The Prospector News

Denarius Metals Announces Final Drill Results from Completed Phase 2 In-Fill Drilling at Its Polymetallic Lomero Project in Spain, Including 10.25 Meters Grading 0.27% Copper, 4.79% Lead, 9.82% Zinc, 161 g/t Ag and 6.82 g/t Au

You have opened a direct link to the current edition PDF

Open PDF CloseDenarius Metals Announces Final Drill Results from Completed Phase 2 In-Fill Drilling at Its Polymetallic Lomero Project in Spain, Including 10.25 Meters Grading 0.27% Copper, 4.79% Lead, 9.82% Zinc, 161 g/t Ag and 6.82 g/t Au

Denarius Metals Corp. (TSX-V: DSLV) (OTCQX: DNRSF) announced that it has received the final assays for 42 drill holes, mainly in-fill holes, totaling approximately 13,225 meters, from the Phase 2 surface validation and in-fill drilling program on its polymetallic Lomero Project in southern Spain. To date, Denarius Metals has completed approximately 41,850 meters of drilling in 128 drill holes, including twinning of historical drill holes. The in-fill phase, totaling 23,920 meters and representing 57% of the total drilling program, is now complete. A final 4,000 meters validation drilling campaign, designed to finish verifying the high-grade underground drill holes drilled in the 1980s by Indumetal/Billiton, is in progress. The full drilling results will be incorporated into the geological model and will be integrated in the Mineral Resource Estimate update to be completed in conjunction with a preliminary economic assessment in the second half of 2023.

Key takeaways from the exploration work carried out at the Lomero Project to date include:

- Phase 2 validation and in-fill drill holes completed on the central part of the deposit have mostly intersected significant copper mineralization in massive sulphides, showing better grades than the Cu average grade of the current MRE, ranging from 0.6% up to 1.86% over intervals up to 15.70 meters thick;

- Phase 2 in-fill drill holes completed on the eastern part of the deposit have intersected significant zinc and lead mineralization showing much better grades than the Zn and Pb average grades of the current MRE, ranging for Zn from 1.08% up to 11.01% over intervals up to 6.65 meters thick, and for Pb from 1.55% to 5.05% over intervals up to 6.65 meters thick. In-fill drilling has also, confirmed high zinc and gold grades over widths that widen to depth at the westernmost end of the permit. Zinc and lead mineralization is hosted primarily in the massive sulphide domain and, to a lesser extent, in the semi-massive sulphide domain;

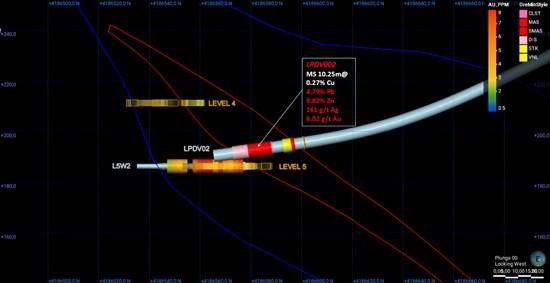

- Validation by directional drilling of the underground drilling program completed in the 1980s by Indumetal/Billiton in short < 60 m horizontal holes from underground stations was successful in returning exceptional high grades from the polymetallic mineralization hosted in the lower part of the historical mine, with drill hole LPDV002 intersecting 10.25 meters grading 0.27% copper, 4.79% lead, 9.82% zinc, 161 g/t Ag and 6.82 g/t Au;

- A PEA-level metallurgical testwork program commenced in April 2023 at Grinding Solution UK’s facilities. The testwork will be completed using two separate composites, one semi-massive sulphide and one massive sulphide, with samples collected from drill cores produced during the Company’s Phase 1 and Phase 2 drill campaigns.

Serafino Iacono, Executive Chairman and CEO of Denarius Metals, commented, “We are encouraged by the Phase 2 drill assays validating the lateral and horizontal continuity of the massive sulphide and semi-massive sulphide mineralized lenses and confirming the presence of higher-grade mineralized zones within the broader resource envelope. In addition, the initial drill assays from the validation drilling program in process are very promising and could potentially increase the grades in the current geological model. For the balance of 2023, activities at the Lomero Project will be focused on completion of the PEA, additional engineering studies to support the future development of the project and execution of the planned greenfield exploration program. The greenfield exploration program comprises 6,000 m of drilling aimed at increasing the tonnage of the MRE update based on Phase 1 and Phase 2 drilling, targeting the Las Merinas and Alianza areas located along two main shear zones discovered in 2022 by field mapping, located to the south and to the north of the shear zone that hosts the Lomero-Poyatos deposit and both of which are E-W trending.”

The Phase 2 surface validation and in-fill drilling program commenced in October 2022 and was completed in February 2023. It was designed to validate some selected historical in-fill holes drilled by Corporacion de Recursos Iberia in 2013 within the central sector of the existing mine and then conduct 50×50 m in-fill drilling to confirm the continuity of widths and grades within the massive sulphide and semi-massive sulphide lenses to upgrade the Inferred MRE to the Indicated category. Extension drilling was also carried out in 3 holes totaling 1,815 meters aimed at testing the combined TEM and gravity anomalies that occur down-dip of the main shear-zone hosting the Lomero-Poyatos deposit.

Key Highlights

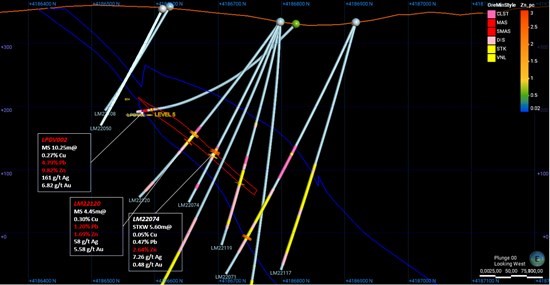

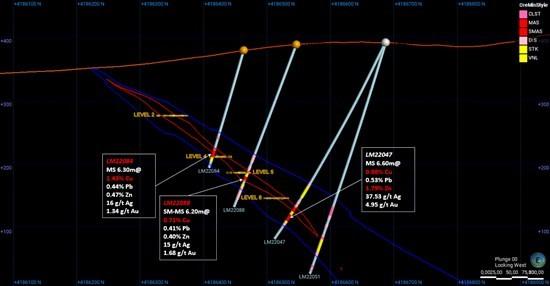

- Validation and in-fill drill holes completed on the central part of the deposit mostly showed cupriferous mineralization with maximum intersection grades of 1.86% Cu, 21 g/t Ag and 2.85 g/t Au over 6.70 meters (LM22091), 1.23% Cu, 7 g/t Ag and 1.67 g/t Au over 15.70 meters, including 1.65 meter at 1.86% Cu, 15 g/t Ag and 0.61 g/t Au (LM22085), and 1.43% Cu, 16 g/t Ag and 1.34 g/t Au over 6.30 meters (LM22084).

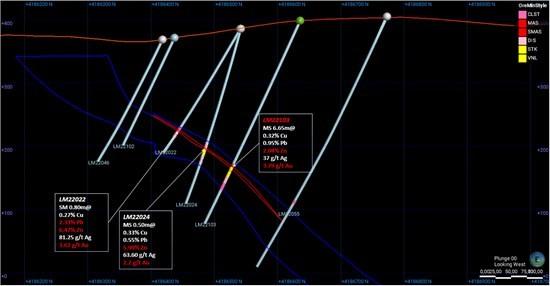

- In-fill drill holes completed on the eastern part of the deposit mostly showed significant zinc and lead mineralization with maximum intersection grades of 6.12% Pb, 11.01% Zn, 95 g/t Ag and 4.01 g/t Au over 2.50 meters (LM22110), 3.43% Pb, 7.54% Zn, 88 g/t Ag and 5.30 g/t Au over 2.30 meters (LM22113), and 3.68% Pb, 3.56% Zn, 127 g/t Ag and 5.62 g/t Au over 1.70 meters (LM22116). Drill hole LM23103 confirms high zinc and gold grades at depth at the westernmost end of the permit, returning 0.32% Cu, 0.95% Pb, 2.04% Zn, 37 g/t Ag and 3.79 g/t Au over 6.65 meters, including 2.15 meters at 0.40% Cu, 1.29% Pb, 2.66% Zn, 52 g/t Ag and 5.09 g/t Au, demonstrating that the deposit remains open to the west.

- Validation by directional drilling of the underground drilling program completed in the 1980’s by Indumetal/Billiton using a series of short < 60 m horizontal holes from underground stations was successful in confirming the high-grade polymetallic mineralization present in the lower part of the historical mine, with drill hole LPDV002 intersecting 10.25 meters grading 0.27% Cu, 4.79% Pb, 9.82% Zn, 161 g/t Ag and 6.82 g/t Au. Polymetallic mineralization is entirely hosted in the massive sulphide domain. Although, the same validation program failed to confirm the unusually wide historical intersections, in consensus with SRK Consulting (U.S.), Inc., the decision was made to continue the program by conventional inclined diamond drilling to speed up drilling, targeting key intersections from the historical program.

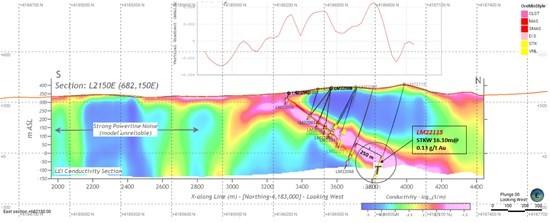

- Extension drill hole LM22115, designed to test the combined TEM and gravity anomalies that occur well below the in-fill drilling carried out so far, intersected a wide zone of thin, dense veinlets, hosted by a much wider stockwork interval, showing trace chalcopyrite and coarse pyrite mineralization filling black chlorite-altered schistosity planes, returning low-grade Au mineralization of 16.10 meters at 0.13 g/t Au. This intercept is interpreted to be of a vertically extensive stringer feeder below the massive sulphide and semi-massive sulphide lenses. Drill holes LM22121 and LM22122 didn’t return any significant Au values.

- The ongoing metallurgical test work program is testing two separate composites, one semi-massive and one massive sulphide, aimed at optimizing the base metal floatation on representative composites with the average deposit grade. The test work is expected to be completed by mid- 2023.

The following table lists the key intercepts from the Phase 2 validation and in-fill drilling program since the issuance of the current MRE with an effective date of July 19, 2022:

| Hole ID | Phase | From (m) |

To (m) |

Length (m) |

Cu % |

Pb % |

Zn % |

Ag g/t |

Au g/t |

CuEq % |

Min. Type |

| LM22081 | Infill | 201.00 | 202.00 | 1.00 | 0.97 | 0.12 | 0.04 | 6 | 2.15 | 2.66 | MS |

| LM22082 | Infill | 215.80 | 223.85 | 8.05 | 1.19 | 0.23 | 0.34 | 20 | 1.02 | 2.30 | MS |

| LM22083 | Infill | 206.50 | 211.00 | 4.50 | 0.60 | 0.06 | 0.08 | 4 | 0.43 | 1.00 | MS |

| LM22084 | Infill | 161.25 | 162.70 | 1.45 | 0.30 | 0.09 | 0.11 | 22 | 3.64 | 3.27 | MS |

| “ | 169.00 | 175.30 | 6.30 | 1.43 | 0.44 | 0.47 | 16 | 1.34 | 2.83 | MS | |

| LM22085 | Infill | 222.95 | 238.65 | 15.70 | 1.23 | 0.07 | 0.05 | 7 | 1.55 | 2.48 | MS |

| “ | 246.45 | 248.10 | 1.65 | 1.86 | 0.15 | 0.17 | 15 | 0.61 | 2.55 | MS | |

| LM22086 | Infill | 224.25 | 226.50 | 2.25 | 0.27 | 0.65 | 0.10 | 33 | 3.93 | 3.70 | MS |

| “ | 226.50 | 231.50 | 5.00 | mine void fill | |||||||

| “ | 240.70 | 243.10 | 2.40 | 0.46 | 0.26 | 0.74 | 10 | 1.02 | 1.59 | MS | |

| LM22087 | Infill | 192.90 | 198.10 | 5.20 | 0.62 | 0.50 | 0.24 | 34 | 3.22 | 3.54 | MS |

| “ | 198.10 | 201.30 | 3.20 | mine void fill | |||||||

| “ | 201.30 | 204.20 | 2.90 | 0.75 | 0.06 | 0.21 | 4 | 0.33 | 1.11 | MS | |

| LM22088 | Infill | 214.70 | 216.70 | 2.00 | 1.26 | 0.18 | 0.06 | 22 | 0.84 | 2.17 | MS-SM |

| “ | 222.10 | 228.30 | 6.20 | 0.71 | 0.41 | 0.40 | 15 | 1.68 | 2.32 | SM-MS | |

| “ | 228.30 | 234.80 | 6.50 | mine void | |||||||

| LM22089 | Infill | 255.55 | 274.50 | 18.95 | 0.50 | 0.42 | 0.78 | 20 | 2.38 | 2.79 | MS-SH |

| including | 259.25 | 265.75 | 6.50 | 0.67 | 1.13 | 2.06 | 48 | 5.03 | 5.75 | MS | |

| LM22089 | 283.70 | 287.50 | 3.80 | 0.51 | 0.32 | 0.65 | 9 | 0.53 | 1.45 | MS | |

| LM22090 | Infill | 201.30 | 203.30 | 2.00 | 0.44 | 0.05 | 0.04 | 13 | 0.94 | 1.29 | MS |

| “ | 209.00 | 211.50 | 2.50 | 0.28 | 0.82 | 0.59 | 102 | 3.81 | 4.52 | MS | |

| “ | 211.50 | 213.80 | 2.30 | mine void | |||||||

| LM22091 | Infill | 236.10 | 249.10 | 13.00 | 1.20 | 0.07 | 0.06 | 12 | 1.61 | 2.55 | MS |

| including | 236.10 | 242.80 | 6.70 | 1.86 | 0.10 | 0.03 | 21 | 2.85 | 4.22 | MS | |

| LM22093 | Infill | 270.90 | 282.70 | 11.80 | 0.43 | 0.54 | 0.40 | 22 | 2.24 | 2.58 | MS-SM |

| including | 270.90 | 276.65 | 5.75 | 0.65 | 0.85 | 0.27 | 36 | 3.80 | 4.12 | MS-SM | |

| LM22095 | Infill | 279.15 | 289.30 | 10.15 | 0.64 | 0.47 | 0.97 | 29 | 3.34 | 3.80 | MS-SH |

| LM22096 | Infill | 274.40 | 281.80 | 7.40 | 0.56 | 0.63 | 2.06 | 31 | 3.59 | 4.28 | MS-SM |

| LM22097 | Infill | 222.60 | 225.85 | 3.25 | 0.15 | 0.88 | 1.63 | 25 | 0.54 | 1.49 | SM |

| LM22098 | Infill | 34.75 | 36.60 | 1.85 | 0.67 | 0.21 | 0.17 | 14 | 1.12 | 1.74 | SH |

| LM22099 | Infill | 205.90 | 207.40 | 1.50 | mine void | ||||||

| “ | 207.40 | 209.30 | 1.90 | 0.48 | 0.33 | 0.75 | 14 | 2.41 | 2.72 | MS | |

| LM22100* | Infill | 75.30 | 78.30 | 3.00 | 0.12 | 0.18 | 0.23 | 9 | 1.24 | 1.03 | SM-LH |

| “ | 78.30 | 81.20 | 2.90 | mine void | |||||||

| LM22103 | Infill | 249.55 | 256.20 | 6.65 | 0.32 | 0.95 | 2.04 | 37 | 3.79 | 4.32 | MS |

| including | 249.55 | 251.70 | 2.15 | 0.40 | 1.29 | 2.66 | 52 | 5.09 | 5.77 | MS | |

| LM22104 | Infill | 309.20 | 310.80 | 1.60 | 0.05 | 0.36 | 0.57 | 13 | 0.84 | 1.06 | STKW |

| LM22105 | Infill | 343.70 | 345.70 | 2.00 | 0.63 | 0.23 | 0.64 | 9 | 0.56 | 1.38 | MS |

| LM22109 | Infill | 162.15 | 168.80 | 6.65 | 1.55 | 1.55 | 1.08 | 49 | 2.83 | 4.84 | MS |

| LM22110 | Infill | 158.80 | 159.60 | 0.80 | 0.61 | 5.05 | 10.15 | 104 | 2.72 | 7.83 | SH |

| “ | Infill | 166.30 | 168.80 | 2.50 | 0.26 | 6.12 | 11.01 | 95 | 4.01 | 8.86 | MS |

| LM22112 | Infill | 173.10 | 175.00 | 1.90 | 0.23 | 0.50 | 2.01 | 14 | 2.41 | 2.84 | MS-DISS |

| LM22113 | Infill | 108.90 | 111.20 | 2.30 | 0.28 | 3.43 | 7.54 | 88 | 5.30 | 8.10 | MS |

| LM22116 | Infill | 62.10 | 66.20 | 4.10 | 0.16 | 1.62 | 1.54 | 59 | 3.04 | 3.86 | SH-MS |

| including | 64.50 | 66.20 | 1.70 | 0.29 | 3.68 | 3.56 | 127 | 5.62 | 7.69 | MS | |

| LM22119 | Infill | 263.00 | 264.00 | 1.00 | 0.56 | 0.15 | 0.84 | 12 | 0.73 | 1.50 | SM |

| LM22120 | Infill | 221.45 | 225.90 | 4.45 | 0.30 | 1.20 | 1.69 | 58 | 5.58 | 5.80 | MS |

| “ | 238.30 | 240.30 | 2.00 | 0.14 | 2.26 | 3.63 | 18 | 0.15 | 2.03 | STKW | |

| LPDV002 | Validation | 276.30 | 286.55 | 10.25 | 0.27 | 4.79 | 9.82 | 161 | 6.82 | 10.96 | MS |

| including | 277.30 | 281.90 | 4.60 | 0.32 | 4.61 | 9.25 | 176 | 9.66 | 13.04 | MS | |

Notes:

(1) The holes were drilled at -45 to -80 degrees from the horizontal. Grades are for semi-massive sulphide to massive sulfide intersections and some stockwork and shear zones. Sample interval grades over CuEq >1% are reported. The width is the sample length and is not necessarily the true width of the intersection. All base and precious metal grades are uncut and are not diluted to a minimum mining width.

(2) The following holes returned intervals grading <1% CuEq and so are not listed in the table: LM22092, LM22094, LM22101, LM22102, LM22106, LM22107; LM22108, LM22111, LM22114, LM22115, LM22117, LM22118, LM22121 and LPDV003.

(3) Equivalent copper grade (CuEq%) was calculated using prices of US$1,800/oz gold, US$25/oz silver, US$3.55/lb copper, US$1.00/lb zinc and US$0.90/lb lead. No adjustments were made for recovery as the project is at an exploration stage and metallurgical data to allow for estimation of recoveries is not yet available.

(4) MS: massive sulfides; SM: semi-massive sulfides; STKW: stockwork; DISS: disseminated; SH: shear-zone.

(5) LM22100 partial reassays by ALS are pending (see QAQC below).

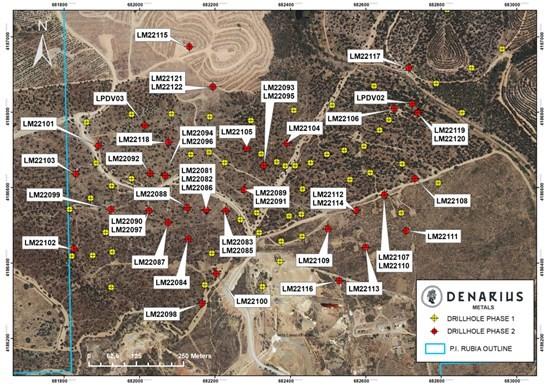

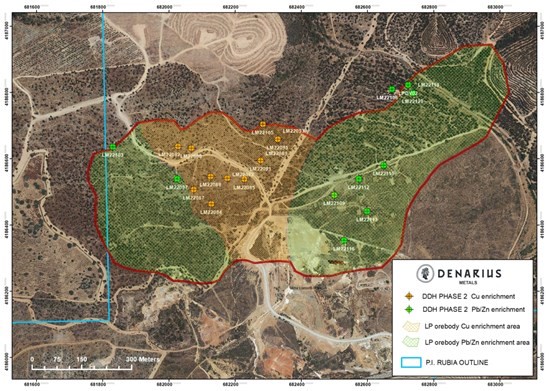

Please refer to the attached illustrative images (Attachments 1 to 7) showing (i) the location of drill holes, (ii) the location of the best copper, lead and zinc drill holes and (iii) five cross sections for drill holes LM22084, LM22088, LM22120, LPDV002, LM22115.

Qualified Persons Review

Dr. Stewart D. Redwood, PhD, FIMMM, FGS, Senior Consulting Geologist to the Company, is a qualified person as defined by National Instrument 43-101 – Standards of Disclosure or Mineral Projects and prepared or reviewed the preparation of the scientific and technical information in this press release. Verification included a review of the quality assurance and quality control samples, and review of the applicable assay databases and assay certificates.

Quality Assurance and Quality Control

The Lomero-Poyatos samples were prepared by ALS Labs (ISO/IEC 17025:2017 and ISO 9001:2015) at their facilities in Seville, Spain and assayed in Clonmel, Ireland. Gold was assayed by 30 g fire assay with AAS finish, while silver and base metals were analyzed in a multi element analysis of base metal ores and mill products by strong oxidizing digestion and ICP-AES finish. Blank, standard and duplicate samples were routinely inserted and monitored for quality assurance and quality control.

As part of its Quality Assurance and Quality Control procedures, Denarius Metals sent 331 pulps and coarse rejects at the end of Phase 2 of drilling to ALS Labs for umpire analysis to check the results from the primary laboratory, AGQ. The results from ALS showed excellent correlation for all elements for Phase 1 drilling. However, certain deviations were observed for the Phase 2 drilling results, in particular for gold fire assay and lead. Following a thorough review of internal laboratory QA/QC procedures, and confirmation assays received from a third laboratory, SGS in Huelva, Spain, the Company decided to send 100% of sample pulps from the massive and semi massive sulphide zones, plus 50% of the stockwork zones, from the

Phase 2 drilling to ALS for check assays. In addition, 20% of massive sulphide samples, 10% of semi-massive sulphide samples, and 5% of stockwork samples from Phase 1 of drilling were sent to ALS for check assays. A total of 514 samples were sent to ALS for check assays.

The check assays received from ALS confirmed that Phase 1 results, as reported by the Company, are reliable. However, the check assays confirmed that there is a bias in the Phase 2 assays of the primary laboratory for gold and lead. Therefore, the AGQ results for Phase 2 were discarded and it was decided only to use results from ALS for Phase 2 drilling. The remainder of the Phase 2 stockwork zone samples are currently being reassayed by ALS for completeness. This affects one significant intersection in hole LM22100 which is reported in the table above as pending reassay results. However, given the low-grade nature of the stockwork mineralization, it is not anticipated the results will demonstrate any material differences. In addition, ALS has been designated as the primary laboratory for all future assays.

About Denarius Metals

Denarius Metals is a Canadian junior company engaged in the acquisition, exploration, development and eventual operation of polymetallic mining projects in high-grade districts, with its principal focus on the Lomero Project in Spain. The Company signed a definitive option agreement with Europa Metals Ltd. in November 2022 pursuant to which Europa has granted Denarius Metals two options to acquire up to an 80% ownership interest in the Toral Zn-Pb-Ag Project, Leon Province, Northern Spain. The Company’s 100%-owned Zancudo Project in Colombia provides an opportunity to develop near-term production and cash flow through local contract miners and long-term growth through exploration.

Attachment 1 – Location of drill holes reported in this press release (numbered holes).

Attachment 2 – Location of drill holes showing Cu and Pb/Zn enrichment of the deposit.

Attachment 3 – Cross section for drill holes LM22084 and LM22088 showing significant Cu mineralization.

Attachment 4 – Cross section for drill holes LPDV002 and LM22120 showing high Pb/Zn grades associated to high Au grades.

Attachment 5 – Cross section for drill hole LM22103 showing high Zn and Au grades at westernmost end of the permit.

Attachment 6 – Cross section for drill hole LPDV002 validating Indumetal/Billiton drill hole L5W2 exceptional high grades.

Attachment 7 – Geophysical cross section for drill hole LM22115 showing TEM conductivity (bottom) and gravity profile (top). Hole LM22115 tested a thick zone of conductivity which is interpreted to be a stockwork feeder zone.

MORE or "UNCATEGORIZED"

Quimbaya Gold Closes $4 Million Financing and Expands Executive Team

Cornerstone investor brings proven regional track record; company... READ MORE

Spanish Mountain Gold Announces Larger Scale Preliminary Economic Assessment With a Base Case NPV5% After-Tax of C$1.0 Billion, 18.2 % IRR and 3.4 Year Payback at US$ 2,450/Oz Gold Price; at US$3,300/Oz Spot Gold Price NPV5% C$2.3 Billion, 32.0% IRR and 2.0 Year Payback; Including an Updated Mineral Resource Estimate for Its Spanish Mountain Gold Project

Spanish Mountain Gold Ltd. (TSX-V: SPA) (FSE: S3Y) (OTCQB: SPAUF)... READ MORE

Aura Announces Preliminary Q2 2025 Production Results

Aura Minerals Inc. (TSX: ORA) (B3: AURA33) (OTCQX: ORAAF) is plea... READ MORE

Cascadia Announces Closing of Financing

Cascadia Minerals Ltd. (TSX-V:CAM) (OTCQB:CAMNF) is pleased to an... READ MORE

Abcourt Closes US$ 8M Loan Facility to Start Sleeping Giant Mine

Abcourt Mines Inc. (TSX-V: ABI) (OTCQB: ABMBF) is pleased to anno... READ MORE