Copper Giant Achieves Up To 92% Copper And 97% Molybdenum Recoveries In Latest Metallurgical Testwork At Mocoa

Copper Giant Resources Corp. (TSX-V: CGNT) (OTCQB: LBCMF) (FRA: 29H0) announces results from its bench-scale, preliminary metallurgical test work on core from the Mocoa copper-molybdenum project. Designed and supervised by SGS del Perú S.A.C., an independent ISO/IEC 17025-accredited laboratory, this initial program establishes the baseline for a comprehensive metallurgical campaign based on a conceptual processing flowsheet to support a future Preliminary Economic Assessment. Test work included comminution, bench-scale rougher flotation recoveries under laboratory conditions with varying grind sizes, pH conditions, and reagent suites, as well as mineralogical characterization and liberation analysis. Results confirm that Mocoa’s mineralization responds well to conventional processing and provides a strong foundation for the next phase of optimization. These results are based on a single 130 kg composite and may not be representative of the full deposit. Additional variability and locked-cycle testing will be required.

- Initial bench-scale rougher flotation laboratory test results show strong recoveries — up to 92% copper and 97% molybdenum, exceeding the assumptions (90% Cu, 75% Mo) used in the current resource model.

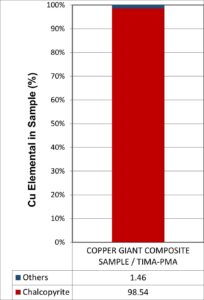

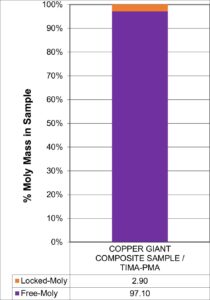

- Grind sizes were relatively coarse with a P80 150–180μm in TIMA analysis. Molybdenum mineralogical analysis shows 97% of molybdenite reported as free grains at P80 150–180μm in TIMA-X (TESCAN Integrated Mineral Analyzer) analysis.

- Copper mineralization is dominated by chalcopyrite, the most processing-friendly copper mineral, indicating a straightforward and conventional flotation pathway.

- Minerals containing deleterious elements were barely detected supporting the potential for clean, high-recovery concentrates.

Figure 1 – Left: Copper-bearing mineral on sample. Right: Molybdenite liberation on sample (CNW Group/COPPER GIANT RESOURCES CORP.)

Figure 1 – Left: Copper-bearing mineral on sample. Right: Molybdenite liberation on sample (CNW Group/COPPER GIANT RESOURCES CORP.)

The Mocoa project keeps getting better. These first metallurgical tests, under laboratory conditions, have already exceeded the recovery assumptions of 90% for copper and 75% for molybdenum used in our current resource model. Molybdenum, a major contributor to Mocoa’s potential value, consistently achieved recoveries above 95% — a significant improvement on what had been assumed. Its strategic importance is underscored by China’s recent export controls on certain molybdenum products and its inclusion on the USGS Draft 2025 Critical Minerals List. Together with copper recoveries above 90% and over 95% of copper hosted in chalcopyrite — the most processing-friendly mineral — these results give us strong confidence in a conventional flowsheet and will inform future economic studies. This program is only the beginning; the next phases will build on this foundation toward a full PEA and beyond.” — Ian Harris, President & CEO

Metallurgical Test Program Summary

All metallurgical test work was performed by SGS. The bench metallurgical test program at Mocoa followed a staged approach:

- Mineralogical characterization: confirmed chalcopyrite and molybdenite as the dominant ore minerals, with no deleterious in their typical minerals observed.

- Grind size optimization: established P80 150 µm as the preferred condition for subsequent testing.

- pH optimization: demonstrated robust flotation performance across pH 9–11, with pH 11 selected as the base case.

- Reagent optimization: using PAX (Potassium Amyl Xanthate) as the primary collector with variations using Matcol 715 as a secondary collector and Aero 7261A as a depressant all delivered strong recoveries.

Flotation test work included bench-scale rougher flotation recoveries under laboratory conditions.

The reagent optimization (see Table 1) were the final results after grind and pH optimization. Under these conditions, copper recoveries ranged from 88.9% to 92.3% and molybdenum from 94.8% to 97.4% — well above the 90% Cu and 75% Mo recoveries currently assumed in the resource model. The results are preliminary in nature and not necessarily indicative of recoveries at commercial scale.

| Test Condition | Mass Pull (%) |

Cu Rec (%) |

Mo Rec (%) |

Key Observations |

| pH = 11 | 9.56 | 88.85 | 95.22 | Standard reagents

(from pH testing) |

| TEST 01 | 11.13 | 92.24 | 97.39 | Additional collector |

| TEST 02 | 9.56 | 89.77 | 96.72 | Addition of iron depressant |

| TEST 03 |

12.09

|

92.30 | 94.80 | Addition of iron depressant |

Table 1 – Flotation recovery results for base and reagent optimization

Sample

The metallurgical test work was carried out on a bulk composite sample weighing over 130-kilograms, collected from multiple drill holes (MD-043, MD-044, MD-045) from depths between 262 and 928-metres to represent key lithologies and alteration types within the Mocoa deposit, including hydrothermal breccia, dacite inter-mineral porphyry and early diorite porphyry. The composite calculated grades of 0.46% Cu and 0.09% Mo, consistent with deposit averages, and provided sufficient mass for comminution, flotation and mineralogical characterization. Results are from one ~130 kg composite built from multiple drill holes to represent major lithologies; they may not be representative of the entire deposit. Variability and locked-cycle testing will follow.

Mineralogical characterization

X-ray Diffraction (XRD) analysis of the metallurgical composite shows the ore is dominated by quartz (~50.3 wt%), muscovite/illite (~17.6wt%), K-feldspar (~17.0wt%), and chlorite (~2.3wt%), with sulfide minerals present as pyrite (3.5wt%), chalcopyrite (1.2wt%), and molybdenite (0.15wt%). This mineralogical composition confirms that chalcopyrite is the main copper-bearing phase and molybdenite the primary molybdenum mineral, with pyrite as the principal gangue sulfide. TIMA-X (TESCAN Integrated Mineral Analyzer) plus PMA (Particle Mineralogical Analysis) mineralogical imaging further verified these results.

TIMA analysis indicates that copper is mainly hosted in chalcopyrite (see Figure 1), with only trace occurrences in secondary sulfides. Chalcopyrite is present as disseminations and within stockwork veinlets, often associated with pyrite. Molybdenum is exclusively present as molybdenite, typically as flakes or fine disseminations along quartz and sericite domains. No alternative Mo-bearing phases were detected, confirming molybdenite as the sole contributor to molybdenum recovery.

Liberation studies show chalcopyrite and molybdenite achieve effective liberation at grind sizes of 150–180 µm. Chalcopyrite shows good exposure at P80 150µm, with a high proportion of free grains or grains attached to quartz. Molybdenite also demonstrates favorable liberation, with the majority (97%) reporting as free-grains (see Figure 1)

Importantly, no deleterious minerals such as enargite, tetrahedrite, or other As-bearing sulfides were observed, supporting the potential for clean flotation products.

Flotation Optimization – Grind size, pH and Reagents

For all rougher flotation test work 10% lime slurry was used to achieve and maintain desired pH. For grind size optimization the following reagents we used: 26.77 µl Matcol 715 (a dithiophospate – collector), 10.47 µl diesel (frother), and 27.08 µl MIBC (methyl isobutyl carbinol – frother).

At a grind size of 180 µm, rougher flotation achieved 85.7% Cu recovery with a concentrate grade of 4.40% Cu and 94.0% Mo recovery (see Table 2). At slightly finer grinding to 150 µm, Cu recovery increased Cu to 88.1% and Mo to 96.2%, while coarser grinding to 210 µm reduced recoveries (80.8% Cu, 93.4% Mo). For subsequent test work optimizing pH and reagents a grind size of 150 µm was used.

| P80 | Mass Pull (%) |

Cu Rec (%) |

Mo Rec (%) |

Cu Conc Grade (%) |

Mo Conc Grade (ppm) |

Key Observations |

| 150 µm | 9.56 | 88.05 | 96.24 | 4.31 | 7094 | Fine grind, higher recovery |

| 180 µm | 11.13 | 85.69 | 94.02 | 4.40 | 7391 | Optimal grind/recovery balance |

| 210 µm | 9.56 | 80.78 | 93.38 | 4.49 | 8513 | Coarse grind lower Mo recovery |

Table 2 – Flotation summary results for grind optimization

For pH size optimization the following reagents were used: 29.74 µl Matcol 715 (collector), 11.63 µl diesel (frother), and 30.09 µl MIBC (frother). Tests across pH 9–11 demonstrated robust flotation response (see Table 3). At pH 10, copper recovery reached 88.4% and molybdenum recovery 95.6%. This condition provided the best overall balance of copper recovery and molybdenum selectivity. pH 11 was selected for reagent optimization because it had the highest Cu recovery.

| pH | Mass Pull (%) |

Cu Rec (%) |

Mo Rec (%) |

Cu Conc Grade (%) |

Mo Conc Grade (ppm) |

Key Observations |

| 9.0 | 9.56 | 88.02 | 96.22 | 4.14 | 6706 | Robust Cu recovery, slightly lower M |

| 10 | 11.13 | 88.43 | 95.55 | 4.25 | 7093 | Best overall Cu–Mo balance |

| 11 | 9.56 | 88.85 | 95.22 | 4.30 | 6782 | Slightly higher Cu recovery, lower Mo |

Table 3 – Flotation summary results for pH optimization

For reagent optimization the following reagents were used: 29.74 µl Matcol 715 (collector), 11.63 µl diesel (frother), and 30.09 µl MIBC (frother). Reagent optimization further improved copper and molybdenum recovery (see Table 4). The pH = 11 was included in the table (see Table 4) as a base result using the standard suite of flotation reagents.

In Test 01 there was added 1.00 ml of PAX (potassium amyl xanthate – collector) 1% as an addition collector. Cu recovery was 92.2% and Mo recovery 97.4%. Test 02 & 03 added 17.07 µl of AERO 7261A (a pyrite depressant) without PAX addition. Test 02 delivered 89.8% Cu recovery and 96.7% Mo recovery, while Test 03 92.30% Cu recovery and 94.80% Mo recovery but poor roughers concentrate grades.

| pH | Mass Pull (%) |

Cu Rec (%) |

Mo Rec (%) |

Cu Conc Grade (%) |

Mo Conc Grade (ppm) |

Key Observations |

| pH = 11 | 9.56 | 88.85 | 95.22 | 4.30 | 6782 | Standard reagents

(from pH testing) |

| TEST 01 | 11.13 | 92.24 | 97.39 | 3.89 | 6866 | Additional collector |

| TEST 02 | 9.56 | 89.77 | 96.72 | 4.32 | 7537 | Addition of iron depressant |

| TEST 03 | 12.09 | 92.30 | 94.80 | 3.57 | 5170 | Addition of iron depressant |

Table 4 – Flotation summary results for reagent optimization

Next steps

This first-pass program establishes the baseline for Mocoa’s metallurgy and confirms the deposit responds well to conventional processing. The results will now be used to design a next-generation metallurgical program focused on:

- Flowsheet development — advancing beyond single-variable tests toward an integrated circuit design.

- Optimization opportunities — including evaluation of regrind and reagent schemes to maximize copper and molybdenum recovery.

- Concentrate deliverables — testing for concentrate quality, grade, and marketability.

The upcoming bench-scale testwork will provide the technical foundation for a preliminary flowsheet and the assumptions required to support a robust PEA.

Qualified Person and Technical Notes

Edwin Naranjo Sierra, Vice-President of Exploration for Copper Giant, is the designated Qualified Person within the meaning of National Instrument 43-101 – Standards of Disclosure for Mineral Projects and has reviewed and approved the technical information in this news release. Mr. Naranjo holds an MSc. in Earth Sciences and is a Fellow of the Australasian Institute of Mining and Metallurgy (FAusIMM). With respect to metallurgical procedures and results, the QP has relied on the qualifications of SGS-Peru and reviewed the data for reasonableness.

Mineralized zones at Mocoa are bulk porphyry-style zones and drilled widths are interpreted to be very close to true widths.

Copper Giant operates according to a rigorous Quality Assurance and Quality Control (QA/QC) protocol consistent with industry best practices. Core diameter is a mix of HQ and NQ depending on the depth of the drill hole. Diamond drill core boxes were photographed, sawed, sampled and tagged in maximum 2-metre intervals, stopping in geological boundaries. Samples were bagged, tagged and packaged for shipment by truck from Copper Giant’s core logging facilities in Mocoa, Colombia to the ActLabs certified sample preparation facility in Medellin, Colombia. ActLabs is an accredited laboratory independent of the Company. Samples are processed in the Medellin facilities where they are analyzed for copper, gold, silver, molybdenum, zinc and lead by 4-Acid digest Atomic Absorption (AA) analysis. The sample pulps are air freighted from Medellin to the ActLabs certified laboratory in Guadalajara, Mexico, where they are analyzed for a suite of 57 elements using 4-Acid digest and ICP-MS. In order to monitor the ongoing quality of assay data and the database, Copper Giant has implemented QA/QC protocols which include standard sampling methodologies, the insertion of certified copper and molybdenum standard materials, blanks, duplicates (field, preparation and analysis) randomly inserted into the sampling sequence. QA/QC program also includes ongoing monitoring of data entry, QA/QC reporting and data validation. No material QA/QC issues have been identified with respect to sample collection, security and assaying.

About the Mocoa Porphyry System

The Mocoa project is located in the department of Putumayo, approximately 10 kilometres from the town of Mocoa in southern Colombia. Copper Giant holds a district-scale land package of over 790 square kilometres through granted titles and applications, covering a substantial portion of the Jurassic porphyry belt – an underexplored and highly prospective metallogenic zone in the northern Andes.

Discovered in 1973 through a regional geochemical survey by the United Nations and the Colombian government, Mocoa has been the subject of multiple exploration campaigns. Between 1978 and 1983, follow-up work included geological mapping, IP and magnetic geophysics, surface sampling, drilling, and metallurgical testing. Additional drilling by B2Gold in 2008 and 2012 helped shape the current geological understanding.

The deposit is hosted in Middle Jurassic dacite and quartz-diorite porphyries intruding andesitic to dacitic volcanics, within Colombia’s Central Cordillera. This 30-kilometre wide tectonic belt extends into Ecuador and hosts other major porphyry systems like Mirador, Warintza, San Carlos, and Panantza. Mocoa displays a classical porphyry-style alteration zonation: potassic core, sericite halo, and outer propylitic zone, with mineralization consisting of disseminated chalcopyrite and molybdenite, and local bornite and chalcocite, associated with stockworks and hydrothermal breccias.

The system features over 1,000 metres of vertical continuity, overlapping hydrothermal stages, and a broad alteration footprint. Multiple intrusive phases, brecciation events, and vein generations suggest a dynamic magmatic-hydrothermal evolution likely driven by more than one porphyry center.

Mocoa remains open in all directions, with several satellite targets identified across the broader land package. These features support the interpretation of a district-scale porphyry system and position Mocoa as one of the most significant undeveloped copper-molybdenum assets in the Andes

1 For further information refer to NI 43-101 Technical Report, entitled “Technical Report on the Mocoa Copper-Molybdenum Project, Colombia”, dated January 17, 2022, prepared by Michael Rowland Brepsant, FAusIMM, Robert Sim, P.Geo, and Bruce Davis, FAusIMM. with an effective date of November 01, 2021.

About Copper Giant

Copper Giant Resources Corp. is part of the Fiore Group, a private and well-established Canadian organization known for building successful, high-impact companies across the natural resource sector. Copper Giant was formed with a singular focus: to advance high-quality copper projects beyond resource definition–responsibly, efficiently, and with long-term positive impact.

The Company is led by a team with uncommon experience, having successfully taken some of the few major copper mines developed in the past two decades from discovery through to construction.

Copper Giant’s current focus is the Mocoa copper-molybdenum deposit in southern Colombia, one of the largest undeveloped resources of its kind in the Americas. Recent exploration success has revealed potential well beyond its original footprint, highlighting Mocoa as a broader district-scale opportunity–and the catalyst for the Company’s name and evolution.

Guided by the values of respect and responsibility, and grounded in its Good Neighbor philosophy, Copper Giant is committed to creating enduring values for all stakeholders and playing a meaningful role in the global energy transition.

MORE or "UNCATEGORIZED"

Delta Reports New Gold Intercept at Nova Target in Wedge Area, 4 Kilometres West of Eureka; Follow-Up Drill Program Underway

Delta Reports New Gold Intercept at Nova Target in Wedge Area, 4 ... READ MORE

Silver One Announces Closing Of Final Tranche Of $32 Million Financing

Silver One Resources Inc. (TSX-V: SVE) (OTCQX: SLVRF) (FSE: BRK1)... READ MORE

SAGA Metals Achieves 100% Drilling Success in 2025—Reports Final Assays from Trapper South at Radar Critical Minerals Project in Labrador

Exceptional grades of Titanium, Vanadium and Iron in all 15 drill... READ MORE

Near Surface Intersection Yields 6.58 g/t gold over 10.35 metres

Intersection is within 33 metres from surface and contained in a ... READ MORE

Alamos Gold Provides Three-Year Operating Guidance Outlining 46% Production Growth by 2028 at Significantly Lower Costs

Further production growth to one million ounces annually expected... READ MORE