Bravo Intersects Exceptional PGM Mineralized Widths with High-Grade Nickel at Luanga

Highlights include 52.9m @ 2.14g/t PGM+Au plus 0.27% Ni

And 67.3m @ 1.35g/t PGM+Au plus 0.28% Ni

Bravo Mining Corp. (TSX-V: BRVO) (OTCQX: BRVMF) announced that it has received assay results from an additional 10 infill diamond drill holes from its Luanga palladium + platinum + rhodium + gold + nickel project, located in the Carajás Mineral Province, state of Pará, Brazil.

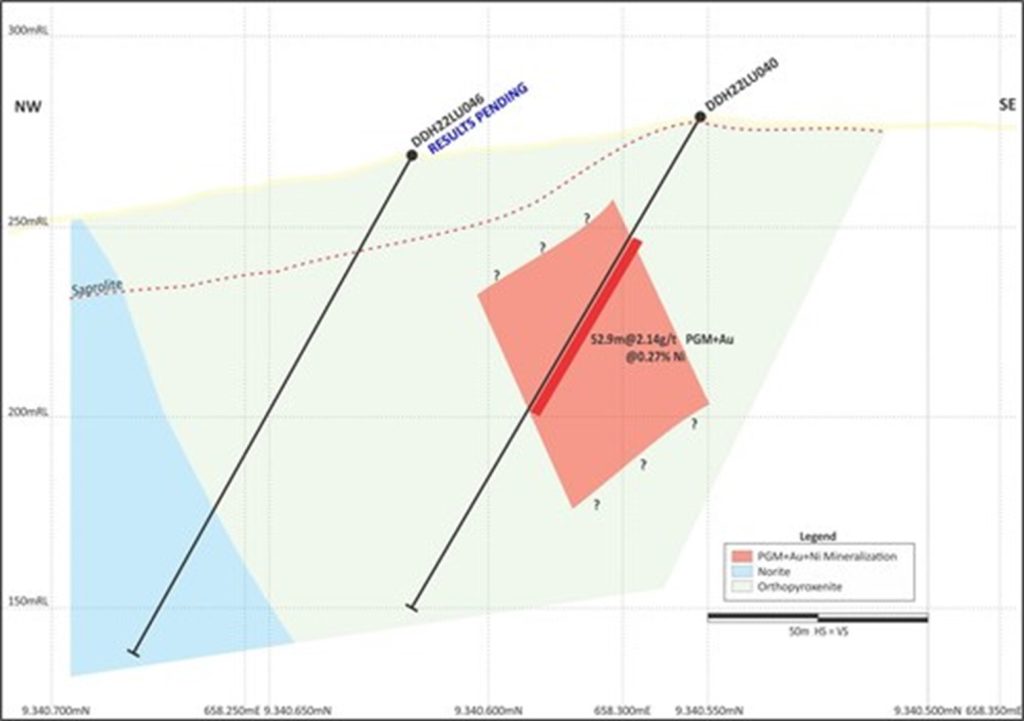

“Assay results from drill holes DDH22LU040 (58.8m @ 2.11g/t PGM+Au from 9.7m) and DDH22LU042 (67.3m @ 1.35g/t PGM+Au from 47m) intersected some of the broadest well mineralized zones to date at Luanga, while both have also returned increased levels of Ni sulphide mineralization (0.27% and 0.28%, respectively) not previously seen over such thicknesses. Also notable is the near surface nature of the intercepts and the presence of generally high rhodium grades across these assay results, which bodes well for our work on Luanga’s historical mineral resource estimate (1) as rhodium was not included. This represents a significant upside opportunity,” said Luis Azevedo, Chairman and CEO of Bravo. “Furthermore, results from both holes are the first assay results to be received on new 100m spaced infill sections in the central portion of the deposit, further increasing our confidence in both the overall PGM+Au+Ni potential at Luanga, and the potential for higher-grade Ni sulphide mineralization.”

Highlights

- The infill drilling campaign continues to advance rapidly, and results compare well with, or exceed, the intercepts in historic drill holes on nearby drill sections, in both tenor and mineralized thicknesses.

- Highlights of Bravo’s most recent intercepts are tabulated below, with details attached:

| HOLE-ID | From

(m) |

To

(m) |

Thickness (m) |

Pd

(g/t) |

Pt

(g/t) |

Rh

(g/t) |

Au (g/t) |

PGM + Au (g/t) |

Ni ** (% Sulphide) |

TYPE |

| DDH22LU031 | 16.6 | 26.5 | 9.9 | 3.27 | 2.42 | 0.35 | 0.04 | 6.07 | NA | Ox |

| DDH22LU032 | 115.2 | 119.8 | 4.6 | 5.52 | 1.27 | 0.26* | 0.02 | 7.07* | 0.01 | FR/LS |

| DDH22LU034 | 109.4 | 144.4 | 35.0 | 0.87 | 0.51 | 0.10 | 0.03 | 1.50 | 0.16 | FR |

| DDH22LU037 | 51.0 | 65.0 | 12.0 | 2.14 | 1.47 | 0.24 | 0.03 | 3.87 | 0.03 | FR |

| And | 100.0 | 118.5 | 18.5 | 1.48 | 0.97 | 0.23 | 0.01 | 2.69 | 0.02 | FR |

| DDH22LU040 | 36.6 | 89.5 | 52.9 | 1.44 | 0.52 | 0.10 | 0.08 | 2.14 | 0.27 | FR |

| DDH22LU042 | 47.0 | 114.3 | 67.3 | 0.89 | 0.33 | 0.06 | 0.07 | 1.35 | 0.28 | FR |

| Including | 83.0 | 114.3 | 31.3 | 1.75 | 0.63 | 0.10 | 0.13 | 2.60 | 0.27 | FR |

| Notes: | All ‘From’, ‘To’ depths, and ‘Thicknesses’ are downhole. | |||||||||

| Given the orientation of the hole and the mineralization, the intercept is estimated to be 80% to 85% of true thickness. | ||||||||||

| Type: Ox = Oxide. LS = Low Sulphur. FR = Fresh Rock. Recovery methods and results will differ based on the type of mineralization. | ||||||||||

| NA: Not Applicable as intercept is oxide or a mix of oxide and fresh rock mineralization. | ||||||||||

| * Includes Rh >1.00g/t result. Overlimit analyses pending. | ||||||||||

| ** Bravo’s nickel grades are sulphide nickel, and do not include non-recoverable silicate nickel, unlike historic total nickel assays. | ||||||||||

- In addition, two diamond drill holes were completed on two drill sections, 50m north and south of DDH22LU047, the hole that intercepted massive sulphides (see August 16th, 2022 news release). All four step out drill holes have intersected varying amounts of semi-massive sulphides (results pending). Downhole Electromagnetic surveys (“EM”) on these 4 drill holes have been completed, while surface EM is underway (results and analysis pending).

- 131 drill holes have been completed by Bravo to date, for a total of 22,440 metres (or 88% of Phase 1 Drilling Program), including completion of all 7 planned twin holes and all 8 planned metallurgical (“Met”) holes.

- Results reported for 39 Bravo drill holes to date. Results for 84 drill holes outstanding (Met not included).

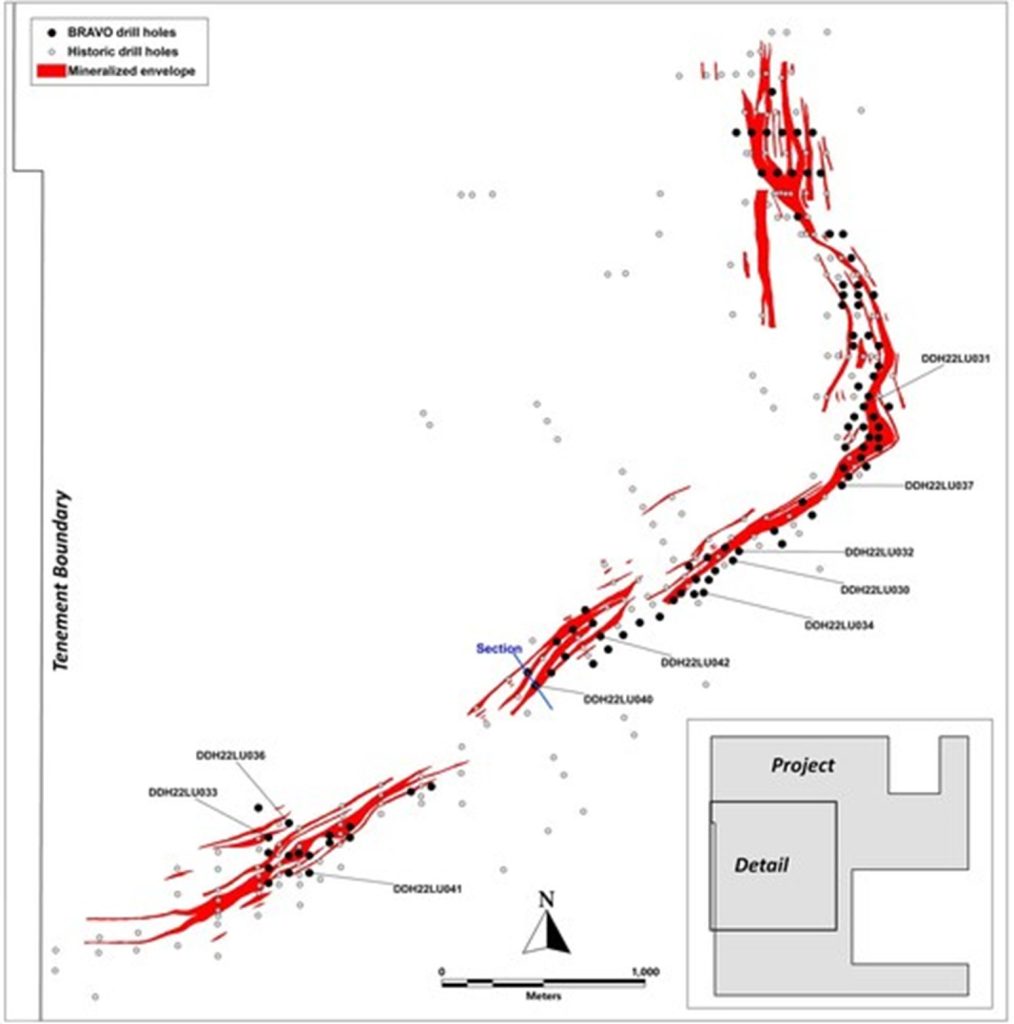

Luanga Drill Program

The Phase 1 diamond drill program continues as planned at Luanga. Six drill rigs are on site, with drilling progressing in various locations along the entire 8.1km strike length of the known Luanga mineralized envelope. To date, 131 drill holes have been completed, for a total of 22,440 metres (or 88%) of the planned 25,500 metre Phase 1 drill program. 22,623 samples submitted for assay to date.

Complete Table of Recent Intercepts

| HOLE-ID | From

(m) |

To

(m) |

Thickness (m) |

Pd

(g/t) |

Pt

(g/t) |

Rh

(g/t) |

Au (g/t) |

PGM + Au (g/t) |

Ni (% Sulphide) |

TYPE |

| DDH22LU030 | No Significant Results | |||||||||

| DDH22LU031 | 16.6 | 26.5 | 9.9 | 3.27 | 2.42 | 0.35 | 0.04 | 6.07 | NA | Ox |

| And | 40.4 | 80.0 | 30.6 | 0.11 | 0.07 | 0.01 | 0.11 | 0.20 | 0.20 | FR |

| And | 102.4 | 112.4 | 10.0 | 0.10 | 007 | 0.01 | 0.01 | 0.19 | 0.20 | FR |

| And | 190.7 | 195.2 | 4.5 | 0.25 | 0.15 | 0.01 | 0.04 | 0.44 | 0.31 | FR |

| DDH22LU032 | 82.2 | 105.2 | 23.0 | 0.58 | 0.32 | 0.05 | 0.01 | 0.96 | 0.08 | FR |

| And | 115.2 | 119.8 | 4.6 | 5.52 | 1.27 | 0.26* | 0.02 | 7.07* | 0.01 | FR/LS |

| DDH22LU033 | 89.2 | 104.8 | 15.6 | 0.96 | 0.35 | 0.06 | 0.01 | 1.38 | 0.16 | FR |

| DDH22LU034 | 109.4 | 144.4 | 35.0 | 0.87 | 0.51 | 0.10 | 0.03 | 1.50 | 0.16 | FR |

| DDH22LU036 | 95.7 | 105.7 | 10.0 | 0.91 | 0.40 | 0.05 | 0.01 | 1.37 | 0.08 | FR |

| DDH22LU037 | 0.0 | 6.2 | 6.2 | 1.26 | 0.75 | 0.11 | 0.02 | 2.13 | NA | Ox |

| And | 51.0 | 65.0 | 12.0 | 2.14 | 1.47 | 0.24 | 0.03 | 3.87 | 0.03 | FR |

| And | 84.0 | 93.0 | 9.0 | 0.30 | 0.64 | 0.07 | 0.01 | 1.02 | 0.05 | FR |

| And | 100.0 | 118.5 | 18.5 | 1.48 | 0.97 | 0.23 | 0.01 | 2.69 | 0.02 | FR |

| And | 124.5 | 130.5 | 6.0 | 0.44 | 0.26 | 0.07 | 0.01 | 0.77 | 0.04 | FR |

| DDH22LU040 | 36.6 | 89.5 | 52.9 | 1.44 | 0.52 | 0.10 | 0.08 | 2.14 | 0.27 | FR |

| DDH22LU041 | 137.6 | 149.6 | 12.0 | 0.83 | 0.40 | 0.05 | 0.12 | 1.40 | 0.06 | FR |

| DDH22LU042 | 47.0 | 114.3 | 67.3 | 0.89 | 0.33 | 0.06 | 0.07 | 1.35 | 0.28 | FR |

| Including | 47.0 | 55.0 | 8.0 | 0.35 | 0.14 | 0.05 | 0.07 | 0.62 | 0.81 | FR |

| Also Including | 83.0 | 114.3 | 31.3 | 1.75 | 0.63 | 0.10 | 0.13 | 2.60 | 0.27 | FR |

| Notes: | All ‘From’, ‘To’ depths, and ‘Thicknesses’ are downhole. | |||||||||

| Given the orientation of the hole and the mineralization, the intercept is estimated to be 80% to 85% of true thickness. | ||||||||||

| Type: Ox = Oxide. LS = Low Sulphur. FR = Fresh Rock. Recovery methods and results will differ based on the type of mineralization. | ||||||||||

| NA: Not Applicable as intercept is oxide or a mix of oxide and fresh rock mineralization. | ||||||||||

| * = Includes Rh >1.00g/t result. Overlimit analyses pending. | ||||||||||

| ** = Bravo’s nickel grades are sulphide nickel, and do not include non-recoverable silicate nickel, unlike historic total nickel assays. | ||||||||||

Overall, results of Bravo’s drilling compare well with, or exceed, the intercepts in historic drill holes on nearby drill sections, in both tenor and mineralized thicknesses for Pd, Pt and Au, a trend that has been evidenced all through Bravo’s drill program to date. As previously reported, this is most likely related to improved assay methods for PGMs versus those available over 20 years ago, and only sporadic rhodium assaying historically. Bravo’s practice of assaying all mineralized samples for Rh is defining potential for significant additional in situ value as a result. Bravo’s nickel results are very similar to those in surrounding holes, indicating that almost all Ni is present as sulphides, with little contribution from unrecoverable nickel silicates.

The very wide intercepts in holes DDH22LU040 and 042 are from resource confirmation drilling in the central section of the deposit and indicate mineralized thicknesses that are wider than indicated in nearby historical holes, with average Ni grades that exceed those in nearby holes. Hole DDH22LU030 was collared to far away from the mineralized horizon considering its planned depth.

About Bravo Mining Corp.

Bravo is a Canada and Brazil-based mineral exploration and development company focused on advancing its Luanga PGM+Au+Ni Project in the world-class Carajás Mineral Province of Brazil.

The Luanga Project benefits from being in a location close to operating mines, with excellent access and proximity to existing infrastructure, including road, rail and clean and renewable hydro grid power. The project area was previously de-forested for agricultural grazing land. Bravo’s current Environmental, Social and Governance activities includes replanting trees in the project area, hiring and contracting locally, and ensuring protection of the environment during its exploration activities.

Technical Disclosure

Technical information in this news release has been reviewed and approved by Simon Mottram, F.AusIMM (Fellow Australia Institute of Mining and Metallurgy), President of Bravo Mining Corp. who serves as the Company’s “qualified person”, as defined in National Instrument 43-101 Standards of Disclosure for Mineral Projects. Mr. Mottram has verified the technical data and opinions contained in this news release.

- Historical Resource Estimate

This press release references a historical resource estimate for the Luanga Project (the “Historical Estimate”) prepared internally by prior owners, VALE SA, in 2017 and contained in a report by Mansur E.T., Ferreira Filho C.F., Oliveira D.P.L. entitled “The Luanga deposit, Carajás Mineral Province, Brazil: Different styles of PGE mineralization hosted in a medium-size layered intrusion.” and published in Ore Geology Reviews (Volume 118, March 2020, 103340). A qualified person has not done sufficient work to classify the Historical Estimate as current mineral resources or mineral reserves under National Instrument 43-101 – Standards of Disclosure for Mineral Projects (“NI 43-101”) and Bravo is not treating the Historical Estimate as current mineral resources or mineral reserves. Bravo cautions that the Historical Estimate was not prepared in accordance with NI 43-101. There can be no certainty, following further evaluation and/or exploration work, that the Historical Estimate can be upgraded or verified as mineral resources or mineral reserves in accordance with NI 43-101. Further, the assays values used to calculate the nickel content in the Historical Estimate are total nickel, and thus contain both sulphide nickel (potentially recoverable) and silicate nickel (unrecoverable by conventional methods). Bravo is not aware whether the nickel content in the Historical Estimate has been modified to account for this or not. In addition, no breakdown of the assay results for the individual metals contributing to this Historical Estimate has been published and the Historical Estimate was not classified in accordance with the mineral resource categories set out in NI 43-101. Nevertheless, Bravo considers the Historical Estimate to be relevant to the reader’s understanding of the status of the Project and its future potential.

Schedule 1: Drill Hole Collar Details

| HOLE-ID | Company | East (m) | North (m) | RL (m) | Datum | Depth (m) | Azimuth | Dip | Sector |

| DDH22LU030 | Bravo | 659282.85 | 9341168.22 | 226.02 | SIRGAS2000 UTM22S | 150.25 | 330.00 | -60.00 | Central |

| DDH22LU031 | Bravo | 659926.52 | 9341925.06 | 265.39 | SIRGAS2000 UTM22S | 253.40 | 90.00 | -60.00 | North |

| DDH22LU032 | Bravo | 659312.96 | 9341214.04 | 225.71 | SIRGAS2000 UTM22S | 150.10 | 330.00 | -60.00 | Central |

| DDH22LU033 | Bravo | 656999.95 | 9339804.99 | 289.53 | SIRGAS2000 UTM22S | 170.35 | 360.00 | -60.00 | Southwest |

| DDH22LU034 | Bravo | 659139.00 | 9341009.99 | 243.33 | SIRGAS2000 UTM22S | 175.15 | 330.00 | -60.00 | Central |

| DDH22LU036 | Bravo | 657100.00 | 9339875.01 | 291.06 | SIRGAS2000 UTM22S | 151.95 | 360.00 | -60.00 | Southwest |

| DDH22LU037 | Bravo | 659818.60 | 9341537.87 | 214.15 | SIRGAS2000 UTM22S | 150.80 | 330.00 | -60.00 | Central |

| DDH22LU040 | Bravo | 658310.99 | 9340552.88 | 280.11 | SIRGAS2000 UTM22S | 150.15 | 330.00 | -60.00 | Central |

| DDH22LU041 | Bravo | 657200.00 | 9339630.32 | 232.45 | SIRGAS2000 UTM22S | 165.00 | 360.00 | -60.00 | Southwest |

| DDH22LU042 | Bravo | 658632.00 | 9340794.97 | 253.04 | SIRGAS2000 UTM22S | 150.35 | 330.00 | -60.00 | Central |

Schedule 2: Assay Methodologies and QAQC

Samples follow a chain of custody between collection, processing, and delivery to the ALS laboratory in Parauapebas, state of Pará, Brazil. The drill core is delivered to the core shack at Bravo’s Luanga site facilities and processed by geologists who insert certified reference materials, blanks, and duplicates into the sampling sequence. Drill core is half cut and placed in secured polyurethane bags, then in security-sealed sacks before being delivered directly from the Luanga site facilities to the Parauapebas ALS laboratory by Bravo staff. Additional information about the methodology can be found on the ALS global website (ALS) in the analytical guides.

Quality Assurance and Quality Control is maintained internally at the lab through rigorous use of internal certified reference materials, blanks, and duplicates. An additional QAQC program is administered by Bravo using certified reference materials, duplicate samples and blank samples that are blindly inserted into the sample batch. If a QAQC sample returns an unacceptable value an investigation into the results is triggered and when deemed necessary, the samples that were tested in the batch with the failed QAQC sample are re-tested.

| Bravo ALS | |||||

| Preparation | Method | Method | Method | Method | |

| For All Elements | Pt, Pd, Au | Rh | Ni-Sulphide | Trace Elements | |

| PREP-31B | PGM-ICP27 | Rh-MS25 | Ni-ICP05 | ME-ICP61 | |

Location of Bravo Drilling Reported in this Document (CNW Group/Bravo Mining Corp.)

New Infill Drilling Section – Showing DDH22LU040 Wide PGM+Au+High-Grade Ni Zone (open) (CNW Group/Bravo Mining Corp.)

MORE or "UNCATEGORIZED"

Eloro Resources Announces Closing of Bought Deal LIFE Private Placement for Gross Proceeds of C$17 Million

Eloro Resources Ltd. (TSX: ELO) (FSE: P2QM) is pleased to announce the closing of its previously an... READ MORE

Minera Alamos Updates Resources and Reserves for the Pan Gold Mine in Nevada

Minera Alamos Inc. (TSX-V: MAI) (OTCQX: MAIFF) is pleased to announce updated Mineral Resource and M... READ MORE

Ero Copper Reports Fourth Quarter and Full Year 2025 Operating and Financial Results

Ero Copper Corp. (TSX: ERO) (NYSE: ERO) is pleased to announce its operating and financial results f... READ MORE

Rare Element Resources Announces Results of Oversubscribed Rights Offering of Common Shares

Rare Element Resources Ltd. (OTCQB: REEMF) is pleased to report that its previously announced... READ MORE

TRX Gold Reports Record Q2 2026 Production and Company Update

TRX Gold Corporation (TSX: TRX) (NYSE American: TRX) is pleased to announce preliminary resu... READ MORE