Canada Nickel Completes Drill Program at Deloro with Resource Estimate Expected in July

Highlights

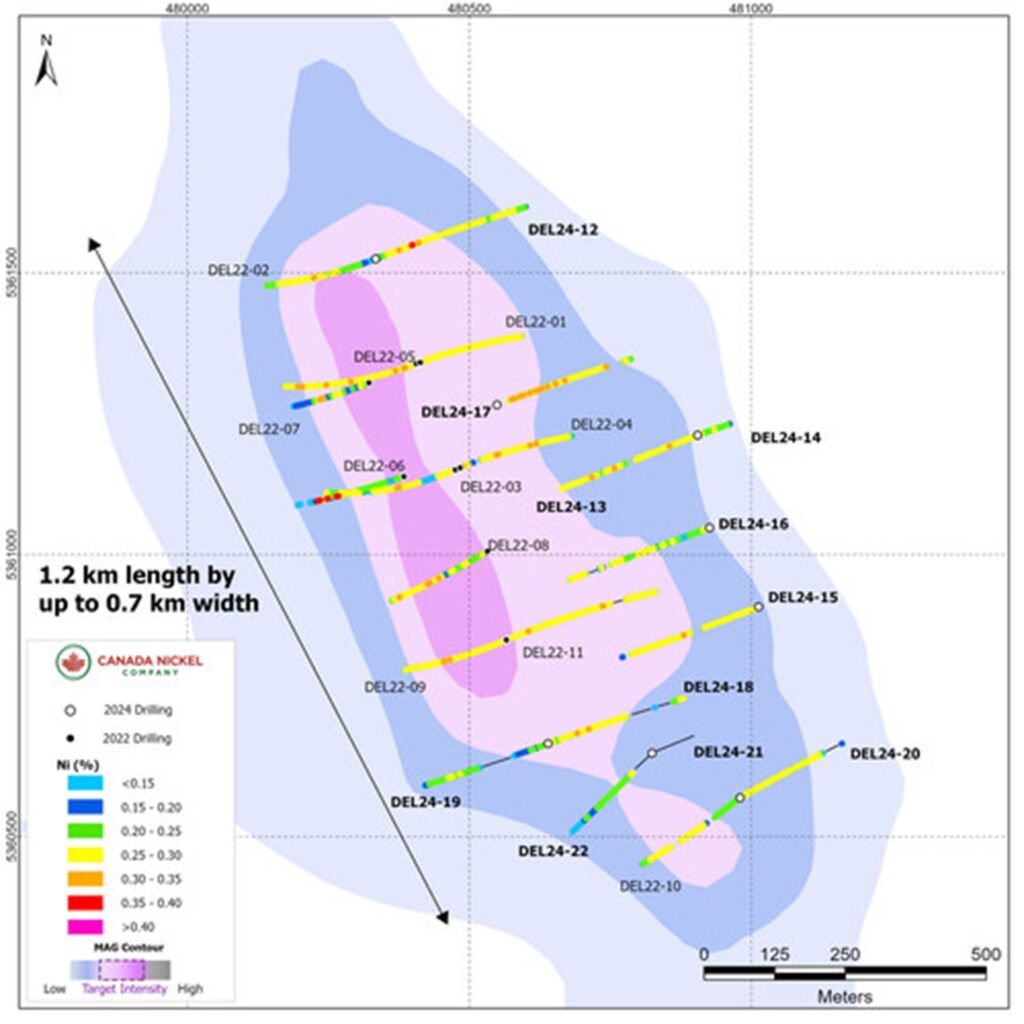

- 2024 drilling increases mineralized footprint by 50% to 1.2 kilometres long by up to 700 metres wide.

- Deloro is located just 8 kilometres south of Timmins with direct road and powerline access and shallow overburden averaging less than 9 metres thick.

- 11 holes successfully completed including DEL24-12 with 0.26% nickel over 431 metres and DEL24-17 with 0.27% nickel over 293 metres.

- Resource estimate is underway and expected to be completed in July 2024.

Canada Nickel Company Inc. (TSX-V: CNC) (OTCQX: CNIKF) is pleased to provide an update on its 2024 exploration program with assay results from eleven holes on its Deloro property, which now completes the infill drilling in advance of the first resource estimate.

Mark Selby, CEO of Canada Nickel said, “We are very pleased with the 2024 drilling program at Deloro which built on our successful campaign in 2022. Deloro is just 8 km south of Timmins, with shallow overburden and a large 1.2 km long and up to 0.7 km wide footprint. Work is now underway on our initial resource on the property which is expected to be one of seven resource estimates that we plan to complete within the next 12 months. With this work amongst the rest of our portfolio, we are clearly demonstrating that our regional exploration program continues to be very successful. We now have seven drill rigs turning. This includes two rigs collecting samples for pilot plant material from Crawford to support downstream processing test work, and five rigs exploring at Reid and Texmont. Once drilling is completed at these properties, we will begin drilling at our Mann properties.”

Deloro Property

The Deloro Property is located just 8 km south of Timmins and is accessible year-round by road as well as located less than 2 km from existing powerlines. The Company has successfully completed its infill drilling program, with ten of eleven drill holes intersecting long intervals of mineralized ultramafic, mostly dunite. The drillholes were collared predominantly near the east and south contacts to infill and extend the previously defined outline of the ultramafic from historic geophysical data. The mineralized ultramafic body is up to 700 m wide and about 1.2 km long, to a depth of 300 m (where it remains open). Mineralization is relatively shallow with less than 9 m of overburden on average across all drillholes.

Canada Nickel has completed a geological model of the deposit and expects an initial resource estimate to be completed in July.

| BHID | From (m) | To (m) | Length (m)* | Ni % | Co % | Pd g/t | Pt g/t | Cr % | Fe % | S % |

| DEL24-12 | 9.9 | 441.0 | 431.1 | 0.26 | 0.01 | 0.003 | 0.005 | 0.28 | 5.25 | 0.10 |

| including | 103.5 | 130.5 | 30.0 | 0.30 | 0.01 | 0.003 | 0.005 | 0.20 | 5.00 | 0.03 |

| DEL24-13 | 6.0 | 187.5 | 181.5 | 0.24 | 0.01 | 0.003 | 0.005 | 0.23 | 4.89 | 0.06 |

| and | 222.0 | 277.0 | 55.0 | 0.25 | 0.01 | 0.003 | 0.005 | 0.22 | 5.25 | 0.05 |

| and | 289.9 | 402.0 | 112.1 | 0.25 | 0.01 | 0.003 | 0.005 | 0.21 | 5.20 | 0.07 |

| DEL24-14 | 5.3 | 92.7 | 87.4 | 0.22 | 0.01 | 0.003 | 0.005 | 0.19 | 4.75 | 0.05 |

| DEL24-15 | 6.0 | 164.0 | 162.0 | 0.24 | 0.01 | 0.004 | 0.006 | 0.17 | 5.59 | 0.09 |

| and | 202.6 | 377.6 | 175.0 | 0.25 | 0.01 | 0.003 | 0.005 | 0.24 | 5.35 | 0.10 |

| DEL24-16 | 9.5 | 219.5 | 210.0 | 0.20 | 0.01 | 0.004 | 0.005 | 0.18 | 5.63 | 0.05 |

| and | 234.0 | 286.5 | 52.5 | 0.23 | 0.01 | 0.003 | 0.004 | 0.24 | 5.70 | 0.04 |

| and | 361.0 | 408.0 | 47.0 | 0.26 | 0.01 | 0.003 | 0.004 | 0.20 | 5.33 | 0.06 |

| DEL24-17 | 35.8 | 329.1 | 293.3 | 0.27 | 0.01 | 0.003 | 0.003 | 0.18 | 5.13 | 0.05 |

| and | 379.0 | 402.0 | 23.0 | 0.23 | 0.01 | 0.003 | 0.003 | 0.22 | 5.11 | 0.04 |

| DEL24-18 | 9.0 | 233.5 | 224.5 | 0.26 | 0.01 | 0.003 | 0.005 | 0.18 | 4.84 | 0.08 |

| and | 371.6 | 401.0 | 29.4 | 0.23 | 0.01 | 0.003 | 0.005 | 0.46 | 5.83 | 0.08 |

| DEL24-19 | 12.0 | 67.0 | 55.0 | 0.17 | 0.01 | 0.006 | 0.006 | 0.33 | 7.52 | 0.01 |

| and | 206.7 | 354.0 | 147.3 | 0.22 | 0.01 | 0.003 | 0.004 | 0.22 | 6.27 | 0.02 |

| DEL24-20 | 3.0 | 319.6 | 316.6 | 0.24 | 0.01 | 0.003 | 0.005 | 0.13 | 4.88 | 0.10 |

| DEL24-22 | 75.2 | 270.0 | 194.8 | 0.19 | 0.01 | 0.007 | 0.011 | 0.38 | 6.84 | 0.04 |

| *True width undetermined. All lengths are drillhole lengths. DEL24-21 drilled parallel on a barren dyke. |

Table 2: Drillhole Orientation

| Hole ID | Easting (mE) | Northing (mN) | Azimuth (⁰) | Dip (⁰) | Length (m) |

| DEL24-12 | 480334 | 5361525 | 71 | -50 | 441 |

| DEL24-13 | 480905 | 5361212 | 250 | -50 | 404 |

| DEL24-14 | 480905 | 5361212 | 70 | -50 | 102 |

| DEL24-15 | 481013 | 5360908 | 250 | -50 | 405 |

| DEL24-16 | 480926 | 5361048 | 250 | -50 | 408 |

| DEL24-17 | 480549 | 5361266 | 70 | -50 | 402 |

| DEL24-18 | 480640 | 5360665 | 70 | -50 | 401 |

| DEL24-19 | 480640 | 5360665 | 250 | -50 | 402 |

| DEL24-20 | 480980 | 5360569 | 60 | -60 | 396 |

| DEL24-21 | 480824 | 5360648 | 62 | -50 | 168 |

| DEL24-22 | 480824 | 5360648 | 225 | -50 | 402 |

Quality Assurance and Control, Drilling and Assaying

Edwin Escarraga, MSc, P.Geo., a “qualified person” as defined by National Instrument 43-101 – Standards of Disclosure for Mineral Projects, is esponsible for the on-going drilling and sampling program, including quality assurance (QA) and quality control (QC). The core is collected from the drill in sealed core trays and transported to the core logging facility. The core is marked and sampled at 1.5 metre lengths and cut with a diamond blade saw. One set of samples is transported in secured bags directly from the Canada Nickel core shack to Actlabs Timmins, while a second set of samples is securely shipped to SGS Lakefield for preparation, with analysis performed at SGS Burnaby or SGS Callao (Peru). All are ISO/IEC 17025 accredited labs. Analysis for precious metals (gold, platinum and palladium) are completed by Fire Assay while analysis for nickel, cobalt, sulphur and other elements are performed using a peroxide fusion and ICP-OES analysis. Certified standards and blanks are inserted at a rate of 3 QA/QC samples per 20 core samples making a batch of 60 samples that are submitted for analysis.

Qualified Person and Data Verification

Stephen J. Balch P.Geo. (ON), VP Exploration of Canada Nickel and a “qualified person” as such term is defined by NI 43-101, has verified the data disclosed in this news release, and has otherwise reviewed and approved the technical information in this news release on behalf of Canada Nickel Company Inc.

About Canada Nickel Company

Canada Nickel Company Inc. is advancing the next generation of nickel-sulphide projects to deliver nickel required to feed the high growth electric vehicle and stainless steel markets. Canada Nickel Company has applied in multiple jurisdictions to trademark the terms NetZero NickelTM, NetZero CobaltTM, NetZero IronTM and is pursuing the development of processes to allow the production of net zero carbon nickel, cobalt, and iron products. Canada Nickel provides investors with leverage to nickel in low political risk jurisdictions. Canada Nickel is currently anchored by its 100% owned flagship Crawford Nickel-Cobalt Sulphide Project in the heart of the prolific Timmins-Cochrane mining camp.

Figure 1 – Deloro – CNC Drillholes Over Total Magnetic Intensity (CNW Group/Canada Nickel Company Inc.)

MORE or "UNCATEGORIZED"

Quimbaya Gold Closes $4 Million Financing and Expands Executive Team

Cornerstone investor brings proven regional track record; company... READ MORE

Spanish Mountain Gold Announces Larger Scale Preliminary Economic Assessment With a Base Case NPV5% After-Tax of C$1.0 Billion, 18.2 % IRR and 3.4 Year Payback at US$ 2,450/Oz Gold Price; at US$3,300/Oz Spot Gold Price NPV5% C$2.3 Billion, 32.0% IRR and 2.0 Year Payback; Including an Updated Mineral Resource Estimate for Its Spanish Mountain Gold Project

Spanish Mountain Gold Ltd. (TSX-V: SPA) (FSE: S3Y) (OTCQB: SPAUF)... READ MORE

Aura Announces Preliminary Q2 2025 Production Results

Aura Minerals Inc. (TSX: ORA) (B3: AURA33) (OTCQX: ORAAF) is plea... READ MORE

Cascadia Announces Closing of Financing

Cascadia Minerals Ltd. (TSX-V:CAM) (OTCQB:CAMNF) is pleased to an... READ MORE

Abcourt Closes US$ 8M Loan Facility to Start Sleeping Giant Mine

Abcourt Mines Inc. (TSX-V: ABI) (OTCQB: ABMBF) is pleased to anno... READ MORE