Bravo Continues to Intersect High-Grade PGM’s and Ni Sulphide at Luanga

Highlights include 16.9m @ 2.82g/t PGM + Au, plus 0.23% Ni Sulphide, and

13.6m @ 2.67g/t PGM + Au, plus 0.23% Ni Sulphide

Bravo Mining Corp. (TSX-V: BRVO), announced that it has received assay results from a further twelve infill diamond drill holes from its wholly owned Luanga PGM (palladium + platinum + rhodium) + gold + nickel project, located in the Carajás Mineral Province, state of Pará, Brazil. Samples for a further 34 drill holes (including 18 re-assay holes) are already at the laboratory for analysis with results pending. Both downhole and surface electromagnetic programs are also underway to follow up on the previously announced massive sulphide intercept.

“The infill drilling and historic core re-assay programs continue to advance rapidly. As we receive more assay results, we continue to see results comparable to the historic grades and thicknesses, increasing our confidence in the prior work completed at Luanga,” said Luis Azevedo, Chairman and CEO of Bravo. “The Company is also following up on the recently discovered nickel and copper massive sulphide mineralization that had not been previously identified at Luanga. Downhole EM assisted with the placement of the two follow-up holes (results pending) and the design for drilling on the next drill section. Surface EM will also start shortly, which we hope will greatly assist in vectoring-in and following these potential feeder zone(s).”

Highlights

- Assay results from infill drilling continue to compare well with the drill holes on their neighbouring historic drill sections in both tenor and mineralized thicknesses.

- Highlights of Bravo’s recent intercepts are tabulated below, with details attached:

| HOLE-ID | From

(m) |

To

(m) |

Thickness (m) |

Pd

(g/t) |

Pt

(g/t) |

Rh

(g/t) |

Au (g/t) |

Ni % (Sulphide) |

PGM + Au (g/t) |

TYPE |

| DDH22LU005 | 93.0 | 124.0 | 31.0 | 1.19 | 0.59 | 0.09 | 0.11 | 0.16 | 1.98 | FR |

| DDH22LU018 | 90.8 | 107.7 | 16.9 | 1.60 | 0.89 | 0.22 | 0.10 | 0.23 | 2.82 | FR |

| DDH22LU019 | 0.0 | 64.2 | 64.2 | 0.58 | 0.29 | 0.04 | 0.07 | NA | 0.99 | Ox/FR |

| Including | 50.6 | 64.2 | 13.6 | 1.58 | 0.80 | 0.14 | 0.16 | 0.22 | 2.67 | FR |

| Notes: | All ‘From’, ‘To’ depths, and ‘Thicknesses’ are downhole. | |||||||||

| Given the orientation of the holes and the mineralization, the intercepts are estimated to range from ~75 to 95% of true thickness. | ||||||||||

| Type: Ox = Oxide. FR = Fresh Rock. Recovery methods and results will differ based on the type of mineralization. | ||||||||||

| NA: Not Applicable as intercept is oxide or a mix of oxide and fresh rock mineralization. | ||||||||||

- Additional results from historic drill hole re-assaying are expected in the following weeks.

- Downhole (DH) Transient Electromagnetic (TEM) survey completed on previously reported (August 16rd, 2022 news release) high-grade Ni/Cu massive sulphide hole DDH22LU047;

- Following DHTEM, two new drill holes on the same section have been completed (results pending);

- Drilling on the next section to the north is expected to start soon; and

- Surface Fixed Loop TEM (FLTEM) surveying is expected to commence shortly.

- 67 drill holes have been completed, for a total of 11,091 metres (or 43% of Phase 1 Drilling Program), including 5 twin holes and 6 metallurgical holes.

- 9,621 samples submitted for assay to date including 2,943 re-assay samples from historic drill core.

- 6 drill rigs operating onsite.

Luanga Drill Program

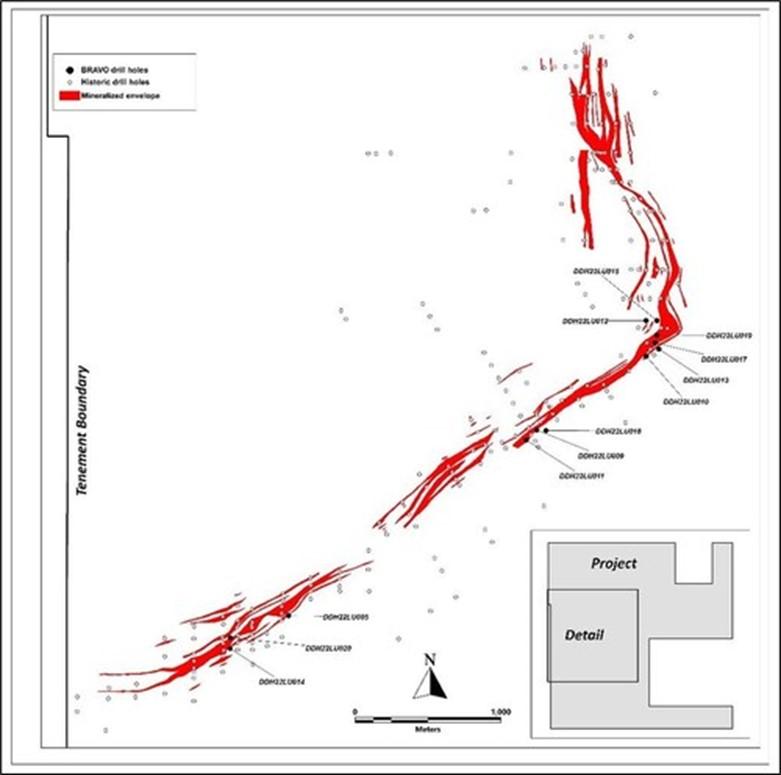

The Phase 1 diamond drill program continues as planned at Luanga. With six drill rigs on site, drilling is now progressing in various locations along the entire 7km strike length of the known Luanga mineralized envelope (defined by historic drilling), including to the north where high-grade massive sulphide nickel/copper mineralization was intersected (see August 16rd, 2022 news release). DHTEM has been completed on this hole (see picture below), and two more drill holes have been completed on the same drill section (results pending), with two more holes about to commence on the section to the north. Surface FLTEM surveying is expected to start soon, to the south of the massive sulphide intercept. To date, 67 DDH have been completed for a total of 11,091m from the planned 25,500m Phase 1 drill program.

Phase 1 drilling is primarily designed to confirm, infill, and step out from the previously defined PGM+Au+Ni mineralization in order to increase confidence in the geological model and provide the basis for future mineral resource estimates. Additionally, drilling will target potential extensions to the mineralization at depth and, given the more recent discovery of massive sulphides, evaluate the potential of this new style of mineralization.

Complete Table of Assay Results

| HOLE-ID | From

(m) |

To

(m) |

Thickness (m)(1) |

Pd

(g/t) |

Pt

(g/t) |

Rh

(g/t) |

Au (g/t) |

Ni % (Sulphide) |

PGM + Au (g/t) |

TYPE |

| DDH22LU005 | 93.0 | 124.0 | 31.0 | 1.19 | 0.59 | 0.09 | 0.11 | 0.16 | 1.98 | FR |

| DDH22LU009 | 47.6 | 62.4 | 14.8 | 1.01 | 0.55 | 0.08 | 0.02 | 0.20 | 1.67 | FR |

| DDH22LU010 | 29.7 | 33.0 | 3.3 | 0.71 | 0.45 | 0.13 | 0.01 | 0.08 | 1.30 | FR |

| And | 47.9 | 55.0 | 7.1 | 0.65 | 0.33 | 0.05 | 0.01 | 0.08 | 1.04 | FR |

| And | 64.0 | 73.1 | 9.1 | 0.77 | 0.35 | 0.06 | 0.01 | 0.10 | 1.19 | FR |

| And | 87.4 | 98.4 | 11.0 | 0.60 | 0.34 | 0.06 | 0.01 | 0.08 | 1.02 | FR |

| DDH22LU011 | 84.2 | 88.2 | 4.0 | 0.98 | 0.46 | 0.09 | 0.03 | 0.14 | 1.56 | FR |

| DDH22LU012 | No Significant Result | |||||||||

| DDH22LU013 | 0.0 | 5.9 | 5.9 | 0.49 | 0.30 | 0.05 | 0.01 | NA | 0.86 | Ox |

| And | 98.9 | EOH | 1.3 | 1.01 | 0.18 | 0.05 | 001 | 0.13 | 1.25 | FR |

| DDH22LU014 | 25.3 | 31.7 | 6.4 | 0.77 | 0.29 | 0.05 | 0.01 | NA | 1.12 | Ox |

| And | 43.4 | 61.4 | 18.0 | 0.55 | 0.22 | 0.04 | 0.03 | 0.09 | 0.83 | FR |

| And | 66.0 | 70.0 | 4.0 | 0.85 | 0.32 | 0.05 | 0.02 | 0.14 | 1.23 | FR |

| And | 81.0 | 90.0 | 9.0 | 0.89 | 0.35 | 0.05 | 0.02 | 0.15 | 1.31 | FR |

| And | 102.0 | 111.6 | 9.6 | 1.07 | 0.39 | 0.06 | 0.03 | 0.08 | 1.55 | FR |

| DDH22LU015 | 0.0 | 28.0 | 28.0 | 0.31 | 0.14 | 0.02 | 0.04 | NA | 0.52 | Ox |

| And | 57.8 | 71.0 | 13.2 | 0.59 | 0.23 | 0.05 | 0.01 | 0.36 | 0.88 | FR |

| And | 88.5 | 100.5 | 12.0 | 0.25 | 0.13 | 0.02 | 0.03 | 0.31 | 0.42 | FR |

| DDH22LU017 | 0.0 | 11.2 | 11.2 | 0.81 | 0.47 | 0.09 | 0.02 | NA | 1.39 | Ox |

| And | 18.2 | 23.2 | 5.0 | 0.52 | 0.51 | 0.08 | 0.01 | NA | 1.12 | Ox |

| And | 85.9 | 88.9 | 3.0 | 1.15 | 0.44 | 0.06 | 0.01 | 0.05 | 1.66 | FR |

| And | 126.0 | 141.0 | 15.0 | 1.22 | 0.54 | 0.10 | 0.08 | 0.17 | 1.95 | FR |

| DDH22LU018 | 59.9 | 71.9 | 12.0 | 0.55 | 0.26 | 0.08 | 0.04 | 0.19 | 0.93 | FR |

| And | 90.8 | 107.7 | 16.9 | 1.60 | 0.89 | 0.22 | 0.10 | 0.23 | 2.82 | FR |

| DDH22LU019 | 0.0 | 64.2 | 64.2 | 0.58 | 0.29 | 0.04 | 0.07 | NA | 0.99 | Ox/FR |

| Including | 50.6 | 64.2 | 13.6 | 1.58 | 0.80 | 0.14 | 0.16 | 0.22 | 2.67 | FR |

| And | 74.2 | 78.8 | 4.6 | 0.60 | 0.52 | 0.07 | 0.02 | 0.10 | 1.21 | FR |

| DDH22LU020 | 0.0 | 9.0 | 9.0 | 1.38 | 0.52 | 0.10 | 0.02 | NA | 2.02 | Ox |

| And | 13.0 | 31.7 | 18.7 | 0.98 | 0.38 | 0.07 | 0.04 | NA | 1.46 | Ox/FR |

| And | 55.4 | 117.4 | 62.0 | 0.35 | 0.25 | 0.01 | 0.01 | 0.01 | 0.61 | FR |

| Notes: | All ‘From’, ‘To’ depths, and ‘Thicknesses’ are downhole. | |||||||||

| Given the orientation of the holes and the mineralization, the intercepts are estimated to range from ~75 to 95% of true thickness. | ||||||||||

| Type: Ox = Oxide. FR = Fresh Rock. Recovery methods and results will differ based on the type of mineralization. | ||||||||||

| NA: Not Applicable as intercept is oxide or a mix of oxide and fresh rock mineralization. | ||||||||||

About Bravo Mining Corp.

Bravo is a Canada and Brazil-based mineral exploration and development company focused on advancing its Luanga PGM + Au + Ni Project in the world-class Carajás Mineral Province of Brazil.

The Luanga Project benefits from being in a location close to operating mines, with excellent access and proximity to existing infrastructure, including road, rail and clean and renewable hydro grid power. The project area was previously de-forested for agricultural grazing land. Bravo’s current Environmental, Social and Governance activities includes replanting trees in the project area, hiring and contracting locally, and ensuring protection of the environment during its exploration activities.

Bravo was founded by a management team and board with extensive Brazilian and PGM exploration, permitting, project financing, construction and operating experience. This includes Luis Azevedo, Executive Chairman & CEO; Simon Mottram, President; Alex Penha, EVP Corporate Development; and Independent Directors, Dr. Nicole Adshead-Bell (Lead Director), Stuart Comline, Tony Polglase and Stephen Quin.

Technical Disclosure

Technical information in this news release has been reviewed and approved by Simon Mottram, F.AusIMM (Fellow Australia Institute of Mining and Metallurgy), President of Bravo Mining Corp. who serves as the Company’s “qualified person”, as defined in National Instrument 43-101 Standards of Disclosure for Mineral Projects. Mr. Mottram has verified the technical data and opinions contained in this news release.

Schedule 1: Drill Hole Collar Details

| HOLE-ID | Company | East (m) | North (m) | RL (m) | Datum | Depth (m) |

Azimuth | Dip | |

| DDH22LU005 | Bravo | 657399.97 | 9339804.76 | 259.36 | SIRGAS2000 UTM22S | 152.35 | 360.00 | -60.00 | |

| DDH22LU009 | Bravo | 659101.84 | 9341075.30 | 232.45 | SIRGAS2000 UTM22S | 200.50 | 360.00 | -60.00 | |

| DDH22LU010 | Bravo | 659852.14 | 9341580.93 | 221.61 | SIRGAS2000 UTM22S | 160.25 | 330.00 | -60.00 | |

| DDH22LU011 | Bravo | 659028.75 | 9341007.34 | 241.87 | SIRGAS2000 UTM22S | 100.20 | 330.00 | -60.00 | |

| DDH22LU012 | Bravo | 659850.54 | 9341825.16 | 255.78 | SIRGAS2000 UTM22S | 200.10 | 330.00 | -60.00 | |

| DDH22LU013 | Bravo | 659938.89 | 9341630.21 | 219.39 | SIRGAS2000 UTM22S | 151.10 | 90.00 | -60.00 | |

| DDH22LU014 | Bravo | 656999.90 | 9339580.01 | 270.50 | SIRGAS2000 UTM22S | 100.15 | 330.00 | -60.00 | |

| DDH22LU015 | Bravo | 659925.01 | 9341825.05 | 265.24 | SIRGAS2000 UTM22S | 151.35 | 360.00 | -60.00 | |

| DDH22LU017 | Bravo | 659913.93 | 9341673.10 | 231.91 | SIRGAS2000 UTM22S | 199.05 | 90.00 | -60.00 | |

| DDH22LU018 | Bravo | 659164.67 | 9341072.65 | 235.07 | SIRGAS2000 UTM22S | 150.30 | 330.00 | -60.00 | |

| DDH22LU019 | Bravo | 659924.98 | 9341725.04 | 239.05 | SIRGAS2000 UTM22S | 150.25 | 330.00 | -60.00 | |

| DDH22LU020 | Bravo | 657000.03 | 9339654.43 | 288.60 | SIRGAS2000 UTM22S | 150.00 | 330.00 | -60.00 |

Schedule 2: Assay Methodologies and QAQC

Samples follow a chain of custody between collection, processing and delivery to the ALS laboratory in Parauapebas, state of Pará, Brazil. The drill core is delivered to the core shack at Bravo’s Luanga site facilities and processed by geologists who insert certified reference materials, blanks and duplicates into the sampling sequence. Drill core is half cut and placed in secured polyurethane bags, then in security-sealed sacks before being delivered directly from the Luanga site facilities to the Parauapebas ALS laboratory by Bravo staff. Additional information about the methodology can be found on the ALS global website (ALS) in the analytical guides.

Quality Assurance and Quality Control is maintained internally at the lab through rigorous use of internal certified reference materials, blanks, and duplicates. An additional QAQC program is administered by Bravo using certified reference materials, duplicate samples and blank samples that are blindly inserted into the sample batch. If a QAQC sample returns an unacceptable value an investigation into the results is triggered and when deemed necessary, the samples that were tested in the batch with the failed QAQC sample are re-tested.

| Bravo ALS | |||||

| Preparation | Method | Method | Method | Method | |

| For All Elements | Pt, Pd, Au | Rh | Ni-Sulphide | Trace Elements | |

| PREP-31B | PGM-ICP27 | Rh-MS25 | Ni-ICP05 | ME-ICP61 | |

Location of Bravo Drilling Reported in this Document (CNW Group/Bravo Mining Corp.)

MORE or "UNCATEGORIZED"

Eloro Resources Announces Closing of Bought Deal LIFE Private Placement for Gross Proceeds of C$17 Million

Eloro Resources Ltd. (TSX: ELO) (FSE: P2QM) is pleased to announce the closing of its previously an... READ MORE

Minera Alamos Updates Resources and Reserves for the Pan Gold Mine in Nevada

Minera Alamos Inc. (TSX-V: MAI) (OTCQX: MAIFF) is pleased to announce updated Mineral Resource and M... READ MORE

Ero Copper Reports Fourth Quarter and Full Year 2025 Operating and Financial Results

Ero Copper Corp. (TSX: ERO) (NYSE: ERO) is pleased to announce its operating and financial results f... READ MORE

Rare Element Resources Announces Results of Oversubscribed Rights Offering of Common Shares

Rare Element Resources Ltd. (OTCQB: REEMF) is pleased to report that its previously announced... READ MORE

TRX Gold Reports Record Q2 2026 Production and Company Update

TRX Gold Corporation (TSX: TRX) (NYSE American: TRX) is pleased to announce preliminary resu... READ MORE