Allied Critical Metals Intersects 12 Metres of 4.27% Tungsten (WO3) Incl. 6 Metres of 8.39% Tungsten (WO3) at Its 100% Owned Borralha Tungsten Project in Northern Portugal

Highlights:

- Drill hole Bo_RC_14/25 intersects 12.0 metres @ 4.27% WO3 including 6.0 metres @ 8.39% WO3 from 252.00 metres downhole, confirming one of the highest-grade tungsten intercepts reported in Western exploration, especially for high quality wolframite tungsten mineralization. This validates early visual observations and supports the presence of a controlled high-grade breccia corridor.

- Over 2,500 metres of drilling completed across nine holes, with multiple intercepts of visible wolframite and chalcopyrite. The remaining 1,600 metres of the 4,200 metre campaign now underway with a further fully funded 1,528 metres now also planned with two rigs active on site.

- Tungsten price reaches high of $545 USD/MTU, up approximately 40% in last 4 months as demand for the critical mineral increases with further supply chain restrictions from non-Western countries.

Allied Critical Metals Inc. (CSE: ACM) (OTCQB: ACMIF) (FSE: 0VJ0), which is focused on its 100% owned past producing Borralha and Vila Verde tungsten projects in northern Portugal, is pleased to announce an update on its ongoing 4,200-metre Reverse Circulation drill program at the Borralha Tungsten Project. The initial phase of the campaign was launched in early June 2025 and continues to deliver strong technical progress, supporting: (i) an updated Mineral Resource Estimate, anticipated in Q4 2025; (ii) advanced metallurgical testing; and (iii) the Company’s Preliminary Economic Assessment for a large scale processing facility located at Borralha, targeted for completion later this year. A further fully funded 1,528 metre drilling is now also planned for the fourth quarter of 2025 to build off of the successes in July.

High-grade results from drill hole Bo_RC_14/25 marks a breakthrough for the Borralha Project, with further drilling and a Preliminary Economic Assessment already underway. The results are particularly timely as tungsten price has reached a new high of $545 USD/MTU, which is an increase of approximately 40% over the past four months as demand for the critical mineral increases in the face of further supply chain restrictions from non-Western countries [Source: FastMarkets].

Roy Bonnell, CEO & Director of Allied, commented, “These initial assay results are a major step forward for the Borralha Project and a clear validation of our geological model. The exceptional tungsten grades intersected in Bo_RC_14/25 place Borralha among the most exciting undeveloped critical mineral assets in Europe. As we advance toward the Mineral Resource update and Preliminary Economic Assessment, these results strengthen our confidence in Borralha’s potential to become a cornerstone of Western countries’ strategic raw material supply.”

As of July 30, 2025, Allied had completed approximately 2,500 metres of drilling across nine drill holes. Drilling operations were temporarily paused during August in compliance with seasonal fire safety restrictions and successfully resumed on September 1, 2025. The program continues to advance towards its objectives, with a clear focus on three key technical priorities:

- Expanding and upgrading the existing tungsten resource in accordance with National Instrument 43-101-Standards of Disclosure for Mineral Projects (“NI 43-101”), with emphasis on increasing tonnage and converting Inferred Resources to Indicated Resources classification; and

- Collecting representative material for metallurgical testing, to validate marketable concentrate grades at 65% WO₃.

Overview of Drilling to Date:

- Drill hole Bo_RC_14/25 confirmed the presence of high-grade tungsten mineralization, with visual observations of massive wolframite supporting the interpretation of a potentially enriched corridor within the breccia-hosted system.

- Drill hole Bo_RC_15/25 aimed to access the west deep step-out potential at the south area of the breccia. Visual inspection confirmed the presence of breccia together with evidence of wolframite. Assays of this drill hole are ongoing.

- Drill holes Bo_RC_16/25 and Bo_RC_17/25 are infill drillholes to increase the Resource resolution and knowledge of the interchange between the large bulkable medium grade central backbone of the south area of the breccia, into the medium size high-grade corridors deeper to west. As expected, breccia with visible mineralization was visible, and the pending assays results will provide proper interpretation.

- Drill holes Bo_RC_18/25 , Bo_RC_19/25 and Bo_RC_26/25 are infill drillholes at the central and lower grade area of the Breccia. Here the goal was to improve the Resource model resolution and grade at this section. Some visible mineralization was identified, but the pending assays are necessary to confirm the potential upgrade.

- Drill holes Bo_RC_21/25 and Bo_RC_22/25 are drillholes meant to step-out the previous discovery of a potential new high-grade large corridor at the Bo_RC_11/24 drill hole that has no resources due to lack of composites pairs. Both drillholes encountered continuous breccia and multiple zones with visible sulphides and polymetallic indicators, including wolframite and chalcopyrite, reinforcing the continuity and depth of the mineralized system. Pending assays will confirm if a new economical vector for considerable Resource expansion is present at the north deep area of the breccia.

Table 1 – Collar locations

| New ID | Coordinates (WGS84) | Az.(º) | Dip .(º) | DEPTH (m) | |

| Bo_RC_14/25 | 585445 | 4611405 | 109 | 80 | 265.00 |

| Bo_RC_15/25 | 585347 | 4611368 | 109 | 70 | 255.00 |

| Bo_RC_16/25 | 585406 | 4611329 | 105 | 60 | 251.00 |

| Bo_RC_17/25 | 585426 | 4611295 | 109 | 75 | 237.00 |

| Bo_RC_18/25 | 585461 | 4611431 | 109 | 75 | 241.00 |

| Bo_RC_19/25 | 585470 | 4611493 | 109 | 82 | 247.00 |

| Bo_RC_21/25 | 585484 | 4611552 | 109 | 85 | 370.00 |

| Bo_RC_22/25 | 585484 | 4611552 | 109 | 70 | 375.00 |

| Bo_RC_26/25 | 585586 | 4611449 | 289 | 60 | 287.00 |

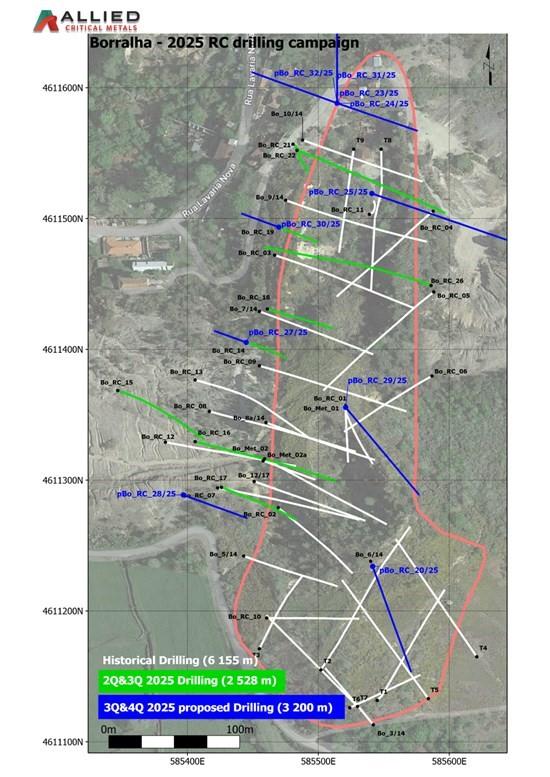

Figure 1 – Drill collar plan showing planned holes for the ongoing 5,728 m RC campaign at the Borralha Project. The red outline delineates the main mineralized breccia zone.

All samples from the nine completed drill holes have been dispatched to ALS Laboratories in Seville for geochemical analysis, with initial assay results now beginning to return. The first results received from hole Bo_RC_14/25 confirm the presence of tungsten mineralization, consistent with earlier visual observations. Additional assay results from the remaining holes are expected over the coming weeks.

Building on Visual Confidence with Excellent Drill Results

The early stages of the 2025 RC drill campaign at Borralha Project were marked by highly encouraging visual intercepts across several holes. With the arrival of the first assays, that confidence has now been materially validated. Initial data confirms not only the continuity of breccia-hosted mineralization but also suggests that the Borralha Project hosts very high-grade tungsten intercepts as described below.

The results from the Bo_RC_14/25 drill hole represents a major technical milestone for Allied. The grade and length of the intercept reinforce the Company’s position that the Borralha Project is one of Europe’s most strategically important undeveloped tungsten assets. These assays will feed directly into the upcoming Mineral Resource Estimate (MRE) and Pre-Economic Assessment (PEA), both of which are expected to underpin Allied’s near-term development plans.

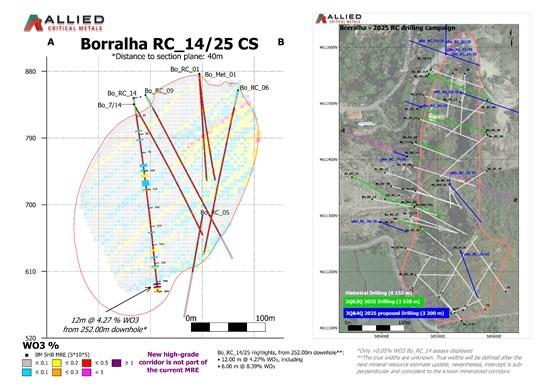

Assay Highlights from Bo_RC_14/25 include, from 252.00m downhole:

- 12.0 m @ 4.27% WO₃*, including

- 6.0 m @ 8.39% WO₃*

*WO3 Tungsten trioxide % converted from W ppm multiplied by 1.2611 stoichiometric factor. W ppm results are from ALS Laboratories analytical method ME-MS81. For the ME-MS81 above detection limit of >10,000 ppm assays, ME-XRF15c is used.

A geological cross section for hole Bo_RC_14/25 is presented below, illustrating the location of the high-grade intercept within the broader breccia-hosted mineralized zone. The section highlights the continuity of the tungsten-bearing structures, the correlation with visual observations, and the potential for further extensions at depth and along strike.

Figure 2 – Geological Cross-Section for hole Bo_RC_14/25.

Technical Information and Quality Control / Quality Assurance

Drillholes were all conducted with RC diamond bit drilling. All sample bags were pre-marked prior to drilling. They were each identified with an internal sequence number used as a sample identifier, both the sample for analysis and its reject samples. Each analytical sample bag is filled with a portion of 2 m length of drilled rock and each reject sample bag will take another representative portion of 1 m length of drilled rock. Thus, each two reject samples will be the equivalent to one assay sample. The splitting is done as part of the drilling process using a rotary splitter.

The analytical samples were collected directly from the rig splitter according to a sampling list that documented the metres and sampling sequence for each drill hole. This list also identified which sample should be collected in duplicate as well as which certified reference material (‘CRM’) were to be placed in the numerical sequence. The CRMs were randomly inserted at every 20 samples (5%), and duplicate samples were collected every 20 samples (5%). Thus, there’s an alternating CRM and Duplicate every 10th sample.

The analytical and reject samples are then transported in boxes from the drilling site to the core shed by a designated employee. The analytical samples were stored on labelled palettes for later direct shipping to the ALS preparation laboratories in Seville, Spain. Later, the pulp and reject samples were securely stored in the logging room on the property.

To the best of the Company’s knowledge, no drilling, sampling, recovery, or other factors exist that would materially compromise the accuracy or reliability of the referenced data

RC samples were prepared by ALS preparation laboratory in Seville, Spain, crushing the sample with up to 70% of the material passing a 2 mm screen, and then each sample was split to 250 g and pulverized with hardened steel to 85% passing a 75 μm screen. Each resultant sub-sample was then direct shipped to their certified assay laboratory Dublin Road, Loughrea, Co., Ireland.

The samples are analyzed by the ME-MS81 ALS method that applies a lithium borate fusion to the sample and the result of this fusion is measured by applying an ICP-MS. It is also applied to the ALS ME-4ACD81 procedure which reports base metals by a 4-acid digestion and later analyzed by an ICP-MS procedure. Any over-limit tungsten values were re-analysed at the same laboratory by a W-XRF15b procedure that uses a lithium borate fusion with an XRF analysis. The analytical results were then securely emailed to the Company.

Qualified Person’s Statement and Data Verification

The scientific and technical information in this news release has been reviewed and approved by Mr. Vítor Arezes, BSc, MIMMM (QMR), Vice-President Exploration of Allied Critical Metals, who is a Qualified Person for the purposes of National Instrument 43-101 – Standards of Disclosure for Mineral Projects. Mr. Arezes is not independent of Allied Critical Metals as he is an officer of the Company.

The Qualified Person has verified the data disclosed herein by reviewing core logs and drill records, validating collar and downhole survey data, assessing database integrity, reviewing assay QA/QC (CRMs, blanks, and duplicates), and reconciling reported intervals to the original laboratory certificates. The verification did not identify any factors that would materially affect the accuracy or reliability of the information presented.

Project Momentum and Strategic Positioning

The drill program is a cornerstone of Allied’s strategy to position Borralha as Europe’s leading high-grade tungsten development, combining grade, scale, and near-term production potential in a secure EU jurisdiction. With tungsten designated as a Critical and Strategic Raw Material by both the European Union and the United States, Borralha directly addresses Western supply vulnerabilities at a time of rising global demand and constrained Chinese exports. As one of the only advanced-stage tungsten assets in Western Europe, Borralha is uniquely placed to support defense readiness, AI, EVs, and the EU’s Critical Raw Materials Act objectives for domestic sourcing.

This campaign also supports Allied’s permitting and development milestones, including the submission of additional technical information in response to follow-up questions from the Environmental Impact Assessment (EIA) evaluation committee–a standard step in the review process. The Company expects to deliver its formal response by third quarter of 2025, with a final decision anticipated in fourth quarter of 2025 or early first quarter of 2026.

Next Steps

Allied is now preparing to complete the final 1,600 metres of drilling to reach the planned total of 4,200 metres for the current Phase 1 campaign. The remaining holes, including Bo_RC_20/25, Bo_RC_23/25, and Bo_RC_24/25 and Bo_RC_25/25, have been selected based on strong visual intercepts, structural continuity, and geological insights from previously completed drilling. Minor adjustments to the drill plan are being implemented to maximize coverage of key mineralized corridors while maintaining program efficiency. In addition, a further 1,528 metres drilling is now also planned for the fourth quarter of 2025 to build off of the successes in July.

Following a scheduled pause in August due to the regional fire season, drilling resumed on September 1 with two rigs operating simultaneously. The campaign has quickly regained momentum and remains on track to complete the targeted meterage within the planned timeframe. Field operations continue to run efficiently, positioning Allied to generate the technical data required for the upcoming Mineral Resource Estimate (MRE) update and Preliminary Economic Assessment (PEA).

New Advisory Role; Other Corporate

The Company is announcing that Colin Padget has resigned his position as director effective September 1, 2025, but is being retained as an advisor to the Company going forward. The Company wishes to thank Colin for his contributions and looks forward to his continued involvement as an advisor to the Company.

In addition, the Company prematurely announced the grant of stock options (Options) and restricted share units (RSUs) in its news release dated September 2, 2025. In light of the drill results in this press release, the Company is postponing the grant to a future date.

About Tungsten

It is critical to understand the difference between wolframite mineralization of tungsten and scheelite mineralization of tungsten. Scheelite often reports higher grades (0.3%-1.0% WO₃) but is more costly and complex to process, requiring flotation methods with higher capital and operating expenditures and lower recoveries.i In contrast, wolframite, which is the focus of Allied Critical Metals can be processed more efficiently using gravity and magnetic separation, resulting in lower costs and higher recoveries, making lower grades (~0.15%-0.25% WO₃) economically viable in wolframite deposits.ii For example, a wolframite deposit with 0.4% WO₃ over 3 metres can be more profitable than a scheelite deposit with 0.7% WO₃ over the same interval due to lower processing costs and higher recovery rates.iii

In Western exploration drilling, scheelite tungsten grades typically range from 0.3% to 1.0% WO₃.iv The cut-off grade for economic viability is generally around 0.1% WO₃, with highly efficient operations able to mine at grades as low as 0.08% WO₃.v Skarn deposits, a common deposit type, typically range from 0.34% to 1.4% WO₃, with intercepts of 0.4% WO₃ over 1-5 metres considered very good and 0.7% WO₃ over 1-3 metres considered very high-grade.vi Intercept lengths can range from 0.6 metres to over 100 metres, with longer intercepts at strong grades generally preferred for economic mining. For example, two leading western tungsten mines demonstrate the standards for scheelite with results like 9.5 m @ 0.76% WO₃ and 14.1 m @ 0.58% WO₃vii at the Sangdong Mine* in South Korea and 18 m @ 1.00% WO₃ reported at the Mt. Carbine Tungsten Project* in Australia.viii

In contrast, the Panasqueira Mine* in Portugal typically reports 1-5 m @ 0.25-0.5% WO₃ as a wolframite depositix A result like 0.5% WO₃ over 3 metres is considered typical and strong within Western tungsten exploration standards, especially for wolframite tungsten mineralization.x

To understand tungsten, it is also important to recognize that China, Russia, and North Korea control approximately 87% of the world’s tungsten supply, using cheap labour and minimal environmental standards in authoritarian regimes.xi As a result, production costs and grades in these countries are not comparable to Western projects, which operate under higher labour, ESG, and energy cost structures.xii Evaluating projects outside these regions provides a realistic benchmark for what grades and intercepts are economically viable while supporting secure, NATO-aligned supply chains.xiii

For Allied, this context is significant, as the Company’s grades, ranging from 0.2% to 1.0% WO₃, are considerable against global wolframite benchmarks, with intercepts that meet or exceed typical Western results.xiv The Company’s focus on wolframite will correspond to lower processing costs and higher recoveries, supporting project economics even at lower grades.xv Allied’s operations in secure jurisdictions align with Western critical mineral needs, avoiding geopolitical risks associated with China and Russia while positioning the Company to benefit from growing tungsten demand across defense, aerospace, and electrification sectors.xvi Allied’s strong grades, low-cost processing advantages, and secure location position it as a strategic and responsible tungsten exploration company, well placed to support robust project economics in a rising-demand market.xvii

*The results cited for the Sangdong Mine, the Panasqueira Mine and the Mt. Carbine Tungsten Project are based on public disclosures and are presented for industry benchmarking and comparison purposes only. Allied has no interests in those mineral projects.

About Allied Critical Metals Inc.

Allied Critical Metals Inc. is a Canadian-based mining company focused on the expansion and revitalization of its 100% owned past producing Borralha Tungsten Project and the Vila Verde Tungsten Project in northern Portugal with advantageous wolframite tungsten mineralization. Tungsten has been designated a critical metal by the United States and other western countries, as they are aggressively seeking friendly sources of this unique metal. Currently, China, Russia and North Korea represent approximately 86% of the total global supply and reserves. Tungsten is used in a variety of industries such as defense, automotive, manufacturing, electronics, and energy.

MORE or "UNCATEGORIZED"

Eloro Resources Announces Closing of Bought Deal LIFE Private Placement for Gross Proceeds of C$17 Million

Eloro Resources Ltd. (TSX: ELO) (FSE: P2QM) is pleased to announce the closing of its previously an... READ MORE

Minera Alamos Updates Resources and Reserves for the Pan Gold Mine in Nevada

Minera Alamos Inc. (TSX-V: MAI) (OTCQX: MAIFF) is pleased to announce updated Mineral Resource and M... READ MORE

Ero Copper Reports Fourth Quarter and Full Year 2025 Operating and Financial Results

Ero Copper Corp. (TSX: ERO) (NYSE: ERO) is pleased to announce its operating and financial results f... READ MORE

Rare Element Resources Announces Results of Oversubscribed Rights Offering of Common Shares

Rare Element Resources Ltd. (OTCQB: REEMF) is pleased to report that its previously announced... READ MORE

TRX Gold Reports Record Q2 2026 Production and Company Update

TRX Gold Corporation (TSX: TRX) (NYSE American: TRX) is pleased to announce preliminary resu... READ MORE