CleanTech Acquires Significant Package of Fluorspar Projects Totaling 7,180 Acres for US$4,000,000 in Illinois-Kentucky Fluorspar District

CleanTech Vanadium Mining Corp. (TSX-V: CTV) (OTCQB: CTVFF) is pleased to announce that, through its 100%-owned subsidiary, it has entered into a binding option-to-purchase agreement with an arm’s-length private party to acquire a package of Fluorspar mining projects, several with historic Fluorspar production, totaling approximately 7,180 acres in Kentucky and Illinois, USA.

Transaction Summary

Under the OTP executed on August 7, 2025, the Vendor agreed to sell to CleanTech, the Fluorspar Projects for a total of US$4,000,000, consisting of:

- US$250,000 upon OTP signing (paid);

- US$250,000 on or before September 1, 2026;

- US$250,000 on or before September 1, 2027;

- US$250,000 on or before September 1, 2028; and

- US$3,000,000 on or before September 1, 2029.

The Fluorspar Projects are divided into two groups, CleanTech has the option to acquire both groups for the Purchase Price or choose any one of the two groups in the Fluorspar Projects and pay a total of only $2,250,000 instead, less any money paid as of the date CleanTech exercises the option to purchase the chosen group of Fluorspar Projects.

Strategic District Position

CleanTech’s Fluorspar Projects consist of over a dozen distinct Fluorspar deposits with over 720 historic drill holes, covering over 7,180 acres and collectively control key segments of the Western Kentucky Fluorspar District’s most productive fault systems, representing approximately 60,000 feet of fault length across major geological structures. Those Fluorspar Projects provide long-term exploration potential across underexplored extensions of proven systems.

The district’s unique geological setting, established transportation infrastructure, and proximity to major industrial consumers positions CleanTech’s Fluorspar Projects as highly strategic domestic fluorspar assets in an import-dependent market in the United States.

“With this transaction, CleanTech has now become one of largest Fluorspar players in the USA in terms of Fluorspar resource holdings and Fluorspar project land size in the heart of the Kentucky-Illinois Fluorspar District,” commented Ron Espell, President of CleanTech. “CleanTech’s goal is to be the leading Fluorspar mining company to supply Florine, a critical mineral and essential ingredient in uranium enrichment to produce nuclear fuel to power plants, in battery electrolytes in most electric vehicles and large-scale energy storage systems, and as a fluxing agent for steel and aluminum production,” further commented by Ron Espell.

Table 1. The Fluorspar Projects Under Option by CTV in Illinois – Kentucky Fluorspar District

| Project | Area Acres | Historic Resource Estimate (tons)* |

CaF2% | Zn% |

| Tabb (Lafayette-Crouch-Simpkins-Travis) | 1,008 | 6,560,000[1] | 14.2 | 3 |

| Babb-Barnes | 324 | 424,000[2] | 44 | |

| Robinson-Lasher | 1,524 | 31 | 14 | |

| Robinson-Lasher Bethel Horizon | 70,000[3] | 32 | ||

| Robinson-Lasher Shetlerville Horizon | 105,000[4] | 30 | ||

| Robinson-Lasher sub-Rosiclare Horizon | 387,225[5] | 5 – 10 | 14 | |

| Carr | 30 | 100,000[6] | 30 | |

| Big Four | 196 | |||

| Pitillo | 170 | |||

| Memphis | 587 | 23,600[7] | 18 | |

| Franklin | 104 | |||

| Kirk-Tyner-Wring | 941 | 72,000[8] | 43 | |

| Eagle-Watson | 99 | 58 | ||

| Beard-Jones | 1,584 | |||

| Susie Beeler | 341.9 | |||

| Lee Mine (IL) | 271.5 | |||

| Campbell-Crotser* | 226 | 805,841[9] | 37 | 3.23 |

* Campbell Crotser is under a separate OTP as described in the Company’s news release dated July 2, 2025

The key assumptions, parameters, and methods used to prepare this historical resource estimate are not available. The Company has not reviewed or validated the historic data, and caution should be taken as a qualified person has not done sufficient work to classify these historical resource estimates as a current mineral resource and the Company is not treating them as a current mineral resource. The historic resource does not demonstrate economic viability and should not be relied on. The Company considers the historical estimate relevant as it indicates significant fluorspar mineralization within the project area; however, the reliability is uncertain given the age of the data, and differences between historical estimation methods and current Canadian Institute of Mining, Metallurgy and Petroleum (“CIM”) Definition Standards. The historical resource categories were defined prior to the adoption of current CIM Definition Standards and differ materially from current categories such as ‘Inferred Mineral Resource.’ The historical estimates do not meet current CIM requirements for mineral resource classification because of insufficient verification, lack of documented estimation methodology, and absence of QA/QC protocols. Steps to verify and upgrade the historical estimates to current CIM standards include (i) compilation and validation of all historical drill data, (ii) twin drilling of select historical holes, (iii) confirmatory drilling in key areas of mineralization, (iv) updated geological modeling, and (v) preparation of a new mineral resource estimate in accordance with NI 43-101.

CleanTech’s Fluorspar Projects Summary

The Western Kentucky Fluorspar District represents one of North America’s most strategically important mineral provinces, containing the United States’ largest known fluorspar districts and most prolific production history from approximately 1896-1975. Located in Crittenden and Livingston counties, Kentucky, and extending into southern Illinois, the Illinois-Kentucky Fluorspar District (“IKFD”) has been the focus of extensive exploration[10] and development activities more than 150 years[11]. Mining operations have extracted 12.5 million tons of refined fluorspar in the IKFD since the late 1800s[12]. The neighboring Illinois portion of the district (north of the Ohio River) is documented in having produced over 20 million tons of crude fluorspar throughout its history[13].

A thorough review of historic and current geological reports by the Company revealed significant mineral resource potential supported by over 720 historic drill holes across CleanTech’s Fluorspar Projects covering approximately 7,180 acres within the heart of Western Kentucky Fluorspar District. Each CleanTech’s Flursopar Project is strategically positioned along major fault systems that have historically controlled mineralization throughout the 1,000-square-mile district.

Geologically, CleanTech’s Fluorspar Projects are within the Kentucky-Illinois fluorspar district, where Mississippian-age limestones are cut by NW-SE normal faults and locally by dikes to which may be related to subsurface intrusive activity. Fluorspar is the principal commodity and accessory sphalerite and galena, occurring in steep fault-fill veins, breccia zones, and localized carbonate replacements along favorable beds. Shoots typically thicken at bends, step-overs, relay ramps, and fault-dike intersections, providing predictable structural controls and repeatable targets across the belt[14],[15].

The IKFD represents one of the most significant fluorspar provinces globally, hosted within Mississippian sedimentary rocks that have been extensively faulted into a complex block pattern[16]. The primary deposits (optioned by CleanTech) – Campbell-Crotser, Tabb, Babb-Barnes, and Robinson-Lasher – occur along steeply-dipping normal faults (70-90°) that displace favorable limestone formations, particularly the St. Genevieve and St. Louis limestones. These fault-hosted vein deposits formed through replacement of pre-existing calcite by fluorite, with ore shoots typically ranging 200-1000 feet in strike length, 200-500 feet in height, and 3-10 feet in width[17]. The Campbell deposit, for example, occurs along the Big Creek Fault with a 12-foot average width and 26-foot total vein width, containing approximately 805,000 tons grading 37% CaF2 and 3.2% zinc[18]. The Tabb fault system, historically the most productive in Kentucky, extends 19 miles through the district with mineralization varying both laterally and vertically along strike.

These deposits are geochemically linked to deeper carbonatite-lamprophyre magmatism, as evidenced by the widespread occurrence of mafic dikes throughout the district and their spatial association with zinc-rich mineralization[19]. The cryptovolcanic Hicks Dome structure, dated at approximately 270 Ma (million years ago), represents a key thermal and geochemical center that likely provided both heat and fluorine-rich volatiles for regional mineralization. The dome is underlain by alkalic igneous rocks and explosive breccias, visible in aeromagnetic data, may reflect deeper ultramafic intrusive activity and suggests that the observed surface mineralization represents the upper expression of a much larger magmatic-hydrothermal system driven by mantle-derived carbonatitic melts[20].

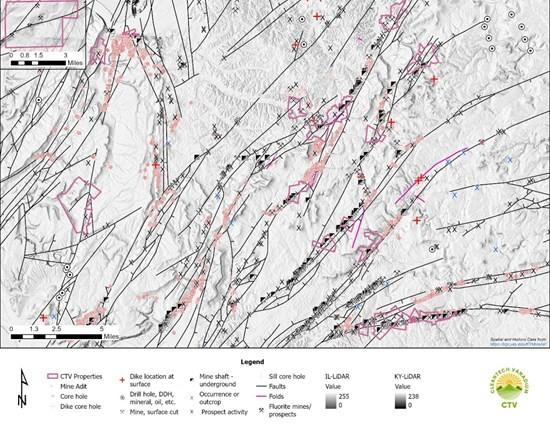

Figure 1. Illinois – Kentucky Fluorspar Projects Map

Highlights from CleanTech’s Fluorspar Projects:

Campbell-Crotser Leads Resource Base

Optioned under a separate OTP by CleanTech described in the Company’s news release dated July 2, 2025, the Campbell-Crotser stands as the flagship asset, hosting a historic resource estimate of 805,841 tons of fluorspar grading 37.10% CaF2, 3.23% zinc, and 0.99% lead. Located along the Rock Creek Fault system near Carrsville, Kentucky, the project controls a critical 3,300-foot segment of what represents a much larger 30,000-foot fault system extending from Illinois into Kentucky[21].

The Rock Creek Fault system, striking northeast at N20°E with a 75° northwest dip, exhibits 650 feet of stratigraphic displacement. The fault places Degonia Formation against Golconda Formation at surface, creating optimal conditions for fluorspar mineralization. Of the total 30,000-foot system length, approximately 6,200 feet shows confirmed mineralization, with Campbell-Crotser controlling the most prospective central segment[22]. The project underwent systematic exploration beginning with Pennwalt Chemicals Corporation’s 13-hole drilling program from 1946-1948. The major exploration effort was conducted by Cerro Corporation from 1972-1974, involving 69 total core holes with approximately 39,600 feet of drilling[23]. The Campbell Deposit shows some of the highest-grade intervals, with individual drill holes reporting 48-60% CaF2 over significant thicknesses. Borehole 37, for example, intersect a 6.6 foot-wide (true-width) vein of 83.65% CaF2 at approximately 775 feet below ground surface.

Tabb (Lafayette-Crouch-Simpkins-Travis) System Demonstrates Exceptional Scale

The Tabb Fault system represents the district’s most significant geological structure, extending 19 miles (100,320 feet) through southern Crittenden and western Caldwell counties. This large fault system has historically produced 30% of all fluorspar mined in the Kentucky portion of the district, totaling over 1.05 million tons[24].

Recent exploration by Honeywell’s Project Joust program focused on the K-4 cluster, a 4,000-foot segment of the eastern Tabb system. Honeywell’s 2012-13 “Project Joust”: 59 HQ holes (of which 50 intersect fluorite bodies on the project), 55,105 ft; 2.41 million tons of historic resource grading 21.26% CaF2 (cut-off 15% CaF2) within a larger historical resource of 6.56 million tons grading 14.02% CaF2[25]. Of the total resource in the system, approximately 496,433 tons are thought to be acid-grade fluorspar. The Tabb system’s mineralized zones typically occur as shoots 250-400 feet long, 100-200 feet high, and averaging 5 feet wide, with mineralization extending to depths exceeding 1,000 feet[26]. The Project Joust drilling revealed substantial continuity with the T33A-2 hole showing nearly 20% CaF2 over 141 feet.

Babb-Barnes Shows Production-Ready Infrastructure

The Eagle Babb-Barnes represents an immediately viable operation, featuring complete mine infrastructure including an 800-foot shaft with stations at 300, 500, and 700-foot levels. The project sits on the Babb Fault system, which extends over 15,000 feet with a 3,300-foot mineralized segment controlled by the operation[27].

Historic production totaled 145,335 tons grading 38% CaF2 and 1.5% zinc between 1973-1979. Estimated historic resource stand at 424,000 tons grading 44% CaF2[28]. This project has also been thoroughly explored with 86 surface HQ holes (45 original + 41 infill) and 172 underground holes; surface footage is approximately 45,000 ft[29]. The minerals are fault controlled and dominated by Veins dip 70-85° NW; true widths 5-10 ft (avg. 7.6 ft) over 3,300 ft strike; mined on the 500, 600 & 700 levels from an 800 ft, three-compartment shaft[30].

Robinson-Lasher Showcases Zinc Potential

The Robinson-Lasher, encompassing 1,524 acres in Livingston County, sits along the Robinson Fault, a near-vertical structure with 20,000 feet of total strike length. The project controls approximately 1,700 feet of the fault system, where bedded replacement deposits have been developed through a 1,270-foot decline to 240 feet vertical depth[31].

This project has undergone extensive exploration with 232 core holes to at least 9,855 ft with a historic resource of 70,000 tons grading 32% CaF2 (Bethel Horizon), 105,000 tons grading 30% CaF2 (Shetlerville Horizon) for 175,000 tons fluorite. (1, pp. 68-70). There is additionally another 387,225 tons grading 14% Zn in lower sub-Rosiclare with 5-10% fluorite according to an internal Dynamex company report[32],[33]. Total footage comes from a Boyce Moodie memo dated April 20, 19761. Dynamex exploration[34] demonstrated that 77% CaF2 grades are achievable in certain intervals, though typically over smaller thicknesses.

Carr: The Carr is located 12 miles northwest of Salem, Kentucky, on the Crittenden-Livingston County line at the confluence of Deer Creek with the Ohio River, covering 30 acres of mineral rights[35]. The entire project lies in the floodplain of the Ohio River, where the Ellis Mine fault is projected onto the project for 1,400 feet[36]. Vein and bedded fluorite-barite mineralization is present at the nearby Ellis Mine, where 300,000 tons of material grading 25% CaF2 and 20% BaSO4 were mined1. Past exploration on the Carr consisted of one angled diamond drill hole that intercepted a narrow width of good-grade fluorite and barite[37]. The project is now inundated due to completion of the Smithland Dam on the Ohio River, limiting its exploration potential but potentially offering value as a barge loading site1.

Big Four: Controls 12,000 feet of the Commodore3. At least 25 boreholes have been drilled on this project totaling approximately 15,000 feet1.

Pittillo: The Pittillo (or Pattillo) is in Crittenden County, 6 miles north of Salem, Kentucky, with mineral rights covering 3 tracts containing a total of 170 acres[38]. The project is situated within one of the major horsts of the district, bounded by the Sheridan fault system, containing two north to northwest-trending faults with small stratigraphic displacement that host known mafic dikes1. Alcoa conducted drilling on the structures and discovered narrow zones of zinc mineralization, primarily sphalerite, in fractured and brecciated St. Louis limestone walls1. The prospect contains sphalerite-dike occurrences like other known deposits in the district, most notably the Hutson zinc mine, but these targets have been inadequately explored[39]. Several vertical core holes are recommended to be drilled in the breccia structures to establish the presence of mineralization in favorable beds within the St. Louis and Salem limestones, with potential for small but high-grade zinc mineralization1.

Memphis: Positioned on the Levias-Crittenden Springs system, controlling 5,600 feet of untested western fault segments plus historic gravel estimates of 23,600 tons grading 18% CaF24. There have been 25 boreholes drilled on this project totaling ~15,000 feet1.

Franklin: The Franklin is in Crittenden County, 6 miles northeast of Salem, Kentucky, encompassing mineral rights under two tracts totaling 104 acres1. The prospect is positioned along the southern portion of the Levias-Crittenden Spring fault system, where the Fredonia formation forms the footwall and the Tar Springs formation forms the hanging wall, with apparent stratigraphic displacement of 700 feet accommodated by four northeast-trending step faults1. The Franklin Mine operated on the project with two shafts and extensive drifting, producing an estimated 40,000 to 60,000 tons of fluorspar of unknown grade based on old mine maps1. The northeast-trending fault structures have never been systematically drilled and appear to represent good targets for additional small-scale fluorspar-zinc mineralization[40].

Kirk-Tyner-Wring: Located on the 26-mile Moore Hill Fault system, controlling 2,500 feet of the principal mineralized zone with a historic estimate of 72,000 tons grading 43% CaF2[41]. This project has been explored by approximately 26 boreholes[42].

Eagle-Watson: Located 3 miles east of Salem, Kentucky on the northeast-trending Moore Hill Fault System, the Eagle-Watson lies on one of the most productive fault systems in the district. The Moore Hill fault system extends approximately 26 miles in length and is one of the longest fault systems in the Kentucky district. Approximately 99 acres of surface and mineral rights are controlled on the Eagle Watson. This project has been explored by at least 9 boreholes and several shallow auger holes of unspecified length[43].

Beard-Jones: The Beard-Jones is located 11 miles northeast of Salem, Kentucky, in Crittenden County, covering 1,584 acres of mineral rights[44]. The project is situated on the northern portion of the Commodore fault system, one of the principal northeast-trending fault systems in the district, with a fault system approximately 2,000 feet wide and stratigraphic separation of at least 450 feet[45]. Historical production from the prospect came from a narrow footwall graben, totaling approximately 15,000 to 20,000 tons of fluorspar from the Beard mine1. Alcoa acquired the properties and drilled approximately 53 holes to explore the footwall graben, with four additional holes drilled on other fault structures1. The available information suggests that 12,000 feet of fault structure remains untested, with geological mapping indicating potential for rotational movement that could produce extraordinary wide vein widths[46].

Susie Beeler: The Susie Beeler is located 2.5 miles east of Salem, Kentucky, encompassing 299 acres of surface rights and 341.9 acres of mineral rights[47]. The project is positioned on the Claylick fault system, one of the principal northeast-trending fault systems in the district, bounded by footwall and hanging wall faults with surface width varying from 500 to 1,000 feet and stratigraphic separation of 550 to 650 feet[48]. Historical production prior to 1945 amounted to approximately 18,000 tons from shafts on two different veins of the fault system1. Alcoa acquired the properties in 1945 and drilled 33 holes, though core recovery was poor due to badly broken ground, with only two holes cutting promising mineralization1. Frontier Spar Corporation conducted additional exploration including nine shallow percussion holes and nine angle diamond holes, revealing a 350-foot-wide breccia zone with some mineralization but determined that most structures contained small shoots[49].

Lee Mine (Hardin Co. IL): Located in Hardin County, Illinois, this is the only project in the portfolio situated outside Kentucky. The project contains 271 acres of mineral rights controlled. The Lee Fault Mine has never been thoroughly explored and remains largely speculative with no established historic estimate or production history documented in the available materials[50].

Fluorspar Market Overview

According to United States Geological Survey, China produced over 60% of the world’s fluorspar in 2024[51]. China produced 5.9 million tons in 2024, followed by Mexico (1.2 million tons) and Mongolia (1.2 million tons). The remaining countries combined produced approximately 1 million tons.

China has shifted from being a net exporter to a significant importer of fluorspar since 2023, due to rising demand from the booming energy storage system including batteries. Chinese customs data indicate that full-year 2024 fluorspar imports (all grades) rose 32% year-on-year to about 1.30 million tons, with Mongolia supplying roughly 88 % of the tonnage[52]. Over the same period China’s outbound shipments contracted sharply: fluorspar exports fell 35% year-on-year to roughly 245,000 tons in 2024, the second annual decline as China prioritized domestic supply. The US fluorspar price has risen from approximately $300 per ton in 2020 to over $450 per ton in 2025.

Qualified Person

The technical and scientific information contained in this news release has been reviewed and approved by Carlos Zamora, CPG, a member of the American Institute of Professional Geologists (AIPG) since 2024, who is an independent Qualified Person as defined by National Instrument 43-101.

About CleanTech Vanadium Mining Corp.

CleanTech is a mining company focused on critical mineral resources in the USA. The Company has an option to acquire 7,180 acres of mineral rights with historic Fluorspar resources across multiple projects in in Illinois-Kentucky Fluorspar district. CleanTech also owns a 100% interest in the Gibellini Vanadium Mine Project in Nevada.

MORE or "UNCATEGORIZED"

Aldebaran Announces Closing of $40 Million Bought Deal Offering

Aldebaran Resources Inc. (TSX-V: ALDE) (OTCQX: ADBRF) is please... READ MORE

Erdene Announces Closing of $25 Million Bought Deal Private Placement

Erdene Resource Development Corp. (TSX:ERD) (MSE:ERDN) (OTCQX: ER... READ MORE

NOVAGOLD Announces Closing of Upsized Bought Deal for Gross Proceeds of US$310 Million

NOVAGOLD RESOURCES INC. (NYSE: NG) (TSX: NG) is pleased to report... READ MORE

Guanajuato Silver Sees Significant Growth in Resources at Valenciana

~ Inferred Mineral Resources Increased by 630% to 20.3M AgEq Ounc... READ MORE

Copper Quest Increases and Closes Unit Offering for Total Gross Proceeds of $2,099,890

Copper Quest Exploration Inc. (CSE: CQX) (OTCQB: IMIMF) (FRA: 3MX... READ MORE