SILVERCORP REPORTS HIGH-GRADE GOLD-SILVER-LEAD-ZINC DRILL RESULTS FROM THE HPG MINE

Silvercorp Metals Inc. (TSX: SVM) (NYSE American: SVM) is pleased to report high-grade gold-silver-lead-zinc intercepts from its ongoing diamond drilling program at the HPG mine in the Ying Mining District, China.

Highlights (all intersections are in core lengths):

- Surface hole ZK1645 intersected an 8.24 metre interval of vein H4 grading 4.31 grams per tonne gold, 15 g/t silver, and 2.10% lead from 56.28 m depth, at an elevation of 819 m;

- Underground hole ZK02N36 intersected a 0.61 m interval of vein H5E grading 3.86 g/t Au, 6,132 g/t Ag, 6.45% Pb, 8.47% zinc and 0.33% copper from 72.36 m depth, at an elevation of 331 m;

- Surface hole ZK3421 intersected a 0.63 m interval of vein H17_1 grading 23.80 g/t Au and 14 g/t Ag, from 71.95 m depth, at an elevation of 761 m;

- Underground hole ZKH12N21 intersected a 4.60 m interval of vein H17 grading 1.23 g/t Au, 193 g/t Ag, 7.56% Pb, 3.79% Zn, and 0.38% Cu from 68.67 m depth, at an elevation of 329 m;

- Underground hole ZK21N11 intersected a 2.05 m interval of vein H16_3 grading 3.75 g/t Au, 128 g/t Ag, 2.26% Pb, and 1.05% Zn, from 148.72 m depth, at an elevation of 381 m;

- Underground hole ZKH21N20 intersected a 2.69 m interval of vein H16_3 grading 2.72 g/t Au, 269 g/t Ag, 1.02% Pb, 0.69% Zn, and 0.80% Cu from 147.79 m depth, at an elevation of 338 m;

- Underground hole ZKH27N03 intersected a 1.70 m interval of vein H14a grading 10.49 g/t Au, 18 g/t Ag, 1.02% Pb, and 0.75% Zn, from 181.11 m depth, at an elevation of 440 m;

- Underground hole ZKH21N22 intersected a 0.95 m interval of vein H16_3 grading 6.62 g/t Au, 507 g/t Ag, 1.77% Pb, 1.35% Zn, and 0.97% Cu from 151.45 m depth, at an elevation of 350 m;

- Underground hole ZK19N15 intersected a 0.45 m interval of vein H10_1 grading 25.80 g/t Au and 216 g/t Ag, from 148.64 m depth, at an elevation of 599 m;

- Underground hole ZK04N14 intersected a 1.01 m interval of vein H13 grading 0.62 g/t Au, 930 g/t Ag, 25.93% Pb, 0.30% Zn, and 1.24% Cu from 63.67 m depth, at an elevation of 683 m;

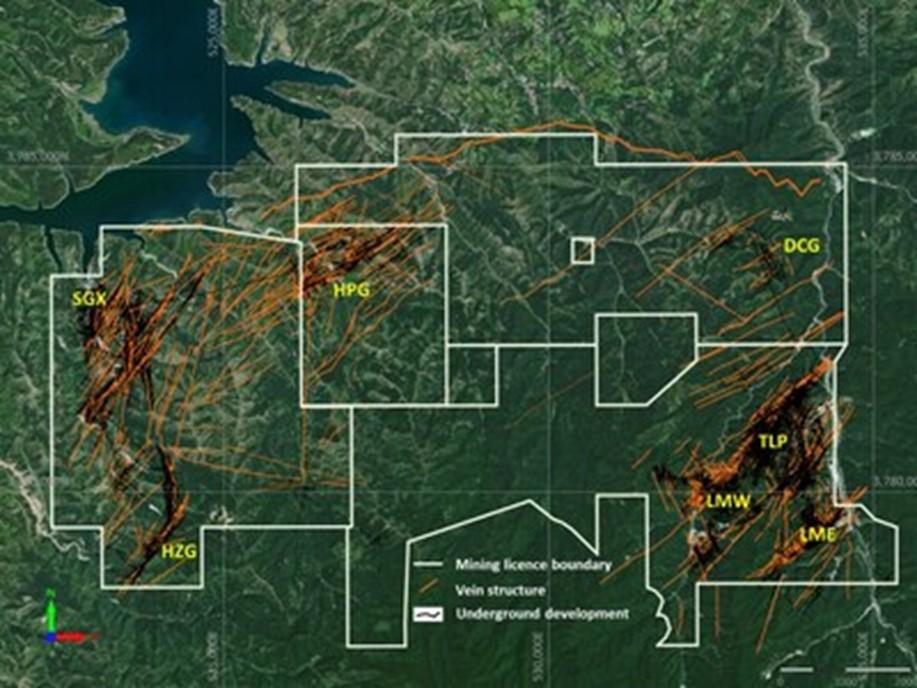

Figure 1: Location of the HPG mine within the Ying mining district.

From January 1, 2022 to November 15, 2023, a total of 45,046 m in 297 diamond drill holes, including 215 underground holes and 82 surface holes, were completed at the HPG mine. Assay results for 270 holes have been received, with 139 holes intercepting mineralization. Currently, there are 8 rigs drilling at the HPG mine.

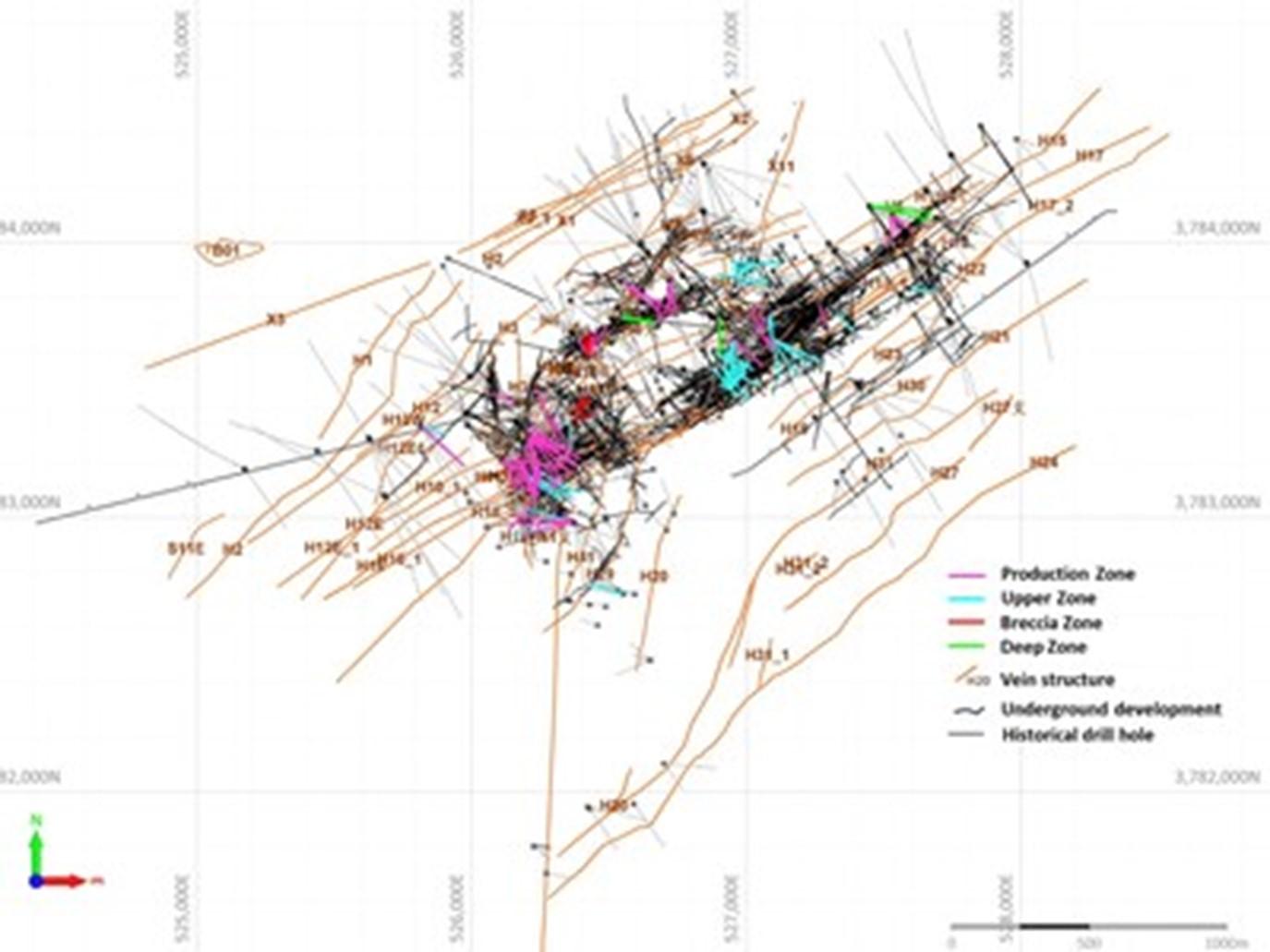

The drilling program at the HPG mine has been focused on three main areas (Figure 2): 1) near surface gold-silver-lead-zinc (Au-Ag-Pb-Zn) vein structures within the resource area which have seen limited exploration drilling and tunneling (upper zone – U); 2) infill drilling above or below previously-mined stopes where production stopped due to higher than expected variability in grades, vein thicknesses, and attitudes of the vein structures (production zone – P); and 3) testing the Au-Ag-Pb-Zn mineralization potential and extent within a rhyolitic breccia dyke that is situated within the current underground mining infrastructure (breccia zone – B).

Figure 2: Location of drill holes and target areas at HPG mine applicable to the reporting period.

Drilling Near Surface Au-Ag-Pb-Zn Vein Structures within the Resource Area – Upper Zone (U)

Previous drilling was primarily focused on testing the strike and downdip extent of known vein structures with a limited focus being placed on the up-dip potential at shallower elevations above 600 m above mean sea level (“amsl”). Extensive drilling from surface and underground drill carbines yielded intercepts of high-grade Au-Ag-Pb-Zn vein structures at higher elevations, which include the H13 series, H15 series, H16 series, H17 series, H32 series, H42 series, H5, H13, H14, H18, and H29 (Table 1).

Drilling Above or Beneath Previously-Mined Stopes within the Resource Area – Production Zone (P)

The majority of the drilling campaign targeted areas of known Au-Ag-Pb-Zn vein structures that were previously underexplored due to higher than expected variation in the thickness and trend of the high grade ore shoots of the veins within the resource areas below the 600 m amsl elevation. The high-grade intercepts are mainly associated with the northwest-dipping H5 series, H 15 series, H16 series, H17 series, H11, H13, and H14, and the east-dipping H20 series, H41 series, H32 series, H29, H40 and H42 veins. These intercepts have led to significant expansion and upgrading of high-grade resources (Table 2).

Testing Au-Ag-Pb-Zn mineralization within the Rhyolitic Breccia Dyke – Breccia Zone (B)

Drilling has been ongoing to test the mineralization within a northwest trending rhyolitic breccia dyke (breccia zone B8) (Table 3) hosting disseminated Au-Ag-Pb-Zn-Cu mineralization across a currently defined zone measuring 50 m long, 30 m high, and 20m wide. The newly discovered B8 orebody has been mined since October 2023 by means of long-hole stoping.

In addition to the drilling outlined above, which focused on drilling vein structures within the current mining infrastructure, some drillholes were aimed at testing the down-dip extension of major vein structures including H15, H16, and H17 below 300 m amsl elevation within the Deep Zone (zone D). Initial drilling confirmed notable mineralization and down dip extension of mineralization along the targeted vein structures (Table 4).

Table 1: Selected intercepts from the drilling programs at the U zone of the HPG mine

| Hole ID | From (m) |

To (m) |

Elevation (m) |

interval (m) |

Au (g/t) |

Ag (g/t) |

Pb (%) |

Zn (%) |

Cu (%) |

Vein |

| ZK02N05 | 53.62 | 54.45 | 661 | 0.83 | 0.19 | 227 | 21.15 | 0.14 | 0.19 | H32 |

| ZK04N10 | 56.67 | 57.10 | 687 | 0.43 | 0.05 | 114 | 9.94 | 0.08 | 0.19 | H32 |

| ZK04N14 | 63.67 | 64.68 | 683 | 1.01 | 0.62 | 930 | 25.93 | 0.30 | 1.24 | H13 |

| ZK04N15 | 58.89 | 59.52 | 666 | 0.63 | 0.21 | 88 | 7.09 | 0.12 | 0.13 | H32 |

| ZK04W02 | 59.54 | 60.08 | 729 | 0.54 | 0.94 | 178 | 15.28 | 0.02 | 0.03 | H15 |

| ZK06N13 | 67.49 | 69.55 | 682 | 2.06 | 0.31 | 184 | 10.59 | 0.09 | 0.25 | H13 |

| ZK06S03 | 124.59 | 125.82 | 717 | 1.23 | 0.20 | 57 | 8.92 | 0.05 | 0.06 | H13 |

| ZK06S04 | 128.02 | 129.58 | 724 | 1.56 | 0.10 | 69 | 1.84 | 0.57 | 0.03 | H15_2 |

| ZK08N13 | 84.64 | 86.04 | 680 | 1.40 | 0.37 | 441 | 11.75 | 0.42 | 0.25 | H13 |

| ZK08N14 | 101.76 | 102.11 | 678 | 0.35 | 0.72 | 261 | 0.93 | 0.49 | 0.20 | H13 |

| ZK08S01 | 90.55 | 91.36 | 760 | 0.81 | 0.37 | 72 | 17.30 | 0.08 | 0.11 | H13 |

| ZK08S05 | 87.75 | 89.40 | 774 | 1.65 | 0.15 | 17 | 4.01 | 0.03 | 0.01 | H15_2 |

| ZK11004 | 105.13 | 105.60 | 605 | 0.47 | 0.04 | 592 | 0.94 | 0.37 | 0.01 | H41W_1 |

| ZK11205 | 103.81 | 105.45 | 614 | 1.64 | 3.31 | 1 | 0.01 | 0.01 | 0.01 | H42a |

| ZK14N23 | 80.61 | 81.11 | 705 | 0.50 | 0.97 | 110 | 13.55 | 0.53 | 0.80 | H15W |

| ZK14N25 | 89.92 | 90.75 | 676 | 0.83 | 0.81 | 41 | 4.37 | 0.02 | 0.04 | H15W |

| ZK14S22 | 36.91 | 37.94 | 731 | 1.03 | 0.07 | 42 | 3.40 | 0.11 | 0.01 | H15 |

| ZK1644 | 190.15 | 190.73 | 689 | 0.58 | 4.71 | 152 | 15.71 | 1.73 | 0.54 | H32a |

| ZK1645 | 56.28 | 64.52 | 819 | 8.24 | 4.31 | 15 | 2.10 | 0.01 | 0.02 | H4 |

| ZK1645 | 210.11 | 210.59 | 671 | 0.48 | 0.61 | 27 | 9.36 | 0.04 | 0.01 | H32a |

| ZK1646 | 66.45 | 67.61 | 809 | 1.16 | 2.48 | 13 | 2.48 | 0.02 | 0.01 | H4 |

| ZK1646 | 204.79 | 206.45 | 675 | 1.66 | 0.05 | 23 | 5.14 | 3.02 | 0.05 | H4a |

| ZK1646 | 218.66 | 219.85 | 662 | 1.19 | 0.39 | 32 | 4.71 | 0.12 | 0.06 | H32a |

| ZK1647 | 222.14 | 224.11 | 663 | 1.97 | 1.72 | 103 | 3.72 | 0.67 | 0.55 | H32a |

| ZK17N05 | 100.28 | 100.75 | 625 | 0.47 | 0.16 | 78 | 4.91 | 0.28 | 0.01 | H9 |

| ZK21N41 | 47.21 | 47.76 | 600 | 0.55 | 1.74 | 76 | 5.97 | 1.73 | 0.01 | H39_2 |

| ZK2346 | 113.21 | 114.22 | 716 | 1.01 | 2.59 | 8 | 0.20 | 0.53 | 0.01 | H42 |

| ZK2346 | 123.36 | 123.91 | 710 | 0.55 | 5.21 | 8 | 1.70 | 1.49 | 0.03 | H15 |

| ZK2347 | 106.66 | 107.46 | 740 | 0.80 | 1.48 | 19 | 1.61 | 0.48 | 0.02 | H16_3 |

| ZK2348 | 56.19 | 56.85 | 776 | 0.66 | 2.13 | 8 | 0.41 | 0.97 | 0.02 | H14 |

| ZK2348 | 64.67 | 66.39 | 771 | 1.72 | 3.16 | 4 | 0.12 | 0.43 | 0.01 | H14a |

| ZK2348 | 132.58 | 133.26 | 733 | 0.68 | 2.00 | 4 | 0.19 | 0.20 | 0.01 | H15 |

| ZK23S03 | 107.58 | 108.43 | 790 | 0.85 | 0.68 | 132 | 0.78 | 0.60 | 0.07 | H16 |

| ZK2412 | 172.03 | 173.06 | 720 | 1.03 | 1.98 | 6 | 0.01 | 0.02 | 0.01 | H17 |

| ZK24S01 | 199.44 | 200.03 | 721 | 0.59 | 0.34 | 95 | 14.67 | 0.88 | 0.01 | H32a |

| ZK29S02 | 211.70 | 212.20 | 684 | 0.50 | 0.16 | 89 | 17.02 | 4.86 | 0.04 | H29 |

| ZK3421 | 71.95 | 72.58 | 761 | 0.63 | 23.80 | 14 | 0.03 | 0.03 | 0.01 | H17_1 |

| ZK3638 | 37.58 | 37.96 | 804 | 0.38 | 1.10 | 197 | 0.19 | 0.08 | 0.03 | H17_1 |

| ZKH00N42 | 48.80 | 50.96 | 635 | 2.16 | 0.68 | 140 | 1.08 | 0.14 | 0.05 | H5 |

| ZKH04S01 | 50.64 | 51.27 | 656 | 0.63 | 0.15 | 659 | 0.31 | 2.29 | 0.14 | H17 |

| ZKH06N01 | 64.39 | 64.71 | 618 | 0.32 | 0.16 | 309 | 0.60 | 0.10 | 0.49 | H32E1 |

| ZKH06N02 | 50.40 | 51.01 | 615 | 0.61 | 5.10 | 28 | 0.48 | 0.12 | 0.01 | H32E1 |

| ZKH06S01 | 99.64 | 101.43 | 606 | 1.79 | 1.03 | 76 | 2.14 | 0.09 | 0.69 | H15 |

| ZKH06S01 | 102.56 | 109.99 | 605 | 7.43 | 0.61 | 89 | 7.08 | 0.19 | 0.36 | H17 |

| ZKH06S09 | 17.36 | 18.28 | 633 | 0.92 | 0.16 | 115 | 0.53 | 1.91 | 0.03 | H13 |

| ZKH12S52 | 45.57 | 47.28 | 718 | 1.71 | 0.11 | 33 | 3.33 | 0.04 | 0.08 | H15 |

| ZKH12S52 | 163.31 | 164.40 | 670 | 1.09 | 0.29 | 133 | 2.02 | 1.40 | 0.06 | H18 |

| ZKH130C01 | 92.85 | 93.96 | 712 | 1.11 | 4.04 | 3 | 0.02 | 0.01 | 0.01 | H15 |

| ZKH14S31 | 38.31 | 39.37 | 730 | 1.06 | 0.05 | 45 | 3.75 | 0.04 | 0.05 | H15 |

| ZKH14S31 | 153.43 | 154.53 | 712 | 1.10 | 2.56 | 41 | 1.32 | 0.82 | 0.02 | H18 |

| ZKH16S51 | 85.99 | 87.16 | 676 | 1.17 | 0.16 | 177 | 0.34 | 0.01 | 0.86 | H15E |

| ZKH16S51 | 168.41 | 169.33 | 619 | 0.92 | 0.45 | 128 | 3.23 | 1.25 | 0.04 | H18 |

| ZKH16S52 | 35.85 | 40.22 | 733 | 4.37 | 0.08 | 28 | 4.13 | 0.03 | 0.03 | H15 |

| ZKH16S52 | 171.30 | 172.25 | 719 | 0.95 | 0.12 | 211 | 1.21 | 0.63 | 0.06 | H18 |

| ZKH18N01 | 147.22 | 147.86 | 756 | 0.64 | 0.04 | 10 | 4.44 | 0.99 | 0.01 | H6 |

| ZKH24S05 | 157.87 | 159.05 | 741 | 1.18 | 0.17 | 22 | 5.65 | 0.81 | 0.03 | H32a |

| ZKH33N10 | 28.61 | 29.06 | 627 | 0.45 | 5.42 | 4 | 0.08 | 0.16 | 0.01 | H12E1 |

Table 2: Selected intercepts from the drilling programs at the P zone of the HPG mine

| Hole ID | From (m) |

To (m) |

Elevation (m) |

interval (m) |

Au (g/t) |

Ag (g/t) |

Pb (%) |

Zn (%) |

Cu (%) |

Vein |

| ZK02N36 | 72.36 | 72.97 | 331 | 0.61 | 3.86 | 6,132 | 6.45 | 8.47 | 0.33 | H5E |

| ZK04N06 | 124.59 | 125.01 | 515 | 0.42 | 0.04 | 27 | 8.36 | 0.65 | 0.03 | H5 |

| ZK04N07 | 165.80 | 166.26 | 467 | 0.46 | 0.47 | 416 | 40.18 | 0.35 | 0.13 | H5E |

| ZK04N08 | 95.05 | 95.63 | 582 | 0.58 | 0.89 | 91 | 1.01 | 0.09 | 0.10 | H5a |

| ZK04N09 | 100.28 | 101.00 | 581 | 0.72 | 0.07 | 284 | 0.09 | 0.02 | 0.03 | H5a |

| ZK04N09 | 102.91 | 104.23 | 580 | 1.32 | 0.61 | 66 | 13.01 | 0.12 | 0.18 | H5 |

| ZK04N19 | 15.15 | 15.48 | 375 | 0.33 | 5.52 | 23 | 0.42 | 0.98 | 0.01 | H5E |

| ZK05N11 | 118.87 | 119.53 | 371 | 0.66 | 2.86 | 15 | 0.05 | 0.03 | 0.01 | H5 |

| ZK07N21 | 101.34 | 103.31 | 332 | 1.97 | 0.26 | 123 | 3.50 | 3.42 | 0.08 | H5 |

| ZK07N22 | 56.03 | 57.57 | 346 | 1.54 | 2.00 | 14 | 0.03 | 0.01 | 0.01 | H5E |

| ZK09N23 | 82.17 | 82.52 | 332 | 0.35 | 21.00 | 120 | 2.85 | 15.03 | 0.09 | H5 |

| ZK09N31 | 2.81 | 3.54 | 462 | 0.73 | 0.21 | 106 | 0.10 | 0.03 | 1.07 | H5E |

| ZK09N31 | 80.42 | 81.30 | 415 | 0.88 | 0.34 | 300 | 1.24 | 0.92 | 0.06 | H5 |

| ZK11007 | 240.47 | 241.68 | 497 | 1.21 | 2.39 | 2 | 0.08 | 0.07 | 0.01 | H12_1 |

| ZK11008 | 225.13 | 225.59 | 518 | 0.46 | 7.44 | 17 | 0.39 | 0.50 | 0.04 | H12_1 |

| ZK11204 | 205.86 | 206.86 | 555 | 1.00 | 2.92 | 5 | 0.14 | 0.04 | 0.01 | H20W |

| ZK11209 | 202.55 | 203.11 | 527 | 0.56 | 2.71 | 8 | 0.76 | 0.75 | 0.03 | H20W1 |

| ZK11211 | 82.05 | 82.40 | 591 | 0.35 | 4.42 | 26 | 1.79 | 0.05 | 0.01 | H41W |

| ZK11614 | 44.23 | 44.80 | 446 | 0.57 | 11.90 | 45 | 3.39 | 0.49 | 0.19 | H20W1 |

| ZK11614 | 46.12 | 46.95 | 445 | 0.83 | 3.26 | 84 | 0.94 | 0.49 | 0.10 | H20W |

| ZK14N18 | 13.94 | 14.58 | 380 | 0.64 | 1.55 | 58 | 2.54 | 9.79 | 0.21 | H32E1 |

| ZK14N19 | 28.10 | 28.52 | 377 | 0.42 | 7.00 | 10 | 0.31 | 0.25 | 0.01 | H32E1 |

| ZK19N15 | 148.64 | 149.09 | 599 | 0.45 | 25.80 | 216 | 0.04 | 0.01 | 0.01 | H10_1 |

| ZK19N20 | 8.53 | 9.40 | 462 | 0.87 | 0.97 | 108 | 16.84 | 0.33 | 0.26 | H11 |

| ZK19N20 | 208.43 | 208.94 | 369 | 0.51 | 3.25 | 5 | 0.40 | 0.14 | 0.01 | H42 |

| ZK21N11 | 148.72 | 150.77 | 381 | 2.05 | 3.75 | 128 | 2.26 | 1.05 | 0.20 | H16_3 |

| ZK21N37 | 131.58 | 132.30 | 435 | 0.72 | 7.51 | 15 | 0.10 | 0.18 | 0.01 | H16_1 |

| ZK21N39 | 126.31 | 128.05 | 432 | 1.74 | 2.10 | 56 | 2.71 | 1.25 | 0.08 | H16_1 |

| ZK21N41 | 114.86 | 117.14 | 559 | 2.28 | 0.25 | 49 | 5.17 | 0.06 | 0.01 | H12_1 |

| ZK21N42 | 55.06 | 55.50 | 589 | 0.44 | 1.01 | 164 | 2.23 | 0.85 | 0.01 | H39_2 |

| ZK21N42 | 131.24 | 131.92 | 533 | 0.68 | 1.35 | 94 | 0.65 | 0.26 | 0.01 | H12_1 |

| ZK22N01 | 99.79 | 100.94 | 588 | 1.15 | 4.59 | 23 | 0.94 | 0.07 | 0.11 | H15 |

| ZK23N05 | 141.55 | 142.62 | 381 | 1.07 | 1.63 | 16 | 1.13 | 0.62 | 0.01 | H16_1 |

| ZK23N32 | 54.49 | 54.93 | 429 | 0.44 | 3.36 | 43 | 0.15 | 0.10 | 0.35 | H17_1W |

| ZK23N34 | 5.54 | 6.15 | 466 | 0.61 | 1.75 | 27 | 0.31 | 0.82 | 0.06 | H11 |

| ZK23N34 | 121.72 | 122.34 | 439 | 0.62 | 2.43 | 11 | 0.48 | 0.23 | 0.04 | H16_1 |

| ZK23N35 | 5.59 | 6.59 | 465 | 1.00 | 1.43 | 28 | 1.88 | 0.24 | 0.09 | H11 |

| ZK23N35 | 181.11 | 181.60 | 405 | 0.49 | 0.09 | 52 | 10.80 | 0.04 | 0.13 | H17_1 |

| ZK25N04 | 55.72 | 56.13 | 435 | 0.41 | 4.48 | 77 | 0.34 | 0.56 | 0.01 | H13 |

| ZK25N05 | 83.43 | 84.69 | 515 | 1.26 | 1.73 | 9 | 0.35 | 0.33 | 0.03 | H16_1 |

| ZK25N08 | 94.53 | 95.59 | 417 | 1.06 | 2.05 | 3 | 0.03 | 0.04 | 0.01 | H16 |

| ZK27N04 | 161.78 | 162.48 | 484 | 0.70 | 1.98 | 9 | 0.24 | 0.15 | 0.02 | H16_1 |

| ZK27N07 | 105.32 | 106.13 | 552 | 0.81 | 2.00 | 13 | 0.20 | 0.08 | 0.03 | H16 |

| ZK27N07 | 137.48 | 138.13 | 534 | 0.65 | 2.21 | 15 | 0.40 | 0.36 | 0.06 | H40 |

| ZK27N08 | 143.28 | 143.82 | 480 | 0.54 | 2.96 | 7 | 0.14 | 0.06 | 0.01 | H16 |

| ZK29N10 | 136.81 | 139.45 | 530 | 2.64 | 2.09 | 4 | 0.39 | 0.21 | 0.01 | H16_1a |

| ZKH02N37 | 127.89 | 128.54 | 324 | 0.65 | 8.78 | 35 | 1.12 | 0.16 | 0.06 | H5_2 |

| ZKH02N38 | 116.61 | 117.60 | 328 | 0.99 | 9.21 | 8 | 0.08 | 0.14 | 0.09 | H5_2W |

| ZKH02N38 | 141.53 | 142.38 | 324 | 0.85 | 0.34 | 73 | 1.56 | 0.42 | 0.07 | H5_2 |

| ZKH02N38 | 172.02 | 172.65 | 320 | 0.63 | 0.13 | 67 | 2.49 | 6.17 | 0.04 | H5E |

| ZKH08N03 | 132.56 | 133.27 | 591 | 0.71 | 0.40 | 382 | 6.23 | 1.38 | 0.51 | H15_2 |

| ZKH12N21 | 67.10 | 67.77 | 330 | 0.67 | 1.17 | 172 | 3.23 | 12.97 | 0.22 | H17_1 |

| ZKH12N21 | 68.67 | 73.27 | 329 | 4.60 | 1.23 | 193 | 7.56 | 3.79 | 0.38 | H17 |

| ZKH12N22 | 28.43 | 28.88 | 361 | 0.45 | 0.28 | 76 | 4.92 | 0.13 | 0.01 | H15 |

| ZKH12N22 | 67.78 | 69.48 | 331 | 1.70 | 0.23 | 61 | 2.04 | 6.67 | 0.21 | H17_1 |

| ZKH12N22 | 71.25 | 73.94 | 328 | 2.69 | 0.53 | 86 | 4.33 | 2.61 | 0.18 | H17 |

| ZKH19N25 | 13.44 | 14.21 | 571 | 0.77 | 0.14 | 190 | 0.28 | 0.17 | 0.28 | H39_1E |

| ZKH21N20 | 64.38 | 65.22 | 361 | 0.84 | 0.29 | 54 | 1.44 | 1.70 | 0.01 | H13 |

| ZKH21N20 | 68.18 | 69.13 | 360 | 0.95 | 0.68 | 382 | 0.54 | 0.57 | 0.02 | H13a |

| ZKH21N20 | 141.43 | 142.15 | 339 | 0.72 | 1.62 | 13 | 1.30 | 1.00 | 0.03 | H16_1 |

| ZKH21N20 | 147.79 | 150.48 | 338 | 2.69 | 2.72 | 269 | 1.02 | 0.69 | 0.80 | H16_3 |

| ZKH21N20 | 160.42 | 161.02 | 334 | 0.60 | 5.66 | 7 | 0.24 | 0.08 | 0.02 | H15Wa |

| ZKH21N20 | 168.74 | 169.82 | 332 | 1.08 | 0.41 | 21 | 5.00 | 0.11 | 0.05 | H15 |

| ZKH21N20 | 188.06 | 188.68 | 326 | 0.62 | 1.87 | 45 | 0.75 | 0.13 | 0.52 | H17_1 |

| ZKH21N22 | 51.71 | 52.66 | 369 | 0.95 | 2.53 | 3 | 0.03 | 0.05 | 0.01 | H11Ea |

| ZKH21N22 | 68.83 | 69.73 | 366 | 0.90 | 0.99 | 84 | 0.28 | 0.61 | 0.01 | H13 |

| ZKH21N22 | 142.40 | 143.19 | 351 | 0.79 | 0.71 | 22 | 1.83 | 1.95 | 0.15 | H16_1 |

| ZKH21N22 | 151.45 | 152.40 | 350 | 0.95 | 6.62 | 507 | 1.77 | 1.35 | 0.97 | H16_3 |

| ZKH21N22 | 165.32 | 166.62 | 347 | 1.30 | 1.71 | 11 | 0.42 | 0.07 | 0.03 | H15 |

| ZKH27N02 | 16.60 | 18.68 | 535 | 2.08 | 2.10 | 74 | 0.31 | 0.12 | 0.28 | H20W |

| ZKH27N03 | 15.14 | 15.86 | 531 | 0.72 | 5.97 | 15 | 0.43 | 0.37 | 0.04 | H20W |

| ZKH27N03 | 120.16 | 122.82 | 473 | 2.66 | 1.27 | 23 | 1.27 | 0.10 | 0.02 | H40 |

| ZKH27N03 | 181.11 | 182.81 | 440 | 1.70 | 10.49 | 18 | 1.02 | 0.75 | 0.03 | H14a |

| ZKH27N04 | 94.47 | 95.70 | 510 | 1.23 | 1.43 | 32 | 1.10 | 0.69 | 0.01 | H16_1 |

| ZKH27N05 | 14.12 | 14.95 | 531 | 0.83 | 3.30 | 9 | 0.24 | 0.11 | 0.09 | H20W |

| ZKH27N06 | 24.51 | 25.40 | 535 | 0.89 | 4.05 | 197 | 0.69 | 0.15 | 0.99 | H17_1 |

| ZKH27N06 | 26.90 | 28.91 | 535 | 2.01 | 0.14 | 240 | 0.68 | 1.37 | 0.41 | H20W |

| ZKH27N06 | 114.53 | 115.25 | 522 | 0.72 | 1.65 | 293 | 2.09 | 0.47 | 0.54 | H16 |

| ZKH27N07 | 34.66 | 35.48 | 515 | 0.82 | 1.34 | 45 | 0.26 | 0.05 | 0.07 | H20W |

| ZKH29N16 | 93.05 | 93.84 | 581 | 0.79 | 1.20 | 33 | 6.92 | 0.77 | 0.04 | H41W |

| ZKH33N11 | 94.57 | 95.44 | 588 | 0.87 | 0.05 | 25 | 6.99 | 0.55 | 0.01 | H12E |

| ZKH36N06 | 132.35 | 133.48 | 368 | 1.13 | 0.11 | 37 | 2.41 | 4.59 | 0.03 | H15_1 |

| ZKH36N07 | 135.56 | 136.22 | 354 | 0.66 | 0.18 | 61 | 7.00 | 3.04 | 0.03 | H15_1 |

| ZKH38N01 | 127.63 | 128.77 | 373 | 1.14 | 0.51 | 32 | 2.36 | 2.85 | 0.04 | H17 |

Table 3: Selected intercepts from the drilling programs at the B zone of the HPG mine

| Hole ID | From (m) |

To (m) |

Elevation (m) |

interval (m) |

Au (g/t) |

Ag (g/t) |

Pb (%) |

Zn (%) |

Cu (%) |

Vein |

| ZK09N23 | 61.99 | 63.77 | 345 | 1.78 | 1.56 | 63 | 0.21 | 0.05 | 0.11 | B |

| ZK09N31 | 18.91 | 19.47 | 452 | 0.56 | 3.04 | 120 | 0.12 | 0.02 | 0.35 | B |

| ZK1323 | 20.66 | 21.40 | 727 | 0.74 | 0.01 | 22 | 1.41 | 3.05 | 0.03 | B07 |

| ZK15N26 | 75.65 | 77.12 | 576 | 1.47 | 0.85 | 135 | 0.72 | 1.50 | 0.15 | B08 |

| ZK15N27 | 91.75 | 92.82 | 555 | 1.07 | 0.62 | 288 | 1.81 | 0.11 | 0.29 | B08 |

| ZK15N30 | 67.58 | 71.80 | 571 | 4.22 | 0.45 | 144 | 0.99 | 0.61 | 0.07 | B08 |

| ZK15N32 | 73.19 | 74.77 | 568 | 1.58 | 1.71 | 93 | 0.22 | 0.08 | 0.02 | B08 |

| ZKH07N12 | 48.07 | 48.81 | 346 | 0.74 | 1.88 | 17 | 0.03 | 0.02 | 0.01 | B02 |

Table 4: Selected intercepts from the drilling programs at the D zone of the HPG mine

| Hole ID | From (m) |

To (m) |

Elevation (m) |

interval (m) |

Au (g/t) |

Ag (g/t) |

Pb (%) |

Zn (%) |

Cu (%) |

Vein |

| ZK03N35 | 174.26 | 174.81 | 267 | 0.55 | 15.55 | 52 | 1.67 | 2.46 | 0.01 | H5 |

| ZK03N37 | 143.41 | 144.00 | 295 | 0.59 | 0.83 | 236 | 12.14 | 7.04 | 0.01 | H5 |

| ZK40N02 | 233.57 | 233.92 | 179 | 0.35 | 0.72 | 185 | 6.51 | 0.01 | 0.01 | H17 |

| ZKH00N39 | 255.51 | 256.21 | 119 | 0.70 | 0.18 | 22 | 1.85 | 5.23 | 0.08 | H5E |

| ZKH06N34 | 106.37 | 107.11 | -11 | 0.74 | 2.60 | 76 | 6.06 | 4.68 | 0.23 | H15_1 |

| ZKH06N34 | 159.08 | 159.74 | -42 | 0.66 | 0.50 | 82 | 3.00 | 1.56 | 0.11 | H17 |

| ZKH4204 | 192.72 | 193.25 | 194 | 0.53 | 4.00 | 434 | 11.02 | 0.06 | 3.02 | H15_1 |

| ZKH4204 | 226.08 | 226.57 | 176 | 0.49 | 0.78 | 118 | 25.65 | 25.81 | 0.11 | H15 |

Quality Control

Drill cores are NQ size. Drill core samples, limited by apparent mineralization contacts or shear/alteration contacts, were split into halves by sawing. The half cores are stored in the Company’s core shacks for future reference and checks, and the other half core samples are shipped in securely sealed bags to the Chengde Huakan 514 Geology and Minerals Test and Research Institute in Chengde, Hebei Province, China, 226 km northeast of Beijing, the Zhengzhou Nonferrous Exploration Institute Lab in Zhengzhou, Henan Province, China, and SGS in Tianjin, China. All three labs are ISO9000 certified analytical labs. For analysis, the sample is dried and crushed to minus 1 mm and then split into a 200-300 g subsample which is further pulverized to minus 200 mesh. Two subsamples are prepared from the pulverized sample. One is digested with aqua regia for gold analysis with atomic absorption spectroscopy (“AAS”), and the other is digested by two-acid digestion for analysis of silver, lead, zinc, and copper with AAS.

Channel samples are collected along sample lines perpendicular to the mineralized vein structure in exploration tunnels. Spacing between sampling lines is typically 5 m along strike. Both the mineralized vein and the altered wall rocks are cut by continuous chisel chipping. Sample length ranges from 0.2 m to more than 1 m, depending on the width of the mineralized vein and the mineralization type. Channel samples are prepared and assayed with AAS at Silvercorp’s mine laboratory (“Ying Lab”) located at the mill complex in Luoning County, Henan Province, China. The Ying lab is officially accredited by the Quality and Technology Monitoring Bureau of Henan Province and is qualified to provide analytical services. The channel samples are dried, crushed and pulverized. A 200 g sample of minus 160 mesh is prepared for assay. A duplicate sample of minus 1 mm is made and kept in the laboratory archives. Gold is analysed by fire assay with AAS finish, while silver, lead, zinc, and copper are assayed by two-acid digestion with AAS finish.

A routine quality assurance/quality control procedure is adopted to monitor the analytical quality at each lab. Certified reference materials, pulp duplicates and blanks are inserted into each batch of lab samples. QA/QC data at the lab are attached to the assay certificates for each batch of samples.

The Company maintains its own comprehensive QA/QC program to ensure best practices in sample preparation and analysis of the exploration samples. Project geologists regularly insert CRMs, field duplicates and blanks to each batch of 30 core samples to monitor the sample preparation and analysis procedures at the labs. The analytical quality of the labs is further evaluated with external checks by sending approximately 3-5% of the pulp samples to higher level labs to check for lab bias. Data from both the Company’s and the labs’ QA/QC programs are reviewed on a timely basis by project geologists.

Guoliang Ma, P. Geo., Manager of Exploration and Resource of the Company, is the Qualified Person for Silvercorp under NI 43-101 and has reviewed and given consent to the technical information contained in this news release.

About Silvercorp

Silvercorp is a profitable Canadian mining company producing silver, lead and zinc metals in concentrates from mines in China. The Company’s goal is to continuously create healthy returns to shareholders through efficient management, organic growth and the acquisition of profitable projects. Silvercorp balances profitability, social and environmental relationships, employees’ wellbeing, and sustainable development.

MORE or "UNCATEGORIZED"

Bonterra Announces Closing of Upsized Brokered Private Placement for Proceeds of $10.5M

Bonterra Resources Inc. (TSX-V: BTR) (OTCQX: BONXF) (FSE: 9BR2) i... READ MORE

ESGold Expands Montauban Mine Building to 4,000 sq. ft. Ahead of Key Operational Milestones

Increased facility footprint reflects advanced construction progr... READ MORE

ARIS MINING COMPLETES INSTALLATION AND COMMISSIONING OF SECOND MILL AT SEGOVIA, ON TIME AND ON BUDGET

Aris Mining Corporation (TSX: ARIS) (NYSE-A: ARMN) announces the... READ MORE

Zodiac Gold Expands Arthington Discovery with Broad Gold Intercepts

Zodiac Gold Inc. (TSXV: ZAU) a West-African gold exploration co... READ MORE

Appia Announces Final Closing of Its Non-Brokered Private Placement

Appia Rare Earths & Uranium Corp. (CSE: API) (OTCQB: APAAF) (... READ MORE