Atlas Critical Minerals Reports Strong Initial Graphite Recovery of 96.6% in Its Minas Gerais Project

Atlas Critical Minerals Corporation (OTCQB: JUPGF) is pleased to report that initial processing and analytical characterization of its natural graphite ore from the Company’s 100%-owned Minas Gerais Graphite Project achieved up to 96.6% of graphite recovery. Surface samples contained up to 15.4% of graphitic carbon. The Project comprises 1,258 hectares in two mineral rights located in the state of Minas Gerais, Brazil. SGS Canada, Inc. was retained to prepare technical reports under U.S. Regulation S-K 1300. In particular, Marc-Antoine Laporte and Yann Camus from SGS are Qualified Persons for the Project. SGS is well-known as a global leader in testing, inspection and certification of mineral properties and projects.

Figure 1 shows a representative sample from the Project area which displays the distinctive metallic sheen typical of graphitic material.

Figure 1 – Surface sample (SMAL-00007) with graphitic carbon grade of 13.37%.

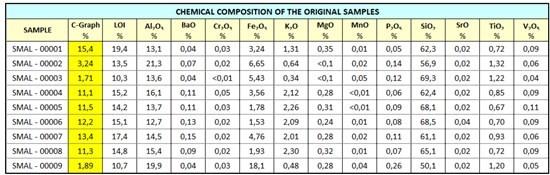

Geochemical analysis was carried out at SGS Geosol, an affiliate of SGS, considered to be the premier analytical laboratory in Brazil and used by major mining companies. Initial results revealed up to 15.4% for the content of graphitic carbon as shown in Table 1.

Table 1: Samples head grade. Source: SGS Report 4181-2503

The principal objective of the scoping level metallurgical test program was to design an initial concentration flowsheet to upgrade the graphite content into a commercially-viable concentrate grading range. The concentration tests were carried out using representative samples collected during the 2025 sampling campaign. The metallurgical tests described in this press release were performed by SGS Geosol, an affiliate of SGS, using 50 kg of representative samples from the Project. The process included rougher flotation, regrinding, and five stages of cleaning with two attrition stages in between. There were no circulating loads, and all flotation tailings were final.

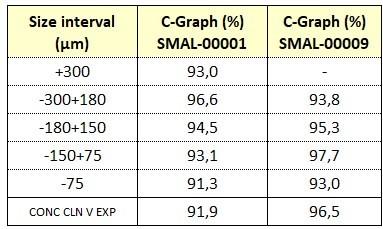

The samples of the highest (15.4%; sample SMAL-00001) and lowest (1.89%; sample SMAL-00009) graphitic carbon content were used in the testing. The main objective of testing these two samples was to ensure the experimental conditions were suitable for the range of the Project’s ore, in order to produce a final concentrate of high grade. The flotation concentrates generated by samples SMAL-00001 and SMAL-00009 were analyzed on a size-size basis. The results summarized in Table 2 indicate that all granulometric ranges achieved grades between 91.3% and 97.7% graphitic carbon.

Table 2: Final Product*. Source: SGS Report 4181-2503

* All carbon analyses were reported as graphite carbon (“C-graph”). The analytical methods that were used to determine the metallurgical results included total carbon analysis by Leco on the final concentrates.

Using conventional flotation, regrinding and attrition techniques, the final graphite concentrates achieved impressive grades of 91.9% and 96.6% total graphite carbon, demonstrating the strong potential of the Project. Figure 2 shows the final material recovered from concentration of the Company’s samples.

Figure 2 – Final Product – Floated material and filtered material after vacuum filtration.

About SGS Metallurgical Services

SGS Geosol Metallurgical group is recognized as a world leader in the development of concentrator flowsheet design and pilot plant testing programs, and has extensive experience in the development of processing routes for graphite ores. The information pertaining to the metallurgical test program presented in this press release has been reviewed by Orivaldo Savassi, PhD, technical director at SGS Geosol.

About Atlas Critical Minerals Corporation

Atlas Critical Minerals Corporation controls a large portfolio of critical mineral rights in Brazil, encompassing over 575,000 acres, and including projects in rare earths, titanium, and graphite – minerals essential for defense applications and electrification. Additionally, we own a quarry for high-quality quartzite and one of our iron ore projects is expected to start production during 2025.

MORE or "UNCATEGORIZED"

Eloro Resources Announces Closing of Bought Deal LIFE Private Placement for Gross Proceeds of C$17 Million

Eloro Resources Ltd. (TSX: ELO) (FSE: P2QM) is pleased to announce the closing of its previously an... READ MORE

Minera Alamos Updates Resources and Reserves for the Pan Gold Mine in Nevada

Minera Alamos Inc. (TSX-V: MAI) (OTCQX: MAIFF) is pleased to announce updated Mineral Resource and M... READ MORE

Ero Copper Reports Fourth Quarter and Full Year 2025 Operating and Financial Results

Ero Copper Corp. (TSX: ERO) (NYSE: ERO) is pleased to announce its operating and financial results f... READ MORE

Rare Element Resources Announces Results of Oversubscribed Rights Offering of Common Shares

Rare Element Resources Ltd. (OTCQB: REEMF) is pleased to report that its previously announced... READ MORE

TRX Gold Reports Record Q2 2026 Production and Company Update

TRX Gold Corporation (TSX: TRX) (NYSE American: TRX) is pleased to announce preliminary resu... READ MORE