimated to be $1.3 billion for Phase I ($1.1 billion net of existing stream agreement), including all costs associated with the construction of the concentrator and associated infrastructure. The construction of the concentrate leach facility in year 4 is estimated at $367 million and includes the cost for the SX/EW plant, acid plant, sulfur burner and precious metals plant. Contingency costs have been applied to direct capital costs at 20% and the PFS assumes capital leasing of mobile equipment. For further details on the capital cost estimates, please refer to Exhibit 1.

Significant Social & Environmental Benefits

Global copper market fundamentals are expected to be strong with a structural deficit emerging in the medium term. Global mine production and available smelter capacity are expected to struggle to keep pace with metal demand boosted by the green energy revolution. The U.S. is expected to remain a net copper importer during this period, and domestic supply will be required to help secure growing U.S. metal demand related to increased manufacturing capacity, infrastructure development, bolstering the country’s energy independence and domestic EV battery supply chain and production needs.

The “Made in America” copper cathode produced at Copper World is expected to be sold entirely to domestic U.S. customers and would make Copper World the third largest domestic cathode producer in the United Statesii. Producing copper cathode would reduce the operation’s total energy requirements, and greenhouse gas (“GHG”) and sulfur (SO2) emissions by eliminating overseas shipping, smelting and refining activities relating to copper concentrate. The company estimates that the project will reduce total energy consumption by more than 10%, including a more than 30% decline in energy consumption relating to downstream processing, when compared to a project design that produces copper concentrates for overseas smelting and refining. The PFS base case is expected to result in an approximate 14% reduction in scope 1, 2 and 3 GHG emissions compared to the flotation only scenario, as highlighted in Figure 4. Hudbay is targeting further reductions in the project’s GHG emissions as part of the company’s specific emissions reduction targets for its existing operations to align with the global 50% by 2030 climate change goal, which are discussed in the section titled “Project Optimization and Upside Opportunities” below.

The Copper World project is expected to generate significant benefits for the community and local economy in Arizona. Over the anticipated 20-year life of the operation, the company expects to contribute more than $850 million in U.S. taxes, including approximately $170 million in taxes to the state of Arizona. Hudbay also expects Copper World to create more than 400 direct jobs and up to 3,000 indirect jobs in Arizona. Copper World will offer competitive wages and benefits and the company intends to engage in partnerships with local apprenticeship readiness programs and community-based workforce training programs across the skilled and technical levels to fill and maintain all positions. The project is also expected to generate approximately $250 million in property taxes over the 20-year mine life.

In July 2023, the U.S. Department of Energy announced the designation of copper as a critical material for energy. Hudbay has applied for tax credits under the Inflation Reduction Act that are being awarded by the U.S. Department of Energy in conjunction with the Internal Revenue Agency for qualifying projects that construct processing facilities for Critical Material for Sustainable Energy Initiatives. The copper cathode produced at Copper World, together with the significant social benefits for the community and local economy, position the project as a strong candidate for government tax incentives. The financial analysis in the PFS does not incorporate any potential benefits from these tax incentives.

Simplified Permitting Process

The permitting process for Copper World is expected to only require state and local permits for Phase I. In July 2022, Hudbay received approval from the Arizona State Mine Inspector for its amended Mined Land Reclamation Plan, the first key state permit required for Copper World. The MLRP was initially approved in October 2021 and was subsequently amended to reflect a larger private land project footprint. This approval by the Arizona State Mine Inspector was challenged in state court but the challenge was dismissed in May 2023 as having no basis. In late 2022, Hudbay submitted the applications for an Aquifer Protection Permit and an Air Quality Permit to the Arizona Department of Environmental Quality. The company expects to receive these two outstanding state permits in mid-2024.

In May 2023, the U.S. Supreme Court issued a favourable decision in the case of Sackett v EPA that clarified the definition of “Waters of the U.S.” and rejected the “significant nexus” test that the agencies had previously used to assert jurisdiction over relatively remote dry washes like those at the Copper World site. This decision strengthens Hudbay’s position that no 404 Permit or other Clean Water Act approvals are required for the Copper World project.

Also, in May 2023, Hudbay received a favourable ruling from the U.S. Court of Appeals for the Ninth Circuit that reversed the U.S. Fish and Wildlife Service’s designation of the Copper World area as jaguar critical habitat. While this ruling does not impact the state permitting process for Phase I of Copper World, it is expected to simplify the federal permitting process for Phase II.

Mineral Reserve and Resource Estimates

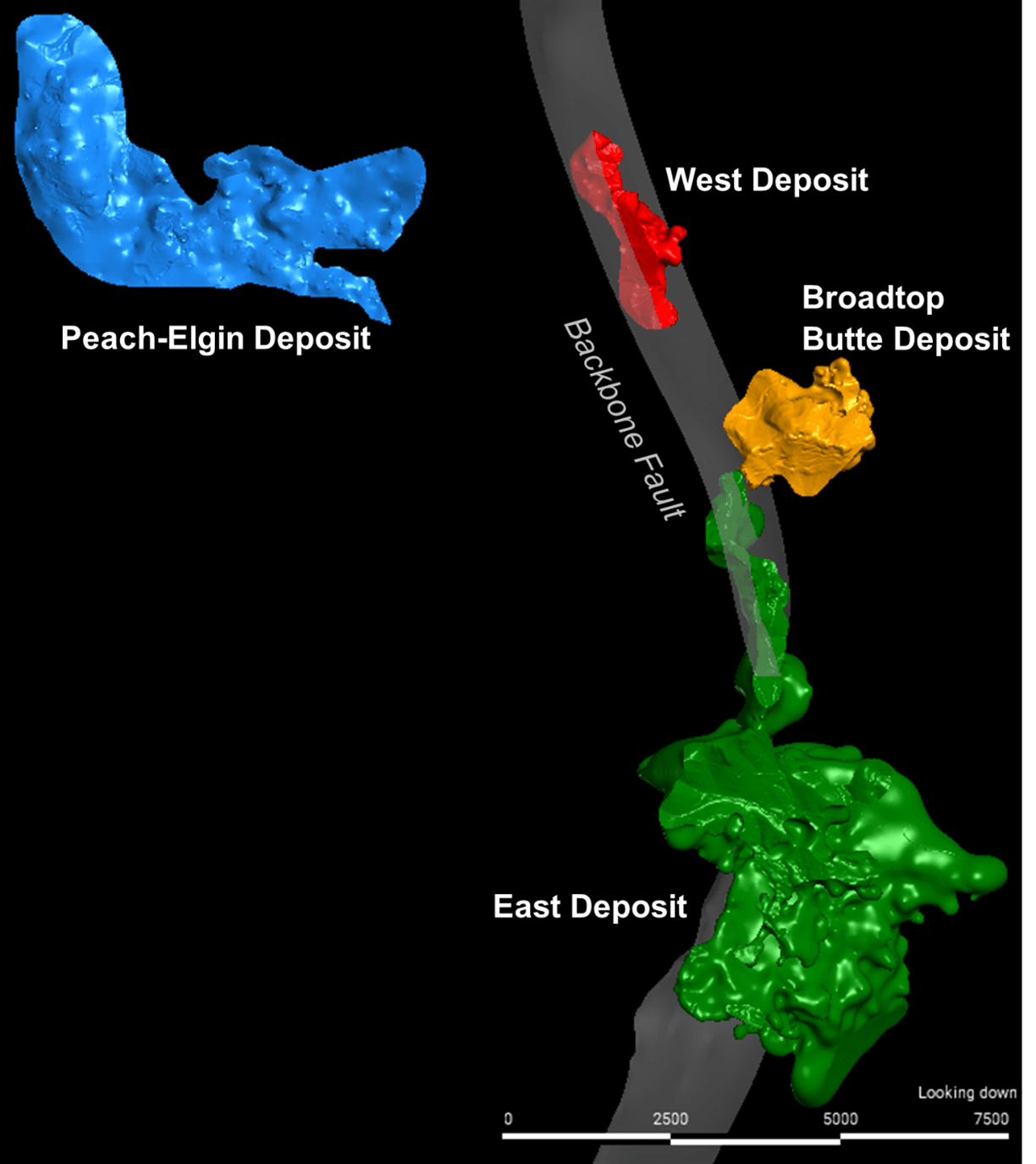

The PFS and mine plan are based on updated mineral resource estimates for the Copper World deposits, which include the Peach-Elgin, West, Broadtop Butte and East deposits, as shown in Figure 5. Based on the new model, contained copper in measured and indicated mineral resources, inclusive of mineral reserves, has increased by 4% as compared to the mineral resources in the 2022 PEA. In addition, contained copper in mill feed increased by 41% in the PFS compared to the contained copper in milled resources in Phase I of the PEA mine plan due to higher grades and the flotation of both copper sulfides and oxides.

The mineral reserves milled is lower than the mineral resources mined in the PFS due to limitations on tailings capacity beyond 20 years in Phase I. There are approximately 40 million tonnes of resources that are economic to mine in the PFS but are excluded from the reserves and cash flow analysis. This additional material provides upside potential that could be included in the mine plan if additional land is accessed for tailings capacity.

The current mineral reserve and resource estimates for Copper World (effective as of July 1, 2023) are summarized below and replace the prior mineral resource estimates set forth in the 2022 PEA.

| Copper World Project Mineral Reserve and Resource Estimates1,2,3,4 |

Tonnes (millions) |

Cu Grade (%) | Soluble Cu Grade (%) | Mo Grade (g/t) | Au Grade (g/t) | Ag Grade (g/t) |

| Proven reserves | 319 | 0.54 | 0.11 | 110 | 0.03 | 5.68 |

| Probable reserves | 66 | 0.52 | 0.14 | 96 | 0.02 | 4.31 |

| Total Proven and Probable Reserves | 385 | 0.54 | 0.12 | 108 | 0.02 | 5.44 |

| Measured resources | 888 | 0.43 | 0.10 | 121 | 0.02 | 4.46 |

| Indicated resources | 317 | 0.38 | 0.10 | 108 | 0.02 | 3.52 |

| Total Measured and Indicated | 1,205 | 0.42 | 0.10 | 117 | 0.02 | 4.22 |

| Inferred resources | 275 | 0.32 | 0.10 | 106 | 0.01 | 2.82 |

Note: totals may not add up correctly due to rounding.

1 Mineral resource estimates are inclusive of mineral reserves and have been calculated using assumed long-term metal prices of $3.75 per pound copper, $12.00 per pound molybdenum, $1,650 per ounce gold and $22.00 per ounce silver.

2 Mineral resource estimates that are not mineral reserves do not have demonstrated economic viability. Mineral resource estimates are based on resource pit design and do not include factors for mining recovery or dilution.

3 Mineral resource estimates are constrained to a Lerch Grossman pit shell with a revenue factor of 1.0 or inside the reserve pit.

4 Mineral resource estimates are using a 0.1% soluble copper cut-off grade and an oxidation ratio higher than 50% for leach material.

| Copper World Comparison of Mineral Resource Estimates1,2 | |||||||

| 2022 | 2023 | % Change | |||||

| Tonnes (millions) | Cu (%) |

Cu (000 tonnes) | Tonnes (millions) | Cu (%) |

Cu (000 tonnes) | Cu (000 tonnes) | |

| Measured and Indicated | 1,173 | 0.41 | 4,829 | 1,205 | 0.42 | 5,020 | 4% |

| Inferred | 262 | 0.37 | 957 | 275 | 0.32 | 893 | -7% |

Note: totals may not add up correctly due to rounding.

1 2023 mineral resource estimates are inclusive of mineral reserve estimates.

2 2022 mineral resource estimates include both flotation and leach material and were based on metals prices and other assumptions set forth in the 2022 PEA.

| Copper World Comparison of Phase I Mill Feed | |||||||

| 2022 PEA | 2023 PFS | % Change | |||||

| Tonnes (millions) | Cu (%) |

Cu (000 tonnes) | Tonnes (millions) | Cu (%) |

Cu (000 tonnes) | Cu (000 tonnes) | |

| Mill Feed | 316 | 0.47 | 1,473 | 385 | 0.54 | 2,082 | 41% |

Note: totals may not add up correctly due to rounding.

Project Optimization and Upside Opportunities

The company has identified many opportunities that may further enhance project economics, reduce environmental impacts, increase annual production and extend mine life, which have not been considered in the Phase I PFS.

- Mine Life Extension Potential – There remains approximately 60% of the total copper contained in measured and indicated mineral resources excluding the PFS reserves, providing significant potential for the Phase II expansion and mine life extension. In addition, the inferred mineral resources estimates are at a comparable copper grade and also provide significant upside potential.

- Increased Concentrate Leach Capacity – The selected concentrate leach technology allows the facility to be scalable in the future to be large enough to process all of the internally produced copper concentrates, further enhancing project economics and IRR. Operating the Albion plant at 100% capacity is estimated to reduce total GHG emissions by 25% compared to an operation that only produces copper concentrate.

- Access to Federal Green Funding Incentives – Hudbay is exploring options for government incentives to help fund the future development of the concentrate leach facility, which may offer attractive financing terms and allow the construction of the concentrate leach facility to occur earlier and potentially at a larger capacity with improved project economics.

- Earlier Receipt of Federal Permits for Phase II Expansion – Hudbay is optimistic that it will be able to secure federal permits well before the end of the life of Phase I, which could allow the mining of more high-value tonnes earlier in the mine life and significantly increase annual copper production, the project economics and IRR.

- Green Opportunities – There are several emission reduction opportunities the company will evaluate with future studies, including the potential to source renewable energy from local providers at a nominal cost, the use of autonomous or electric haul trucks at the operation and various post-reclamation land uses such as domestic renewable energy production. Also, if Hudbay is able to secure additional private land to improve the tailings configuration, there is the potential to accelerate dry stack tailings deposition into Phase I, which would reduce water consumption.

Prudent Financing Plan and Disciplined Capital Allocation

As part of Hudbay’s disciplined financial planning approach to Copper World, the company has introduced a three prerequisites plan (“3-P”), including specific leverage targets that it would need to achieve prior to making an investment decision in the project:

- Permits – receipt of all state level permits required for Phase I

- Plan – completion of a definitive feasibility study with an internal rate of return of greater than 15%

- Prudent Financing Strategy – multi-faceted financing strategy including

- a committed minority joint venture partner;

- a renegotiated precious metals stream agreement optimized for the current project;

- net debt to EBITDA ratio of less than 1.2 times;

- a minimum cash balance of $600 million; and,

- limited non-recourse project level debt of up to $500 million.

Under the existing precious metals stream agreement with Wheaton Precious Metals, Hudbay is entitled to receive a deposit payment of $230 million for delivery of gold and silver production from Copper World. The estimated total initial funding requirement for Phase I of Copper World, net of the stream agreement, amounts to approximately $1.1 billion.

Hudbay intends to complete a minority joint venture partner process after receiving permits and prior to commencing a definitive feasibility study, which will allow the potential joint venture partner to participate in the funding of definitive feasibility study activities in 2024 as well as in the final project design for Copper World. The opportunity to sanction Copper World is not expected until 2025 based on current estimated timelines. The decision to sanction Copper World will ultimately be evaluated against other competing investment opportunities as part of Hudbay’s capital allocation process.

Non-IFRS Financial Performance Measures

Cash cost and sustaining cash cost per pound of copper produced are shown because the company believes they help investors and management assess the performance of its operations, including the margin generated by the operations and the company. Unit operating costs are shown because these measures are used by the company as a key performance indicator to assess the performance of its mining and processing operations. EBITDA is shown to provide additional information about the cash generating potential in order to assess the company’s capacity to service and repay debt, carry out investments and cover working capital needs. These measures do not have a meaning prescribed by IFRS and are therefore unlikely to be comparable to similar measures presented by other issuers. These measures should not be considered in isolation or as a substitute for measures prepared in accordance with IFRS and are not necessarily indicative of operating profit or cash flow from operations as determined under IFRS. Other companies may calculate these measures differently. For further details on these measures, please refer to page 42 of Hudbay’s management’s discussion and analysis for the three and six months ended June 30, 2023 available on SEDAR+ at www.sedarplus.ca and EDGAR at www.sec.gov.

Qualified Person and NI 43-101

The scientific and technical information contained in this news release has been approved by Olivier Tavchandjian, P. Geo, Hudbay’s Senior Vice-President, Exploration and Technical Services. Mr. Tavchandjian is a qualified person pursuant to Canadian Securities Administrators’ National Instrument 43-101 – Standards of Disclosure for Mineral Projects (“NI 43-101”).

A copy of the NI 43-101 technical report for the PFS will be made available on Hudbay’s SEDAR+ profile at www.sedarplus.ca and on Hudbay’s EDGAR profile at www.sec.gov. The new technical report supports the disclosure in this news release and will be the current technical report in respect of all the mineral properties that form part of the Copper World project and shall supersede and replace the 2022 PEA in its entirety.

About Hudbay

Hudbay is a copper-focused mining company with three long-life operations and a world-class pipeline of copper growth projects in tier-one mining-friendly jurisdictions of Canada, Peru and the United States.

Hudbay’s operating portfolio includes the Constancia mine in Cusco (Peru), the Snow Lake operations in Manitoba (Canada) and the Copper Mountain mine in British Columbia (Canada). Copper is the primary metal produced by the company, which is complemented by meaningful gold production. Hudbay’s growth pipeline includes the Copper World project in Arizona, the Mason project in Nevada (United States), the Llaguen project in La Libertad (Peru) and several expansion and exploration opportunities near its existing operations.

The value Hudbay creates and the impact it has is embodied in its purpose statement: “We care about our people, our communities and our planet. Hudbay provides the metals the world needs. We work sustainably, transform lives and create better futures for communities.” Hudbay’s mission is to create sustainable value and strong returns by leveraging its core strengths in community relations, focused exploration, mine development and efficient operations.

Exhibit 1: Detailed Cash Flow Model and Key Assumptions

A detailed cash flow model containing annual production and cost information is shown below. Overall assumptions for commodity prices, marketing parameters, operating costs and capital costs are also provided.

| Phase I: Physicals | UNIT | TOTAL | Y-01 | Y01 | Y02 | Y03 | Y04 | Y05 | Y06 | Y07 | Y08 | Y09 | Y10 | Y11 | Y12 | Y13 | Y14 | Y15 | Y16 | Y17 | Y18 | Y19 | Y20 | |||||

| Material Moved | Pre-strip | |||||||||||||||||||||||||||

| Resources mined | Mtonne | 426.0 | 18.1 | 27.4 | 33.8 | 42.8 | 25.3 | 25.0 | 20.7 | 21.1 | 22.9 | 23.1 | 21.4 | 19.9 | 19.9 | 19.9 | 17.1 | 15.3 | 15.3 | 12.6 | 14.4 | 9.8 | – | |||||

| Waste mined | Mtonne | 776.6 | 36.3 | 43.7 | 51.9 | 46.0 | 61.8 | 62.4 | 65.0 | 67.4 | 63.7 | 66.7 | 54.4 | 43.6 | 43.6 | 39.1 | 17.5 | 10.9 | 2.0 | 0.3 | 0.1 | 0.1 | – | |||||

| Rehandle | Mtonne | 62.4 | – | 1.5 | 0.5 | 1.1 | 2.7 | 2.4 | 4.1 | 1.3 | 3.2 | – | 1.2 | – | 0.0 | – | 2.7 | 4.5 | 4.5 | 7.3 | 5.4 | 10.0 | 9.9 | |||||

| Total material moved | Mtonne | 1,265.0 | 54.4 | 72.6 | 86.2 | 89.8 | 89.8 | 89.8 | 89.8 | 89.8 | 89.8 | 89.8 | 77.1 | 63.5 | 63.5 | 59.0 | 37.3 | 30.8 | 21.8 | 20.2 | 20.0 | 20.0 | 9.9 | |||||

| Strip Ratio | Pre-strip | |||||||||||||||||||||||||||

| Strip ratio | X:X | 1.82 | 2.01 | 1.59 | 1.54 | 1.08 | 2.44 | 2.49 | 3.15 | 3.19 | 2.78 | 2.89 | 2.54 | 2.20 | 2.20 | 1.97 | 1.02 | 0.71 | 0.13 | 0.02 | 0.01 | 0.01 | – | |||||

| Reserves Milled | ||||||||||||||||||||||||||||

| Reserves milled | Mtonne | 385.1 | – | 17.6 | 19.9 | 19.9 | 19.9 | 19.9 | 19.9 | 19.9 | 19.9 | 19.9 | 19.9 | 19.9 | 19.9 | 19.9 | 19.9 | 19.9 | 19.9 | 19.9 | 19.9 | 19.9 | 9.9 | |||||

| Headgrade – Cu | % | 0.54 % | – | 0.64 | 0.54 | 0.50 | 0.49 | 0.54 | 0.79 | 0.60 | 0.59 | 0.58 | 0.58 | 0.48 | 0.44 | 0.48 | 0.58 | 0.53 | 0.56 | 0.54 | 0.58 | 0.41 | 0.24 | |||||

| Headgrade – Au | g/tonne | 0.03 | – | 0.02 | 0.02 | 0.02 | 0.01 | 0.02 | 0.03 | 0.03 | 0.03 | 0.04 | 0.03 | 0.03 | 0.03 | 0.03 | 0.04 | 0.03 | 0.03 | 0.03 | 0.04 | 0.03 | 0.01 | |||||

| Headgrade – Ag | g/tonne | 6.00 | – | 3.73 | 4.09 | 4.28 | 4.11 | 8.00 | 8.06 | 8.12 | 5.27 | 7.89 | 7.21 | 6.01 | 6.41 | 6.91 | 7.89 | 4.56 | 4.79 | 5.41 | 7.76 | 5.06 | 2.29 | |||||

| Headgrade – Mo | % | 0.01 % | – | 0.02 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | |||||

| Recovery to Concentrate | ||||||||||||||||||||||||||||

| Cu | % | 79.00% | – | 82.91 | 81.78 | 83.02 | 83.18 | 82.50 | 70.14 | 82.20 | 82.31 | 84.13 | 84.29% | 83.39% | 83.16% | 83.27% | 69.02% | 68.08% | 82.02% | 71.49% | 82.37 | 67.54 | 63.23 | |||||

| Au | % | 41.21% | – | 42.65 | 40.58 | 42.85 | 43.16 | 41.88 | 38.03 | 41.33 | 41.52 | 45.02 | 45.32% | 43.57% | 43.11% | 43.33% | 37.65% | 37.33% | 41.01% | 38.48% | 41.65% | 37.15% | 35.66% | |||||

| Ag | % | 56.43% | – | 57.95 | 55.56 | 58.17 | 58.53 | 57.06 | 52.60 | 56.43 | 56.66 | 60.65 | 60.99% | 59.00% | 58.48% | 58.73% | 52.16% | 51.79% | 56.06% | 53.13% | 56.80% | 51.58% | 49.83% | |||||

| Mo | % | 53.67% | – | 56.19 | 52.26 | 56.56 | 57.16 | 54.71 | 47.57 | 53.67 | 54.04 | 60.76 | 61.36% | 57.95% | 57.07% | 57.49% | 46.88% | 46.31% | 53.08% | 48.39% | 54.27% | 45.98% | 43.33% | |||||

| Cu Conc Produced – Sold to Market | ||||||||||||||||||||||||||||

| Cu Concentrate | Ktonne | 2,991 | – | 401 | 456 | 398 | 319 | 48 | 130 | 130 | 139 | 127 | 82 | 57 | 76 | 99 | 57 | 129 | 150 | 111 | 81 | – | – | |||||

| Grade – Cu | % | 23.16 % | – | 23.22% | 19.36% | 20.51% | 25.21% | 33.21% | 29.12% | 25.26% | 24.58% | 25.34% | 29.73% | 25.44% | 21.92% | 22.29% | 25.28% | 18.64% | 22.33% | 20.84% | 28.61% | – | – | |||||

| Grade – Au | g/tonne | 0.51 | – | 0.36 | 0.29 | 0.35 | 0.32 | 0.65 | 0.68 | 0.55 | 0.70 | 1.05 | 0.71 | 0.72 | 0.73 | 0.84 | 0.84 | 0.53 | 0.64 | 0.63 | 0.89 | – | – | |||||

| Grade – Ag | g/tonne | 157.86 | – | 94.61 | 98.86 | 124.25 | 149.86 | 340.27 | 222.62 | 235.48 | 150.38 | 248.45 | 267.41 | 224.95 | 224.42 | 227.22 | 261.56 | 121.93 | 131.63 | 155.86 | 261.78 | – | – | |||||

| Cu cont’d in concentrate | Ktonne | 693 | – | 93 | 88 | 82 | 80 | 16 | 38 | 33 | 34 | 32 | 25 | 14 | 17 | 22 | 14 | 24 | 33 | 23 | 23 | – | – | |||||

| Au cont’d in concentrate | Koz | 49 | – | 5 | 4 | 4 | 3 | 1 | 3 | 2 | 3 | 4 | 2 | 1 | 2 | 3 | 2 | 2 | 3 | 2 | 2 | – | – | |||||

| Ag cont’d in concentrate | Koz | 15,181 | – | 1,219 | 1,451 | 1,591 | 1,535 | 530 | 934 | 986 | 672 | 1,015 | 709 | 410 | 549 | 725 | 480 | 505 | 633 | 556 | 682 | – | – | |||||

| Cu Conc Produced – To Conc Leach Facility | ||||||||||||||||||||||||||||

| Cu Concentrate | Ktonne | 3,870 | – | – | – | – | – | 218 | 248 | 256 | 256 | 256 | 244 | 256 | 256 | 256 | 256 | 256 | 256 | 256 | 253 | 227 | 122 | |||||

| Grade – Cu | % | 24.61 % | – | – | – | – | – | 33.21% | 29.12% | 25.26% | 24.58% | 25.34% | 29.73% | 25.44% | 21.92% | 22.29% | 25.28% | 18.64% | 22.33% | 20.84% | 28.61% | 24.02% | 12.24% | |||||

| Grade – Au | g/tonne | 0.72 | – | – | – | – | – | 0.65 | 0.68 | 0.55 | 0.70 | 1.05 | 0.71 | 0.72 | 0.73 | 0.84 | 0.84 | 0.53 | 0.64 | 0.63 | 0.89 | 0.84 | 0.39 | |||||

| Grade – Ag | g/tonne | 214.74 | – | – | – | – | – | 340.27 | 222.62 | 235.48 | 150.38 | 248.45 | 267.41 | 224.95 | 224.42 | 227.22 | 261.56 | 121.93 | 131.63 | 155.86 | 261.78 | 228.70 | 92.69 | |||||

| Cu cont’d in concentrate | Ktonne | 952 | – | – | – | – | – | 72 | 72 | 65 | 63 | 65 | 73 | 65 | 56 | 57 | 65 | 48 | 57 | 53 | 72 | 54 | 15 | |||||

| Au cont’d in concentrate | Koz | 90 | – | – | – | – | – | 5 | 5 | 4 | 6 | 9 | 6 | 6 | 6 | 7 | 7 | 4 | 5 | 5 | 7 | 6 | 2 | |||||

| Ag cont’d in concentrate | Koz | 26,722 | – | – | – | – | – | 2,387 | 1,776 | 1,940 | 1,236 | 2,041 | 2,099 | 1,853 | 1,844 | 1,867 | 2,149 | 1,005 | 1,082 | 1,281 | 2,131 | 1,666 | 364 | |||||

| Mo Conc Produced | ||||||||||||||||||||||||||||

| Mo Concentrate | Ktonne | 44.5 | – | 3.4 | 3.0 | 2.7 | 2.4 | 2.0 | 2.6 | 1.7 | 2.3 | 3.0 | 2.1 | 2.4 | 2.8 | 1.9 | 1.4 | 1.6 | 2.2 | 2.0 | 2.4 | 2.1 | 0.6 | |||||

| Grade – Mo | % | 50.00 % | – | 50.00% | 50.00% | 50.00% | 50.00% | 50.00% | 50.00% | 50.00% | 50.00% | 50.00% | 50.00% | 50.00% | 50.00% | 50.00% | 50.00% | 50.00% | 50.00% | 50.00% | 50.00% | 50.00% | 50.00% | |||||

| Mo cont’d in concentrate | Ktonne | 22.3 | – | 1.7 | 1.5 | 1.4 | 1.2 | 1.0 | 1.3 | 0.9 | 1.1 | 1.5 | 1.1 | 1.2 | 1.4 | 0.9 | 0.7 | 0.8 | 1.1 | 1.0 | 1.2 | 1.0 | 0.3 | |||||

| Purchased Cu Conc | ||||||||||||||||||||||||||||

| Cu Concentrate | Ktonne | 129.7 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 29.7 | 100.0 | |||||

| Grade – Cu | % | 28.00 % | – | – | – | – | – | 28.00% | 28.00% | 28.00% | 28.00% | 28.00% | 28.00% | 28.00% | 28.00% | 28.00% | 28.00% | 28.00% | 28.00% | 28.00% | 28.00% | 28.00% | 28.00% | |||||

| Grade – Au | g/tonne | 0.30 | – | – | – | – | – | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | |||||

| Grade – Ag | g/tonne | 110.00 | – | – | – | – | – | 110.00 | 110.00 | 110.00 | 110.00 | 110.00 | 110.00 | 110.00 | 110.00 | 110.00 | 110.00 | 110.00 | 110.00 | 110.00 | 110.00 | 110.00 | 110.00 | |||||

| Recovery to Cu Cathode | ||||||||||||||||||||||||||||

| From Mill | % | 98.12 % | – | – | – | – | – | 98.10% | 98.22% | 98.11% | 98.11% | 98.00% | 97.99% | 98.05% | 98.06% | 98.05% | 98.23% | 98.25% | 98.12% | 98.21% | 98.10% | 98.25% | 98.31% | |||||

| From Purchased | % | 97.80 % | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 97.80% | 97.80% | |||||

| Cu Cathode Produced | ||||||||||||||||||||||||||||

| From Mill | Ktonne | 934.5 | – | – | – | – | – | 71.1 | 71.0 | 63.5 | 61.6 | 63.5 | 71.1 | 63.9 | 54.9 | 55.8 | 63.5 | 46.9 | 56.0 | 52.3 | 71.1 | 53.5 | 14.7 | |||||

| From Purchased | Ktonne | 35.5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 8.1 | 27.4 | |||||

| Total Cu cathode | Ktonne | 970.0 | – | – | – | – | – | 71.1 | 71.0 | 63.5 | 61.6 | 63.5 | 71.1 | 63.9 | 54.9 | 55.8 | 63.5 | 46.9 | 56.0 | 52.3 | 71.1 | 61.6 | 42.1 | |||||

| Doré Produced | ||||||||||||||||||||||||||||

| From Mill | Moz | 27.3 | – | – | – | – | – | 2.4 | 1.8 | 2.0 | 1.3 | 2.1 | 2.1 | 1.9 | 1.9 | 1.9 | 2.2 | 1.0 | 1.1 | 1.3 | 2.2 | 1.7 | 0.4 | |||||

| From Purchased | Moz | 0.4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 0.1 | 0.3 | |||||

| Total Dore | Moz | 27.7 | – | – | – | – | – | 2.4 | 1.8 | 2.0 | 1.3 | 2.1 | 2.1 | 1.9 | 1.9 | 1.9 | 2.2 | 1.0 | 1.1 | 1.3 | 2.2 | 1.8 | 0.7 | |||||

| Au in Doré | % | 86 | – | – | – | – | – | 4 | 5 | 4 | 5 | 8 | 5 | 6 | 6 | 7 | 7 | 4 | 5 | 5 | 7 | 6 | 2 | |||||

| Ag in Doré | % | 25,520 | – | – | – | – | – | 2,245 | 1,671 | 1,825 | 1,162 | 1,920 | 1,975 | 1,743 | 1,734 | 1,756 | 2,021 | 945 | 1,017 | 1,204 | 2,004 | 1,656 | 642 | |||||

| Acid Plant | ||||||||||||||||||||||||||||

| Purchased sulphur | Ktonne | 1,721.7 | – | – | – | – | – | 107.8 | 108.2 | 106.6 | 107.8 | 105.8 | 104.2 | 106.8 | 108.1 | 108.4 | 110.7 | 111.5 | 107.5 | 110.0 | 106.3 | 109.2 | 102.8 | |||||

| Excess acid produced | Ktonne | 5,994.5 | – | – | – | – | – | 374.7 | 374.7 | 374.7 | 374.6 | 374.7 | 374.7 | 374.7 | 374.7 | 374.7 | 374.7 | 374.6 | 374.6 | 374.6 | 374.7 | 374.7 | 374.7 | |||||

| Total Production | ||||||||||||||||||||||||||||

| Cu – contained in conc sold | Ktonne | 693 | – | 93 | 88 | 82 | 80 | 16 | 38 | 33 | 34 | 32 | 25 | 14 | 17 | 22 | 14 | 24 | 33 | 23 | 23 | – | – | |||||

| Cu – cathode from conc leach | Ktonne | 970 | – | – | – | – | – | 71 | 71 | 64 | 62 | 63 | 71 | 64 | 55 | 56 | 63 | 47 | 56 | 52 | 71 | 62 | 42 | |||||

| Cu – total production | Ktonne | 1,663 | – | 93 | 88 | 82 | 80 | 87 | 109 | 96 | 96 | 96 | 96 | 78 | 72 | 78 | 78 | 71 | 89 | 75 | 94 | 62 | 42 | |||||

| Cu Eq Production | Ktonne | 1,974.3 | – | 102.7 | 97.9 | 91.2 | 88.9 | 105.3 | 128.3 | 114.5 | 112.5 | 117.3 | 114.2 | 95.8 | 90.2 | 96.0 | 95.0 | 85.2 | 105.5 | 91.4 | 113.6 | 77.1 | 51.7 | |||||

| Phase I: Unit Costs | Unit | Phase I | Y01 | Y02 | Y03 | Y04 | Y05 | Y06 | Y07 | Y08 | Y09 | Y10 | Y11 | Y12 | Y13 | Y14 | Y15 | Y16 | Y17 | Y18 | Y19 | Y20 |

| Mining ($/t material moved excl. Pre-strip) | ||||||||||||||||||||||

| Mining | $/tonne | 2.48 | 1.80 | 1.74 | 1.85 | 2.02 | 2.23 | 2.30 | 2.29 | 2.29 | 2.30 | 2.60 | 2.93 | 2.83 | 3.03 | 3.57 | 3.76 | 4.24 | 4.20 | 4.13 | 3.73 | 2.24 |

| Deferred stripping | $/tonne | (0.30) | (0.00) | (0.40) | (0.22) | (0.62) | (0.27) | (0.57) | (0.61) | (0.42) | (0.49) | (0.34) | (0.12) | (0.12) | – | – | – | – | – | – | – | – |

| Mining ex def stripping | $/tonne | 2.18 | 1.79 | 1.35 | 1.63 | 1.41 | 1.96 | 1.72 | 1.68 | 1.87 | 1.81 | 2.26 | 2.81 | 2.71 | 3.03 | 3.57 | 3.76 | 4.24 | 4.20 | 4.13 | 3.73 | 2.24 |

| Processing ($/tonne Ore Milled) | ||||||||||||||||||||||

| Flotation | $/tonne | 4.07 | 4.11 | 4.11 | 4.09 | 4.06 | 4.04 | 4.08 | 4.09 | 4.09 | 4.08 | 4.06 | 4.06 | 4.06 | 4.07 | 4.06 | 4.09 | 4.09 | 4.08 | 4.06 | 4.03 | 4.03 |

| Concentrate Leach Facility | $/tonne | 2.04 | – | – | – | – | 2.48 | 2.52 | 2.51 | 2.51 | 2.50 | 2.48 | 2.51 | 2.50 | 2.51 | 2.55 | 2.52 | 2.49 | 2.51 | 2.52 | 2.52 | 3.88 |

| Tailings & water | $/tonne | 0.80 | 0.79 | 0.79 | 0.80 | 0.79 | 0.79 | 0.79 | 0.80 | 0.79 | 0.79 | 0.79 | 0.80 | 0.79 | 0.79 | 0.79 | 0.80 | 0.79 | 0.79 | 0.79 | 0.80 | 0.79 |

| Labor & other | $/tonne | 0.74 | 0.54 | 0.54 | 0.54 | 0.54 | 0.79 | 0.79 | 0.79 | 0.79 | 0.79 | 0.79 | 0.79 | 0.79 | 0.79 | 0.79 | 0.79 | 0.79 | 0.79 | 0.79 | 0.79 | 0.79 |

| Total | $/tonne | 7.65 | 5.44 | 5.45 | 5.43 | 5.39 | 8.11 | 8.19 | 8.19 | 8.18 | 8.17 | 8.13 | 8.16 | 8.16 | 8.17 | 8.19 | 8.19 | 8.17 | 8.17 | 8.17 | 8.14 | 9.50 |

| Other Unit Costs ($/tonne ore milled) | ||||||||||||||||||||||

| Onsite G&A | $/tonne | 0.90 | 0.91 | 0.80 | 0.80 | 0.80 | 0.80 | 0.85 | 0.85 | 0.85 | 0.85 | 0.85 | 0.90 | 0.90 | 0.90 | 0.90 | 0.90 | 1.05 | 1.05 | 1.05 | 1.05 | 1.05 |

| Cash Cost ($/lb Cu – ex. purchased conc) | ||||||||||||||||||||||

| Cash cost | $/lb | 1.47 | 1.68 | 1.83 | 2.07 | 1.89 | 1.48 | 1.18 | 1.34 | 1.44 | 1.28 | 1.35 | 1.63 | 1.73 | 1.69 | 1.38 | 1.59 | 1.13 | 1.22 | 0.86 | 1.35 | 1.87 |

| Sustaining cash cost | $/lb | 1.81 | 2.01 | 2.20 | 2.38 | 2.42 | 1.85 | 1.71 | 1.84 | 1.86 | 1.74 | 1.72 | 1.95 | 2.05 | 1.95 | 1.63 | 1.79 | 1.31 | 1.41 | 1.03 | 1.54 | 2.17 |

| PHASE I: CASH FLOWS | Unit | TOTAL | Y-03 | Y-02 | Y-01 | Y01 | Y02 | Y03 | Y04 | Y05 | Y06 | Y07 | Y08 | Y09 | Y10 | Y11 | Y12 | Y13 | Y14 | Y15 | Y16 | Y17 | Y18Y19Y20Y21Y22Y23Y24Y25 | |||||||||||||||

| Cash Flows | ||||||||||||||||||||||||||||||||||||||

| Gross revenue – internal | $M | 14,993 | – | – | – | 786 | 738 | 684 | 674 | 817 | 1,000 | 884 | 882 | 899 | 888 | 749 | 697 | 737 | 734 | 667 | 828 | 713 | 882541192—– | |||||||||||||||

| Gross revenue – purchased | $M | 305 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | -70236—– | |||||||||||||||

| TC/RC | $M | (440) | – | – | – | (56) | (58) | (52) | (44) | (10) | (22) | (18) | (21) | (21) | (14) | (12) | (14) | (15) | (8) | (17) | (22) | (17) | (15)(4)(1)—– | |||||||||||||||

| Freight | $M | (602) | – | – | – | (75) | (86) | (75) | (60) | (13) | (27) | (27) | (28) | (27) | (19) | (13) | (17) | (21) | (14) | (26) | (30) | (23) | (18)(3)(1)—– | |||||||||||||||

| Royalty | $M | (339) | – | – | – | (17) | (15) | (14) | (15) | (20) | (24) | (21) | (20) | (22) | (22) | (18) | (16) | (17) | (17) | (14) | (18) | (15) | (21)(12)(3)—– | |||||||||||||||

| Opex – Mining | $M | (2,641) | – | – | – | (130) | (116) | (146) | (126) | (176) | (155) | (151) | (168) | (163) | (174) | (178) | (172) | (179) | (133) | (116) | (93) | (85) | (83)(75)(22)—– | |||||||||||||||

| Opex – Processing | $M | (2,947) | – | – | – | (96) | (108) | (108) | (107) | (161) | (163) | (163) | (163) | (162) | (162) | (162) | (162) | (162) | (163) | (163) | (162) | (162) | (162)(162)(94)—– | |||||||||||||||

| Opex – Purch Cu Conc | $M | (272) | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | -(62)(210)—– | |||||||||||||||

| Opex – Onsite G&A | $M | (348) | – | – | – | (16) | (16) | (16) | (16) | (16) | (17) | (17) | (17) | (17) | (17) | (18) | (18) | (18) | (18) | (18) | (21) | (21) | (21)(21)(10)—– | |||||||||||||||

| Opex – Property tax | $M | (247) | – | – | – | (24) | (23) | (23) | (22) | (21) | (20) | (18) | (17) | (15) | (14) | (12) | (10) | (8) | (6) | (6) | (2) | (2) | (2)(2)(2)—– | |||||||||||||||

| Opex – Surety bond fees | $M | (27) | – | – | – | (1) | (1) | (1) | (1) | (1) | (1) | (1) | (1) | (1) | (1) | (1) | (1) | (1) | (1) | (1) | (1) | (1) | (1)(1)(1)—– | |||||||||||||||

| Closure Costs1 | $M | (133) | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | —(36)(36)(2)(2)(20) | |||||||||||||||

| End of life salvage/scrap | $M | 62 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | —62—- | |||||||||||||||

| Pre-operating costs | $M | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | ——– | |||||||||||||||

| Tax – Federal income | $M | (441) | (3) | (3) | – | – | – | – | – | – | (3) | (1) | (3) | (7) | (26) | (22) | (24) | (31) | (43) | (34) | (67) | (53) | (83)(31)(6)—– | |||||||||||||||

| Tax – State income | $M | (113) | – | (3) | – | – | – | – | – | – | – | – | – | (2) | (9) | (6) | (6) | (8) | (11) | (8) | (17) | (13) | (21)(8)(1)—– | |||||||||||||||

| Tax – State severance | $M | (55) | – | – | – | – | – | – | – | (1) | (3) | (2) | (3) | (4) | (4) | (3) | (3) | (3) | (4) | (3) | (6) | (5) | (7)(3)(1)—– | |||||||||||||||

| Tax – BEAT | $M | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | ——– | |||||||||||||||

| Cash From Ops before WC | $M | 6,754 | (3) | (6) | – | 371 | 315 | 249 | 282 | 398 | 565 | 465 | 442 | 458 | 427 | 304 | 254 | 274 | 315 | 261 | 390 | 316 | 4492277425(36)(2)(2)(20) | |||||||||||||||

| WC Changes – AR | $M | (0) | – | – | – | (60) | 4 | 4 | 0 | (15) | (14) | 9 | 0 | (1) | 0 | 11 | 5 | (3) | (0) | 6 | (13) | 9 | (14)211535—- | |||||||||||||||

| WC Changes – AP | $M | 0 | 27 | 68 | 30 | (50) | (0) | 0 | 62 | (55) | 5 | (6) | 0 | 1 | 2 | (5) | (1) | 2 | (6) | (5) | 4 | (6) | 6(7)(5)(53)-(6)– | |||||||||||||||

| WC Changes – Stream | $M | 230 | 162 | 68 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | ——– | |||||||||||||||

| Cash From Operations | $M | 6,985 | 187 | 130 | 30 | 261 | 319 | 253 | 345 | 329 | 555 | 467 | 442 | 457 | 428 | 309 | 257 | 273 | 309 | 263 | 381 | 319 | 441242847(36)(8)(2)(20) | |||||||||||||||

| Growth – EPCM | $M | (1,006) | (96) | (395) | (208) | – | – | – | (307) | – | – | – | – | – | – | – | – | – | – | – | – | – | ——– | |||||||||||||||

| Growth – Owners Costs | $M | (602) | (47) | (98) | (454) | – | – | – | (4) | – | – | – | – | – | – | – | – | – | – | – | – | – | ——– | |||||||||||||||

| Growth – Contingency | $M | (250) | (19) | (78) | (96) | – | – | – | (57) | – | – | – | – | – | – | – | – | – | – | – | – | – | ——– | |||||||||||||||

| Sustaining capital | $M | (701) | – | – | – | (95) | (52) | (51) | (62) | (64) | (61) | (30) | (30) | (30) | (30) | (30) | (28) | (28) | (27) | (18) | (17) | (15) | (14)(10)(7)—– | |||||||||||||||

| Deferred stripping | $M | (362) | – | – | – | (0) | (34) | (19) | (55) | (24) | (51) | (54) | (37) | (44) | (27) | (8) | (8) | – | – | – | – | – | ——– | |||||||||||||||

| Cash From Investing | $M | (2,920) | (162) | (571) | (757) | (95) | (87) | (70) | (484) | (88) | (112) | (85) | (68) | (74) | (57) | (38) | (36) | (28) | (27) | (18) | (17) | (15) | (14)(10)(7)—– | |||||||||||||||

| Loan – draw | $M | 482 | – | 8 | 159 | 37 | 26 | 24 | 32 | 36 | 84 | 18 | 13 | 11 | 15 | 15 | 4 | – | – | – | – | – | ——– | |||||||||||||||

| Loan – repayment | $M | (482) | – | – | (1) | (29) | (38) | (45) | (52) | (59) | (31) | (39) | (38) | (37) | (34) | (30) | (15) | (12) | (10) | (8) | (4) | (1) | ——– | |||||||||||||||

| Loan – interest | $M | (106) | – | – | (1) | (12) | (12) | (11) | (10) | (8) | (7) | (11) | (9) | (7) | (6) | (4) | (3) | (2) | (2) | (1) | (0) | (0) | ——– | |||||||||||||||

| Cash From Financing | $M | (106) | – | 8 | 157 | (4) | (23) | (32) | (30) | (32) | 47 | (32) | (35) | (33) | (24) | (19) | (14) | (14) | (11) | (8) | (5) | (1) | ——– | |||||||||||||||

| Net cash flow | $M | 3,959 | 25 | (433) | (571) | 162 | 208 | 150 | (170) | 209 | 490 | 351 | 340 | 350 | 347 | 252 | 207 | 231 | 271 | 236 | 359 | 303 | 427232777(36)(8)(2)(20) | |||||||||||||||

| Discount factors 8%2 | # | 0.981 | 0.926 | 0.857 | 0.794 | 0.735 | 0.681 | 0.630 | 0.583 | 0.540 | 0.500 | 0.463 | 0.429 | 0.397 | 0.368 | 0.340 | 0.315 | 0.292 | 0.270 | 0.250 | 0.232 | 0.2150.1990.1840.1700.1580.1460.1350.125 | ||||||||||||||||

| Discount factors 10%2 | # | 0.976 | 0.909 | 0.826 | 0.751 | 0.683 | 0.621 | 0.564 | 0.513 | 0.467 | 0.424 | 0.386 | 0.350 | 0.319 | 0.290 | 0.263 | 0.239 | 0.218 | 0.198 | 0.180 | 0.164 | 0.1490.1350.1230.1120.1020.0920.0840.076 | ||||||||||||||||

| NPV @ 8% | $M | 1,100.4 | ||||||||||||||||||||||||||||||||||||

| NPV @ 10% | $M | 770.7 | 1 Post closure costs beyond year 25 have been discounted to year 25 at 10% and added to the year 25 closure cost cash flow in the above table. Total column is the undiscounted total $ over the mine life | |||||||||||||||||||||||||||||||||||

| IRR | % | 19.21% | 2 Year -3 is a half year | |||||||||||||||||||||||||||||||||||

| PRICE DECK | ||

| PRICE / RATE | UNIT | LONG TERM |

| Metals | ||

| Copper | $/lb | 3.75 |

| Copper cathode net premium1 | $/lb | 0.02 |

| Molybdenum | $/lb | 12.00 |

| Gold – offtaker | $/oz | 1,650.00 |

| Silver – offtaker | $/oz | 22.00 |

| Gold – stream | $/oz | 450.00 |

| Silver – stream | $/oz | 3.90 |

| Stream contracted escalator2 | % per year | 1.00 |

| Other | ||

| Molten sulfur – purchases | $/tonne | 215.00 |

| Acid – sales | $/tonne | 145.00 |

| Electricity | $/kWh | 0.071 |

| NSR royalty | % | 3.00 |

1 Copper cathode premium net of cathode transport charge

2 Annual escalator begins in Year 3

| MARKETING ASSUMPTIONS | ||

| PRICE / RATE | UNIT | LONG TERM |

| Molybdenum Concentrate | ||

| Realization % (of contained value) | % | 88.00 |

| Dore | ||

| Refining charge – doré bar | $/oz | 0.40 |

| Refining charge – Au | $/oz | 0.55 |

| Payable % – Au | % | 99.90 |

| Payable % – Ag | % | 99.90 |

| Freight | $/oz | 1.40 |

| Cu Concentrate – Sales | ||

| Treatment charge | $/DMT | 75.00 |

| Refining charge – Cu | $/lb | 0.075 |

| Payable % – Cu | % | 96.50 |

| Payable % – Au | % | 90.00 |

| Payable % – Ag | % | 90.00 |

| Min deduction – Cu | % | 1.00 |

| Min grade – Au | g/tonne | 1.00 |

| Min grade – Ag | g/tonne | 30.00 |

| Freight | $/WMT | 173.00 |

| Moisture | % | 8.00 |

| Cu Concentrate – Purchases | ||

| Purchase price | $/tonne | 2,100.97 |

| Cu grade | % | 28.00 |

| Mo grade | % | 0.23 |

| Au grade | g/tonne | 0.30 |

| Ag grade | g/tonne | 110.00 |

| Zn grade | % | 0.25 |

| S grade | % | 34.00 |

| Freight capture | $/DMT | 80.00 |

| OPERATING COST DETAILS – MINING | ||

| METRIC | UNIT | Total |

| Labor | $M | $773 |

| Maintenance | $M | $877 |

| Fuel | $M | $781 |

| Power | $M | $18 |

| Blasting | $M | $359 |

| Indirect | $M | $196 |

| Subtotal* | $M | $3,003 |

| Deferred stripping | $M | ($362) |

| Total* | $M | $2,641 |

*Excludes pre-stripping costs

| OPERATING COST DETAILS – PROCESSING | ||

| METRIC | UNIT | LOM |

| Sulfide flotation | $M | $1,456 |

| Molybdenum flotation | $M | $71 |

| Concentrate leaching | $M | $359 |

| Precious metal plant | $M | $86 |

| Acid plant | $M | $5 |

| Molten sulfur purchased | $M | $370 |

| Tailings & water | $M | $313 |

| Labor | $M | $272 |

| Other | $M | $14 |

| Total | $M | $2,947 |

| CAPITAL COST SUMMARY | ||||

| METRIC | UNIT | Cu Concentrator | Cu Leach | Total |

| Growth – EPCM | $M | $833 | $364 | $1,197 |

| Growth – owner’s costs | $M | $490 | $4 | $494 |

| Growth – subtotal | $M | $1,323 | $367 | $1,690 |

| Sustaining | $M | $542 | $0 | $542 |

| Deferred stripping | $M | $362 | $0 | $362 |

| Total | $M | $2,227 | $367 | $2,595 |

| GROWTH CAPITAL DETAILS – EPCM | ||||

| METRIC | UNIT | Cu Concentrator | Cu Leach | Total |

| Sitewide | $M | $22 | $0 | $22 |

| Mining | $M | $34 | $0 | $34 |

| Primary crushing | $M | $31 | $0 | $31 |

| Sulfide plant | $M | $270 | $0 | $270 |

| Molybdenum plant | $M | $21 | $0 | $21 |

| Reagents | $M | $10 | $3 | $14 |

| Plant services | $M | $12 | $0 | $12 |

| Acid plant | $M | $0 | $79 | $79 |

| Concentrate leach SX/EW | $M | $0 | $28 | $28 |

| Precious metal plant | $M | $0 | $7 | $7 |

| Leach plant (Albion) | $M | $0 | $140 | $140 |

| Site services and utilities | $M | $4 | $0 | $4 |

| Internal infrastructure | $M | $52 | $0 | $52 |

| External infrastructure | $M | $112 | $0 | $112 |

| Common construction | $M | $33 | $13 | $46 |

| Other | $M | $98 | $37 | $134 |

| Contingency | $M | $134 | $57 | $191 |

| Total | $M | $833 | $364 | $1,197 |

| GROWTH CAPITAL DETAILS – OWNER’S COSTS | ||||

| METRIC | UNIT | Cu Concentrator | Cu Leach | Total |

| Mining fleet and equipment | $M | $218 | $0 | $218 |

| Less: equipment financing | $M | ($167) | $0 | ($167) |

| Pre-stripping | $M | $89 | $0 | $89 |

| Tailings storage | $M | $84 | $0 | $84 |

| Earthworks and roads | $M | $26 | $0 | $26 |

| G&A and other | $M | $149 | $4 | $153 |

| Indirects and contingency | $M | $90 | $0 | $90 |

| Total | $M | $490 | $4 | $494 |

| SUSTAINING CAPITAL DETAILS | ||

| METRIC | UNIT | Total |

| Mining – fleet | $M | $186 |

| Less: equipment financing | $M | ($158) |

| Mining – all other | $M | $422 |

| Processing | $M | 57 |

| Admin | $M | 37 |

| Total | $M | 542 |

Figure 1: Copper World Phase I Open Pit Footprint

Phase I is expected to consist of four open pits and all associated infrastructure within a footprint that requires only state and local permits for 20 years of operation.

Figure 2: Copper World General Plant Site Layout

Phase I includes a 60,000 ton per day conventional concentrator with an expansion in year 5 to include a concentrate leach facility to produce copper cathode onsite.

Figure 3: Copper World Phase I Tailings Storage Facilities

The project assumes conventional tailings deposition in three tailings storage facilities located on land requiring only state and local permits for Phase I.

Figure 4: Reduction in GHG Emissions from Concentrate Leach Facility

One of the many benefits of producing copper cathode on site using the concentrate leach facility as presented in the PFS is that the cathode is likely to be sold entirely to the domestic U.S. market, thereby reducing total GHG emissions by an estimated 14% compared to an operation that solely produces copper concentrate (flotation only). Constructing the full 100% capacity concentrate leach facility at inception would reduce total GHG emissions by 25%.

Figure 5: Copper World Mineral Resources

The mineral resource estimates were prepared using a 0.1% copper cut-off and include four deposits: Peach-Elgin, West, Broadtop Butte and East.

i Cash cost and sustaining cash cost exclude the cost of purchasing external concentrate, which may vary in price and or potentially be replaced with additional internal feed. By-product credits calculated using amortization of deferred revenue for gold and silver stream sales as per the company’s approach in its quarterly financial reporting. By-product credits also include the revenue from the sale of excess acid produced at a price of $145 per tonne. Sustaining cash cost includes sustaining capital expenditures and royalties. Cash cost and sustaining cash cost are non-IFRS financial performance measures with no standardized definition under IFRS. For further details on why Hudbay believes cash costs are a useful performance indicator, please refer to the company’s Management’s Discussion and Analysis for the three and six months ended June 30, 2023.

ii Sourced from Wood Mackenzie (Q2 2023 dataset).

iii Sourced from S&P Global, August 2023.

MORE or "UNCATEGORIZED"

Eloro Resources Announces Closing of Bought Deal LIFE Private Placement for Gross Proceeds of C$17 Million

Eloro Resources Ltd. (TSX: ELO) (FSE: P2QM) is pleased to announce the closing of its previously an... READ MORE

Minera Alamos Updates Resources and Reserves for the Pan Gold Mine in Nevada

Minera Alamos Inc. (TSX-V: MAI) (OTCQX: MAIFF) is pleased to announce updated Mineral Resource and M... READ MORE

Ero Copper Reports Fourth Quarter and Full Year 2025 Operating and Financial Results

Ero Copper Corp. (TSX: ERO) (NYSE: ERO) is pleased to announce its operating and financial results f... READ MORE

Rare Element Resources Announces Results of Oversubscribed Rights Offering of Common Shares

Rare Element Resources Ltd. (OTCQB: REEMF) is pleased to report that its previously announced... READ MORE

TRX Gold Reports Record Q2 2026 Production and Company Update

TRX Gold Corporation (TSX: TRX) (NYSE American: TRX) is pleased to announce preliminary resu... READ MORE