Canada Nickel Achieves Best Drill Results to Date at Reid

Highlights

- Best Reid interval to date – 661 metres of 0.29% nickel including 100 metres of 0.42% nickel and 40 metres of 0.51% nickel in REI-24-35

- All 8 holes targeting Reid Central Core intersected core lengths greater than 620 metres with average grades of 0.21% to 0.29% nickel

Canada Nickel Company Inc. (TSX-V: CNC) (OTCQX: CNIKF) is pleased to announce positive assay results from its ongoing 2024 exploration program at its Reid property, located 37 kilometres northwest of Timmins, Ontario.

All 34 holes drilled this year at Reid have intersected long intervals of targeted mineralized dunite and minor peridotite. Complete assay results for 18 holes have been received, 13 of which are announced today with assay results for the remaining holes pending. Assay results for five holes were previously released on March 18 and May 6, 2024.

Mark Selby, CEO of Canada Nickel said, “Reid continues to deliver excellent results, including the best individual hole to date with long core lengths grading in excess of 0.4% and 0.5% nickel and all holes delivering large intervals of target mineralization. With a target geophysical footprint larger than our flagship Crawford project and a width in the central core more than double Crawford, we look forward to the initial resource estimate for Reid expected to be released in the fourth quarter of 2024.”

Mr. Selby continued, “The ongoing success of our regional exploration program clearly demonstrates the potential scale of the Timmins Nickel District. We now have seven drill rigs drilling five separate targets – Reaume, Reid, Mann Central, Mann Northwest-SE, and Mann Northwest-NE – which are in addition to the two properties where we have already published a resource. Few companies have more than one project resource and we remain on-track and expect to deliver seven additional resources by this time next year.”

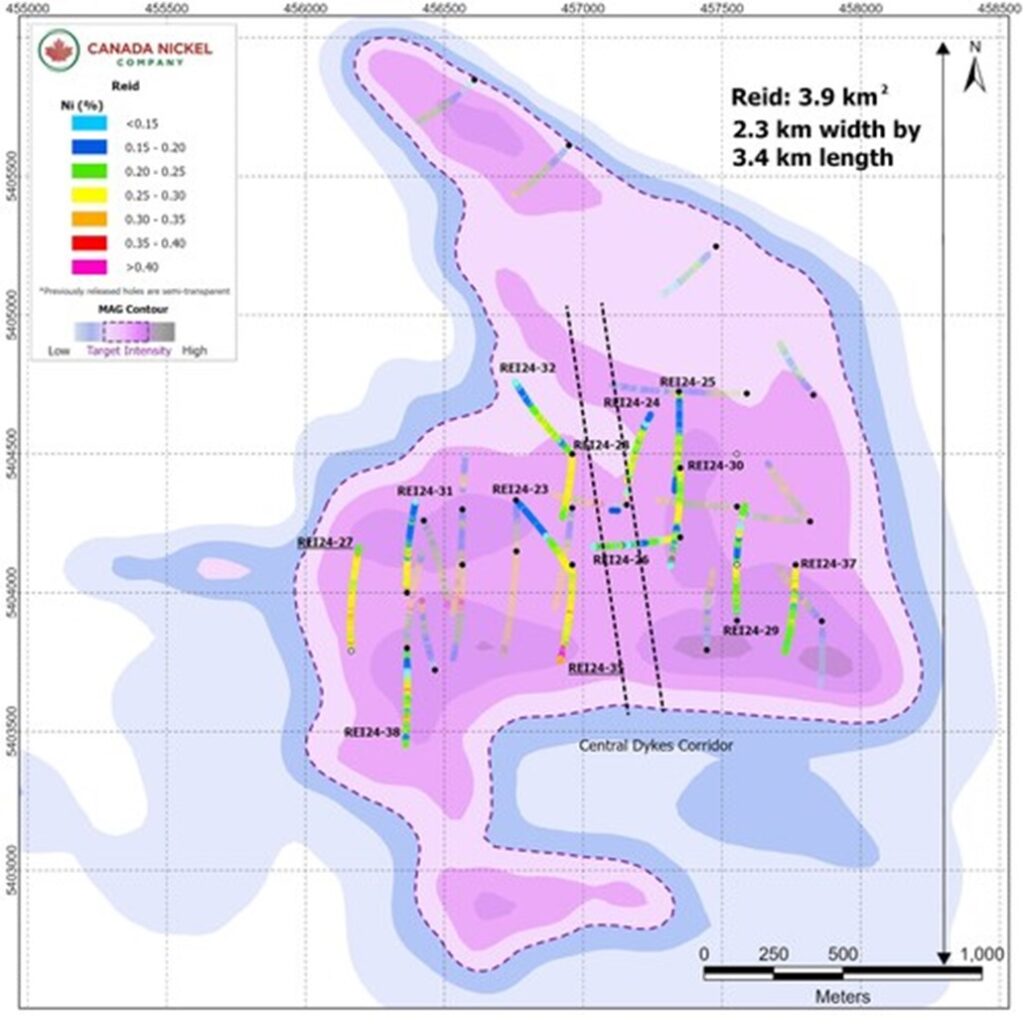

Reid Property

The Reid Property is located just 16 km southwest of Crawford and contains a geophysical target of 3.9 km2, which is nearly 2.4 times larger than Crawford (see Figure 1). The Company expects to complete the first phase of drilling later in August and to produce an initial resource at Reid in Q4 2024. The remaining drillhole assays will be released once they have been received.

Hole REI24-35 was collared near the very center of the ultramafic body and drilled south. The full interval of 661.5 metres, beginning at 40.5 metres downhole, assayed 0.29% nickel including 100.5 metres of 0.42% nickel, and 40.5 metres of 0.51% nickel, ending the hole in strong mineralization. In this area the ultramafic sequence opens to the north and is more than 900 metres wide, roughly twice the width of Crawford’s Main Zone. Hole REI24-27 was collared near the west border of the ultramafic body and drilled north. The full interval of 674.8 metres, beginning at 27.2 metres downhole, assayed 0.27% nickel including 34.5 metres of 0.30% nickel. In this area the ultramafic sequence is more than 800 metres thick, nearly twice that of Crawford’s main zone. Holes REI24-27, REI24-28, REI24-29, REI24-30, REI24-31, REI24-32, REI24-35, REI24-37, REI24-38 were drilled to continue to infill the Central Core area of the deposit with an approximate width of 900 metres and strike length of 1.7 kilometres.

The drilling campaign has identified a NNW-SSE trending corridor of dykes running through the center of the deposit which is approximately 150 metres wide, less than 7% of the overall strike length of 2.2 kilometres in the central core. Holes REI24-23, REI24-24, REI24-25, REI24-26 were drilled to identify the extent of mineralization within the local dunite, and better define the structural controls and extent of the dykes.

Table 1 – Reid drilling downhole composite.

| Hole ID | From (m) | To (m) | Length (m)* | Ni % | Co % | Pd g/t | Pt g/t | Cr % | Fe % | S % |

| Central Core | ||||||||||

| REI24-27 | 27.2 | 702.0 | 674.8 | 0.27 | 0.012 | 0.013 | 0.008 | 0.67 | 5.62 | 0.076 |

| including | 60.0 | 94.5 | 34.5 | 0.30 | 0.013 | 0.024 | 0.007 | 0.66 | 5.76 | 0.110 |

| REI24-28 | 18.6 | 705.0 | 686.4 | 0.26 | 0.012 | 0.010 | 0.006 | 0.84 | 5.90 | 0.023 |

| including | 235.5 | 250.5 | 15.0 | 0.30 | 0.012 | 0.006 | 0.008 | 0.87 | 5.46 | 0.025 |

| REI24-29 | 54.0 | 568.6 | 514.6 | 0.23 | 0.010 | 0.011 | 0.008 | 0.63 | 6.59 | 0.028 |

| and | 642.6 | 696.0 | 53.4 | 0.24 | 0.014 | 0.017 | 0.011 | 0.85 | 7.46 | 0.026 |

| REI24-30 | 30.0 | 702.0 | 672.0 | 0.24 | 0.013 | 0.014 | 0.010 | 0.70 | 6.79 | 0.060 |

| including | 633.0 | 640.5 | 7.5 | 0.42 | 0.018 | 0.080 | 0.040 | 0.63 | 8.13 | 0.288 |

| and | 664.5 | 673.5 | 9.0 | 0.37 | 0.019 | 0.071 | 0.046 | 0.51 | 8.75 | 0.275 |

| REI24-31 | 28.0 | 648.4 | 620.4 | 0.22 | 0.013 | 0.013 | 0.009 | 0.61 | 6.85 | 0.072 |

| including | 31.5 | 340.5 | 309.0 | 0.27 | 0.012 | 0.010 | 0.006 | 0.71 | 6.11 | 0.074 |

| including | 39.0 | 52.0 | 13.0 | 0.41 | 0.014 | 0.026 | 0.014 | 0.69 | 5.68 | 0.075 |

| and | 279.0 | 306.0 | 27.0 | 0.29 | 0.014 | 0.016 | 0.005 | 0.68 | 7.61 | 0.131 |

| REI24-32 | 21.0 | 696.0 | 675.0 | 0.21 | 0.012 | 0.008 | 0.007 | 0.71 | 6.43 | 0.034 |

| including | 166.5 | 421.5 | 255.0 | 0.25 | 0.011 | 0.005 | 0.004 | 0.89 | 5.57 | 0.038 |

| REI24-35 | 40.5 | 702.0 | 661.5 | 0.29 | 0.012 | 0.018 | 0.013 | 0.69 | 5.67 | 0.052 |

| including | 340.5 | 361.5 | 21.5 | 0.34 | 0.013 | 0.221 | 0.094 | 0.66 | 5.85 | 0.074 |

| and | 601.5 | 702.0 | 100.5 | 0.42 | 0.015 | 0.035 | 0.019 | 0.59 | 6.26 | 0.123 |

| including | 645.0 | 685.5 | 40.5 | 0.51 | 0.015 | 0.040 | 0.023 | 0.59 | 6.21 | 0.149 |

| REI24-37 | 42.2 | 697.5 | 655.3 | 0.24 | 0.013 | 0.012 | 0.009 | 0.57 | 6.28 | 0.032 |

| including | 42.2 | 312.0 | 269.8 | 0.27 | 0.013 | 0.023 | 0.018 | 0.60 | 6.19 | 0.029 |

| including | 202.5 | 219.0 | 16.5 | 0.41 | 0.015 | 0.241 | 0.146 | 0.49 | 7.16 | 0.093 |

| REI24-38 | 27.0 | 702.0 | 675.0 | 0.22 | 0.012 | 0.024 | 0.018 | 0.63 | 6.55 | 0.045 |

| including | 238.0 | 550.5 | 312.5 | 0.26 | 0.012 | 0.048 | 0.035 | 0.69 | 6.04 | 0.056 |

| including | 301.5 | 327.0 | 25.5 | 0.32 | 0.012 | 0.009 | 0.006 | 0.78 | 5.97 | 0.078 |

| and | 510.0 | 540 | 30 | 0.33 | 0.012 | 0.174 | 0.229 | 0.74 | 6.16 | 0.103 |

| Central Dyke Corridor | ||||||||||

| REI24-23 | 24.0 | 303.0 | 279.0 | 0.18 | 0.014 | 0.010 | 0.012 | 0.53 | 7.82 | 0.016 |

| and | 343.8 | 564.0 | 220.2 | 0.25 | 0.013 | 0.010 | 0.006 | 0.77 | 7.47 | 0.038 |

| REI24-24 | 78.9 | 94.9 | 16.0 | 0.27 | 0.012 | 0.067 | 0.024 | 0.68 | 5.89 | 0.098 |

| and | 174.1 | 247.2 | 73.1 | 0.25 | 0.012 | 0.006 | 0.005 | 0.83 | 5.61 | 0.036 |

| and | 260.0 | 627.0 | 367.0 | 0.24 | 0.011 | 0.004 | 0.007 | 0.85 | 5.79 | 0.063 |

| and | 674.0 | 705.0 | 31.0 | 0.19 | 0.012 | 0.003 | 0.006 | 0.55 | 7.32 | 0.028 |

| REI24-25 | 28.0 | 312.0 | 284.0 | 0.18 | 0.013 | 0.009 | 0.011 | 0.58 | 7.64 | 0.035 |

| and | 322.7 | 717.0 | 394.3 | 0.23 | 0.012 | 0.008 | 0.007 | 0.78 | 6.13 | 0.034 |

| REI24-26 | 30.6 | 106.5 | 75.9 | 0.27 | 0.011 | 0.016 | 0.013 | 0.77 | 5.47 | 0.034 |

| and | 122.9 | 280.0 | 157.1 | 0.20 | 0.013 | 0.050 | 0.018 | 0.56 | 7.65 | 0.033 |

| and | 321.4 | 488.5 | 167.1 | 0.20 | 0.014 | 0.024 | 0.016 | 0.50 | 8.25 | 0.032 |

| *True width undetermined. All lengths are drillhole lengths. | ||||||||||

Table 2: Drillhole Orientation

| Hole ID | Easting (mE) | Northing (mN) | Azimuth (⁰) | Dip (⁰) | Length (m) |

| REI24-23 | 456758 | 5404333 | 135 | -55 | 564 |

| REI24-24 | 457157 | 5404317 | 0 | -60 | 705 |

| REI24-25 | 457345 | 5404725 | 180 | -60 | 717 |

| REI24-26 | 457350 | 5404200 | 258 | -50 | 528 |

| REI24-27 | 456165 | 5403790 | 0 | -60 | 702 |

| REI24-28 | 456960 | 5404500 | 180 | -70 | 705 |

| REI24-29 | 457555 | 5403900 | 0 | -55 | 696 |

| REI24-30 | 457350 | 5404450 | 180 | -60 | 702 |

| REI24-31 | 456365 | 5404000 | 0 | -60 | 648 |

| REI24-32 | 456960 | 5404500 | 315 | -60 | 705 |

| REI24-35 | 456960 | 5404100 | 180 | -60 | 702 |

| REI24-37 | 457765 | 5404100 | 180 | -60 | 697 |

| REI24-38 | 456365 | 5403800 | 180 | -60 | 702 |

Quality Assurance and Control, Drilling and Assaying

Edwin Escarraga, MSc, P.Geo., a “qualified person” as defined by National Instrument 43-101, is responsible for the on-going drilling and sampling program, including quality assurance (QA) and quality control. The core is collected from the drill in sealed core trays and transported to the core logging facility. The core is marked and sampled at 1.5 metre lengths and cut with a diamond blade saw. One set of samples is transported in secured bags directly from the Canada Nickel core shack to Actlabs Timmins, while a second set of samples is securely shipped to SGS Lakefield for preparation, with analysis performed at SGS Burnaby or SGS Callao (Peru). All are ISO/IEC 17025 accredited labs. Analysis for precious metals (gold, platinum and palladium) are completed by Fire Assay while analysis for nickel, cobalt, sulphur and other elements are performed using a peroxide fusion and ICP-OES analysis. Certified standards and blanks are inserted at a rate of 3 QA/QC samples per 20 core samples making a batch of 60 samples that are submitted for analysis.

Qualified Person and Data Verification

Stephen J. Balch P.Geo. (ON), VP Exploration of Canada Nickel and a “qualified person” as such term is defined by National Instrument 43-101, has verified the data disclosed in this news release, and has otherwise reviewed and approved the technical information in this news release on behalf of Canada Nickel Company Inc.

About Canada Nickel Company

Canada Nickel Company Inc. is advancing the next generation of nickel-sulphide projects to deliver nickel required to feed the high growth electric vehicle and stainless steel markets. Canada Nickel Company has applied in multiple jurisdictions to trademark the terms NetZero NickelTM, NetZero CobaltTM, NetZero IronTM and is pursuing the development of processes to allow the production of net zero carbon nickel, cobalt, and iron products. Canada Nickel provides investors with leverage to nickel in low political risk jurisdictions. Canada Nickel is currently anchored by its 100% owned flagship Crawford Nickel-Cobalt Sulphide Project in the heart of the prolific Timmins-Cochrane mining camp.

Figure 1 – Reid – Drillholes Over Total Magnetic Intensity. (CNW Group/Canada Nickel Company Inc.)

MORE or "UNCATEGORIZED"

Eloro Resources Announces Closing of Bought Deal LIFE Private Placement for Gross Proceeds of C$17 Million

Eloro Resources Ltd. (TSX: ELO) (FSE: P2QM) is pleased to announce the closing of its previously an... READ MORE

Minera Alamos Updates Resources and Reserves for the Pan Gold Mine in Nevada

Minera Alamos Inc. (TSX-V: MAI) (OTCQX: MAIFF) is pleased to announce updated Mineral Resource and M... READ MORE

Ero Copper Reports Fourth Quarter and Full Year 2025 Operating and Financial Results

Ero Copper Corp. (TSX: ERO) (NYSE: ERO) is pleased to announce its operating and financial results f... READ MORE

Rare Element Resources Announces Results of Oversubscribed Rights Offering of Common Shares

Rare Element Resources Ltd. (OTCQB: REEMF) is pleased to report that its previously announced... READ MORE

TRX Gold Reports Record Q2 2026 Production and Company Update

TRX Gold Corporation (TSX: TRX) (NYSE American: TRX) is pleased to announce preliminary resu... READ MORE