IsoEnergy Summer Drilling Intersects Multiple Areas of Radioactivity Highlighting the Prospectivity of the Larocque Trend

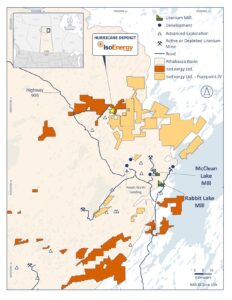

IsoEnergy Ltd. (TSX: ISO) (OTCQX: ISENF) is pleased to announce completion of its expanded summer exploration program at the Larocque East Project, located in the eastern Athabasca Basin (Figure 1). The Company successfully completed 30 diamond drill holes, totaling 13,015m, exceeding the originally budgeted 9,825m, along the Larocque Trend, an important regional structure that hosts the world-class Hurricane Deposit and other notable high-grade occurrences including those on Cameco/Orano’s Dawn Lake joint venture (Figure 2). Drilling tested multiple targets identified through Ambient Noise Tomography (“ANT“) surveys across 9km of the Laroque Trend on the Project.

Highlights

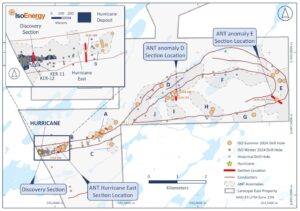

- Drilling confirmed prospectivity for additional mineralization at the Project regionally through the identification of two new high priority zones (Areas D and E) and immediately adjacent to Hurricane, referred to as Hurricane East (Figure 3).

- First pass drilling in Areas D and E returned elevated radioactivity associated with significant alteration, enhancing the prospectivity of the Project’s eastern extent.

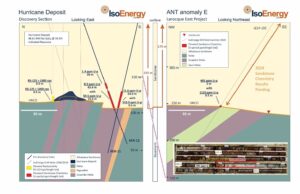

- In Area E, a 1km by 2km ANT anomaly located 8km east of Hurricane, five holes were drilled highlighted by hole LE24-192 which intersected 2.0m at 495 parts per million uranium partial (“ppm U-p“) and 3,410 counts per second (“cps“), including 0.5m at 1,110 ppm U-p and 7,483 cps (Figure 4).

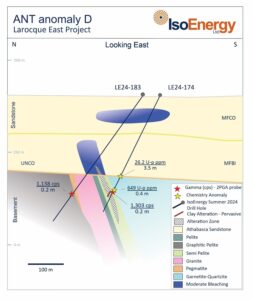

- In Area D, a 2.5km by 1km ANT anomaly located 8 km east of Hurricane, five holes were drilled highlighted by hole LE24-174 which intersected 3.5m, from 254m, at 26.2 ppm U-p and 257 cps and 0.2m at 1,303 cps (Figure 5).

- These results are comparable to pre-discovery holes drilled by Cameco just 40 meters from the high-grade Hurricane Deposit, KER-11, which returned 0.5m at 518.0 ppm U-p and KER-12 (Figure 4). We believe this emphasizes the strong proximal potential within the geochemical halos of the known deposits, where sharply defined uranium mineralization boundaries are evident.

- Drilling in Hurricane East within 600 meters of Hurricane returned elevated radioactivity, indicating potential for resource expansion.

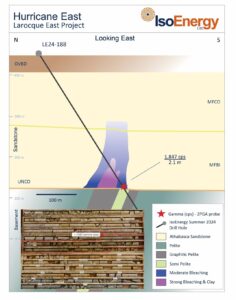

- A single hole drilled 290m east of Hurricane, LE24-188, intersected 2.1m at 1,847 cps, indicating a potential for near resource expansion (Figure 6).

- In Area B, a 250m by 180m ANT target anomaly centred 500meast of Hurricane, seven holes were drilled. Hole LE24-165 intersected 6.0 m at 1,359 cps, including a higher-grade interval of 0.5m at 3,067 cps.

- These results suggest that the Hurricane resource may remain open for further expansion.

- Additional results are expected in the coming weeks with 33% of the geochemical results received to date (Table 1). Initial results are highly encouraging, with strong hydrothermal alteration and elevated geochemical signatures – key indicators typically associated with uranium mineralization.

- Follow up drilling commencing in January 2025 is currently anticipated with a focus on high-priority areas including D, E and Hurricane East, as well as additional first pass drilling in other untested ANT anomalies (Figure 3).

Dr. Dan Brisbin, Vice President Exploration, commented, “Our summer drill results at Larocque East are highly encouraging. The structural disruption, bleaching, desilicification and clay alteration intersected within and adjacent to the ANT velocity anomalies are all hallmarks of Athabasca uranium deposits. The significantly anomalous radioactivity and sandstone uranium geochemistry are indicative of the fertility of these alteration zones; and several kilometres of strike length along graphitic-pyritic conductor corridors east of the Hurricane Deposit provide ample exploration space for potential additional discoveries along the Hurricane trend.”

The Larocque Trend is a northeast-trending regional structural feature that extends over 160 kilometres, hosting numerous anomalous uranium occurrences (Figure 2). Most notably, it is home to the Hurricane Deposit, a discovery that has significantly enhanced the prospectivity of the entire trend, further underscoring its potential for additional high-grade uranium discoveries.

Recent exploration drilling and geophysical programs have successfully defined the alteration and geochemical footprint of the Hurricane Deposit. While the mineralized footprint is relatively small—ranging from 20 to 125 meters wide, 375 meters long, and 2 to 12 meters thick (Figures 4)—it is hosted within a much larger zone of hydrothermal clay alteration, spanning up to 500 meters wide, 1 km long, and 200 to 300 meters thick. Within this broader alteration zone, the boundaries of the uranium mineralization are remarkably sharp and have been precisely delineated by drilling (Figure 4). Typically, uranium grades in the Hurricane Deposit decline sharply, dropping from greater than 1% to less than 20 ppm U-p over 30 metres in the both the horizontal and vertical directions. This abrupt decrease in uranium grade over such short distances presents a challenge in identifying additional high-grade zones. However, the broader, low-level geochemical signature of uranium mineralization provides a larger, more accessible target for initial drill testing, offering valuable vectors for potential follow-up drilling. This understanding has informed the design and analysis of the recent summer drill program (Figure 3), with drilling in seven of ten ANT anomalous target areas defined by 2023 and 2024 surveys. As a result, three target areas – East Hurricane, D and E – have been prioritized for future drill testing, with the details of the high priority targets reviewed in figures and tables below. Integration of new geological, mineralogical, geochemical and geophysical (ANT) information obtained in 2024 with historical information is already underway to generate new drill targets.

Table 1: Geochemical and elevated downhole results using Mount Sopris 2PGA probe received to date. 65% of the analytical are results pending.

| Hole | From

(m) |

To

(m) |

Length

(m) |

U-partial

(ppm) |

Gamma-2PGA

(cps) |

Collar Orientation

(Azimuth / Dip) |

Unconformity Depth in Hole

(m) |

Target

Area |

|

| LE24-165 | 240.0 | 305.0 | 65.0 | 10.8 | 254 | 173/-78.5 | 305 | B | |

| incl. | 260.0 | 300.0 | 40.0 | 13.9 | 282 | ||||

| and | 305.0 | 311.0 | 6.0 | 165 | 1,359 | ||||

| incl. | 307.5 | 310.5 | 3.0 | 277 | 2,025 | ||||

| and Incl. | 309.0 | 309.5 | 0.5 | 396 | 3,067 | ||||

| LE24-167 | 278.2 | 287.0 | 8.8 | 55.0 | 387 | 158/-77.5 | 276.7 | B | |

| incl. | 278.2 | 278.7 | 0.5 | 83.1 | 487 | ||||

| and | 279.1 | 280.0 | 0.9 | – | 1,152 | ||||

| LE24-168 | 266.2 | 306.2 | 40.0 | 6.4 | 166 | 173/-84 | 306.2 | B | |

| incl. | 301.2 | 306.2 | 5.0 | 9.2 | 299 | ||||

| incl. | 305.6 | 306.2 | 0.6 | 23.4 | 843 | ||||

| and | 306.7 | 307.7 | 1.0 | 105 | 1,100 | ||||

| LE24-169 | 294.1 | 296.1 | 2.0 | 21.1 | 266 | 165/-65 | 294.6 | A | |

| LE24-170 | 336.0 | 338.0 | 2.0 | 18.7 | 126 | 173/-69 | 338 | B | |

| LE24-172 | 288.5 | 289.0 | 0.5 | 13.6 | 81 | 337/-60 | 289 | D | |

| LE24-173 | 295.8 | 296.3 | 0.5 | 6.9 | 100 | 157/-60 | 300.3 | A | |

| LE24-174 | 254.0 | 257.5 | 3.5 | 26.2 | 257 | 345/-65 | 257.5 | D | |

| and | 305.7 | 306.1 | 0.4 | 649 | 989 | ||||

| incl. | 305.8 | 306.0 | 0.2 | – | 1,303 | ||||

| LE24-178 | 263.6 | 263.7 | 0.1 | pending | 1,420 | 160/-59.6 | 268.3 | D | |

| and | 268.0 | 268.5 | 0.5 | pending | 1,830 | ||||

| incl. | 268.2 | 268.3 | 0.1 | pending | 2,340 | ||||

| LE24-180 | 162.1 | 164.6 | 2.5 | 238 | 1,579 | 090/-76.1 | 164.1 | E | |

| incl. | 163.6 | 164.1 | 0.5 | 462 | 3,286 | ||||

| LE24-181 | 292.1 | 292.6 | 0.5 | 163 | 180 | 189/-85.8 | 292.6 | B | |

| and | 292.6 | 294.1 | 1.5 | 279 | 160 | ||||

| incl. | 292.6 | 293.1 | 0.5 | 555 | 126 | ||||

| and | 298.4 | 299.6 | 1.2 | pending | 2,678 | ||||

| Incl. | 298.7 | 299.0 | 0.3 | pending | 4,643 | ||||

| LE24-182 | 273.3 | 274.3 | 1.0 | pending | 1,344 | 177/-85.0 | 307.9 | B | |

| and | 307.8 | 308.1 | 0.3 | pending | 1,253 | ||||

| LE24-183 | 328.7 | 328.9 | 0.2 | pending | 1,138 | 360/-53.0 | 281.5 | D | |

| LE24-184 | 298.3 | 298.8 | 0.5 | pending | 1,128 | 179.8/-80.0 | 292.6 | B | |

| LE24-186 | 346.2 | 346.8 | 0.6 | pending | 1,668 | 134.7/-59.9 | 344.3 | B | |

| incl. | 346.5 | 346.6 | 0.1 | pending | 2,119 | ||||

| LE24-188 | 376.7 | 377.2 | 0.5 | pending | 1,324 | 173.8/-56.0 | 388.6 | B | |

| and | 377.5 | 379.6 | 2.1 | pending | 1,847 | ||||

| and | 382.0 | 382.1 | 0.1 | pending | 1,156 | ||||

| and | 382.4 | 382.8 | 0.4 | pending | 1,838 | ||||

| LE24-191 | 307.7 | 308.4 | 0.7 | pending | 1,730 | 360/-60.0 | 255.5 | G | |

| incl. | 307.8 | 307.9 | 0.1 | pending | 2,936 | ||||

| and | 309.7 | 310.0 | 0.3 | pending | 1,507 | ||||

| LE24-192 | 199.5 | 201.5 | 2.0 | 495 | 3,410 | 330/-58.6 | 200.5 | E | |

| incl. | 200.5 | 201.5 | 1.0 | 667 | 5,013 | ||||

| incl. | 200.5 | 201.0 | 0.5 | 1,110 | 7,483 | ||||

| incl. | 200.7 | 200.8 | 0.1 | – | 11,035 | ||||

| LE24-193c1 | 188.7 | 189.4 | 0.7 | pending | 2,117 | 088/-56.0 | 197.3 | E | |

| and | 193.0 | 193.2 | 0.2 | pending | 1,193 | ||||

| and | 193.5 | 194.0 | 0.5 | pending | 1,190 |

| Notes: | |

| 1. | Measurement of downhole total gamma cps are an indication of uranium content but may not correlate with uranium chemical assays. |

| 2. | Complete geochemical results have not been received for: LE24-173, 180, 181 and 192 listed in Table 1 |

| 3. | The 30 holes drilled in the summer 2024 are numbered from LE24-164 to LE24-193c1. Where drill holes are not listed in Table 1 geochemical results may not have been received but radioactivity measured by the 2PGA gamma probe is less than 1000 cps. |

Corporate Update

The Company announces that Dr. Darryl Clark, Executive Vice President of Exploration and Development, has resigned to pursue new opportunities. Dr. Clark will, however, continue to support the exploration team in his new role as Technical Advisor.

Dr. Dan Brisbin has assumed accountability for IsoEnergy’s exploration activities in Canada, USA, and Australia. Dan has 45 years exploration and mine geology experience, including 20 years in the Athabasca Basin and other uranium districts. He holds a PhD in economic geology from Queen’s University and is a Professional Geoscientist in Saskatchewan, Manitoba, and Ontario.

Quality Assurance and Quality Control (QA/QC)

Quality Assurance in uranium exploration benefits from the use of down-hole gamma probes and hand- held scintillometers/spectrometers, as discrepancies between radioactivity levels and geochemistry can be readily identified.

IsoEnergy implemented its QA/QC program in 2019. CRMs are used to determine laboratory accuracy in the analysis of mineralized and unmineralized samples. Duplicate samples are used to determine analytical precision and repeatability. Blank samples are used to test for cross contamination during preparation and analysis stages. For each mineralized drill hole at least one certified reference material (CRM) blank, one CRM standard, and one duplicate sample (MDUP) is inserted in the MINZ sample series. One of two CRM standards is used: OREAS 124 (O124) if maximum grade is <1% eU3O8 or BL-5 (BL5) if maximum grade is >1% eU3O8.

For unmineralized samples such as composite and spot samples, field insertions are made at the rate of 1% for blanks, 2% for duplicates and 1% CRMs. The following protocols are followed:

- Sample IDs ending in 00 will be certified blanks (BLA1).

- Sample IDs ending in 25 and 75 will be duplicates (DUPL) of the preceding sample.

- Sample IDs ending in 50 will be CRM OREAS 120 (O120).

In addition to IsoEnergy’s QA/QC program, SRC conducted an independent QA/QC program, and its laboratory repeats (REPT), non-radioactive laboratory standards (LSTD), and radioactive lab standards (BL2A, BL4A, BL5) were monitored and tracked by IsoEnergy staff.

No QA/QC samples are inserted for reflectance samples as analyses are semi-quantitative only.

Assaying and Analytical Procedures

Composite and spot samples were shipped to SRC Geoanalytical Laboratories in Saskatoon for sample preparation and analysis. SRC is an independent laboratory with ISO/IEC 17025: 2005 accreditation for the relevant procedures.

The samples were then dried, crushed, and pulverized as part of the ICPMS Exploration Package (codes ICPMS1 and ICPMS2) plus boron (code Boron). Samples were analyzed for uranium content, a variety of pathfinder elements, rare earth elements, and whole rock constituents with the ICPMS Exploration Package (plus boron). The Exploration Package consists of three analyses using a combination of inductively coupled plasma – mass spectrometry, inductively coupled plasma-optical emission spectrometry (“ICP- OES”), and partial or total acid digestion of one aliquot of representative sample pulp per analysis. Total digestion is performed via a combination of hydrofluoric, nitric, and perchloric acids while partial digestion is completed via nitric and hydrochloric acids. In-house quality control performed by SRC consists of multiple instrumental and analytic checks using an in-house standard ASR316. Instrumental check protocols consist of two calibration blanks and two calibration standards. Analytical protocols require one blank, two QA/QC standards, and one replicate sample analysis.

Samples with radioactivity over 350 CPS measured by Radiation Solutions RS- 125 were also shipped to SRC. Sample preparation procedures are the same as for the ICPMS Exploration Package, samples were analyzed by ICP-OES only (Code ICP1) and for U3O8 using hydrochloric and nitric acid digestion followed by ICP-OES finish, capable of detecting U3O8 weight percent as low as 0.001%.

Selective samples to be analyzed for gold, and in some instances, platinum and palladium, by fire assay using aqua regia digestion with ICP-OES finish. Analytical protocols utilized replicate sample analysis; however, no in-house standards were used for these small batches. Boron analysis has a lower detection limit of 2 ppm and is completed via ICP-OES after the aliquot is fused in a mixture of sodium superoxide (NaO2) and NaCO3. SRC in-house quality control for boron analysis consists of a blank, QC standards and one replicate with each batch of samples.

Borehole Radiometric Probing Method

All successfully completed 2024 drillholes are radiometrically logged using calibrated downhole Mount Sopris 2PGA-1000 probe which collects reading every 10 cm along the length of the drillhole. The 2PGA-probe was sourced from Alpha Nuclear and was calibrated for the summer 2024 program by IsoEnergy geologists at Saskatchewan Research Council facility in Saskatoon in May 2024. The total count gamma readings using the 2PGA-1000 probe may not be directly or uniformly related to uranium grades of the interval measured and are only a preliminary indication of the presence of radioactive minerals.

Sample Collection Methods

All drill core is systematically logged to record its geological and geotechnical attributes by IsoEnergy geologists and geological technicians. All drill core is systematically photographed and scanned for radioactivity with a handheld Radiation Solutions RS-125 spectrometer. IsoEnergy geologists mark sample intervals and sample types to be collected based on geological features in the core and on radioactivity measured with the RS-125 in counts per second. Geologists and geological technicians complete the on-site collection of several types of samples from drill cores.

Composite geochemistry samples consist of roughly one-centimetre-long chips of core collected every 1.5 m to geochemically characterize unmineralized sections of sandstone and basement. Composite sample lengths are between five and ten m (typically 3 to 7 chips per sample). For five metres above and two metres below the unconformity composite sample intervals are 0.5 m long and the samples are composed of several chips of core in each interval.

Split-core “spot” samples are collected through zones of significant but unmineralized alteration and/or structure. Spot sample length varies depending on the width of the feature of interest but are generally 0.5 m in length.

Split-core mineralization (“MINZ”) samples are collected through zones of elevated radioactivity exceeding 350 CPS measured via RS-125 handheld spectrometer. MINZ samples are generally 0.5 m in length. One half of the core is collected for geochemical analysis while the remaining half is returned to the core box for storage on site. Intervals covered by MINZ samples are contiguous with and do not overlap intervals covered by composite samples.

Systematic short-wave infrared (“SWIR”) reflectance (“REFL”) samples are collected from approximately the middle of each composite sample for analysis of clays, micas, and a suite of other generally hydrous minerals which have exploration significance. Spot reflectance samples are collected where warranted (i.e., fracture coatings). Reflectance samples are not collected through mineralized zone.

For lithogeochemistry samples, sample tags with the sample number are placed in the sample bags before they are sealed and packed in plastic pails or steel drums for shipment to the Saskatchewan Research Council in Saskatoon, Saskatchewan. A second set of sample tags with the depth interval and sample number are stapled in the core box at the end of each sample interval. A third set of sample tag with the drill hole number, sample depth interval, and sample number is retained in the sample book for archiving. SWIR reflectance samples are tagged in a similar fashion as lithogeochemistry samples.

Geologists enter all geological, geotechnical and sample interval data into IsoEnergy’s drill hole database during core logging.

Sample Shipment and Security

Drill core was delivered from the drill to IsoEnergy’s core handling facilities at the Larocque Lake camp thereafter. Individual core samples were collected at the core facilities by manual splitting. They were tagged, bagged, and then packaged in five-gallon plastic buckets or steel IP-2 drums for shipment to SRC Geoanalytical labs in Saskatoon. Shipment to the laboratory was completed by IsoEnergy’s expeditor, Little Rock Enterprises of La Ronge, Saskatchewan and by Points North Freight Forwarding Inc. of Points North Landing, Saskatchewan.

Qualified Person Statement

The scientific and technical information contained in this news release was reviewed and approved by Dr. Dan Brisbin, P.Geo., IsoEnergy’s Vice President, Exploration, who is a “Qualified Person”.

For additional information regarding the Company’s Larocque East Project, including its quality assurance and quality control procedures applied to the exploration work described in this news release, please see the Technical Report titled “Technical Report on the Larocque East Project, Northern Saskatchewan, Canada” dated August 4, 2022, on the Company’s profile at www.sedarplus.ca.

About IsoEnergy Ltd.

IsoEnergy Ltd. (TSX: ISO) (OTCQX: ISENF) is a leading, globally diversified uranium company with substantial current and historical mineral resources in top uranium mining jurisdictions of Canada, the U.S., and Australia, at varying stages of development, providing near, medium, and long-term leverage to rising uranium prices. IsoEnergy is currently advancing its Larocque East Project in Canada’s Athabasca Basin, which is home to the Hurricane deposit, boasting the world’s highest grade Indicated uranium Mineral Resource.

IsoEnergy also holds a portfolio of permitted, past-producing conventional uranium and vanadium mines in Utah with a toll milling arrangement in place with Energy Fuels Inc. These mines are currently on stand-by, ready for rapid restart as market conditions permit, positioning IsoEnergy as a near-term uranium producer.

Figure 1 – Location map of the Hurricane Deposit and IsoEnergy’s exploration projects, including the Larocque East project, in the eastern Athabasca Basin. (CNW Group/IsoEnergy Ltd.)

Figure 2 – Location map of the Larocque Trend spanning across IsoEnergy’s projects. (CNW Group/IsoEnergy Ltd.)

Figure 3 – ANT survey targets across the eastern portion of the Larocque East Project with 2024 summer drill holes and respective section locations for Areas D, E and Hurricane East. (CNW Group/IsoEnergy Ltd.)

Figure 4 – Cross-sections of the Hurricane Deposit, including pre-discovery holes KER-11 and KER-12 (left), illustrating the geochemical halo surrounding to the deposit, as a guide for interpreting exploration drill results along the trend and Area E section showing comparable results in drill hole LE24-192 (right) which intersected elevated radioactivity and hydrothermal alteration proximal to unconformity (175 m below surface). (CNW Group/IsoEnergy Ltd.)

Figure 5 – Area D Section showing drill holes LE24-174 and LE24-183 which intersected moderately bleached sandstone. Elevated radioactivity coincident with pervasive clay alteration in basement in drill hole LE24-174 is indicative of potential basement mineralization at Larocque East. (CNW Group/IsoEnergy Ltd.)

MORE or "UNCATEGORIZED"

Antimony Resources Corp. (ATMY) (K8J0) Reports Massive Antimony Bearing Stibnite - Drills 4.17% Sb over 7.40 meters Including Three Zones of Massive Antimony Bearing Stibnite which returned 28.8% Sb, 21.9% Sb, and 17.9% Sb Respectively

Highlights Assays received High-grade assays returned for Drill H... READ MORE

Kenorland Minerals and Auranova Resources Report Drill Results at the South Uchi Project, Ontario; Auranova Completes Initial Earn-in

Kenorland Minerals Ltd. (TSX-V: KLD) (OTCQX: KLDCF) (FSE: 3WQ0) a... READ MORE

Wallbridge Exploration Drilling Continues to Intercept High-Grade Gold Mineralization at Martiniere

Wallbridge Mining Company Limited (TSX: WM) (OTCQB:WLBMF) announc... READ MORE

ValOre Reports Results from Successful 87 Hole Trado® Auger Drilling Campaign at Pedra Branca, Including 10.0 m at 12.95 g/t 2PGE+Au from Surface

Provides Update on Pedra Branca PGE Project and Strategic Growth ... READ MORE

Pasinex Announces 2024 Annual and 2025, Q1 Financial Results

Pasinex Resources Limited (CSE: PSE) (FSE: PNX) announced financi... READ MORE