NorthWest Reports Significant Improved Recoveries for Gold at Kwanika Ranging from 94.6%-96.3%

NorthWest Copper Corp. (TSX-V: NWST) is pleased to report successful results from its 2025 metallurgical program at its Kwanika project, adding to the positive results from the 2025 drilling. The program tested higher-grade1 zones and demonstrated material improvements in recoveries of 34% for gold and 37% for silver. These results will be reflected in an updated mineral resource at Kwanika in the first quarter followed by a new Preliminary Economic Assessment targeted for mid 2026.

The positive results confirm that a refined flow sheet, including leaching, can deliver substantially improved precious metal recoveries compared to recoveries of higher-grade material used in the 2023 PEA2. Gold recoveries ranging from ~94.6% to 96.3% and silver recoveries of ~96.3% can be achieved, while maintaining strong copper recovery ranging from ~88.9% to 90.2%.

Compared to higher-grade zones tested in the 2023 PEA3, flotation recoveries are similar for copper, 7% higher for gold, and 14% higher for silver. However, when combined with flotation tails leaching, overall recoveries increase materially by 34% for gold and 37 % for silver. These results highlight the potential to meaningfully enhance overall project performance.

Paul Olmsted, CEO of NorthWest commented: “We are extremely pleased with the results from the metallurgical test work, which demonstrate the opportunity to materially improve recoveries at Kwanika. In early 2025, we refined our strategy at Kwanika to prioritize higher-grade zones within the existing mineral resource and executed exploration and metallurgical programs to test potential benefits. Drill results from the 2025 program have consistently demonstrated higher grades over significant widths. When combined with these recovery results, the work exceeded our expectations and aligns with our objective of supporting a more economically compelling open pit and underground development plan than that presented in the 2023 PEA. We look forward to reflecting the successful outcomes in an updated PEA, targeted for mid 2026.”

Test Work Result Highlights

- Significantly higher recoveries from higher-grade material compared to previous test work:

| Metal | Concentrate Recovery4 | Leaching Recovery | Total Recovery | |

| Copper | 88.9%-90.2% | – | 88.9%-90.2% | |

| Gold | 75.4%-77.1% | 19.2% | 94.6%-96.3% | |

| Silver | 79.9% | 16.4% | 96.3% | |

- Attractive concentrate grades ranging from 22.7%-26.2% copper containing gold at 37.9-42.6 g/t, silver at 71.6 g/t and palladium at 1.1 g/t.

- Demonstrated that conventional processing methods, including ball mill grinding, flotation and tails leaching can be used to materially improve overall metal recoveries.

Geoff Chinn, VP Business Development and Exploration added: “This year’s metallurgical program focused on higher-grade underground mineralized zones and successfully demonstrated improved gold and silver recoveries using conventional flotation and leach processing. These improvements were achieved through finer grinding than previously tested and by modifying the flowsheet to address the mineralization more appropriately. The metallurgical program was also expanded to include additional variability testing, reflecting our improved understanding of metal zonation from copper-dominant to gold-dominant zones within the mineralization, as informed by our 2025 drill program. These results support our objective of evaluating a more selective bulk underground mining method at Kwanika and will also inform our planned drilling program for 2026. Importantly, test work reported in the 2023 PEA indicated that concentrates were not anticipated to incur smelter penalties.”

Metallurgical Program

On September 22, 2025, the Company announced that it had engaged Canenco Consulting Corp. to design and manage a follow-up metallurgical testing program at Kwanika.

Canenco identified gaps in previous metallurgical test work and designed a program to evaluate copper and gold recoveries at grind sizes finer than those used in the 2023 PEA, but at levels still achievable with conventional ball milling. The program also included leach testing of flotation tailings to assess opportunities to further improve gold recovery, as well as an evaluation of ore sorting as a potential pre-treatment option to provide further additive benefits.

During the summer of 2025, a total of 312 kg of NQ and HQ sized half core material was collected from 2021 and 2022 drill core, representing low-angle intersections in the Central and Western zones at Kwanika. Five holes from different areas of the deposit were sampled to produce a representative composite of higher-grade zones at depths greater than 300 meters down hole. The drill holes sampled were K-21-206, K-21-216, K-21-222, K-22-242, and K-22-255.

The samples were shipped to Intertek Base Met Labs in Kamloops, where testing was conducted under the supervision of Canenco. Following completion of the initial flotation testing and optimization of the process flowsheet, the program was expanded to include additional variability testing of additional metallurgical zones, sourced from historical samples, through the same processing circuit.

Results from the testing of this material from Kwanika, presented in this press release, demonstrate the merits of the program and indicate that meaningful improvements in both copper, gold and silver recoveries can be achieved through conventional processing methods.

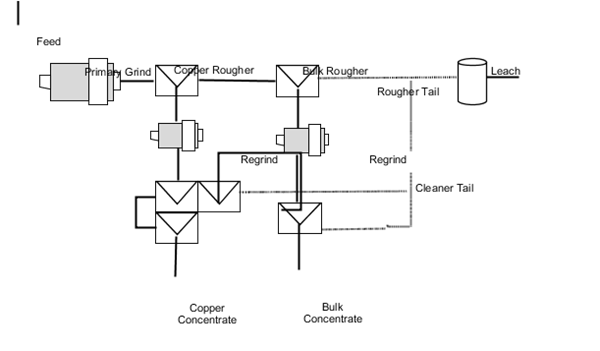

Process Flowsheet Schematic

The composited sample was ground to a primary grind P80 of approximately 53 microns, which is achievable with conventional ball mills. After some initial tests, it was determined that the majority of the copper mineralisation floated quickly, and that other mineralisation would be better dealt with in its own bulk circuit. With a better understanding of the mineralogy and additional tests, it was observed that treating the two different mineralogy’s separately significantly improved overall recoveries. With the majority of the copper mineralization being removed to concentrates, the next logical step was leaching of tailings as potential reagent consumption would likely be minimized given lower copper content.

Figure 1: Optimized Process Flowsheet Schematic

Flotation and Leach Test Results

Metallurgical test results are summarized in Table 1 at each of the key processing stages, where two separate circuits of flotation produce a copper concentrate and a bulk concentrate followed by leaching two separate tailings streams, referred to as the cleaner and rougher tail streams. Additional processing and test results are provided in Table 2 for completeness.

Table 1: 2025 Metallurgical Test Results Summary5 6 7

| Mass Pull (%) | Cu (%) | Au (g/t) | Ag (g/t) | Cu Rec. (%) | Au Rec. (%) | Ag Rec. (%) | CN (kg/t) | |

| Metallurgical Sample | ||||||||

| Head Grade | – | 0.88 – 0.91 | 1.72-1.78 | 3.0-3.6 | – | – | – | |

| Flotation Concentrate | ||||||||

| Cu Concentrate | 2.8 – 3.3 | 28.1 – 24.0 | 39.8 – 45.4 | 75.9 | 88.1-88.4 | 74.3-75.0 | 78.3 | |

| Bulk Concentrate | 0.2 – 0.3 | 3.1 – 5.9 | 8.1 – 13.7 | 18.4 | 0.8 – 1.7 | 1.1 – 2.1 | 1.6 | |

| Cu + Bulk Concentrate | 3.0 – 3.6 | 22.7-26.2 | 37.9 – 42.6 | 71.6 | 88.9 – 90.2 | 75.4 – 77.1 | 79.9 | |

| Leaching Tails | ||||||||

| Cleaner Tails | 11.9 – 12.9 | – | 1.06 – 2.15 | 0.54 | – | 7.0 | 1.9 | 0.92 |

| Rougher Tails | 83.5 – 85.1 | – | 0.34 – 0.36 | 0.61 | – | 12.2 | 14.5 | 0.86 |

| Cleaner + Rougher Tails | 96.4 – 97.0 | 19.2 | 16.4 | 1.78 | ||||

| Flotation + Leach | ||||||||

| Combined Total | 88.9 – 90.2 | 94.6 – 96.3 | 96.3 |

Table 2: Additional Metallurgical Processing Parameters and Test Results

| Parameter | Unit | Value |

| Grind – Primary ~P80 – Rougher | micron | 53 |

| Grind – Regrind ~P80 – Cleaner | micron | 11-18 |

| Cu Rougher Mass Pull | % | 8.2 – 12.8 |

| Bulk Rougher Mass Pull | % | 4.9 – 5.4 |

| Pd in Cu + Bulk Concentrate | g/t | 1.1 |

| Au Rec. – Cleaner Tails Leach | % | 90.2 |

| Au Rec. – Rougher Tails Leach | % | 80.7 – 85.3 |

| Ag Rec. – Cleaner Tails Leach | % | 90.2 |

| Ag Rec. – Rougher Tails Leach | % | 80.7 |

Technical aspects of this news release have been reviewed, verified, and approved by Geoff Chinn, P.Geo., VP Business Development and Exploration for NorthWest, and Stacy Freudigmann P.Eng., F.Aus.IMM, CEO of Canenco who are qualified persons as defined by National Instrument 43-101 – Standards of Disclosure for Minerals Projects.

About NorthWest:

NorthWest is a copper-gold exploration and development company with a pipeline of advanced and early-stage projects in British Columbia, including Kwanika-Stardust, Lorraine-Top Cat and East Niv. With a robust portfolio in an established mining jurisdiction, NorthWest is well positioned to participate fully in strengthening global copper and gold markets. The Company is committed to responsible mineral exploration, working collaboratively with First Nations to help ensure future development incorporates stewardship best practices and respects traditional land use.

MORE or "UNCATEGORIZED"

Eloro Resources Announces Closing of Bought Deal LIFE Private Placement for Gross Proceeds of C$17 Million

Eloro Resources Ltd. (TSX: ELO) (FSE: P2QM) is pleased to announce the closing of its previously an... READ MORE

Minera Alamos Updates Resources and Reserves for the Pan Gold Mine in Nevada

Minera Alamos Inc. (TSX-V: MAI) (OTCQX: MAIFF) is pleased to announce updated Mineral Resource and M... READ MORE

Ero Copper Reports Fourth Quarter and Full Year 2025 Operating and Financial Results

Ero Copper Corp. (TSX: ERO) (NYSE: ERO) is pleased to announce its operating and financial results f... READ MORE

Rare Element Resources Announces Results of Oversubscribed Rights Offering of Common Shares

Rare Element Resources Ltd. (OTCQB: REEMF) is pleased to report that its previously announced... READ MORE

TRX Gold Reports Record Q2 2026 Production and Company Update

TRX Gold Corporation (TSX: TRX) (NYSE American: TRX) is pleased to announce preliminary resu... READ MORE