Bravo Intercepts Shallow PGMs and Magmatic Ni Sulphides at Luanga

71.4m at 1.94g/t PGM+Au from Surface; 39.0m at 2.34g/t PGM+Au, 0.26% Ni; 9.0m at 4.02g/t PGM+Au, 0.10% Ni and 3.0m at 13.09g/t PGM+Au

Bravo Mining Corp. (TSX-V: BRVO) (OTCQX: BRVMF) announced that it has received assay results from a further nineteen infill diamond drill holes from its 100% owned Luanga palladium + platinum + rhodium + gold + nickel project, located in the Carajás Mineral Province, state of Pará, Brazil.

“Recent assay results from infill drilling at Luanga continue to consistently enhance our understanding of the historical data. In the Southwest Sector, DDH22LU116 intersected the thickest known interval of continuous PGM+Au mineralization,” said Luis Azevedo, Chairman and CEO of Bravo. “Further trenching is planned in the Southwest Sector to determine whether there is an increase in grade and thickness at surface, similar to what we observed in trenching the Central Sector. Meanwhile, results from drilling of the Central Sector continue to show mineralization dominated by a single thick zone, with higher-than-expected nickel concentrations as drilling continues to advance at depth. We look forward to further testing the potential for mineralization at depth with the Phase 2 drill program, and in particular the commencement of the HeliTEM survey at the end of this month, designed to cover the whole area of the Luanga Project.”

Highlights Include:

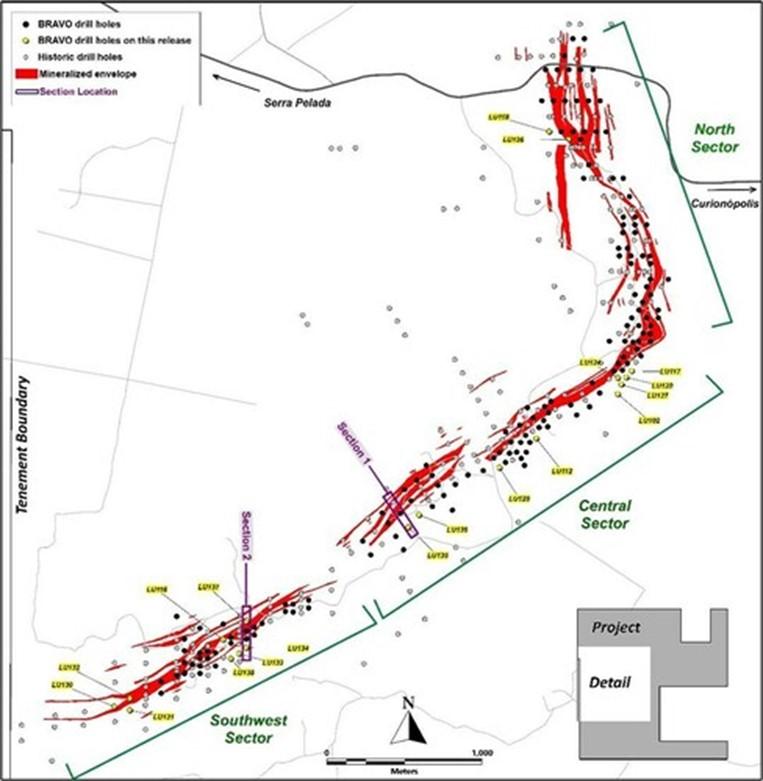

- DDH22LU116 intersected the thickest known interval of continuous mineralization to date in the Southwest Sector, and where mineralization was previously interpreted to narrow (Figure 5).

- Drilling continues to intercept magmatic nickel sulphides at depth, especially in the Central Sector where results from Bravo’s drilling outperforms historical shallower drilling results.

- Assay results continue to compare well with intercepts in historic drilling on nearby drill sections, both in tenor and mineralized thickness, and to previously reported results from Bravo drilling on the same drill sections.

- The Phase 2 drilling program commenced in the Central Sector, systematically targeting extensions to Luanga mineralization at depth.

- HeliTEM (airborne electromagnetics (“EM”)) over the whole area of the Luanga project is scheduled to begin at the end of May.

| HOLE-ID | From

(m) |

To

(m) |

Thickness (m) |

Pd

(g/t) |

Pt

(g/t) |

Rh

(g/t) |

Au (g/t) |

PGM + Au (g/t) |

Ni* (%) | Cu (%) | TYPE |

| DDH22LU112 | 158.3 | 182.0 | 23.7 | 1.29 | 0.74 | 0.10 | 0.03 | 2.16 | 0.15 | 0.02 | FR |

| DDH22LU116 | 0.0 | 71.4 | 71.4 | 1.19 | 0.55 | 0.05 | 0.14 | 1.94 | NA | – | Ox/FR |

| Including | 0.0 | 18.9 | 18.9 | 2.29 | 0.95 | 0.10 | 0.30 | 3.64 | NA | – | Ox |

| Including | 39.6 | 60.5 | 21.0 | 1.18 | 0.62 | 0.06 | 0.16 | 2.02 | 0.22 | – | FR |

| DDH22LU118 | 81.1 | 114.2 | 33.1 | 0.45 | 0.85 | 0.02 | 0.00 | 1.32 | 0.02 | 0.01 | FR |

| DDH22LU126 | 121.0 | 124.0 | 3.0 | 5.83 | 6.00 | 1.16 | 0.09 | 13.09 | 0.01 | – | FR |

| DDH23LU134 | 140.2 | 163.2 | 23.0 | 1.10 | 0.59 | 0.06 | 0.15 | 1.90 | 0.14 | – | FR |

| DDH23LU135 | 191.1 | 230.1 | 39.0 | 1.70 | 0.54 | 0.09 | 0.02 | 2.34 | 0.26 | – | FR |

| DDH23LU136 | 207.1 | 228.9 | 21.8 | 1.18 | 0.41 | 0.06 | 0.10 | 1.75 | 0.18 | – | FR |

| DDH23LU137 | 37.1 | 46.1 | 9.0 | 2.64 | 1.15 | 0.19 | 0.03 | 4.02 | 0.10 | – | FR |

| DDH23LU138 | 139.9 | 153.9 | 14.0 | 0.91 | 0.47 | 0.05 | 0.21 | 1.64 | 0.13 | – | FR |

| Notes: | All ‘From’, ‘To’ depths, and ‘Thicknesses’ are downhole. ‘NA’ Not applicable for Oxide material. ‘-‘ Not Assayed. | ||||||||||

| Given the orientation of the hole and the mineralization, the intercepts are estimated to 105% to 120% of true thickness. | |||||||||||

| Type: Ox = Oxide. LS = Low Sulphur. FR = Fresh Rock. Recovery methods and results will differ based on the type of mineralization. | |||||||||||

| * Bravo’s nickel grades are sulphide nickel, and do not include non-recoverable silicate nickel, unlike historic total nickel assays | |||||||||||

Luanga Drilling Assay Results Update

A total of 178 drill holes (43 in 2023) have been completed by Bravo to date, for 32,799 metres, including all 8 planned twin holes and all 8 metallurgical holes (not subject to routine assaying).

Results have been reported for 138 Bravo drill holes to date, which includes all drilling completed in 2022. Excluding the metallurgical holes, results for 32 Bravo drill holes are currently outstanding.

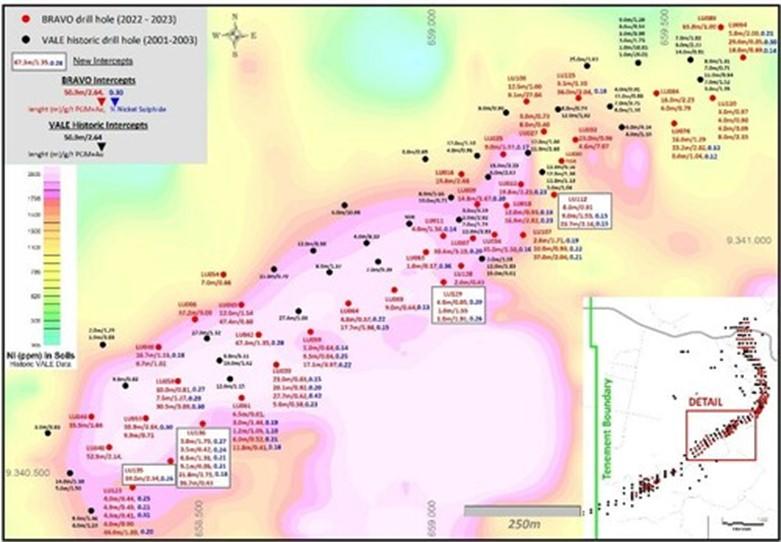

Drill results received from all three sectors at Luanga continue to compare well with intercepts in historic drilling on nearby drill sections and/or results from Bravo and historical drilling on the same drill sections (Figures 1, 3 and 4).

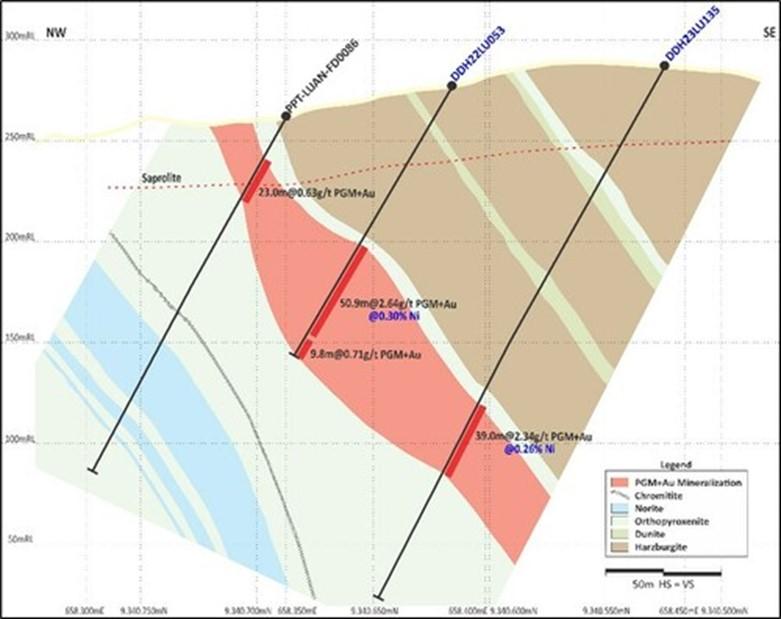

The Central Sector (Figure 1) continues to show mineralization dominated by one thick zone, with consistent thicknesses on section (Figure 3 – Section 1). Phase 2 drilling, which commenced in the Central Sector in April 2023, is systematically targeting the extension of existing PGM+Au+Ni mineralization to a greater depth.

Elevated nickel values (Figure 2) also continue to be a feature of the Central Sector, compared to historical results and in comparison to the North and Southwest Sectors, on a broad scale. This may be related to a significantly thicker basal (footwall) harzburgite (ultramafic) sequence, which is also coincident with a more prolific nickel-in-soil geochemical footprint.

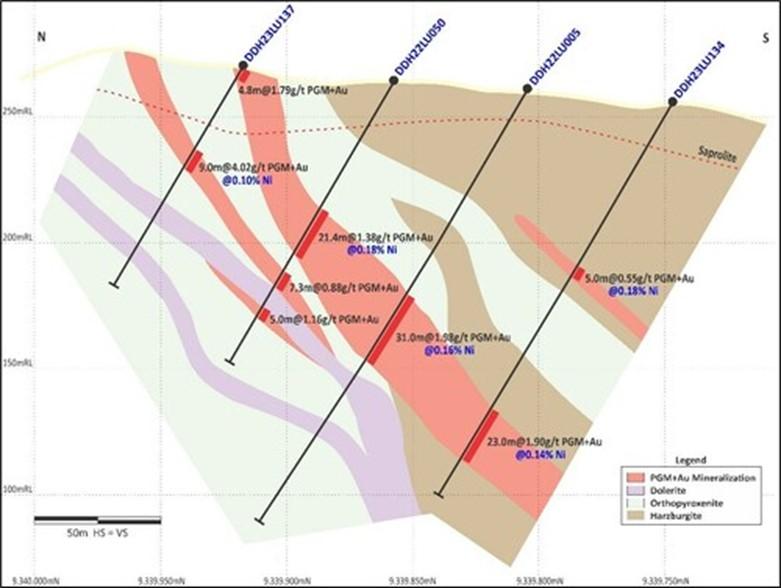

Drilling in the Southwest Sector also shows consistency with assay results both for PGMs and magmatic nickel sulphides (Figure 4 – Section 2), comparing well with intercepts in historic drilling on neighbouring drill sections and with drilling by Bravo on the same section.

Phase 2 Program

The Phase 2 program commenced in April 2023, with 21,500 meters of drilling planned, focused on extensional drilling to depth (below the known mineralization) and exploration of new targets.

Surface geophysical programs, micro-gravity and detailed ground magnetics remain in progress at Luanga, while HeliTEM (airborne EM) covering the entire Luanga project is scheduled to begin at the end of May.

Complete Table of Recent Intercepts

| HOLE-ID | From

(m) |

To

(m) |

Thickness (m) |

Pd

(g/t) |

Pt

(g/t) |

Rh

(g/t) |

Au (g/t) |

PGM + Au (g/t) |

Ni* (%) | Cu (%) | TYPE |

| DDH22LU102 | 68.5 | 71.5 | 3.0 | 1.19 | 0.48 | 0.00 | 0.25 | 1.92 | 0.10 | 0.19 | FR |

| And | 108.4 | 111.4 | 3.0 | 0.72 | 0.32 | 0.01 | 0.02 | 1.07 | 0.21 | 0.04 | FR |

| And | 165.4 | 182.4 | 17.0 | 0.63 | 0.31 | 0.05 | 0.01 | 1.00 | 0.10 | 0.02 | FR |

| And | 184.4 | 190.4 | 6.0 | 0.73 | 0.33 | 0.04 | 0.00 | 1.11 | 0.11 | 0.02 | FR |

| And | 224.3 | 232.3 | 8.0 | 0.32 | 0.12 | 0.01 | 0.02 | 0.48 | 0.10 | 0.06 | FR |

| And | 235.3 | 244.3 | 9.0 | 0.60 | 0.36 | 0.05 | 0.08 | 1.09 | 0.16 | 0.02 | FR |

| DDH22LU112 | 123.9 | 131.9 | 8.0 | 0.48 | 0.31 | 0.00 | 0.12 | 0.91 | 0.09 | 0.02 | FR |

| And | 133.9 | 142.9 | 9.0 | 0.76 | 0.49 | 0.00 | 0.27 | 1.53 | 0.15 | 0.04 | FR |

| And | 158.3 | 182.0 | 23.7 | 1.29 | 0.74 | 0.10 | 0.03 | 2.16 | 0.15 | 0.02 | FR |

| DDH22LU116 | 0.0 | 71.4 | 71.4 | 1.19 | 0.55 | 0.05 | 0.14 | 1.94 | NA | – | Ox/FR |

| Including | 0.0 | 18.9 | 18.9 | 2.29 | 0.95 | 0.10 | 0.30 | 3.64 | NA | – | Ox |

| Including | 39.6 | 60.5 | 21.0 | 1.18 | 0.62 | 0.06 | 0.16 | 2.02 | 0.22 | – | FR |

| DDH22LU117 | 153.0 | 161.0 | 8.0 | 0.56 | 0.25 | 0.05 | 0.01 | 0.86 | 0.07 | 0.01 | FR |

| And | 178.2 | 180.3 | 2.1 | 0.50 | 0.31 | 0.08 | 0.01 | 0.90 | 0.01 | 0.01 | FR |

| DDH22LU118 | 0.0 | 8.0 | 8.0 | 0.34 | 1.03 | 0.02 | 0.02 | 1.41 | NA | NA | Ox |

| And | 72.9 | 77.1 | 4.3 | 0.23 | 0.83 | 0.00 | 0.00 | 1.06 | 0.02 | 0.01 | FR |

| And | 81.1 | 114.2 | 33.1 | 0.45 | 0.85 | 0.02 | 0.00 | 1.32 | 0.02 | 0.01 | FR |

| DDH22LU120 | 72.3 | 75.3 | 3.0 | 0.48 | 0.25 | 0.00 | 0.05 | 0.78 | 0.04 | 0.03 | FR |

| And | 106.3 | 110.3 | 4.0 | 0.61 | 0.15 | 0.02 | 0.02 | 0.80 | 0.15 | 0.03 | FR |

| DDH22LU124 | 0.0 | 5.1 | 5.1 | 0.69 | 0.98 | 0.03 | 0.27 | 1.96 | NA | NA | Ox |

| And | 43.2 | 46.8 | 3.6 | 3.84 | 0.24 | 0.13 | 0.01 | 4.23 | 0.27 | 0.03 | FR |

| And | 100.8 | 103.8 | 3.0 | 1.45 | 0.88 | 0.33 | 0.02 | 2.68 | 0.04 | 0.02 | FR |

| And | 125.8 | 136.8 | 11.0 | 1.09 | 0.75 | 0.12 | 0.01 | 1.97 | 0.05 | 0.01 | FR |

| DDH22LU126 | 6.0 | 18.4 | 12.4 | 0.22 | 0.35 | 0.03 | 0.00 | 0.60 | NA | – | Ox |

| And | 28.9 | 37.4 | 8.5 | 0.22 | 0.35 | 0.01 | 0.00 | 0.58 | NA | – | Ox/FR |

| And | 121.0 | 124.0 | 3.0 | 5.83 | 6.00 | 1.16 | 0.09 | 13.09 | 0.01 | – | FR |

| DDH22LU127 | 105.7 | 108.8 | 3.1 | 0.51 | 0.21 | 0.00 | 0.01 | 0.73 | 0.19 | 0.04 | FR |

| And | 133.9 | 138.9 | 5.0 | 0.41 | 0.10 | 0.01 | 0.01 | 0.53 | 0.02 | 0.01 | FR |

| DDH22LU129 | 45.1 | 49.1 | 4.0 | 0.04 | 0.01 | 0.00 | 0.01 | 0.05 | 0.20 | – | FR |

| And | 97.8 | 98.8 | 1.0 | 0.69 | 0.83 | 0.00 | 0.03 | 1.55 | 0.05 | – | FR |

| And | 111.8 | 112.8 | 1.0 | 1.32 | 0.43 | 0.00 | 0.15 | 1.91 | 0.26 | – | FR |

| DDH23LU130 | 80.9 | 88.9 | 8.1 | 0.31 | 0.11 | 0.02 | 0.02 | 0.46 | 0.09 | – | FR |

| And | 98.9 | 104.9 | 6.0 | 0.28 | 0.26 | 0.00 | 0.05 | 0.59 | 0.01 | – | FR |

| And | 112.9 | 129.9 | 17.0 | 0.83 | 0.28 | 0.03 | 0.01 | 1.16 | 0.14 | – | FR |

| DDH23LU131 | 123.7 | 127.3 | 3.6 | 0.41 | 0.15 | 0.01 | 0.03 | 0.60 | 0.32 | – | FR |

| And | 129.3 | 150.7 | 21.4 | 0.15 | 0.20 | 0.00 | 0.01 | 0.36 | 0.02 | – | FR |

| DDH23LU132 | 80.9 | 84.9 | 4.0 | 1.07 | 0.98 | 0.03 | 0.04 | 2.13 | 0.02 | – | FR |

| And | 112.9 | 127.9 | 15.0 | 0.75 | 0.25 | 0.04 | 0.04 | 1.06 | 0.18 | – | FR |

| DDH23LU133 | 55.0 | 58.0 | 3.0 | 0.16 | 0.08 | 0.00 | 0.03 | 0.28 | 0.22 | – | FR |

| And | 73.0 | 78.0 | 5.0 | 0.06 | 0.03 | 0.01 | 0.00 | 0.10 | 0.20 | – | FR |

| And | 98.0 | 104.0 | 6.0 | 0.17 | 0.05 | 0.04 | 0.03 | 0.29 | 0.27 | – | FR |

| And | 143.5 | 153.5 | 10.1 | 0.73 | 0.37 | 0.02 | 0.15 | 1.27 | 0.09 | – | FR |

| DDH23LU134 | 74.1 | 79.1 | 5.0 | 0.37 | 0.15 | 0.00 | 0.03 | 0.55 | 0.18 | – | FR |

| And | 140.2 | 163.2 | 23.0 | 1.10 | 0.59 | 0.06 | 0.15 | 1.90 | 0.14 | – | FR |

| DDH23LU135 | 191.1 | 230.1 | 39.0 | 1.70 | 0.54 | 0.09 | 0.02 | 2.34 | 0.26 | – | FR |

| DDH23LU136 | 103.7 | 106.7 | 3.0 | 1.07 | 0.38 | 0.00 | 0.24 | 1.70 | 0.27 | – | FR |

| And | 131.7 | 135.2 | 3.5 | 0.26 | 0.11 | 0.05 | 0.01 | 0.42 | 0.24 | – | FR |

| And | 147.4 | 154.0 | 6.6 | 0.82 | 0.30 | 0.01 | 0.19 | 1.31 | 0.21 | – | FR |

| And | 189.0 | 198.1 | 9.1 | 0.55 | 0.20 | 0.03 | 0.08 | 0.86 | 0.21 | – | FR |

| And | 207.1 | 228.9 | 21.8 | 1.18 | 0.41 | 0.06 | 0.10 | 1.75 | 0.18 | – | FR |

| And | 263.6 | 300.3 | 36.7 | 0.21 | 0.21 | 0.00 | 0.01 | 0.43 | 0.02 | – | FR |

| DDH23LU137 | 0.0 | 4.8 | 4.8 | 1.11 | 0.58 | 0.05 | 0.05 | 1.79 | 0.01 | – | Ox |

| And | 37.1 | 46.1 | 9.0 | 2.64 | 1.15 | 0.19 | 0.03 | 4.02 | 0.10 | – | FR |

| DDH23LU138 | 139.9 | 153.9 | 14.0 | 0.91 | 0.47 | 0.05 | 0.21 | 1.64 | 0.13 | – | FR |

| Notes: | All ‘From’, ‘To’ depths, and ‘Thicknesses’ are downhole. ‘NA’ Not applicable for Oxide material. ‘-‘ Not Assayed. | ||||||||||

| Given the orientation of the hole and the mineralization, the intercepts are estimated to 105% to 120% of true thickness. | |||||||||||

| Type: Ox = Oxide. LS = Low Sulphur. FR = Fresh Rock. Recovery methods and results will differ based on the type of mineralization. | |||||||||||

| * Bravo’s nickel grades are sulphide nickel, and do not include non-recoverable silicate nickel, unlike historic total nickel assays | |||||||||||

About Bravo Mining Corp.

Bravo is a Canada and Brazil-based mineral exploration and development company focused on advancing its Luanga PGM+Au+Ni Project in the world-class Carajás Mineral Province of Brazil.

The Luanga Project benefits from being in a location close to operating mines, with excellent access and proximity to existing infrastructure, including road, rail and clean and renewable hydro grid power. The project area was previously de-forested for agricultural grazing land. Bravo’s current Environmental, Social and Governance activities includes replanting trees in the project area, hiring and contracting locally, and ensuring protection of the environment during its exploration activities.

Technical Disclosure

Technical information in this news release has been reviewed and approved by Simon Mottram, F.AusIMM (Fellow Australia Institute of Mining and Metallurgy), President of Bravo Mining Corp. who serves as the Company’s “qualified person” as defined in National Instrument 43-101 Standards of Disclosure for Mineral Projects. Mr. Mottram has verified the technical data and opinions contained in this news release.

Schedule 1: Drill Hole Collar Details

| HOLE-ID | Company | East (m) | North (m) | RL (m) | Datum | Depth (m) | Azimuth | Dip | Sector |

| DDH22LU102 | Bravo | 659791.97 | 9341382.61 | 198.887 | SIRGAS2000 UTM22S | 260.20 | 330.00 | -60.00 | Central |

| DDH22LU112 | Bravo | 659266.72 | 9341095.83 | 229.070 | SIRGAS2000 UTM22S | 230.75 | 330.00 | -70.00 | Central |

| DDH22LU116 | Bravo | 657250.02 | 9339800.48 | 268.650 | SIRGAS2000 UTM22S | 190.00 | 360.00 | -60.00 | Southwest |

| DDH22LU117 | Bravo | 659880.80 | 9341531.75 | 206.157 | SIRGAS2000 UTM22S | 180.25 | 330.00 | -60.00 | Central |

| DDH22LU118 | Bravo | 659349.88 | 9343074.98 | 244.918 | SIRGAS2000 UTM22S | 150.20 | 90.00 | -60.00 | North |

| DDH22LU120 | Bravo | 659846.14 | 9341490.49 | 210.630 | SIRGAS2000 UTM22S | 150.35 | 330.00 | -60.00 | Central |

| DDH22LU124 | Bravo | 659790.31 | 9341487.81 | 210.871 | SIRGAS2000 UTM22S | 150.50 | 330.00 | -60.00 | Central |

| DDH22LU126 | Bravo | 659474.70 | 9343025.05 | 271.020 | SIRGAS2000 UTM22S | 150.70 | 90.00 | -60.00 | North |

| DDH22LU127 | Bravo | 659815.31 | 9341444.81 | 205.615 | SIRGAS2000 UTM22S | 150.15 | 330.00 | -60.00 | Central |

| DDH22LU129 | Bravo | 659029.33 | 9340907.84 | 250.009 | SIRGAS2000 UTM22S | 150.10 | 330.00 | -60.00 | Central |

| DDH23LU130 | Bravo | 656550.00 | 9339367.75 | 240.317 | SIRGAS2000 UTM22S | 150.00 | 360.00 | -60.00 | Southwest |

| DDH23LU131 | Bravo | 656649.97 | 9339344.85 | 255.735 | SIRGAS2000 UTM22S | 150.70 | 360.00 | -60.00 | Southwest |

| DDH23LU132 | Bravo | 656649.99 | 9339419.92 | 260.180 | SIRGAS2000 UTM22S | 150.15 | 360.00 | -60.00 | Southwest |

| DDH23LU133 | Bravo | 657353.76 | 9339708.35 | 244.741 | SIRGAS2000 UTM22S | 250.40 | 360.00 | -60.00 | Southwest |

| DDH23LU134 | Bravo | 657399.92 | 9339747.06 | 254.662 | SIRGAS2000 UTM22S | 180.70 | 360.00 | -60.00 | Southwest |

| DDH23LU135 | Bravo | 658443.19 | 9340523.33 | 286.852 | SIRGAS2000 UTM22S | 300.20 | 330.00 | -60.00 | Central |

| DDH23LU136 | Bravo | 658512.05 | 9340603.56 | 285.997 | SIRGAS2000 UTM22S | 300.30 | 330.00 | -60.00 | Central |

| DDH23LU137 | Bravo | 657400.00 | 9339917.61 | 268.977 | SIRGAS2000 UTM22S | 100.45 | 360.00 | -60.00 | Southwest |

| DDH23LU138 | Bravo | 657300.05 | 9339676.24 | 235.495 | SIRGAS2000 UTM22S | 200.20 | 360.00 | -60.00 | Southwest |

Schedule 2: Assay Methodologies and QAQC

Samples follow a chain of custody between collection, processing, and delivery to the SGS laboratory in Parauapebas, state of Pará, Brazil. The drill core is delivered to the core shack at Bravo’s Luanga site facilities and processed by geologists who insert certified reference materials, blanks, and duplicates into the sampling sequence. Drill core is half cut and placed in secured polyurethane bags, then in security-sealed sacks before being delivered directly from the Luanga site facilities to the Parauapebas SGS laboratory by Bravo staff. Additional information about the methodology can be found on the SGS Geosol website (SGS) in their analytical guides. Information regarding preparation and analysis of historic drill core is also presented in the table below, where the information is known.

Quality Assurance and Quality Control is maintained internally at the lab through rigorous use of internal certified reference materials, blanks, and duplicates. An additional QAQC program is administered by Bravo using certified reference materials, duplicate samples and blank samples that are blindly inserted into the sample batch. If a QAQC sample returns an unacceptable value an investigation into the results is triggered and when deemed necessary, the samples that were tested in the batch with the failed QAQC sample are re-tested.

| Bravo SGS Geosol | |||||

| Preparation | Method | Method | Method | Method | |

| For All Elements | Pt, Pd, Au | Rh | Sulphide Ni, Cu | Trace Elements | |

| PRP102_E (95% at 150#) | FAI515 | FAA35J | ICP04B | ICP40B | |

Figure 1: Central Sector (~2km strike) showing consistently improving results at depth, including consistently strong magmatic nickel results. (CNW Group/Bravo Mining Corp.)

Figure 2: Core Photos from Central Sector drilling (DDH23LU135 and 136), with PGM+Au and magmatic nickel sulphide mineralization. (CNW Group/Bravo Mining Corp.)

Figure 3: Central Sector (Section 1 on Figure 5) – Continuation of mineralization at depth, with higher levels of magmatic nickel. (CNW Group/Bravo Mining Corp.)

Figure 4: Southwest Sector (Section 2 on Figure 5) – Continuation of mineralization at depth. (CNW Group/Bravo Mining Corp.)

Figure 5: Location of Bravo Drilling and Sections Reported in this News Release (CNW Group/Bravo Mining Corp.)

MORE or "UNCATEGORIZED"

McEwen Mining Announces Friendly Acquisition of Timberline Resources

McEwen Mining Inc. (NYSE: MUX) (TSX: MUX) is pleased to announce ... READ MORE

Royal Helium and Sparrow Hawk Developments Enter Into a $25 Million Economic Partnership and LOI for Resource Development and New Facility Construction in Saskatchewan

Royal Helium Ltd. (TSX-V: RHC) (TSXV: RHC.WT.A) (OTCQB: RHCCF) a... READ MORE

Robex Announces Resilient Q1 2024 Production

Robex Resources Inc. (TSX-V: RBX) is please to announce productio... READ MORE

Calibre Announces Closing of C$115 Million Financing

Calibre Mining Corp. (TSX: CXB) (OTCQX: CXBMF) is pleased to anno... READ MORE

Pan American Energy’s Collaboration with the University of Saskatoon Receives Federal NSERC Funding

Pan American Energy Corp. (CSE: PNRG) (OTCQB: PAANF) (FRA: SS60) ... READ MORE