Gunnison Copper Reports Positive Results from Initial Mineral Sorting “High-Value-Add” Work Program at the Gunnison Copper Project in Southeast Arizona

Sorting Tests Reduced Acid Consumption, a Key Operating Cost Driver, on the Highest Acid Consuming Mineralized Material by Approximately 75% While Maintaining Copper Recovery

Gunnison Copper Corp. (TSX: GCU) (OTCQB: GCUMF) (FSE: 3XS0) is pleased to announce encouraging results from its initial mineralized material sorting test program at the flagship Gunnison Copper Project in southeast Arizona, one of the largest and most advanced copper development projects in the United States.

“These initial results are extremely encouraging, showing the potential to significantly reduce acid consumption while maintaining copper recovery,” stated Roland Goodgame, Gunnison’s SVP of Business Development. “This type of high-value-add program can materially improve the Project’s already robust economics and feed directly into our upcoming update to our preliminary economic assessment and planned pre-feasibility study. These results support Gunnison’s vision of producing cost-effective, sustainable, and 100% Made-in-America copper.”

Initial Mineralized Material Sorting Results:

- Sample: A half-ton sample consisting of 2″ to 6″ pieces of PQ drill core from the Martin Formation, collected as part of Gunnison’s recently completed metallurgical drilling program. The Martin Formation is the highest acid consuming rock type in the deposit and makes up ~44% of the resource base. The sample was comprised of ~54% mineralized material and ~46% internal waste, consistent with the overall Martin Formation.

- Waste Reduction: Over 90% of the internal acid-consuming waste was successfully removed from the mineralized material using optical mineral sorting equipment at a commercial scale.

- Acid Consumption Reduction: Due to the removal of the high-acid-consuming waste, the sorted material is expected to require up to 4x lower acid consumption.

- Copper Recovery: Less than 1% of total copper was lost to waste, ensuring strong copper recovery and protecting revenue.

- Testing Location: Initial sorting tests were conducted at Steinert’s facilities in Kentucky in August 2025.

Table 1: Results of mineral sorting test work on the Martin Formation from the Gunnison Open Pit resource. 57% of the sample sorted to mineralized and 43% sorted to waste.

| Category | Total Copper %* |

Acid Soluble Copper % |

Sample Weight (lbs) |

% of Materials in Samples |

| All materials (Martin core) | 0.35 | 0.30 | 1,028 | 100% |

| Sorted to mineralization | 0.62 | 0.54 | 591 | 57% |

| Sorted to waste | 0.03 | 0.01 | 437 | 43% |

*Copper grades estimated from assays on hand-sized samples from recently drilled core

Should further test work remain consistent with the initial testing results, it suggests approximately 40% of the mined Martin Formation can be removed as internal waste by optical mineral sorting prior to processing on the leach pad. This would result in a near doubling of the process head grade, and significantly reduced process operating costs.

Next Steps:

- Optimization testing on different size fractions of the Martin formation

- Mineral Sorting samples will be crushed at Base Metallurgical Labs in Tucson.

- Crushed materials will then be returned to Steinert for further mineral sorting tests to determine further liberation and sizing characteristics.

- Following the mineralization being separated from internal waste, column leach testing will be conducted on sorted products.

- Some samples may be sent to Germany for testing using Steinert’s advanced M Sorters.

- Incorporating results into updated PEA expected in the first quarter of 2026.

About Mineralized Material Sorting:

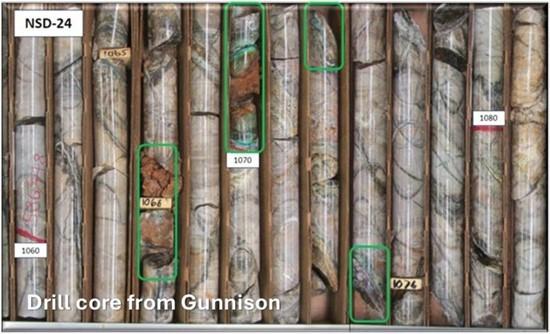

Copper oxide exists on visually distinct blue-green and red-brown zones that are ideally suited to optical mineralized material sorting. Preliminary testing was 100% successful and data suggest sorting of this material has the potential to greatly reduce acid consumption and volume of material leached by removing 40 to 50 percent of the process stream as unmineralized, higher acid consuming, waste (See Figure-1). This would result in significant savings on operating costs.

Figure 1 – Drill core showing Martin formation mineralization at the Gunnison Open Pit project. The green boxes show mineralized portions of the rock that test work has shown can be optically sorted from the remaining internal waste.

ABOUT GUNNISON COPPER

Gunnison Copper Corp. is a multi-asset pure-play copper developer and producer that controls the Cochise Mining District (the district), containing 12 known deposits within an 8 km economic radius, in the Southern Arizona Copper Belt.

Its flagship asset, the Gunnison Copper Project, has a Measured and Indicated Mineral Resource containing over 831.6 million tons with a total copper grade of 0.31% (Measured Mineral Resource of 191.3 million tons at 0.37% and Indicated Mineral Resource of 640.2 million tons at 0.29%), and a preliminary economic assessment yielding robust economics including an NPV8% of $1.3Billion, IRR of 20.9%, and payback period of 4.1 years. It is being developed as a conventional operation with open pit mining, heap leach, and SX/EW refinery to produce finished copper cathode on-site with direct rail link.

The PEA is preliminary in nature and includes Inferred Mineral Resources that are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves. There is no certainty that the conclusions reached in the PEA will be realized. Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

In addition, Gunnison’s Johnson Camp Asset, which is now in production, is fully funded by Nuton LLC, a Rio Tinto Venture, with a production capacity of up to 25 million lbs of finished copper cathode annually.

Other significant deposits controlled by Gunnison in the district, with potential to be economic satellite feeder deposits for Gunnison Project infrastructure, include Strong and Harris, South Star, and eight other deposits.

For additional information on the Gunnison Project, including the PEA and mineral resource estimate, please refer to the Company’s technical report entitled “Gunnison Project NI 43-101 Technical Report Preliminary Economic Assessment” dated effective November 1, 2024 and available on SEDAR+ at www.sedarplus.ca.

Roland Goodgame, Senior Vice President Business Development of the Company is a Qualified Person as defined by NI 43-101. Dr. Goodgame has reviewed and is responsible for the technical information contained in this news release.

Dr. Goodgame has verified the data disclosed in this news release, including the assay and test data underlying the information or opinions contained in this news release. Dr. Goodgame verified the data disclosed in this news release by reviewing imported and sorted assay data; checking the performance of blank samples and certified reference materials; and reviewing grade calculation formulas. Dr. Goodgame detected no significant QA/QC issues during review of the data and is not aware of any sampling, recovery or other factors that could materially affect the accuracy or reliability of the data referred to in this news release.

MORE or "UNCATEGORIZED"

Cerro de Pasco Resources Enters Project Development Funding Agreement with U.S. International Development Finance Corporation for Quiulacocha

Cerro de Pasco Resources Inc. (TSX-V: CDPR) (OTCQB: GPPRF) (BVL: CDPR) announces that it has ... READ MORE

NorthWest Announces Updated Mineral Resource at Kwanika Reflecting Strategic Shift to Higher-Grade Copper-Gold Focus

NorthWest Copper Corp. (TSX-V: NWST) is pleased to announce an updated mineral resource estimate for... READ MORE

Monument Reports Second Quarter Fiscal 2026 Results

Monument Mining Limited (TSX-V: MMY) (FSE: D7Q1) today announced its financial results for the three... READ MORE

Taseko announces First Cathode Harvest at Florence Copper

Taseko Mines Limited (TSX: TKO) (NYSE American: TGB) (LSE: TKO) is pleased to announce its F... READ MORE

Highland Copper Closes Sale of 34% Interest in White Pine for US$30 Million

Highland Copper Company Inc. (TSX-V: HI) (OTCQB: HDRSF) is pleased to announce, further to its press... READ MORE