First Atlantic Nickel Expands RPM Zone Awaruite Nickel-Alloy (Ni₃Fe) Discovery: 400-Meter Northern Extension Yields 1.47% Nickel Concentrate Over 351 Meters in DTR Metallurgical Recovery Testing

First Atlantic Nickel Corp. (TSX-V: FAN) (OTCQB: FANCF) (FSE: P21) is pleased to announce positive Davis Tube Recovery metallurgical test results from drill hole AN-24-05, the final hole completed during the Phase 1 drilling at the RPM Zone, part of its district scale Atlantic Nickel Project. Drill hole AN-24-05 returned a continuous interval of 351 meters averaging 1.47% nickel and 1.53% chromium in magnetic concentrate, with a mass pull of 8.21%. This corresponds to a magnetically recoverable nickel grade (DTR grade) of 0.12% over the 351 meter interval. Located approximately 400-meters north of the initial RPM discovery hole AN-24-02, this step out hole confirms that widespread disseminated, visible awaruite mineralization extends significantly northward toward Pipestone Pond.

Phase 2 drilling is currently underway, building on the success of Phase 1, which already defined a 400-meter by 500-meter area of awaruite nickel mineralization. All four holes drilled at the RPM Zone in Phase 1 intersected disseminated awaruite mineralization, returning consistent nickel grades and recoveries. Concentrate grades from these holes ranged from 1.32% to 1.47% nickel, with mass pulls between 8.21% and 9.53%. Notably, all drill holes ended in mineralization and remain open in all directions, indicating significant expansion potential. The consistent magnetic concentrate grades and mass pulls across the drilled area underscore the extensive nature of the awaruite nickel mineralization in the RPM Zone.

Highlights:

- AN-24-05 Extends RPM Zone 400 Meters North, Confirming Continuity of Awaruite Mineralization: Drill hole AN-24-05, the fourth hole completed during the Phase 1 drill program at the RPM Zone, extends the drill-defined mineralization approximately 400 meters north of the initial discovery hole (AN-24-02). The results confirm the continuity of widespread disseminated awaruite nickel mineralization within the RPM Zone.

- Metallurgical Testing of AN-24-05 Returns 1.47% Nickel Concentrate Over 351 Meters: Davis Tube Recovery (DTR) testing of the 351meter mineralized interval in AN-24-05 returned a nickel grade of 1.47% in magnetic concentrate, with a mass pull of 8.21%. This equates to a magnetically recoverable DTR nickel grade of 0.12%. The total nickel recovery was 50.26% from a head grade of 0.24% total nickel, highlighting the effectiveness of magnetic separation as a metallurgical process for upgrading awaruite nickel mineralization.

- Phase 1 Drilling Expands Awaruite Nickel Discovery at RPM Zone: The Phase 1 drill program has delineated an initial mineralized zone measuring 400 x 500 meters. All four holes within the RPM Zone intersected significant awaruite nickel mineralization, returning consistently high DTR concentrate grades ranging from 1.32% to 1.47% nickel and mass pulls of 8.21% to 9.53%. These results yielded magnetically recoverable DTR nickel grades between 0.11% to 0.14%, establishing a strong foundation for Phase 2 expansion drilling.

- RPM Zone Discovery Highlights District-Scale Potential of Atlantic Nickel Project: The RPM Zone discovery occurs within a 30 km long, highly magnetic ultramafic nickel belt known as the Pipestone Ophiolite Complex. The zone is located approximately 25 kilometers south of historic awaruite nickel-alloy (Ni₃Fe) mineralization identified by Altius Resources and Cliffs Natural Resources in 2010 at the Atlantic Lake Zone. Average DTR nickel grades of 0.11% to 0.14% from the RPM Zone demonstrate the potential for district-scale awaruite mineralization within multiple target areas of the project.

- Phase 2 Exploration and Expansion Drilling Underway to Expand RPM Mineralized Footprint: The Phase 2 drilling campaign is currently underway, utilizing a systematic grid-based drill plan designed to step out from the Phase 1 footprint. The program aims to expand the RPM Zone’s mineralized area and further define the extent of awaruite nickel mineralization.

RPM ZONE DRILL HOLE AN-24-05 RESULTS

Table 1: DTR Metallurgical Test Results Summary – Drill Hole AN-24-05 (RPM Zone)

| Parameter | Average | Maximum | Drill Length |

| Nickel – Magnetic Concentrate Grade (Davis Tube Recovery Concentrate assayed by XRF-Fusion) |

1.47% | 2.61% | 351m |

| Chromium – Magnetic Concentrate Grade (Davis Tube Recovery Concentrate assayed by XRF-Fusion) |

1.53% | 2.88% | 351m |

| Mass Pull (Magnetic Concentrate mass as % of Davis Tube test starting mass) |

8.21% | 10.9% | 351m |

| Total Nickel Grade (Whole Rock ICP-OES assay) |

0.24% | 0.29% | 351m |

| DTR Nickel Grade – Magnetically Recovered Nickel (Calculated with Davis Tube Recovery method) |

0.12% | 0.17% | 351m |

| Total Nickel Recovery Magnetically Recovered Nickel as a Percentage of Total Nickel Content (from Whole Rock Assay Analysis) |

50.26% | 69.8% | 351m |

The Company’s final drill hole from the Phase 1 program at the RPM zone, AN-24-05, has returned positive DTR metallurgical test results that extend the known awaruite mineralization approximately 400 meters to the north of the initial RPM Zone discovery hole (AN-24-02). Drill hole AN-24-05 intersected 351 meters of awaruite mineralization averaging 1.47% nickel and 1.53% chromium in magnetic concentrate. The interval demonstrated a consistent mass pull averaging 8.21% and a DTR nickel grade of 0.12%, with total nickel recovery averaging 50.26% over the 351meter interval. These results highlight the strong and uniform metallurgical properties of the northern extension of the RPM Zone.

With the completion of AN-24-05, Phase 1 drilling has delineated an initial mineralized footprint measuring approximately 400-meters by 500-meters. All four holes from the program successfully intersected broad zones of disseminated awaruite-bearing nickel mineralization. The metallurgical results are notably consistent across all holes, indicating uniform nickel alloy mineralization hosted within ultramafic host rocks and strong lateral continuity of the mineralization system, which remains open in all directions and at depth. Across the RPM Zone, Phase 1 drilling returned magnetic concentrate grades ranging from 1.32% to 1.47% nickel, with mass pulls between 8.21% and 9.53%. Corresponding DTR nickel grades averaged 0.11% to 0.14%, confirming the RPM Zone as an extensive awaruite-dominated nickel system with robust metallurgical characteristics. All Phase 1 holes ended in mineralization, providing a solid foundation for the Phase 2 drilling program, which aims to expand the mineralized footprint and further delineate the RPM Zone’s scale and continuity.

Table 2: DTR Metallurgical Test Results Summary from Drill Hole AN-24-05 (RPM Zone)

| Hole ID | From (m) |

To (m) |

Interval (m) |

Mass Pull (%) |

Nickel – Magnetic Concentrate Grade Ni (%) |

Nickel – Total Grade Ni (%) |

DTR Nickel Grade – Magnetically Recovered Ni (%) |

Total Nickel Recovery (%) |

Chromium – Magnetic Concentrate Grade Cr (%) |

Chromium Total Grade Cr (%) |

DTR Chromium Grade – Magnetically Recovered Cr (%) |

Cobalt – Magnetic Concentrate Grade Co (%) |

| Hole AN-24-05 | 6 | 357 | 351 | 8.21 | 1.47 | 0.24 | 0.12 | 50.26% | 1.53 | 0.29 | 0.12 | 0.06 |

| including | 6 | 207 | 201 | 8.36 | 1.39 | 0.23 | 0.12 | 49.13% | 1.58 | 0.30 | 0.13 | 0.07 |

| including | 207 | 309 | 102 | 7.82 | 1.76 | 0.24 | 0.14 | 56.95% | 1.50 | 0.27 | 0.12 | 0.07 |

| including | 309 | 357 | 48 | 8.32 | 1.18 | 0.24 | 0.10 | 40.59% | 1.39 | 0.29 | 0.11 | 0.05 |

| Including “up to” | 10.90 | 2.61 | 0.29 | 0.17 | 69.78% | 2.88 | 0.55 | 0.28 | 0.09 | |||

Table 3: RPM Phase 1 DTR Metallurgical Results Summary

| Drill hole | Interval (m) |

Magnetic Concentrate Nickel Percent Grade |

Mass Pull (%) |

Magnetically Recoverable Nickel Grade (DTR Ni%) |

Drill Ended in Mineralization |

| AN-24-02 | 383 | 1.37% | 9.49 | 0.13 | YES |

| AN-24-03 | 216 | 1.32% | 9.12 | 0.11 | YES |

| AN-24-04 | 366 | 1.46% | 9.53 | 0.14 | YES |

| AN-24-05 | 357 | 1.47% | 8.21 | 0.12 | YES |

Note: DTR Nickel Grade (%) is a derived parameter calculated by multiplying the nickel grade of the magnetic concentrate (determined by XRF-Fusion assay) by the mass pull percentage, which is calculated by dividing the weight of the magnetic concentrate by the initial sample weight. Magnetically Recoverable Nickel (DTR Ni %) represents the amount of nickel in the sample that can be recovered using magnetic separation. For a visual explanation of the Davis Tube Recovery process, see: https://www.youtube.com/watch?v=q3zsgDtLWns

Table 4: AN-24-05 Drill Hole Collar Location Information

| Hole ID | Easting (UTM) | Northing (UTM) | Elevation (m) | Azimuth (°) | Dip (°) | Depth (m) |

| AN-24-05 | 567322 | 5357995 | 230 | 90 | -60 | 402 |

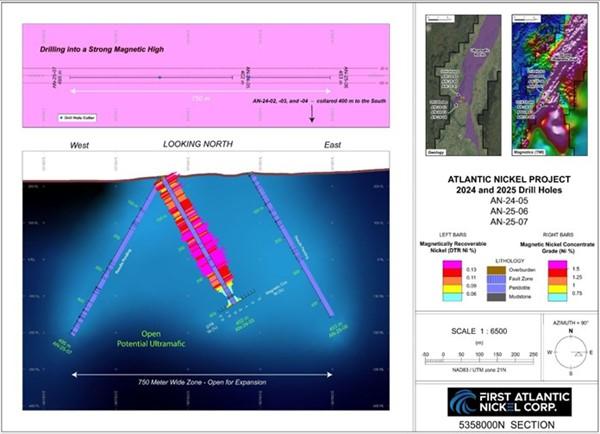

Figure 1: Cross-sectional view of the RPM Zone Hole AN-24-05 located 400 meters north of discovery hole AN-24-02. Showing the distribution of magnetic concentrate and DTR nickel values. Drill hole AN-24-05 averages 1.47% nickel and 1.53% chromium in continuous metallurgical DTR magnetic concentrate, with an average 8.21% Mass Pull and 0.12% DTR nickel over the 351meter interval.

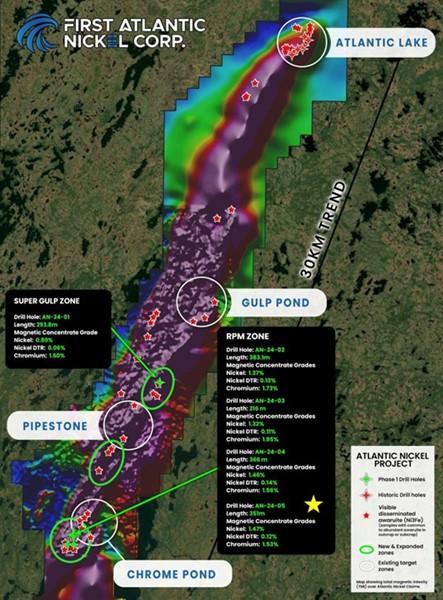

Figure 2: Map of the 30-kilometer-long nickel trend within the Pipestone Ophiolite Complex, illustrating the locations of Phase 1 drill holes (AN-24-01 through AN-24-05) and corresponding nickel and chromium assay results. The map highlights the spatial distribution of mineralized intercepts and outlines key target areas.

Figure 3: Drill Core and Microscopic Images – AN-24-05 at 28 Meters Depth (RPM Zone). Top image: Drill core from hole AN-24-05 at 28 meters depth showing disseminated awaruite (sulfur-free nickel-iron alloy) hosted in serpentinized peridotite with associated magnetite veining. Bottom images: Microscopic images of awaruite grains from the same interval, with individual grains measuring up to 349 microns.

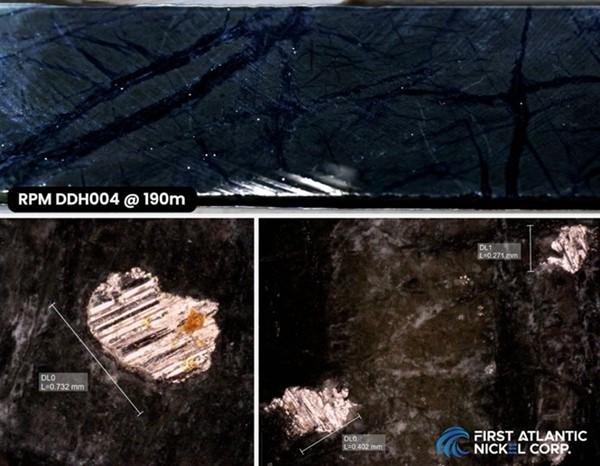

Figure 4: Drill Core and Microscopic Images – AN-24-05 at 190 Meters Depth (RPM Zone). Top image: Drill core from hole AN-24-05 at 190 meter depth showing disseminated awaruite (a sulfur-free nickel alloy) hosted in serpentinized ultramafic peridotite within the RPM Zone. Bottom images: Microscopic images of awaruite grains from the same depth, measuring up to 732 microns. Saw blade streaks are visible across the grains, illustrating the ductile and highly-magnetic properties of awaruite.

PHASE 2 DRILLING UNDERWAY TO EXPAND RPM ZONE MINERALIZATION

Phase 2 drilling is actively underway at the RPM Zone, with a program strategically designed to expand the current mineralized footprint beyond the approximately 400-meter length by 500-meter width area defined by the initial Phase 1 drill holes. Strategic step-out drilling at greater depths is now actively testing further expansion of mineralization in all directions – north toward Pipestone Pond, east toward Chrome Pond, and west into the RPM fault zone. Results from drill hole AN-24-05 highlight the strong potential for further expansion, with consistent DTR grades encountered throughout the hole, ending in mineralization. These findings indicate that the mineralized awaruite system extends further north, making the area towards Pipestone Pond a high-priority target.

The fully funded Phase 2 program is further supported by upgraded project infrastructure, including improved road access and expanded camp facilities. In addition, equipment optimizations have enabled deeper drilling capabilities, enhancing the Company’s ability to test the full vertical and lateral extent of the mineralized system. Together, these advancements position the Phase 2 campaign to meaningfully grow the RPM Zone’s known mineralized footprint across in all target directions.

Awaruite (Nickel-iron alloy Ni₂Fe, Ni₃Fe)

Awaruite, a naturally occurring sulfur-free nickel-iron alloy composed of Ni₃Fe or Ni₂Fe with approximately ~75% nickel content, offers a proven and environmentally safe solution to enhance the resilience and security of North America’s domestic critical minerals supply chain. Unlike conventional nickel sources, awaruite can be processed into high-grade concentrates exceeding 60% nickel content through magnetic processing and simple floatation without the need for smelting, roasting, or high-pressure acid leaching1. Beginning in 2025, the US Inflation Reduction Act’s (IRA) $7,500 electric vehicle (EV) tax credit mandates that eligible clean vehicles must not contain any critical minerals processed by foreign entities of concern (FEOC)2. These entities include Russia and China, which currently dominate the global nickel smelting industry. Awaruite’s smelter-free processing approach could potentially help North American electric vehicle manufacturers meet the IRA’s stringent critical mineral requirements and reduce dependence on FEOCs for nickel processing.

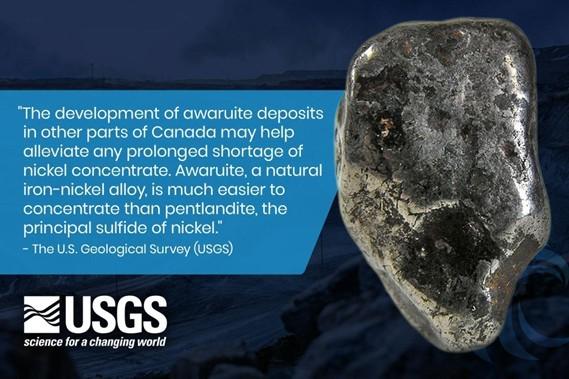

The U.S. Geological Survey (USGS) highlighted awaruite’s potential, stating, “The development of awaruite deposits in other parts of Canada may help alleviate any prolonged shortage of nickel concentrate. Awaruite, a natural iron-nickel alloy, is much easier to concentrate than pentlandite, the principal sulfide of nickel”3. Awaruite’s unique properties enable cleaner and safer processing compared to conventional sulfide and laterite nickel sources, which often involve smelting, roasting, or high-pressure acid leaching that can release toxic sulfur dioxide, generate hazardous waste, and lead to acid mine drainage. Awaruite’s simpler processing, facilitated by its amenability to magnetic processing and lack of sulfur, eliminates these harmful methods, reducing greenhouse gas emissions and risks associated with toxic chemical release, addressing concerns about the large carbon footprint and toxic emissions linked to nickel refining.

Figure 5: Quote from USGS on Awaruite Deposits in Canada

The development of awaruite resources is crucial, given China’s control in the global nickel market. Chinese companies refine and smelt 68% to 80% of the world’s nickel4 and control an estimated 84% of Indonesia’s nickel output, the largest worldwide supply5. Awaruite is a cleaner source of nickel that reduces dependence on foreign processing controlled by China, leading to a more secure and reliable supply for North America’s stainless steel and electric vehicle industries.

Disclosure

Adrian Smith, P.Geo., a director and the Chief Executive Officer of the Company is a qualified person as defined by NI 43-101. The qualified person is a member in good standing of the Professional Engineers and Geoscientists Newfoundland and Labrador (PEGNL) and is a registered professional geoscientist (P.Geo.). Mr. Smith has reviewed and approved the technical information disclosed herein.

Analytical Method & QA/QC

Samples were split in half on site, with one half remaining in the core box for future reference and the other half securely packaged for laboratory analysis. The QA/QC protocol included the insertion of blanks, duplicates, and certified reference material (standards), with one QA/QC sample being inserted every 20 samples to monitor the precision and accuracy of the laboratory results. All analytical results successfully passed QA/QC screening at the laboratory, and all Company inserted standards and blanks returned results within acceptable limits.

Samples were submitted to Activation Laboratories Ltd. in Ancaster, Ontario, an ISO 17025 certified and accredited laboratory operating independently of First Atlantic. Each sample was crushed, with a 250 g sub-sample pulverized to 95% – 200 mesh. A magnetic separate was then generated by running the pulverized sub-sample through a magnetic separator which splits the sub-sample into magnetic and non-magnetic fractions. This involves running a 30 g split of the pulp through a Davis Tube magnetic separator as a slurry using a constant flow rate, a magnetic field strength of 3,500 Gauss, and a tube angle of 45 degrees to produce magnetic and non-magnetic fractions.

The magnetic fractions are collected, dried, weighed and the magnetic fraction is fused with a lithium metaborate/tetraborate flux and lithium bromide releasing agent and then analyzed on a wavelength dispersive XRF for multiple elements including nickel, cobalt, iron and chromium. The magnetically recovered nickel grade was then calculated by multiplying the XRF fusion nickel value by the weight of the magnetic fraction and dividing by the total recorded feed weight or magnetic mass pulled from the sample.

True widths are currently unknown. However, the nickel bearing ultramafic ophiolite and peridotite rocks being targeted and sampled in the Phase 1 drilling program at the Atlantic Nickel Project are mapped as several hundred meters to over 1 kilometer wide and approximately 30 kilometers long.

About First Atlantic Nickel Corp.

First Atlantic Nickel Corp. is a Canadian mineral exploration company developing the 100%-owned Atlantic Nickel Project, a large-scale nickel project strategically located near existing infrastructure in Newfoundland, Canada. The Project’s nickel occurs as awaruite, a natural nickel-iron alloy containing approximately 75% nickel with no-sulfur and no-sulfides. Awaruite’s properties allow for smelter-free magnetic separation and concentration, which could strengthen North America’s critical minerals supply chain by reducing foreign dependence on nickel smelting. This aligns with new US Electric Vehicle US IRA requirements, which stipulate that beginning in 2025, an eligible clean vehicle may not contain any critical minerals processed by a FEOC (Foreign Entities Of Concern)6.

First Atlantic aims to be a key input of a secure and reliable North American critical minerals supply chain for the stainless steel and electric vehicle industries in the USA and Canada. The company is positioned to meet the growing demand for responsibly sourced nickel that complies with the critical mineral requirements for eligible clean vehicles under the US IRA. With its commitment to responsible practices and experienced team, First Atlantic is poised to contribute significantly to the nickel industry’s future, supporting the transition to a cleaner energy landscape. This mission gained importance when the US added nickel to its critical minerals list in 2022, recognizing it as a non-fuel mineral essential to economic and national security with a supply chain vulnerable to disruption.

MORE or "UNCATEGORIZED"

Eloro Resources Announces Closing of Bought Deal LIFE Private Placement for Gross Proceeds of C$17 Million

Eloro Resources Ltd. (TSX: ELO) (FSE: P2QM) is pleased to announce the closing of its previously an... READ MORE

Minera Alamos Updates Resources and Reserves for the Pan Gold Mine in Nevada

Minera Alamos Inc. (TSX-V: MAI) (OTCQX: MAIFF) is pleased to announce updated Mineral Resource and M... READ MORE

Ero Copper Reports Fourth Quarter and Full Year 2025 Operating and Financial Results

Ero Copper Corp. (TSX: ERO) (NYSE: ERO) is pleased to announce its operating and financial results f... READ MORE

Rare Element Resources Announces Results of Oversubscribed Rights Offering of Common Shares

Rare Element Resources Ltd. (OTCQB: REEMF) is pleased to report that its previously announced... READ MORE

TRX Gold Reports Record Q2 2026 Production and Company Update

TRX Gold Corporation (TSX: TRX) (NYSE American: TRX) is pleased to announce preliminary resu... READ MORE