Surge Delivers Preliminary Economic Assessment For High-Grade Nevada North Lithium Project; After-Tax NPV8% US$9.21 Billion and After-Tax IRR of 22.8% OPEX of US$5,097/tonne LCE

NNLP PEA Highlights:

- After-tax NPV8%: US$9.21 Billion, IRR of 22.8% at US$24,000/t LCE price

- Operating cost: US$5,097/t LCE

- Near-surface, high-grade mineralization provide Surge NNLP advantage

- PEA mine and processing plan produces 3.6 Mt battery-grade lithium carbonate equivalent over the 42-year life of mine

- Average Annual Production of 86,300 tonnes LCE

- Peak Production of 109,100 tonnes LCE in Year 6

- Lithium Plant will be built in two phases

- Phase 1 Capital Cost: US$2.97 Billion, Phase 2 CAPEX: US$2.35 Billion, total of US$5.30 Billion

- Sustaining Capital: US$1.51 Billion

- After-tax payback: 4.7 years

- Average LOM annual after-tax cash flow: US$1.06 Billion

Surge Battery Metals Inc. (TSX-V: NILI) (OTCQX: NILIF) (FSE: DJ5) is pleased to report the results of its 2025 Preliminary Economic Assessment Study for the Nevada North Lithium Project located in Elko County north-northeast of Wells, Nevada.

The PEA, completed jointly by lead consultants M3 Engineering & Technology Corp. and Independent Mining Consultants, confirms robust economics for a low-cost, large-scale and long-life conventional open pit and dry-stack tailings operation producing battery-grade lithium carbonate through on-site treatment of the mined material processed through a sulfuric acid leaching circuit. The PEA scenario envisions 2 phases over the initial 42-year mine life. Phase 1 includes 2.58 million tonnes per annum (“Mtpa”) processing throughput doubling to 5.15 Mtpa in Phase 2, which comes online in Year 4 of production. A combination of the shallowest and highest lithium grades is prioritized for processing, resulting in a variable battery-grade lithium carbonate production that peaks in Year 6 at 109,100 tonnes LCE, and averages 86,300 tonnes/year LCE for a total of 3.63 million tonnes LCE over the LOM at a lithium recovery of 82.8%.

The PEA is derived using the inferred Mineral Resource Estimate effective as of October 9, 2024 and completed by Dr. Bruce Davis. The effective date of the PEA is May 19, 2025, and a NI-43101 compliant technical report will be filed under the corporations SEDAR+ profile within 45 days of this news release.

The preliminary economic assessment is preliminary in nature and includes inferred mineral resources that are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves. There is no certainty that the preliminary economic assessment will be realized. Mineral resources that are not mineral reserves do not have demonstrated economic viability.

The figures shown above represent the NNLP’s potential economics with certain LCE selling price assumptions. The NNLP’s sensitivity to LCE selling prices is detailed below in Table 2. To model 100% ownership of the subsurface mineral rights on privately held land, Surge has assumed a 2% gross revenue royalty in its economic model on all revenues from the private land.

Mr. Greg Reimer, Chief Executive Officer and Director, commented, “We are ecstatic to present the results of this PEA for the Nevada North Lithium Project. Our goal was to demonstrate that even using best in class environmental practices, NNLP could potentially be a major low-cost producer of battery-grade lithium carbonate for the United States battery industry, and we have taken a major step in achieving that with today’s results. The NNLP will benefit the local community with a long and stable 42-year mine life, with significant extension potential, that will bring thousands of high paying jobs to northeastern Nevada. Additionally, all of this is possible with a design that doesn’t produce a tailings pond. The combination of low OPEX, great ROI, and the ability to produce large quantities of battery-grade lithium carbonate including a peak of 109,100 tonnes in one year showcases the Tier 1 status of NNLP. We received the last assays from our initial drill program in January 2023 and are now reporting an NPV of US$9.21 Billion in a period of 2.5 years. Our goal is to continue to advance and derisk the NNLP at a rapid pace, and we hope for further improvements in the Pre-Feasibility and Feasibility stages of development.”

Table 1 – NNLP PEA Key Financial Highlights2

| Description | Units | NNLP PEA |

| LCE Selling Price | $/tonne LCE | $24,000 |

| Life of Mine | years | 42 |

| Processing Rate P1 / P2 | ROM Mtpa | 2.58 Mtpa / 5.15 Mtpa |

| Average Throughput (LOM) | t/y | 4.88 Mtpa |

| LCE Produced (average LOM) | t/y | 86,300 |

| LCE Produced (total LOM) | tonnes | 3,626,000 |

| Operating Cost (OPEX) LOM | $/tonne LCE | $5,097 |

| Gross Revenue | $ B | $87.0 |

| Capital Cost (CAPEX) P1 | $ M | $2,973 |

| Capital Cost (CAPEX) P2 | $ M | $2,350 |

| Total Capital Cost (CAPEX) | $M | $5,323 |

| Sustaining Capital Costs (undiscounted) | $ M | $1,514 |

| Project Economics | ||

| Pre-Tax | ||

| Net Present Value (NPV) (8%) | $ M | $11,395 |

| Internal Rate of Return (IRR) | % | 25.5% |

| Initial Payback Period (undiscounted) | years | 4.3 |

| Average Annual Cash Flow (LOM) | $ M | $1,269 |

| Cumulative Cash Flow (undiscounted) | $ M | $60,911 |

| Post-Tax1 | ||

| Net Present Value (NPV)8%) | $ M | $9,214 |

| Internal Rate of Return (IRR) | % | 22.8% |

| Payback Period (undiscounted) | years | 4.7 |

| Average Annual Cash Flow (LOM) | $ M | $1,062 |

| Cumulative Cash Flow (undiscounted) | $ M | $50,973 |

Notes:

1. Tax calculation includes Federal Taxes, all Nevada State taxes and royalties and Elko County Property Tax estimates as well as available producer tax credits.

2. The tabulated calculations are based on inferred mineral resources.

Sensitivity Analysis

Table 2 presents the NNLP Project’s sensitivity to LCE selling price.

Table 2 – NNLP Sensitivity Analysis

| Sensitivity ($)/t LCE |

$15,000 | $18,000 | $21,000 | Base Case $24,000 |

$27,000 | $30,000 | $33,000 |

| Post-tax NPV8% (millions) | 2,792 | 4,983 | 7,099 | 9,214 | 11,314 | 13,354 | 15,394 |

| Post-tax IRR (%) | 13.0% | 16.6% | 19.8% | 22.8% | 25.7% | 28.2% | 30.6% |

Project Details

The Nevada North Lithium Project is in Elko County in northern Nevada, USA. The Project is approximately 73 kilometers (km) north-northeast of Wells, Nevada, 87 km west of the Utah Border and 35 km due south of the Idaho border. The Project is accessible via a paved highway and county-maintained gravel roads with good regional infrastructure including power and rail. Northern Nevada is a major hub for open pit mining operations and is recognized as one of the most concentrated areas in the world for skilled mining labor. Nevada is home to experienced regulators where Federal and State of Nevada agencies flow well-established protocols for hard rock mine permitting.

Drilling has identified a strongly mineralized zone of lithium bearing clays occupying a strike length of more than 4,300 meters and a known width of greater than 1500 meters. The Nevada North Lithium Project has a pit-constrained Inferred Resource containing an estimated 8.65 Mt of Lithium Carbonate Equivalent (LCE) grading 2,956 ppm Lithium at a 1,250 ppm cutoff.

Mine Life & Production

The NNLP is planned as a simple truck and shovel operation that targets the shallow, high-grade portions of the resource in the early mine life. A total of 205 Mt of mineralized material will be mined from the open pit at an average lithium grade of 4,016 ppm. A total of 238 Mt of waste material will be extracted, resulting in a low strip ratio of 1.16. The open pit operation will be executed in 14 pit phases over 42 years, including 3 months of pre-production, with an owner-operated mining fleet.

- Average LOM production of approximately 86,300 tonnes/year LCE for 42 years.

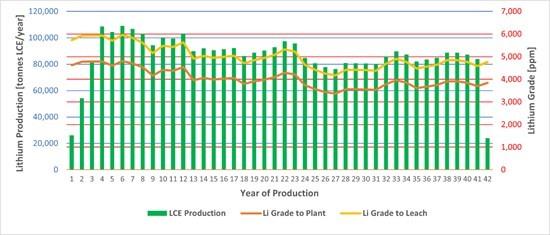

- Figure 1 shows the lithium production and lithium grades in the plant feed and the post-beneficiation leached lithium grade by Production Year.

- The process is based on sulfuric acid leaching and industry standard techniques with a flowsheet that produces a high-purity lithium carbonate that is subsequently upgraded to battery-grade in a refining step. On-site acid production from elemental sulfur minimizes traffic to site, eliminates the hazards of acid shipping, reduces the plant electricity demand, and ensures that best-in-class environmental practices are employed.

- Beneficiation is employed using Falcon ‘C’ Concentrators, which results in an average boost of 25% to the lithium grades prior to leaching (see press release dated October 29, 2025 available on the Company’s SEDAR Profile).

Figure 1 – NNLP Lithium Production and Lithium Grades over LOM

Table 3 – LOM NNLP Mining & Production Parameters

| Parameter | Unit | Value |

| Mine Production Life | Years | 42 |

| Material mined | LOM Mt | 443 |

| Average Grade Mined | ppm Li | 4,016 |

| Peak ROM head grade to beneficiation1 | ppm Li | 4,807 |

| Peak Head Grade to Leach1 | ppm Li | 5,964 |

| Recovered LCE | LOM Mt | 3.63 |

| Lithium Recovery | % | 82.8% |

| Waste | LOM Mt | 238.4 |

| Total Mineralize Material throughput | LOM Mt | 204.8 |

| Strip Ratio (LOM) | (tw:to) | 1.16 |

Notes:

1. A combination of shallowest and highest head grades is prioritized through the mine plan. This peak occurs in Year 6.

Operating Expense (OPEX) Estimate

The operating expenses are based on an operation achieving a LOM average annual production of approximately 86,300 tonnes/year of battery-grade LCE. The average operating cost estimated for the mine and processing facilities are as follows:

Table 4 – NNLP OPEX Estimate

| Area | $/tonne LCE | Percent of Total |

| Mine | $413 | 8.1% |

| Tailings | $287 | 5.6% |

| Lithium Processing1 | $4,260 | 83.6% |

| General & Administrative | $137 | 2.7% |

| Total | $5,097 | 100% |

Notes:

1. Tailings cost includes coarse gangue, clay tailings, and salt tailings

Capital Expense Estimate

The initial Phase 1 CAPEX is estimated to be US$2.95 Billion with a mine CAPEX of $23 million for a total of US$2.97 Billion. The Phase 2 CAPEX is estimated to be US$2.35 Billion. Sustaining Capex is estimated to total US$1.51 Billion over the LOM. The CAPEX is a Class 5 AACE estimate, and includes offsite infrastructure, owner’s cost and contingency.

The total Phase 1 construction period, including early works, commissioning and start-up is expected to be 3.5 years. Phase 2 is expected to be a 3-year construction and commissioning schedule.

Table 5 – NNLP CAPEX Estimates

| Area | Phase 1 Capex ($M) | Phase 2 Capex ($M) | Sustaining Capital ($M) | LoM ($M) |

| Mine | $23 | $142 | $165 | |

| Process Plant & Infrastructure | $2,950 | $2,350 | $1,371 | $6,671 |

| Total | $2,973 | $2,350 | $1,514 | $6,836 |

Qualified Persons

Daniel Roth, PE and Joshua Huss, PE, of M3 Engineering & Technology, Independent Qualified Persons as defined by National Instrument 43-101 Standards of Disclosure for Mineral Projects (“NI 43-101”) have prepared or supervised the preparation of, or have reviewed and approved, the scientific and technical data pertaining to the financial modelling and metallurgical information contained in this release.

John Marek, PE, of Independent Mining Consultants, Independent Qualified Person as defined by NI 43-101, has prepared or supervised the preparation of, or has reviewed and approved, the scientific and technical data pertaining to mining and mine scheduling contained in this release.

William van Breugel, PEng., of SGS Geological Services, Independent Qualified Person as defined by NI 43-101, has prepared or supervised the preparation of, or has reviewed and approved, the data pertaining to the lithium carbonate base case selling price.

All of the Qualified Persons above are independent of the Company as defined in, and required by, NI 43-101 and NI 43-101CP.

About M3 Engineering & Technology Corp.

M3 Engineering & Technology Corporation, a full-service Engineering, Procurement, Construction & Management firm, is recognized for its experience and capabilities in the development and construction of mining and mineral processing projects. In addition to base metals, precious metals, and semi-precious metals, M3 has increasingly applied its expertise to the industrial and critical minerals market. This has included conventional and novel processes of lithium extraction.

About Independent Mining Consultants

Independent Mining Consultants, Inc. has provided mine engineering services to the mineral industry for over 40 years. Mine planning, equipment selection, and mine cost estimation are part of the services provided by IMC.

About Surge Battery Metals Inc.

Surge Battery Metals, a Canadian-based mineral exploration company, is at the forefront of securing the supply of domestic lithium through its active engagement in the Nevada North Lithium Project. The project focuses on exploring clean, high-grade lithium energy metals in Nevada, USA, a crucial element for powering the electric vehicles of tomorrow. With a primary listing on the TSX Venture Exchange in Canada and the OTCQX Market in the US, Surge Battery Metals Inc. is strategically positioned as a key player in advancing lithium exploration, contributing significantly to the sustainable future of the electric vehicle industry.

MORE or "UNCATEGORIZED"

Eloro Resources Announces Closing of Bought Deal LIFE Private Placement for Gross Proceeds of C$17 Million

Eloro Resources Ltd. (TSX: ELO) (FSE: P2QM) is pleased to announce the closing of its previously an... READ MORE

Minera Alamos Updates Resources and Reserves for the Pan Gold Mine in Nevada

Minera Alamos Inc. (TSX-V: MAI) (OTCQX: MAIFF) is pleased to announce updated Mineral Resource and M... READ MORE

Ero Copper Reports Fourth Quarter and Full Year 2025 Operating and Financial Results

Ero Copper Corp. (TSX: ERO) (NYSE: ERO) is pleased to announce its operating and financial results f... READ MORE

Rare Element Resources Announces Results of Oversubscribed Rights Offering of Common Shares

Rare Element Resources Ltd. (OTCQB: REEMF) is pleased to report that its previously announced... READ MORE

TRX Gold Reports Record Q2 2026 Production and Company Update

TRX Gold Corporation (TSX: TRX) (NYSE American: TRX) is pleased to announce preliminary resu... READ MORE