The Prospector News

Spanish Mountain Gold Drills Extensive Mineralization Over 140.67 metres Grading 0.68 g/t Including 1.07 g/t Over 17.00 metres and 0.95 g/t Over 67.31 metres and Extends the Orca Fault Target Trend 130 m to Southeast Drilling 26.46 metres Grading 0.80 g/t Gold

You have opened a direct link to the current edition PDF

Open PDF CloseSpanish Mountain Gold Drills Extensive Mineralization Over 140.67 metres Grading 0.68 g/t Including 1.07 g/t Over 17.00 metres and 0.95 g/t Over 67.31 metres and Extends the Orca Fault Target Trend 130 m to Southeast Drilling 26.46 metres Grading 0.80 g/t Gold

Spanish Mountain Gold Ltd. (TSX-V: SPA) (FSE: S3Y) (OTCQB: SPAUF) is pleased to provide additional assay results from exploration drill holes 25-DH-1300, 25-DH-1302, and 25-DH-1304 that were completed as part of its 2025 Fall Diamond Drill program for the Spanish Mountain Gold project, which is located in the Cariboo Gold Corridor, British Columbia, Canada.

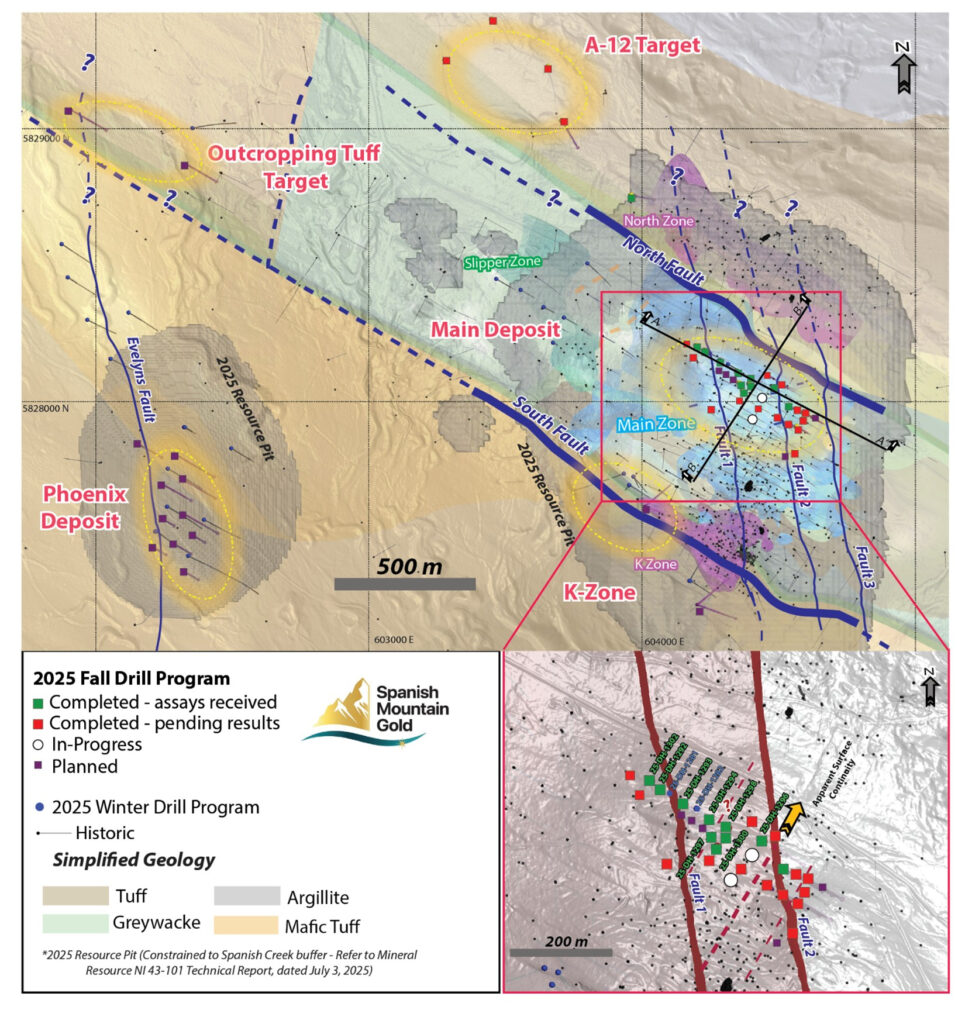

The company has completed approximately 7,800 m of drilling to date of the 9,000 to 10,000 metres of exploration drilling planned under the 2025 Fall Drill Program. Assays and geochemistry are pending receipt from the laboratory and or reporting from sixteen additional drill holes completed on the newly defined Orca Fault area, and from three completed drill holes on the A12 target.

Highlights:

- 25-DH-1300 intersected from 53.84 to 194.51 m, 140.67 m of 0.68 g/t gold including two high-grade intervals of 17.00 m of 1.07 g/t gold and 67.31 m of 0.95 g/t gold with a subset of 12.78 m of 2.85 g/t gold;

- 25-DH-1302 intersected two key intervals:

- from 49.64 to 152.20 m, 102.56 m of 0.55 g/t gold including 47.99 m of 0.81 g/t gold with a higher-grade subset of 12.63 m of 1.44 g/t gold;

- from 200.64 to 273.75 m, 73.11 m of 0.50 g/t gold including 33.15 m of 0.77 g/t gold with a higher-grade subset of 16.38 m of 1.23 g/t gold; and

- 25-DH-1304 intersected from 62.72 to 89.18 m, 26.46 m of 0.80 g/t gold including 8.03 m of 1.61 g/t gold with a higher-grade subset of 4.28 m of 2.26 g/t gold, noting that the remainder of the drill hole results are still pending receipt from the laboratory

Key Findings:

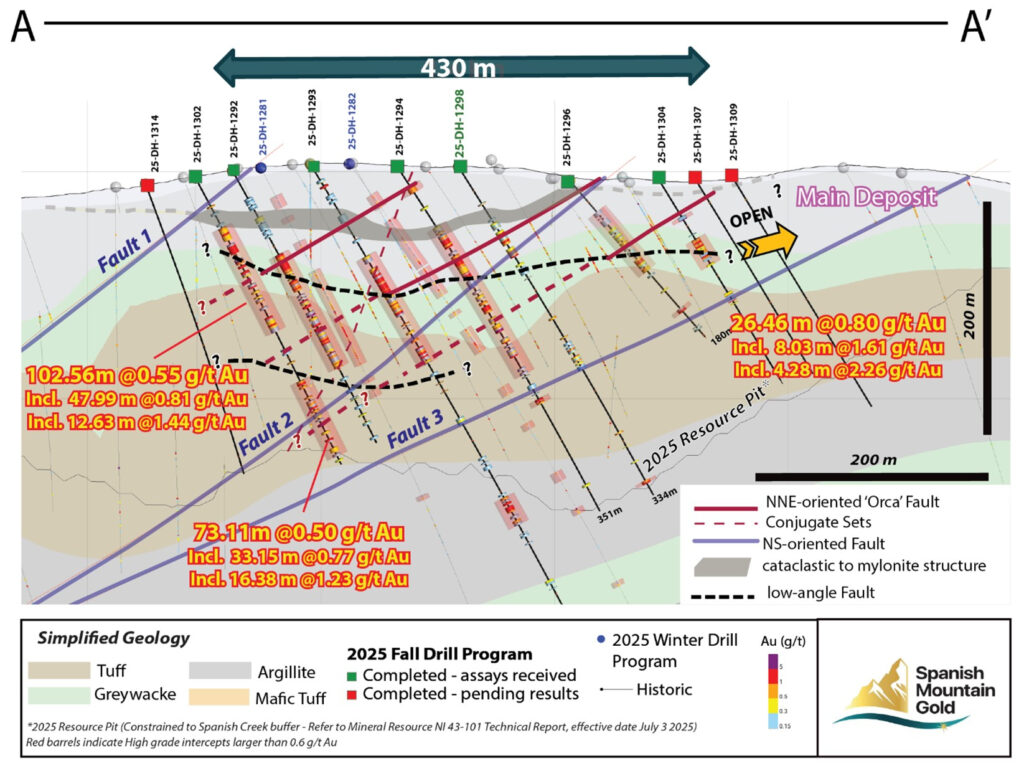

- Current exploration drilling assay results continues to intersect significant higher-grade mineralization over 430 m in strike length in the newly defined Orca Fault target (Figure 1 and 2) and the continuity can now be traced across multiple parallel, adjacent drill sections.

Peter Mah, Spanish Mountain Gold’s President & CEO commented, “These most recent Orca Fault area drill results continue to extend new higher grade gold mineralization in the heart of the Main Deposit. Gold assays received from three new holes reported intersecting large, near surface gold mineralization above the global average resource grade. Additionally, assays included multiple near surface high-grade intersections in each hole approaching and exceeding 1 g/t gold. The company is pleased with the consistency and growing number of above 1 g/t gold assays that further demonstrate the potential for growth through new high-grade gold mineralization within the Main Deposit. This coupled with ore sorting defines the Company’s twofold strategy to scale up gold production at its proposed mining operation in the Tier 1 Cariboo Gold Corridor, British Columbia, Canada.”

Main Deposit – Orca Fault area

Drill hole 25-DH-1300 (see Table 1) was designed to not only confirm the new Orca Fault target but also to start building stronger continuity northeast to southwest across section lines to increase the overall confidence in the geological interpretation of this important area (Figure 2). The drill hole intersected higher-grade mineralization approximately 36 m northeast of drill hole 25-DH-1299 (see December 1, 2025 news release) intersecting 140.67 m of 0.68 g/t gold including two high-grade intervals of 17.00 m of 1.07 g/t gold and 67.31 m of 0.95 g/t gold with a subset of 12.78 m of 2.85 g/t gold. It should be noted that this intercept aligns closely to the intersections in 25-DH-1299, which had a first interval near surface from 48.18 to 188.00 m of 0.82 g/t gold over 139.82 m and a second near the base of constraining open pit shell for the 2025 Mineral Resource Estimate (see July 3, 2025 news release) from 284.00 to 329.54 m, grading 1.67 g/t gold over 45.54 m, including 33.54 m of 2.19 g/t gold. The deeper intercept in 25-DH-1299 highlights the mineral potential at depth that will require additional drilling to further delineate, but investors should be cautioned it is not guaranteed that additional drilling will result in conversion of this area into the mineral resource estimate.

Drill hole 25-DH-1302 (Table 2) was designed to examine a critical area along the northwest trend of the new Orca Fault target at edge of the block model from the last mineral resource estimate (“MRE”) in the recent Preliminary Economic Assessment (see July 3, 2025 news release). The drill hole was collared 33 m northeast of 25-DH-1292 (Figure 3) and it intersected two key intervals of higher-grade mineralization (Figure 1), the first interval from 49.64 to 152.20 m, 102.56 m of 0.55 g/t gold including 47.99 m of 0.81 g/t gold with a higher-grade subset of 12.63 m of 1.44 g/t gold, and the second from 200.64 to 273.75 m, 73.11 m of 0.50 g/t gold including 33.15 m of 0.77 g/t gold with a higher-grade subset of 16.38 m of 1.23 g/t gold. These results compare very favorably with drill hole 25-DH-1292 (see November 3, 2025 news release) and extend gold mineralization to the northwest, highlighting the opportunity of systematically exploring these new structural trends both inside and outside of the MRE block model (Figure 1).

Drill hole 25-DH-1304 (Table 3), like 25-DH-1296 (see November 17, 2025 news release), it was designed to step into the structural domain between Fault 2 and Fault 3, looking to extend the high-grade gold mineralization to the southeast, where it is interpreted to be a southeasterly extension of the new Orca Fault target (Figure 1). This drill hole intersected 26.46 m of 0.80 g/t gold from 62.72 to 89.18 m, including 8.03 m of 1.61 g/t gold with a higher-grade subset of 4.28 m of 2.26 g/t gold (Figure 1) within the constraining open pit for the MRE (see July 3, 2025 news release). Although gold mineralization has been successfully hit historically in this area, it has not been through applying a systematic exploration approach using the preferred drilling orientation of 120-degrees that has proven successful in this work program.

The results from these three new exploration drill holes add significant confidence to the geological and structural interpretation of the new Orca Fault target area, when incorporating 25-DH-1281 and 25-DH-1282 (see April 21, 2025 news release), 25-DH-1292 and 25-DH-1293 (see November 3, 2025 news release), 25-DH-1294 and 25-DH-1296 (see November 17, 2025 news release), and 25-DH-1297, 25-DH-1298, and 25-DH-1299 (see December 1, 2025 news release). All these results continue to show that tighter exploration drill spacing at the preferred azimuth of 120-degrees is unlocking additional mineral potential in the Main deposit. These exploration drill holes are presented on a drill section (Figure 1 and Figure 2) that shows the alignment of the higher-grade mineralization to the new Orca Fault target.

Table 1: Assay Results for 25-DH-1300

| Drill hole | From (m) | To (m) | Width (m) | Gold (g/t) | Apparent True Thickness |

| 25-DH-1300 | 53.84 | 194.51 | 140.67 | 0.68 | Note 3) |

| including | 53.84 | 85.83 | 31.99 | 0.70 | Note 3) |

| including | 67.00 | 84.00 | 17.00 | 1.07 | Note 3) |

| including | 127.20 | 202.40 | 75.20 | 0.86 | Note 3) |

| including | 127.20 | 194.51 | 67.31 | 0.95 | Note 3) |

| including | 162.00 | 194.51 | 32.51 | 1.37 | Note 3) |

| including | 181.73 | 194.51 | 12.78 | 2.85 | Note 3) |

| 253.94 | 257.80 | 3.86 | 1.99 | Note 3) |

Table 2: Assay Results for 25-DH-1302

| Drill hole | From (m) | To (m) | Width (m) | Gold (g/t) | Apparent True Thickness |

| 25-DH-1302 | 49.64 | 152.20 | 102.56 | 0.55 | Note 3) |

| including | 49.64 | 97.63 | 47.99 | 0.81 | Note 3) |

| including | 67.45 | 94.72 | 27.27 | 1.15 | Note 3) |

| Including | 82.09 | 94.72 | 12.63 | 1.44 | Note 3) |

| 200.64 | 273.75 | 73.11 | 0.50 | Note 3) | |

| Including | 225.75 | 258.90 | 33.15 | 0.77 | Note 3) |

| including | 242.52 | 258.90 | 16.38 | 1.23 | Note 3) |

Table 3: Assay Results for 25-DH-1304

| Drill hole | From (m) | To (m) | Width (m) | Gold (g/t) | Apparent True Thickness |

| 25-DH-1304 | 39.50 | 42.70 | 3.20 | 1.34 | Note 3) |

| 42.00 | 42.70 | 0.70 | 5.44 | Note 3) | |

| 62.72 | 89.18 | 26.46 | 0.80 | Note 3) | |

| including | 62.72 | 81.89 | 19.17 | 0.97 | Note 3) |

| including | 62.72 | 70.75 | 8.03 | 1.61 | Note 3) |

| including | 62.72 | 67.00 | 4.28 | 2.26 | Note 3) |

| Notes for Table 1, 2, and 3: | ||

| 1) | Reported intersections are calculated using a 0.15 g/t Au cut-off grade. | |

| 2) | The complete assay table is available on the Company’s website | |

| 3) | True thickness of mineralization is unknown as the project is still at the exploration stage | |

The integration of assay results from 25-DH-1300, 25-DH-1302, and 25-DH-1304 with other recently released drill holes, strengthens the continuity for the new Orca Fault target and the association of higher-grade mineralization over a strike length of 430 m, northwest to southeast (see Figure 1 and Figure 2) now spanning two parallel, adjacent drill sections.

The current interpretation is that there is strong continuity between these section lines linking geology, structure and the higher-grade mineralization. The mineralization in these drill holes occurs in faults and quartz-dominated veins that appear to extend for more than 25 m beyond each drill hole. Two dominant sets of veins were identified, high-angle and low-angle. The lower-angle veins (~45 degrees) occur in proximity to the Orca Fault (see November 3, 2025 news releases).

Figure 3 illustrates the locations for three drill hole results outlined in this news release and the drill holes currently in the assay lab, or in process of being drilled. Drill collar location coordinates are summarized for the 2025 Fall Drill Program in Table 4 at the end of this news release.

Abbreviations: metres = m, grams per tonne = g/t, gold = Au, mineral resource estimate = MRE, Spanish Mountain Gold = SMG

Drill Core Processing, Data Verification and Quality Assurance – Quality Control Program

Once received from the drill and processed, all drill core samples were sawn in half, labeled, and bagged. The remaining half of the drill core was securely stored on-site. Numbered security tags were applied to sample shipments to ensure chain of custody compliance. The Company inserts quality control (QC) samples at regular intervals, including blanks and reference materials, for all sample shipments to monitor laboratory performance. Standards and blanks account for a minimum of 20% of the samples in addition to the laboratory’s internal quality assurance programs. The QAQC program was overseen by the Company’s Qualified Person, Julian Manco, P.Geo, Director of Exploration (as described below).

The data verification process involved a multi-step approach to ensure accuracy and integrity. This included a detailed quality control (QC) analysis of the data, which was performed using both internal and external platforms, such as the MxDeposit™ software. These QC checks involved the analysis of certified reference materials (CRMs), blanks, and duplicates to confirm the reliability of the assay results. In addition, a field inspection of the specific drill intervals mentioned in this release has been conducted to directly observe the geological features and verified the nature of the results presented.

Drill core samples were submitted to MSALABS’s analytical facility in Prince George, British Columbia, for sample preparation and PhotonAssay™ analysis. The MSALABS facilities are accredited to the International Standards ISO/IEC 17025 and ISO 9001 standard for gold and multi-element assays, with all analytical methods incorporating quality control materials at defined frequencies and established data acceptance criteria. MSALABS Inc. is independent of the Company.

PhotonAssay™

The PhotonAssay™ method utilizes gamma ray analysis for gold detection using the Chrysos PhotonAssay™ instrument (PA1408X). This non-destructive, fully automated technique offers high accuracy for analyzing ores and pulps. Sample preparation begins with drying and crushing up to 1 kg of material to achieve at least 70% passing through a 2-millimetre (mm) sieve. The sample is then riffle split to obtain a suitable aliquot for 2 testing cycles (MSALABS Method CPA-Au1).

The PhotonAssay™ instrument bombards 400- to 600-gram samples contained in sealed containers with gamma rays. These containers remain sealed throughout the process, preserving the sample for potential further testing. The analysis is performed robotically, with results that integrate into existing laboratory management systems. Each sample is accompanied by a reference disc traceable to a Certified Reference Material (CRM). Both the sample and reference disc undergo gamma ray exposure, with signals detected and analyzed to ensure accurate and reliable results. The method offers a gold detection range from 0.015 parts per million (ppm – lower limit) to 10,000 ppm (upper limit). Quality control includes the use of reference materials and blanks, with all results reviewed by a competent person before reporting.

Spanish Mountain Gold implemented two QAQC methodologies to validate the accuracy of PhotonAssay™ results, both demonstrating good comparability: 1) comparative analysis of diverse mineralization styles using Total Au screen metallic methods with both FAS-415 (gravimetric finish) and FAS-211 (AAS finish), and 2) comprehensive testing of both sample aliquots and rejects using FAS-211 (AAS finish). QAQC Testing typically can include the following spot checks: 1) Pulverizing tests to evaluate variability in sample preparation, 2) Cross-analysis at external laboratories using screen metallic method, and 3) Four-cycle radiation testing to identify and calibrate potential variability in gold results with variable radiation intensity.

Multi-Elemental Analysis

For the 2025 drilling campaign Spanish Mountain Gold used IMS-230 method to provide multi-element determination using a four-acid digestion followed by ICP-OES and ICP-MS analysis.

Key Process Steps:

Sample Preparation: Samples are dried and ground to a specific criterion (85% passing 75 microns (μm) for rocks and drill core; 180μm for soils and sediments). A homogeneous 10-gram sample is required. Digestion: Samples undergo sequential digestion with nitric, perchloric, hydrofluoric, and hydrochloric acids, followed by dilution with deionized water.

Analysis: The solution is analyzed via ICP-OES and ICP-MS for multi-element quantification. Quality Control: The process includes reference materials, blanks, and duplicates, with corrections for spectral interferences and thorough review before final reporting.

Qualified Person

Julian Manco, M.Sc., P.Geo., Director of Exploration with Spanish Mountain Gold, is the Qualified Person as defined under National Instrument 43-101 who has reviewed the technical information in this news release and has approved the content for dissemination.

About Spanish Mountain Gold Ltd.

Spanish Mountain Gold Ltd. is focused on advancing its 100%-owned Spanish Mountain Gold Project (Project) towards construction of the next gold mine in the Cariboo Gold Corridor, British Columbia. On August 18, 2025, the Company filed an NI 43-101 Technical Report on SEDAR+ that sets out the Project’s de-risked and optimized Preliminary Economic Assessment (PEA), with an updated Mineral Resource Estimate (MRE). We will continue to advance the Project to position the Company to make a construction decision in 2027. We are striving to be a leader in community and Indigenous relations by leveraging technology and innovation to build the ‘greenest’ gold mine in Canada. The Relentless Pursuit for Better Gold means seeking new ways to achieve optimal financial outcomes that are safer, minimize environmental impact and create meaningful sustainability for communities.

Table 4: Drill Collar Information for Drill Holes

| Hole ID | EAST | NORTH | ELEV | AZIMUTH | DIP | DEPTH | COMMENT |

| 25-DH-1325 | 604385 | 5827966 | 1103 | 120 | -60 | N/A | In Progress |

| 25-DH-1324 | 604343 | 5828053 | 1080 | 120 | -60 | N/A | In Progress |

| 25-DH-1323 | 604286 | 5828046 | 1097 | 120 | -60 | 338 | Successfully completed per design |

| 25-DH-1322 | 604279 | 5827995 | 1106 | 120 | -60 | 231 | Successfully completed per design |

| 25-DH-1321 | 604350 | 5828016 | 1099 | 120 | -60 | 348 | Successfully completed per design |

| 25-DH-1320 | 604561 | 5827809 | 1126 | 120 | -60 | 57 | Ended early due to major fault zone |

| 25-DH-1319 | 604404 | 5827992 | 1095 | 120 | -70 | 198 | Successfully completed per design |

| 25-DH-1318 | 604445 | 5828098 | 1055 | 120 | -60 | 243 | Successfully completed per design |

| 25-DH-1317 | 604186 | 5828166 | 1076 | 120 | -60 | 282 | Successfully completed per design |

| 25-DH-1316 | 604514 | 5828073 | 1050 | 120 | -60 | 177 | Successfully completed per design |

| 25-DH-1315 | 604231 | 5828163 | 1075 | 120 | -60 | 282 | Successfully completed per design |

| 25-DH-1314 | 604160 | 5828218 | 1056 | 120 | -70 | 270 | Successfully completed per design |

| 25-DH-1313 | 604566 | 5827908 | 1100 | 120 | -60 | 204 | Successfully completed per design |

| 25-DH-1312 | 604538 | 5827921 | 1095 | 120 | -60 | 205 | Successfully completed per design |

| 25-DH-1311 | 604590 | 5827935 | 1084 | 120 | -60 | 330 | Successfully completed per design |

| 25-DH-1310 | 604592 | 5827961 | 1091 | 120 | -60 | 211 | Successfully completed per design |

| 25-DH-1309 | 604592 | 5827958 | 1071 | 120 | -60 | 237 | Successfully completed per design |

| 25-DH-1308 | 603280 | 5829250 | 966 | 120 | -60 | 150 | Successfully completed per design |

| 25-DH-1307 | 604565 | 5827974 | 1068 | 120 | -60 | 200 | Successfully completed per design |

| 25-DH-1306 | 603451 | 5829400 | 927 | 120 | -60 | 123 | Successfully completed per design |

| 25-DH-1305 | 603657 | 5829226 | 919 | 120 | -60 | 126 | Successfully completed per design |

| 25-DH-1304 | 604536 | 5827986 | 1067 | 120 | -60 | 225 | Successfully completed per design |

| 25-DH-1303 | 603960 | 5828754 | 943 | 100 | -55 | 156 | Successfully completed per design |

| 25-DH-1302 | 604194 | 5828180 | 1066 | 120 | -63 | 282 | Successfully completed per design |

| 25-DH-1301 | 603708 | 5829029 | 929 | 150 | -55 | 188 | Successfully completed per design |

| 25-DH-1300 | 604388 | 5828063 | 1085 | 120 | -60 | 274 | Successfully completed per design |

| 25-DH-1299 | 604369 | 5828043 | 1093 | 120 | -60 | 336 | Successfully completed per design |

| 25-DH-1298 | 604402 | 5828088 | 1074 | 120 | -59 | 334 | Successfully completed per design |

| 25-DH-1297 | 604354 | 5828069 | 1084 | 120 | -59 | 342 | Successfully completed per design |

| 25-DH-1296 | 604484 | 5828054 | 1061 | 120 | -50 | 180 | Successfully completed per design |

| 25-DH-1295 | 604484 | 5828054 | 1061 | 120 | -60 | 33 | Ended early due to drill trace spacing |

| 25-DH-1294 | 604345 | 5828120 | 1075 | 120 | -58 | 351 | Successfully completed per design |

| 25-DH-1293 | 604284 | 5828149 | 1076 | 120 | -60 | 453 | Successfully completed per design |

| 25-DH-1292 | 604223 | 5828189 | 1068 | 120 | -62 | 270 | Successfully completed per design |

Figure 1: Drill Long Section Through Orca Fault Area (looking northeast); section line A-A’ (see Figure 3)

Figure 2: Drill Cross Section Through Orca Fault Area (looking northwest); section line B-B’ (see Figure 3)

Figure 3: Drill Collar Location Map for 2025 Fall Drill Program

MORE or "UNCATEGORIZED"

First Phosphate Receives Conditional Approval for up to $16.7 Million Non-Repayable Contribution from the Government of Canada

First Phosphate Corp. (CSE: PHOS) (OTCQX: FRSPF) (OTCQX ADR: FPHOY) (FSE: KD0) has been cond... READ MORE

Gold X2 Drills 117m of 1.21 g/t Au, Including 10m of 4.37g/t Au; High-Grade Zone Intersected 280m Beneath the Resource Pit Demonstrating Underground Potential at the Moss Gold Deposit

Gold X2 Mining Inc. (TSX-V: AUXX) (OTCQB: GSHRF) (FWB: DF8), is pleased to announce initial drilling... READ MORE

Tectonic Raises Over C$92 Million; Completes Upsized Private Placement With Full Over-Allotment Exercised

Tectonic Metals Inc. (TSX-V: TECT) is pleased to announce the successful closing of the Company’s ... READ MORE

Cerro de Pasco Resources Enters Project Development Funding Agreement with U.S. International Development Finance Corporation for Quiulacocha

Cerro de Pasco Resources Inc. (TSX-V: CDPR) (OTCQB: GPPRF) (BVL: CDPR) announces that it has ... READ MORE

NorthWest Announces Updated Mineral Resource at Kwanika Reflecting Strategic Shift to Higher-Grade Copper-Gold Focus

NorthWest Copper Corp. (TSX-V: NWST) is pleased to announce an updated mineral resource estimate for... READ MORE