Bravo Updates Mineral Resources at its Luanga Project

Bravo Mining Corp. (TSX-V: BRVO) (OTCQX: BRVMF), is pleased to report the results of its 2025 Mineral Resource Estimate at its 100% owned Luanga palladium + platinum + rhodium + gold + nickel deposit, located in the Carajás Mineral Province, Pará State, Brazil. The 2025 MRE shows substantial improvements over the previously reported 2023 MRE (See press release October 22, 2023) using the same metal prices and similar other assumptions.

Highlights of Bravo’s 2025 MRE at a 0.50 g/t PdEq1 cut-off grade:

-

- 154% increase in Measured + Indicated contained PdEq1 ounces

- 117% increase in Measured + Indicated tonnes

- 17% increase in Measured + Indicated PdEq1grades

- 34% increase in Inferred PdEq1 grade

- Measured & Indicated Resources now make up 67% of total resources

- Measured + Indicated resources total 158 million tonnes (“Mt”) grading 2.04 grams per tonne (“g/t”) PdEq1, for a total of 10.4 Moz of PdEq1 contained.

The MRE introduces Measured mineral resource for the first time. The combined Measured + Indicated tonnes have improved by 117% as compared to the Indicated tonnes in the 2023 MRE, while grade has improved by 17%, resulting in a 154% increase in contained PdEq1 ounces. - Inferred Resources of 78 Mt grading 2.01 g/t PdEq1for 5.0 Moz PdEq1.

Tonnes of Inferred resources decreased, as most of previous Inferred tonnages were reclassified to higher-confidence categories while new Inferred resources were added beyond the limits of the prior MRE, and grades improved by 34% in the Inferred category. - Measured & Indicated Resources now make up 67% of total MRE, a significant improvement from the 2023 MRE where 38% of the mineral resource was in the Indicated category.

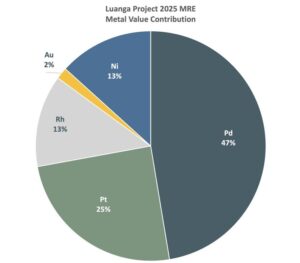

- Relative percentages of each metal by PdEq1 value contribution to the MRE, are estimated at: 47% Pd, 25% Pt, 13% Rh, 13% sulphide Ni, and 2% Au.

- 2025 MRE outcome was achieved using the same metal prices as the prior MRE, somewhat more conservative metallurgical recoveries and otherwise similar modifying factors.

- The MRE remains open at depth along the 8.1km strike of the deposit, with many of the areas below current drilling depths are considered l within potential open pit extraction depths.

“The delivery of our 2025 MRE update is a significant achievement by our team. We have exceeded our own expectations for resource growth in declared tonnes, grade and contained metal, with a considerable increase to the confidence levels in resource categories. The 2025 MRE firmly establishes our Luanga Project as one of the few large-scale, multi-million-ounce, open-pit PGM deposits available globally, in mining friendly, geopolitically favourable locations”, said Luis Azevedo, Chairman and CEO. “Centrally located in the Americas and within reach of major PGM consumers, Luanga also stands out for having access to all essential infrastructure for mining development and operations, including access to cost-efficient renewable power, highways, rail, ports and a skilled mining workforce. With strong community support, as evident in our successful recent public hearing for the permitting process, Bravo Mining is well positioned for continued success, complemented by our continuing copper exploration.”

_________________________________________________________________

1For grades by individual metals, see Table 1 below, where the footnotes also detail the basis of the PdEq1 calculation

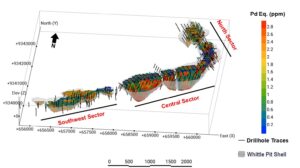

Figure 2: Oblique View of Luanga 2025 MRE PdEq1 grade distribution within constraining pit shell, over 8.1km of Strike. (CNW Group/Bravo Mining Corp.)

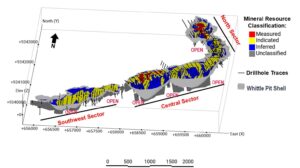

Figure 3: Oblique View of Luanga 2025 MRE within Constraining pit shell, showing resource classification distribution over 8.1km of Strike. (CNW Group/Bravo Mining Corp.)

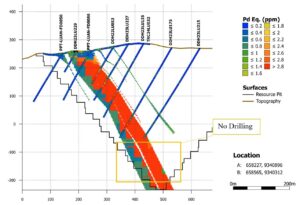

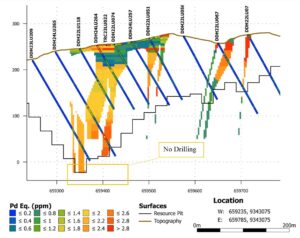

Figure 4: 2025 MRE Section Central Sector. Deepest part of the MRE, showing opportunity to convert additional high-grade Inferred blocks at depth in the MSZ, where blocks are supported by deeper drilling on adjacent sections. Mineralization remains open at depth. (CNW Group/Bravo Mining Corp.)

Figure 5: 2025 MRE Section Southwest Sector, showing MRE constraining pit shell reaching the limit of drilling data, and the presence of additional mineralized zones stratigraphically higher. (CNW Group/Bravo Mining Corp.)

2025 MRE Details:

Bravo’s 2025 pit constrained MRE has an effective date of February 18, 2025, and it is comprised of 158 Mt grading 2.04 g/t PdEq1 for a total of 10.4 Moz of PdEq1 in the Measured + Indicated category, and 78 Mt grading 2.01 g/t PdEq1 for 5.0 Moz PdEq1 in the Inferred category. Table 1 shows a breakdown of the MRE by tonnage, grade and metal content for each metal, weathering type, and resource classification category. Mineral resources that are not mineral reserves do not have demonstrated economic viability. There is no certainty that all mineral resources will be converted into mineral reserves. This MRE includes Inferred Mineral Resources which have had insufficient work to classify them as Indicated mineral resources. It is uncertain but reasonably expected that Inferred mineral resources could be upgraded to Indicated mineral resources with continued exploration.

Table 1: MRE Declaration at a Cut-off of 0.5g/t PdEq1*

| Resource Classification |

Weathering | Average Grades and Contained Metal Estimates | ||||||||||||

| Tonnes | PdEq1 | Pd | Pt | Rh | Au | Ni | ||||||||

| Mt | g/t | Oz | g/t | Oz | g/t | Oz | g/t | Oz | g/t | Oz | % | Tonnes | ||

| Measured | Oxide | 4 | 1.51 | 197 | 0.90 | 117 | 0.88 | 115 | 0.12 | 15 | 0.05 | 7 | — | — |

| High talc | — | — | — | — | — | — | — | — | — | — | — | — | — | |

| Fresh Rock | 32 | 2.06 | 2,144 | 0.97 | 1,009 | 0.67 | 694 | 0.08 | 88 | 0.04 | 46 | 0.11 | 35,282 | |

| Total | 36 | 2.00 | 2,340 | 0.96 | 1,126 | 0.69 | 809 | 0.09 | 104 | 0.04 | 53 | 0.10 | 35,282 | |

| Indicated | Oxide | 6 | 1.51 | 314 | 0.97 | 200 | 0.73 | 151 | 0.11 | 23 | 0.04 | 9 | — | — |

| High talc | 2 | 1.83 | 146 | 1.12 | 89 | 0.54 | 43 | 0.08 | 6 | 0.11 | 9 | 0.13 | 3,160 | |

| Fresh Rock | 113 | 2.09 | 7,599 | 0.99 | 3,583 | 0.59 | 2,133 | 0.09 | 318 | 0.05 | 193 | 0.14 | 156,406 | |

| Total | 122 | 2.06 | 8,058 | 0.99 | 3,872 | 0.59 | 2,326 | 0.09 | 348 | 0.05 | 210 | 0.13 | 159,566 | |

| Measured + Indicated |

Oxide | 10 | 1.51 | 510 | 0.94 | 317 | 0.79 | 266 | 0.11 | 38 | 0.04 | 15 | — | — |

| High talc | 2 | 1.83 | 146 | 1.12 | 89 | 0.54 | 43 | 0.08 | 6 | 0.11 | 9 | 0.13 | 3,160 | |

| Fresh Rock | 145 | 2.08 | 9,743 | 0.98 | 4,592 | 0.60 | 2,827 | 0.09 | 407 | 0.05 | 239 | 0.13 | 191,688 | |

| Total | 158 | 2.04 | 10,399 | 0.98 | 4,998 | 0.62 | 3,135 | 0.09 | 451 | 0.05 | 262 | 0.12 | 194,848 | |

| Inferred | Oxide | 3 | 1.57 | 130 | 0.88 | 73 | 1.04 | 86 | 0.13 | 11 | 0.05 | 4 | — | — |

| High talc | 0.1 | 1.76 | 5 | 1.08 | 3 | 0.53 | 2 | 0.07 | 0 | 0.10 | 0 | 0.14 | 133 | |

| Fresh Rock | 75 | 2.02 | 4,878 | 0.97 | 2,344 | 0.58 | 1,389 | 0.08 | 191 | 0.05 | 123 | 0.13 | 97,586 | |

| Total | 78 | 2.01 | 5,013 | 0.97 | 2,421 | 0.59 | 1,476 | 0.08 | 202 | 0.05 | 128 | 0.13 | 97,719 | |

* Notes:

- The MRE has been prepared by Bernardo Horta de Cerqueira Viana, Geologist, BSc (Geology), FAIG, CEO of GE21 Consultoria Mineral Ltda. and Porfírio Cabaleiro Rodriguez, Mining Engineer, BSc (Mine Eng), FAIG, CKO of GE21 Consultoria Mineral Ltda., both independent Qualified Person (“QP”) for the purposes of National Instrument 43-101 Standards of Disclosure for Mineral Projects (“NI 43-101”). The effective date of the MRE is 18 February 2025.

- Mineral resources are reported using the 2014 CIM Definition Standards and were estimated in accordance with the CIM 2019 Best Practices Guidelines, as required by National Instrument 43-101 Standards of Disclosure for Mineral Projects (“NI 43-101”).

- The MRE Estimate is reported/confined within an economic pit shell generated by Dassault Geovia Whittle software, using the following assumptions:

- Generated from work completed by Bravo and historical test work:

- Metallurgical recovery in sulphide material of 77% Pd, 81% Pt, 51% Rh, 48% Au, 50% Ni to a Ni-PGM concentrate.

- Metallurgical recovery in oxide material of 81% Pd, 23% Pt, 54% Rh, 90% Au to a PGM ash residue (Ni not applicable).

- Metallurgical recovery in high-talc sulphide material of 51% Pd, 55% Pt, 27% Rh, 27% Au, 50% Ni to a Ni-PGM concentrate.

- Independent Geotechnical Testwork – Overall pit slopes of 40 degrees in oxide and 50 degrees in Fresh Rock.

- Densities are based on 27,170 drillhole core and 112 in situ samples density measurements. The Mineral Resources are reported on a dry density basis.

- External downstream payability has not been included, as the base case MRE assumption considers internal downstream processing, with operating costs for downstream processing included in the calculation of the 0.5g/t PdEq1 cut-off used for the declared MRE.

- Payable royalties of 2%.

- Metal Pricing

- For the 2025 MRE, the same pricing regime has been used, as there have been no significant changes in prices. This also allows for a direct comparison between the new 2025 MRE and the now superseded 2023 model (a 10-year trailing average – 2014-2023): Pd price of US$1,380/oz, Pt price of US$1,100/oz, Rh price of US$6,200/oz, Au price of US$1,500/oz, Ni price of US$7.10/lb.

- Palladium Equivalent (“PdEq1“) Calculation:

- The PdEq equation is: PdEq1 = Pd g/t + F1 + F2 + F3 + F4

- Where: F1 = (Ptp*PtR)/(Pdp*PdR) Ptt F2 = (Rhp*RhR)/(Pdp*PdR) Rht F3 = (Aup*AuR)/(Pdp*PdR) Aut F4 = (Nip*NiR)/(Pdp*PdR) Nit

- P = Metal Price

- R = Metallurgical Recover

- Costs are taken from comparable projects in GE21’s extensive database of mining operations in Brazil, which includes not only operating mines, but recent actual costs from what could potentially be similarly sized operating mines in the Carajás. Costs considered a throughput rate of ca. 10Mtpa.

- Mining costs: US$2.00/t oxide, US$3.00/t Fresh Rock. Processing costs: US$9.00/t fresh rock, US$7.50/t oxide. US$1.50/t processed, for General & Administration. US$1.00/t processed for grade control. US$0.50/t processed for rehabilitation.

- Several of these considerations (metallurgical recovery, metal price projections for example) should be regarded as preliminary in nature, and therefore PdEq1 calculations should be regarded as preliminary in nature.

- The current MRE supersedes and replaces the Previous Estimate (2023), which should be no longer relied upon.

- The QP is not aware of political, environmental, or other risks that could materially affect the potential development of the Mineral Resources other than those typical for mining projects at this stage of development, including those listed in the Technical Report dated October 22nd, 2023 and in the Company’s Annual Information Form dated April 22nd, 2024.

- Totals may not sum due to rounding.

Luanga Mineral Resource Estimate

The Luanga deposit mineral resource database consists of 531 drillholes (Bravo + historic drilling) inside the Luanga deposit, with 108,343 metres of drilling between 1992 to 2025. This database includes 107,516 metres of assayed drill intervals at an average interval of approximately 1m per assay interval.

All assayed drill interval lengths of core used in the mineralized domains are HQ diameter diamond drill core in the oxide and NQ2 diameter diamond drill core in fresh rock.

All historic data used for the MRE has been validated statistically to show no significant bias, either by twinned drillholes, extensive re-sampling and assaying of historic drill core, statistical comparison of historical data with Bravo drilling, and by field validation of collar locations. In addition, the MRE included sample assay results from 45 trenches for 8,714 metres and 9,355 assays at an average sampling interval approximately to 1m.

Thirteen mineralized style domains were generated based on position in deposit and geological and metallurgical behaviour, with most of the tonnage contained within the Main Sulphide Zone.

There are no known issues that materially affect the MRE, other than the usual risks faced by any mining project in Brazil or other jurisdictions, such as the risks and uncertainties inherent in mineral exploration and development, environmental, permitting, taxation, socio-economic, marketing, political factors or any additional risks listed in the Technical Report dated October 22nd, 2023, the Company’s Annual Information Form April 22nd, 2024 and “Forward-Looking Statements” section in this news release.

The metallurgical recovery assumptions for the 2025 MRE have been based on results generated from multiple phases of laboratory-scale metallurgical test work including approximately 150 flotation tests conducted for Bravo Mining (2022 – 2025) at independent laboratories in Brazil and Canada.

Oxide recoveries used in the MRE calculation are based on results generated from exploratory and detailed parameter leaching programs (2022 – 2024) performed for Bravo through independent laboratories in Brazil. Refer to Schedule 2 of this press release for further details.

Metal price assumptions were previously derived in the 2023 MRE from the 10-year trailing price averages to smooth out volatility and price cycle movement in each of these metals. For the 2025 MRE, the same pricing regime has been used, as there have been no significant changes in prices. This also allows for a direct comparison between the new 2025 MRE and the now superseded 2023 model.

The current 2025 MRE supersedes and replaces the previous estimate (2023), which should be no longer relied upon.

For illustration purposes, the pie chart below (Figure 1) shows the relative percentages of metal value contribution to the Luanga MRE using ‘grade x metallurgical recovery x metal price’ for each metal.

Based on recoveries and GE21’s estimates of costs, a cut-off grade (“COG“) of 0.5 g/t PdEq1 was determined for reporting the base case of the MRE. Refer to Schedule 1 of this press release for further details on the factors contributing to the COG estimate. A sensitivity analysis of the COG on the MRE, from 0.1 to 1.0 g/t PdEq1, in increments of 0.1 g/t is shown in Table 2.

Table 2: MRE Sensitivity (grade/tonnes/cut-off) with a 0.5g/t PdEq1 selected for the base case.

| MEASURED + INDICATED | INFERRED | ||||

| PdEq1

Cut-off grade |

Tonnes | Recovered Pd/Eq1 |

PdEq1

Cut-off grade |

Tonnes | Recovered Pd/Eq1 |

| (g/t) | Mt | (g/t) | (g/t) | Mt | (g/t) |

| 0.1 | 165 | 1.97 | 0.1 | 80 | 1.96 |

| 0.2 | 164 | 1.99 | 0.2 | 79 | 1.97 |

| 0.3 | 162 | 2.00 | 0.3 | 79 | 1.98 |

| 0.4 | 161 | 2.02 | 0.4 | 79 | 1.99 |

| 0.5 | 158 | 2.04 | 0.5 | 78 | 2.01 |

| 0.6 | 147 | 2.15 | 0.6 | 74 | 2.07 |

| 0.7 | 134 | 2.30 | 0.7 | 67 | 2.23 |

| 0.8 | 124 | 2.43 | 0.8 | 57 | 2.48 |

| 0.9 | 118 | 2.52 | 0.9 | 54 | 2.59 |

| 1.0 | 115 | 2.55 | 1.0 | 53 | 2.61 |

*Notes:

- See footnotes below Table 1 on Page 2.

- The PdEq1 calculation (as defined by the formula in the footnotes below Table 1) includes metallurgical recovery for each metal. Therefore, the PdEq1 grade is one that has a reasonable expectation of what can be recovered after allowing for mining and processing costs and recoveries.

Mineral Resource growth potential

The Company believes that there is further potential to increase this updated MRE at Luanga, as follows:

- The mineralization is open at depth along the entire 8.1km of strike.

- The 2025 MRE generally extends to drilled depths that align with the depths of the Phase 1, 2, 3 and 4 drilling, typically up to 400m below surface in the Central Sector (Figure 4) and approximately 250 metres from surface in the North (Figure 4) and Southwest Sectors and is largely untested below those depths.

- This depth potential can be seen in section in Figure 4, where modelling of Inferred resource block on this section is supported by deeper drilling on the sections on either side, leaving opportunity to further extend mineralization at depth and, on this section (Figure 4), the opportunity to convert Inferred resources to a higher category with infill drilling.

- There are few drill holes that extend below the 2025 MRE constraining pit shell. Drilling in the Phase 1 (completed) program targeted the depth extent of historical drilling (typically up to ~150m), while the Phase 2, 3 and 4 programs tested the extensions of mineralization to >250m below surface. To date, only the Central Sector drilling has reached depths of >300m below surface, with the constraining pit shell still reaching or passing the limit of the drill data (Figure 4). The section shown in Figure 4 in the Central Zone is one of the deepest parts of the 2025 MRE constraining pit shell.

- The cross-section in Figure 5 (Southwest Sector) also shows how the lack of data at depth is restricting the potential for MRE extensions at depth.

- Similarly, in Figure 3, the interpreted continuation of mineralization at depth (unclassified, coloured grey) also demonstrates where deeper drilling is required.

- Many of the deeper drill holes completed by Bravo, the deepest on their individual sections (See examples in press release February 10, 2025), intersected wider and higher-grade mineralization intervals than typical of the MRE. This indicates potential for higher grades and greater widths of mineralization below the limit of the current MRE, with potential for additional tonnage.

- Some of Bravo’s drilling has also intersected mineralized horizons stratigraphically above or below the Main Sulphide Zone (“MSZ”). However, existing drilling in the 2025 MRE does fully test some of these other zones, or their extensions at depth (Figure 5). As a result, they are relatively minor contributors to the 2025 MRE, and present further opportunity, as these mineralized zones may develop into more significant contributors in the future.

About Bravo Mining Corp.

Bravo is a Canadian and Brazil-based mineral exploration and development company focused on advancing its PGM+Au+Ni Luanga Project, as well as our Cu-Au exploration opportunities in the world-class Carajás Mineral Province, Para State, Brazil.

Bravo is one of the most active explorers in Carajás. The team, comprising of local and international geologists and engineers, has a proven track record of PGM, nickel, and copper discoveries in the region and elsewhere. The individuals in the team have successfully taken a past IOCG greenfield project from discovery to development and production in the Carajás.

The Luanga Project is situated on mature freehold farming land and benefits from being located close to operating mines and a mining-experienced workforce, with excellent access and proximity to existing infrastructure, including road, rail, ports, and hydroelectric grid power. Bravo’s current Environmental, Social and Governance activities includes planting more than 30,000 high-value trees in and around the project area in the past 30 months, while hiring personnel and contracting services locally.

Schedule 1: Key Assumptions and Methods Used for the MRE

Variography and Interpolations

Grade estimation for sulphide material was completed using the E-type post-processing of the conditional TBS for each element and each domain. 50 simulations with 400 bands were performed. Raw Variography and raw histogram were validated according to the TBS simulation. No grade variables were capped. The simulations are compared and validated with the OK methodology and Nearest Neighbor Estimation.

The conditional TBS was performed in a block size of 2.5mx2.5mx2.5m and was upscaled for a parental block model of 25mx25mx5m. The parental block model was then sub-blocked with a minimum block size of 3.125m m x 3.125 m x 1.25 m. Grade estimation for oxide material was completed using the OK technique for each element and each domain in the parental block size.

Cut-off Grade

The PdEq1 COG of 0.5 g/t was calculated by taking the all-in cost (oxide and fresh rock) and dividing them by the value of one gram of Pd multiplied by metallurgical recovery. From this a global average COG of 0.5 g/t PdEq1 was calculated.

| COG (PdEq1) | ||

| Oxide | Units | |

| Costs | 14.0 | US$/t |

| DGV1 | 31.95 | US$/g |

| Cut-Off | 0.43 | PdEq1/ g/t |

| Downstream OPEX allowance | 14 | % |

| 2025 Cut-off | 0.49 | PdEq1/ g/t |

| High Talc | Units | |

| Costs | 16.0 | US$/t |

| DGV1 | 35.5 | US$/g |

| Cut-Off | 0.44 | PdEq1/ g/t |

| Downstream OPEX allowance | 14 | % |

| 2025 Cut-off | 0.50 | PdEq1/ g/t |

| Fresh | Units | |

| Costs | 16.0 | US$/t |

| DGV1 | 35.5 | US$/g |

| Cut-Off | 0.44 | PdEq1/ g/t |

| Downstream OPEX allowance | 14 | % |

| 2025 Cut-off | 0.50 | PdEq1/ g/t |

| Avg Cut-off | 0.5 | PdEq1/ g/t |

1 Deposit Grade Value (“DGV”) = (P-Pd/31.1035) * R-Pd

Where: P-Pd = Palladium Price in US$/oz,

R-Pd = Palladium Metallurgical Recovery

Classification of Mineral Resource

A study of spatial continuity for Pd was conducted using variography and conditional simulation to classify mineral resources.

This study established a continuity zone suitable to consider as “Measured Mineral Resources,” with a drilling grid of approximately 45m x 45m, requiring a minimum of 3 drillholes in perpendicular sections.

Establishing a continuity zone of “Indicated Mineral Resources” was considered with a drilling grid of approximately 75m x 75m, with a minimum of 2 drillholes in perpendicular sections. Subsequently, manual post-processing was undertaken to construct wireframes representing the volumes categorized as Measured and Indicated while considering the blocks within the resource pit shell. Any remaining blocks within the resource-limiting pit were classified as “Inferred Mineral Resources.”

Reasonable Prospect for Eventual Economic Extraction

The reported MRE is pit-constrained, using Whittle software to create a pit shell with reasonable prospects for eventual economic extraction. Relevant parameters used in the MRE are shown below the MRE table and include commodity prices used, metallurgical recoveries, geotechnical assumptions, and cost structures.

Further, no known environmental or community matters are likely to constrain the future extraction of the reported MRE.

Schedule 2: Metallurgical Analysis

Metallurgical recoveries used in the MRE calculation are as follows:

- Sulphide (Fresh rock) recovery inputs: Pt 81%, Pd 77%, Rh 51%, Au 48%, Ni 50% (for an ≥80g/t concentrate).

- High talc recovery inputs: Pt 55%, Pd 51%, Au 27%, Rh 27%, (for an ≥80g/t concentrate).

- Oxide recovery inputs: Au 90%, Pd 81%, Rh 54%, Pt 23% (for an ≥80g/t concentrate).

Fresh rock recoveries used in the 2025 MRE calculation are based on results generated from multiple phases of laboratory flotation testwork performed by Bravo (117 flotation tests) and three programs of historical flotation testwork, including two historical pilot plant tests. Results indicate that Luanga mineralization has the metallurgical character to potentially produce saleable PGM + sulphide Ni concentrates at grades in line with grades achieved for PGM operators in established jurisdictions around the world, including concentrate grades of ≥80g/t PGM, 5-10% Ni + Sulphur of 15–20%, at the feed grade range of 2g/t PGM.

Bravo testwork considered geospatially representative samples with feed grades ranging from 0.9 – 7.0 g/t PdEq1. Final concentrate grades produced in the Bravo test work ranged from 37–475 g/t PGM. Metallurgical recovery assumptions are based on target concentrate grade of 80g/t.

Input assumptions for the generation of the MRE constraining pit were derived from a grade-recovery curve based on relevant results generated from the 2022 – 2024 test work programs. Where applicable, specific recoveries have been assigned to geological domains that demonstrate materially different metallurgical character and performance relative to the general mineralization observed across the Luanga deposit.

Mini plant tests were also conducted to generate a wide spectrum of concentrate chemistries for pyrometallurgical evaluation. Metallurgical data generated from the mini plant tests were further incorporated into the MRE assumptions. The sample source for the mini plant were inherited, historical, large diameter diamond cores, drilled into a localized, high talc zone in the SW sector of the Luanga deposit. Recoveries achieved were broadly in line with current assumptions (73% 4E PGM) but due to high talc contamination, target concentrate grade was not achieved under the utilised circuit configuration (35g/t). Recovery assumptions for the high talc zone were domained separately, while recoveries for all other zones are based on an 80g/t concentrate.

The resultant reduced metallurgical recovery assumption of 51% (4E PGM) was assigned to the high talc domain.

Oxide recoveries used in the MRE calculation are based on results generated from two programs (2022 – 2024) of conventional leaching test work performed for Bravo.

The conceptual oxide processing flowsheet has been validated at each processing stage through testwork, including: PGM and Au solubility in the presence of cyanide at ambient temperature/pressure and within reasonable reagent dosage conditions; PGM and Au adsorption onto carbon; Final product generation as saleable high grade PGM ash residue (“ashing” or “ashed” is the burning of the loaded carbon for final mass reduction to an ultra-high grade ash residue) with an assayed average grade of 119,100g/t PGM (or 11.91% PGM). Bravo’s current data demonstrates a reasonable probability for economic recovery of PGM from oxide material at Luanga through conventional cyanide leaching, carbon-in-leach extraction, and high grade ‘ashed’ residue production. The recommendations for oxide metallurgical input into the MRE are based on laboratory-generated data for each stage of processing to a final product, from the Luanga 2022 – 2024 programs. Key factors that have contributed to successful recovery of PGM from oxide material include:

- Intense host rock weathering in oxide and a high degree of naturally liberated PGM, contributing to lower mining and comminution costs.

- High degree of solubility in cyanide, particularly for Pd and Au.

- High PGM absorption kinetics and recovery for PGM onto carbon.

Details of the metallurgical programs and their results will be documented in the Technical Report prepared in accordance with NI 43-101, which will be filed under the Company’s SEDAR profile within 45 days of this news release.

Schedule 3: Geological Interpretation

The Luanga Complex is a 6km long and up to 3.5km wide (~18km²) mafic-ultramafic layered intrusion that belongs to the Neoarchean Large Igneous Province (“LIP”) of the Carajás Mineral Province. Host rocks of the Luanga Complex consist of highly foliated gneisses and migmatites of the Xingu Complex and mafic volcanics plus iron formations of the Grão Pará Group. The igneous layers have consistent steep dips to the SE in the Central and Southwestern portions of the complex, indicating that the layered sequence is tectonically overturned. The Luanga complex is up to 3,500m thick in the central portion of the complex, which is likely to represent the axial portion of the original magma chamber. Metamorphic assemblages are at the transition of greenschist to amphibolite facies and commonly replace the primary igneous minerals of the Luanga complex. This metamorphic alteration is heterogeneous, largely preserving primary textures, bulk rock compositions and the compositional domains of igneous minerals, thus allowing the identification of primary rocks throughout the intrusion. The layered sequence is subdivided based on the different type and/or proportion of cumulus minerals in three zones, Ultramafic Zone (“UZ”), Transition Zone (“TZ”) and Mafic Zone (“MZ”).

The UZ is up to 800m thick and consists of wehrlite (Olivine (“Ol”) + Clinopyroxene (“Cpx”) cumulates) and lesser dunite and Cpx. The contact of the UZ with the stratigraphically overlying TZ is indicated by a few meters thick upward transition from Cpx bearing cumulates to Opx bearing cumulates (orthopyroxenite (“Opx”) and minor harzburgite(“Hz”)) in the TZ. Typically, ultramafic rocks of the TZ are partially to extensively altered, consisting mainly of serpentinites. The UZ follows the stratigraphy of the Luanga complex but at the northern portion the UZ occurs as discordant irregular zones of variably altered ultramafic cumulates within host rocks.

The TZ consists of an up to 500m thick pile of interlayered ultramafic and mafic cumulate rocks. Interlayering of different rock types is a distinctive feature of the TZ. Cumulate rocks have variable textures, from adcumulate to orthocumulate, and variable assemblages of cumulus and intercumulus minerals. The most common rock types are Opx and lesser interlayered norite and Hz. Chromitite layers with variable thickness (commonly 10cm but up to 60cm) and textures occur mainly in the upper portions of the TZ and the lowermost portion of the MZ. Chromitites are fine- to medium-grained chromite cumulates with variably altered intercumulus plagioclase (“Pl”) and orthopyroxene.

The MZ, about 5km long and up to 1.5km thick, comprises a thick monotonous pile of noritic rocks. Norite (Opx + Pl cumulate) consists of medium-grained massive rocks variably altered to fine-grained aggregates consisting mainly of amphiboles (hornblende-actinolite), chlorite and epidote-group minerals. Minor interlayered ultramafic rocks in the MZ, including Opx and minor chromitite, have petrographic features like those described in the TZ.

The Luanga mineralized envelope is continuous along the arc-shaped structure of the mafic-ultramafic complex, striking for approximately 8.1km. The deposit is subdivided into three separate mineralized sectors, named North, Central and Southwestern. The mineralized envelope of the Luanga Complex hosts several PGM mineralized zones, including the Main Sulphide Zone (“MSZ”), which hosts the bulk of current mineral resources. Other mineralized zones are identified within the UZ, the TZ, as well as mineralization hosted in chromitites layers or lenses distributed within the TZ and the immediate contact with the overlying MZ.

Mineralized zones of the Luanga complex are grouped into six different styles of PGM mineralization: (1) MSZ; (2) Low Sulphide Zone (“LSZ”); (3) Chromite-associated Zone (“Chr-PGM”); (4) Ni-Rh Sulphide Zone (“Ni-Rh”); (5) Sulphide Zone (“SZ”) and (6) Massive Sulphides (“MASU”).

- MSZ: PGM mineralization associated with disseminated sulphides in the MSZ hosts the bulk of PGM+Au+Ni mineral resources of the Luanga complex. The stratigraphic interval hosting the MSZ consists of a 10–50m thick interval with disseminated sulphides located along the contact of the UZ and TZ. The MSZ is stratabound-style PGM mineralization consisting of interstitial sulphides (~1-5 vol.%) hosted by Opx and minor Hz. The MSZ is characterized by very high Ni tenors (10-15%) and Pt-Pd (up to 100 ppm) tenors (content of 100% sulphides), Pt/Pd < 0.5, and Pd/Rh ~0.05.

- Low Sulphide Zone (“LSZ”). The LSZ style of mineralization comprises PGM-mineralized rocks devoid of base metal sulphides and/or abundant chromite. The LSZ mineralization of the Luanga Complex consists of up to 30m thick stratabound zones across the TZ. These zones do not show extensive lateral continuity and commonly occur at the contact between layers of distinct cumulate rocks. The host rocks, mainly Hz and Opx, do not show any distinctive texture or change in modal composition that characterizes the PGM enrichment. The LSZ is characterized by very low Ni content, Pt-Pd contents < 1-2 ppm, and Pt/Pd ~ 1.0-2.0. Pt-Pd show moderate to strong positive correlation.

- Chromite-associated Zone (“Chr-PGM”). Chr-PGM mineralization occurs as chromitite pods (< 60cm thick) closely associated with intersections containing disseminated clusters of chromite within Opx, Hz and norite. The Chr-PGM style of mineralization is characterized by very low Ni content, high Pt/Pd ratio (~4.0), and Rh/Pt ~0.3.

- Ni-Rh Sulphide Zone (“Ni-RhZ”). The Ni-RhZ mineralized zone has been identified only within the UZ and occurs as lenses of disseminated to net-textured sulphides (up to 25%) interstitial to cumulus Cpx and Ol or their pseudomorphs. Ni-Rh zones have variable thicknesses (up to 40 m) and are commonly hosted by interlayered wehrlite and dunite, and minor clinopyroxenite. Ni-RhZ mineralization has Pt/Pd and Rh/Pd ratios of around 0.15 and 0.20, respectively. The high modal percentage of pentlandite (i.e. around 30-40% of the total sulphides) indicates very high Ni tenor (~10-12%) for the Ni-Rh zones.

- Sulphide Zone (“SZ”). The SZ mineralization style is recognized exclusively in the Northern sector, characterized by mineralized bands of variable thickness hosted in rocks of the TZ. SZ occurs as several irregular north-south trending zones of disseminated sulphides hosted mainly in Opx. The SZ is characterized by moderate to high PGM contents (30-40 m intercepts with 2-3 g/t of Pt + Pd) with predominantly low Pt/Pd ratios (commonly < 0.5, but up to 1.0) and variable Ni contents (up to 0.20%). Weak positive correlation between Pd-Ni and Pd-Rh possibly results from variably altered sulphides.

- (vI) Massive Sulphide Zone (“MASU”). The MASU is a new zone and style of mineralization identified by Bravo during infill drilling. A robust intercept of MASU (DDH22LU047 – 11m at 4.24 g/t 3PGM+Au, 2.04% Ni, 1.23% Cu) occurs within a hydrothermal alteration zone at the eastern border of the North sector. Host rocks and the footwall sequence of the MASU intercepted in DDH22LU047 consist of massive rocks with variable proportions of amphibole-garnet-biotite-magnetite, and banded iron formation. Sulphide-bearing Opx and interlayered norite occur above the MASU and in adjacent drill holes. Cumulate rocks close to the alteration zone are partially to pervasively replaced by Fe-Ca-K hydrothermal minerals, including MASU to semi-MASU breccias. Sulphides consist mainly of pyrrhotite (~80-90%) and pentlandite (~10-20%) with local chalcopyrite-rich domains (up to 60-70% cpy). Pentlandite occurs mainly associated with po as fine-grained exsolutions (e.g., flames, flakes). MASU has variable contents of Ni, Cu and PGM, generally with Ni>Cu and Pd>Pt. Except for the broad positive correlation between Ni and Pd, correlations between metals are only subtle, including Pd-Pt, Ni-Cu and Pd-Rh. Contents of Ni (< 6.0%), Pd (< 6.0 ppm), Pt (< 2.5 ppm) and Rh (0.2 ppm) in samples of MASU provide approximate tenors for these metals in this style of mineralization.

The bulk of the world’s PGM resources are mined from mafic-ultramafic layered intrusions, commonly from stratiform mineralized layers located near the transition from mafic to ultramafic cumulate rocks. Magmatic Ni-Cu-PGM sulphides formed by the accumulation of immiscible sulphide liquid, that scavenged chalcophile elements from a coexisting silicate magma. Textural relationships between sulphides and their host silicates are key evidence for their origin as immiscible sulphide liquids. The magmatic origin of the Luanga deposit is supported by textural and mineralogical features described in different styles of PGM mineralization, particularly the MSZ, Ni-Rh and SZ. In these different PGM zones, sulphide blebs consisting of pyrrhotite + pentlandite ± chalcopyrite are interstitial to cumulus olivine and/or pyroxene. In addition, sulphide blebs enclosed in cumulate crystals, as well as their rounded/corroded faces, provide unequivocal evidence for a magmatic origin of sulphides and PGM. Variable litho-chemical features in PGM zones located in distinct stratigraphic horizons of the Luanga complex, including different metal tenors, as well Pt/Pd and Rh/Pd ratios, indicate that several events of mineralization occurred during the magmatic evolution of the Luanga complex. The occurrence of several mineralized horizons in the Luanga complex, including PGM mineralization hosted in chromitites, has remarkable similarity with reef-type productive deposits (e.g., Bushveld and Stillwater).

The widespread alteration of rocks from the Luanga complex has partially disrupted their primary magmatic features. In the Luanga complex, magmatic silicates are partially altered and commonly occur as pseudomorphs. The magmatic sulphides have also been partially altered during the widespread alteration. The most common alteration of primary sulphides (pyrrhotite – pentlandite – chalcopyrite) consists of their replacement by magnetite and Fe-hydroxides. Because this alteration is heterogeneous at different scales (from mineral crystals up to several hundred meters thick zones) and largely preserves primary textures and compositions of cumulate rocks and PGM mineralized zones, magmatic features can be recognized throughout the layered intrusion.

Schedule 4: Assay Methodologies and QAQC

Samples follow a chain of custody between collection, processing, and delivery to the SGS Geosol laboratory in Parauapebas, state of Pará, Brazil. The drill core is delivered to the core shack at Bravo’s Luanga site facilities and processed by geologists who insert certified reference materials, blanks, and duplicates into the sampling sequence. Drill core is half cut and placed in secured polyurethane bags, then in security-sealed sacks before being delivered directly from the Luanga site facilities to the Parauapebas SGS Geosol laboratory by Bravo staff. Additional information about the methodology can be found on the SGS Geosol website (SGS) in their analytical guides. Information regarding preparation and analysis of historic drill core is also presented in the table below, where the information is known. Historical drilling used a similar QAQC procedure, and as described in the section “Luanga Mineral Resource Estimate”. Data generated by this work has been validated statistically to show no significant bias, prior to inclusion.

Quality Assurance and Quality Control (“QAQC“) is maintained internally at the lab through rigorous use of internal certified reference materials, blanks, and duplicates. An additional QAQC program is administered by Bravo using certified reference materials, duplicate samples and blank samples that are blindly inserted into the sample batch. If a QAQC sample returns an unacceptable value an investigation into the results is triggered and when deemed necessary, the samples that were tested in the batch with the failed QAQC sample are re-tested.

| Bravo SGS Geosol | ||||

| Preparation | Method | Method | Method | Method |

| For All Elements | Pt, Pd, Au | Rh | Sulphide Ni | Trace Elements |

| PRPCLI (85% at 200#) | FAI515 | FAI30V | AA04B | ICP40B |

| Historic Drill Assaying SGS Geosol | ||||

| Preparation | Method | Method | Method | Method |

| For All Elements | Pt, Pd, Au | Rh | TOTAL Ni | Trace Elements |

| Crushed to <200 mesh | FA30A | FA30B | ICP-117 | ICP-117 |

MORE or "UNCATEGORIZED"

Eloro Resources Announces Closing of Bought Deal LIFE Private Placement for Gross Proceeds of C$17 Million

Eloro Resources Ltd. (TSX: ELO) (FSE: P2QM) is pleased to announce the closing of its previously an... READ MORE

Minera Alamos Updates Resources and Reserves for the Pan Gold Mine in Nevada

Minera Alamos Inc. (TSX-V: MAI) (OTCQX: MAIFF) is pleased to announce updated Mineral Resource and M... READ MORE

Ero Copper Reports Fourth Quarter and Full Year 2025 Operating and Financial Results

Ero Copper Corp. (TSX: ERO) (NYSE: ERO) is pleased to announce its operating and financial results f... READ MORE

Rare Element Resources Announces Results of Oversubscribed Rights Offering of Common Shares

Rare Element Resources Ltd. (OTCQB: REEMF) is pleased to report that its previously announced... READ MORE

TRX Gold Reports Record Q2 2026 Production and Company Update

TRX Gold Corporation (TSX: TRX) (NYSE American: TRX) is pleased to announce preliminary resu... READ MORE