Osisko Gaspé Expansion Hole Intersects 133.7 Metres Averaging 1.04% Cu

Infill Hole Returns 1091.5 Metres Averaging 0.20% Cu, 1.52 g/t Ag, 0.02% Mo (0.28% CuEq)

Osisko Metals Incorporated (TSX: OM) (OTCQX: OMZNF) (FRANKFURT: 0B51) is pleased to announce new drill results from the Gaspé Copper Project, located in the Gaspé Peninsula of Eastern Québec.

Osisko Metals CEO Robert Wares commented: “The growth potential of the Gaspé Copper deposit continues to be demonstrated with today’s new high-grade results. Holes 30-1106 and 30-1109 reveal the presence of a thick, higher grade tabular zone lying at depth around the E Zone horizon near the eastern margin of our 2024 MRE model. This tabular zone may extend significantly to the east if it correlates to historical drilling results. Our expansion drilling is exceeding expectations, hand-in-hand with the solid infill results on our main resource area.”

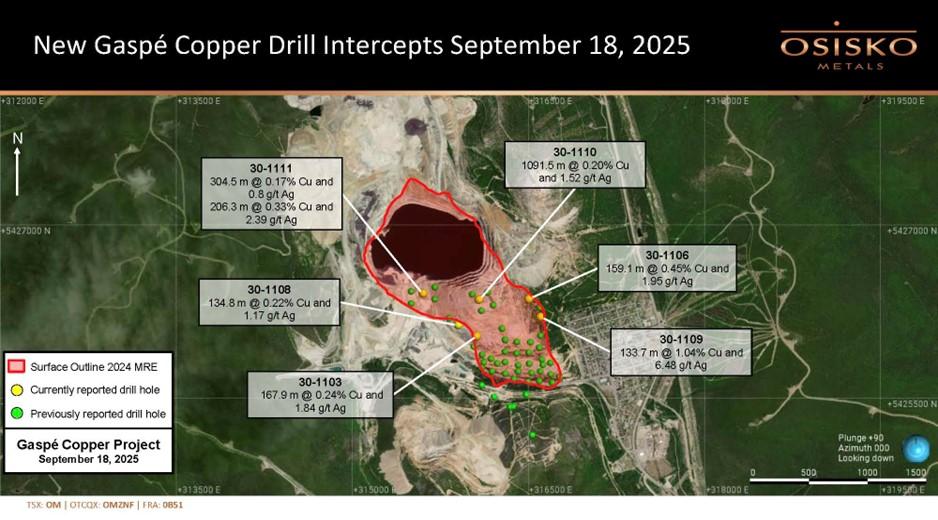

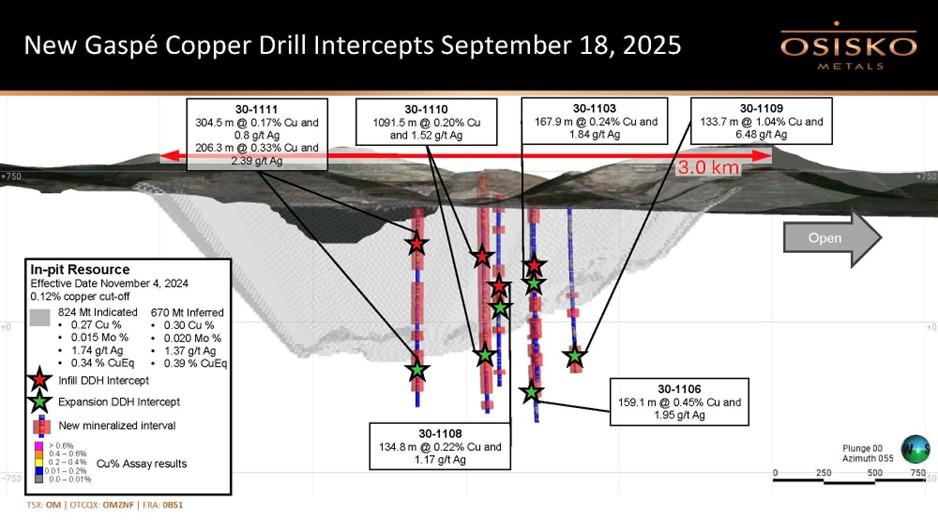

New analytical results are presented below (see Table 1), including 26 mineralized intercepts from six new drill holes. Infill intercepts are located inside the 2024 MRE model (see November 14, 2024 news release), and are focused on upgrading inferred mineral resources to measured or indicated categories, as applicable. Expansion intercepts are located outside the 2024 MRE model and may potentially lead to additional resources that will be classified appropriately within the next MRE update. Some of the reported intercepts have contiguous shallower infill as well as deeper expansion (noted on Table 1 below as “Both”). Maps showing hole locations are available at www.osiskometals.com.

Highlights:

- Drill hole 30-1110

- 1091.5 metres averaging 0.20% Cu (infill and expansion)

- Drill hole 30-1109

- 133.7 metres averaging 1.04% Cu (expansion)

- Drill hole 30-1106

- 159.1 metres averaging 0.45% Cu (expansion)

- Drill hole 30-1103

- 167.9 metres averaging 0.24% Cu (infill)

- Drill hole 30-1108

- 134.8 metres averaging 0.22% Cu (infill and expansion)

- Drill hole 30-1111

- 304.5 metres averaging 0.17% Cu (infill)

- 206.3 metres averaging 0.33% Cu (expansion)

Table 1: Infill and Expansion Drilling Results

| DDH No. | From (m) | To (m) | Length (m) | Cu % | Ag g/t | Mo % | CuEq* | Type** |

| 30-1103 | 14.6 | 144.0 | 129.4 | 0.17 | 1.40 | <0.005 | 0.19 | Infill |

| And | 322.6 | 490.5 | 167.9 | 0.24 | 1.84 | 0.014 | 0.30 | Infill |

| And | 510.0 | 583.5 | 73.5 | 0.27 | 2.02 | 0.029 | 0.40 | Expansion |

| And | 618.0 | 714.0 | 96.0 | 0.12 | 1.09 | 0.024 | 0.20 | Expansion |

| And | 790.5 | 854.0 | 63.5 | 0.26 | 1.38 | 0.010 | 0.30 | Expansion |

| 30-1106 | 595.5 | 634.5 | 39.0 | 0.40 | 3.58 | <0.005 | 0.44 | Infill |

| And | 694.0 | 716.0 | 22.0 | 0.29 | 1.60 | 0.008 | 0.32 | Expansion |

| And | 741.0 | 802.5 | 61.5 | 0.18 | 0.97 | 0.014 | 0.23 | Expansion |

| And | 844.7 | 1003.8 | 159.1 | 0.45 | 1.95 | 0.011 | 0.50 | Expansion |

| (including) | 864.2 | 898.0 | 33.8 | 1.04 | 3.60 | 0.011 | 1.10 | Expansion |

| 30-1108 | 9.0 | 53.0 | 44.0 | 0.20 | 1.80 | <0.005 | 0.21 | Infill |

| And | 67.0 | 96.0 | 29.0 | 0.17 | 1.62 | <0.005 | 0.19 | Infill |

| And | 160.5 | 199.5 | 39.0 | 0.12 | 1.05 | 0.008 | 0.16 | Infill |

| And | 354.0 | 417.0 | 63.0 | 0.19 | 1.42 | 0.006 | 0.22 | Infill |

| And | 442.2 | 579.0 | 134.8 | 0.22 | 1.17 | 0.030 | 0.34 | Both |

| And | 662.7 | 695.8 | 33.1 | 0.22 | 0.75 | 0.021 | 0.31 | Expansion |

| And | 877.5 | 900.3 | 22.8 | 0.62 | 5.14 | <0.005 | 0.67 | Expansion |

| 30-1109 | 463.5 | 487.5 | 24.0 | 0.36 | 2.83 | <0.005 | 0.39 | Infill |

| And | 543.0 | 583.5 | 40.5 | 1.35 | 8.29 | 0.012 | 1.44 | Infill |

| And | 727.3 | 861.0 | 133.7 | 1.04 | 6.48 | 0.017 | 1.14 | Expansion |

| 30-1110 | 8.0 | 1099.5 | 1091.5 | 0.20 | 1.52 | 0.017 | 0.28 | Both |

| (including) | 8.0 | 743.6 | 735.6 | 0.20 | 1.50 | 0.015 | 0.27 | Infill |

| (including) | 743.6 | 1099.5 | 355.9 | 0.21 | 1.55 | 0.021 | 0.30 | Expansion |

| And | 1138.5 | 1177.5 | 39.0 | 0.12 | 0.90 | 0.014 | 0.17 | Expansion |

| 30-1111 | 28.5 | 333.0 | 304.5 | 0.17 | 0.80 | 0.007 | 0.20 | Infill |

| And | 391.5 | 602.5 | 210.5 | 0.16 | 0.78 | 0.028 | 0.27 | Infill |

| And | 634.7 | 682.5 | 47.8 | 0.13 | 1.06 | 0.008 | 0.16 | Expansion |

| And | 730.0 | 936.3 | 206.3 | 0.33 | 2.39 | 0.016 | 0.41 | Expansion |

* See explanatory notes below on copper equivalent values and Quality Assurance/Quality Controls.

** “Both” indicates drill holes that have contiguous shallower infill as well as deeper expansion intercepts.

Discussion

Drill holes 30-1103 and 30-1108, both located near the western margin of the 2024 MRE model, cut multiple intersections of mineralized material, 20 to 168 metres thick, distributed in “layer cake” fashion from surface to a vertical depth of 854 and 900 metres, respectively.

Drill hole 30-1106, located near the eastern margin of the 2024 MRE model, cut unmineralized material to a depth of about 600 metres, followed by four mineralized intervals to a vertical depth of 1004 metres. These include a higher-grade interval of 33.8 metres averaging 1.04% Cu and 3.60 g/t Ag located at the level of (and immediately below) the E Zone skarn horizon.

Drill hole 30-1109, also located near the eastern margin of the 2024 MRE model, cut unmineralized material to a depth of about 460 metres, followed by three mineralized intervals to a vertical depth of 860 metres. These also include a higher-grade interval of 133.7 metres averaging 1.04% Cu and 6.48 g/t Ag located in skarn and porcellanites above and below the E Zone skarn horizon.

Both 30-1106 and 30-1109 suggest potential for the presence of a higher-grade tabular deposit around the E Zone horizon that, when combined with historical drilling data, indicates a potential extension eastward towards the previously mined E-32 Zone over a lateral distance of 800 metres.

Drill hole 30-1110, located on top of Copper Mountain near the central part of the 2024 MRE model, intersected 1091.5 metres averaging 0.20% Cu, 1.52 g/t Ag, and 0.017% Mo (0.28% CuEq), including 735.6 metres averaging 0.20% Cu, 1.50 g/t Ag, and 0.015% Mo (infill) and 355.9 metres averaging 0.21% Cu, 1.55 g/t Ag, and 0.021% Mo (expansion), extending mineralization to a vertical depth of 1100 metres and again confirming continuity of mineralization in the core of the deposit.

Drill hole 30-1111, located immediately west of Copper Mountain near the southern lip of the pit, intersected 304.5 metres (from surface) averaging 0.17% Cu and 0.80 g/t Ag followed by three more intersections that included expansion at depth of 206.3 metres averaging 0.33% Cu, 2.39 g/t Ag, and 0.016% Mo, extending mineralization in this area to a vertical depth of 936 metres. The central porphyry intrusion was then intersected and returned 76 metres averaging negligible copper (0.08% Cu) but significant molybdenum (0.023% Mo).

Mineralization at Gaspé Copper is of porphyry copper/skarn type and occurs as disseminations and stockworks of chalcopyrite with pyrite or pyrrhotite and minor bornite and molybdenite. At least five retrograde vein/stockwork mineralizing events have been recognized at Copper Mountain, which overprint earlier prograde skarn and porcellanite-hosted mineralization throughout the Gaspé Copper system. Porcellanite is a historical mining term used to describe bleached, pale green to white potassic-altered hornfels. Subvertical stockwork mineralization dominates at Copper Mountain whereas prograde bedding-replacement mineralization, that is mostly stratigraphically controlled, dominates in the area of Needle Mountain, Needle East, and Copper Brook. High molybdenum grades (up to 0.5% Mo) were locally obtained in both the C Zone and E Zone skarns away from Copper Mountain.

The 2022 to 2024 Osisko Metals drill programs were focused on defining open-pit resources within the Copper Mountain stockwork mineralization (see May 6, 2024 MRE press release). Extending the resource model south of Copper Mountain into the poorly-drilled prograde skarn/porcellanite portion of the system subsequently led to a significantly increased resource, mostly in the Inferred category (see November 14, 2024 MRE press release).

The current drill program is designed to convert the November 2024 MRE to Measured and Indicated categories, as well as test the expansion of the system deeper into the stratigraphy and laterally to the south and southwest towards Needle East and Needle Mountain respectively. The November 2024 MRE was limited at depth to the base of the L1 skarn horizon (C Zone), and all mineralized intersections below this horizon represent potential depth extensions to the deposit, to be included in the next scheduled MRE update in Q1 2026.

All holes are being drilled sub-vertically into the altered calcareous stratigraphy, which dips 20 to 25 degrees to the north. The L1 (C Zone) the L2 (E Zone) skarn/marble horizons were intersected in most holes, as well as intervening porcellanites that host the bulk of the disseminated copper mineralization.

Table 2: Drill hole locations

| DDH No. | Azimuth (°) | Dip (°) | Length (m) | UTM E | UTM N | Elevation |

| 30-1103 | 0.00 | -90.00 | 930.0 | 316056.0 | 5426038.0 | 634.7 |

| 30-1106 | 0.00 | -90.00 | 1131.0 | 316500.0 | 5426360.0 | 628.7 |

| 30-1108 | 0.00 | -90.00 | 960.00 | 315900.0 | 5426136.0 | 638.9 |

| 30-1109 | 0.00 | -90.00 | 861.00 | 316600.0 | 5426205.0 | 608.2 |

| 30-1110 | 0.00 | -90.00 | 1200.00 | 316077.0 | 5426355.0 | 742.7 |

| 30-1111 | 0.00 | -90.00 | 1014.00 | 315600.0 | 5426408.0 | 590.0 |

Explanatory note regarding copper-equivalent grades

Copper Equivalent grades are expressed for purposes of simplicity and are calculated taking into account: 1) metal grades; 2) estimated long-term prices of metals: US$4.25/lb copper, US$20.00/lb molybdenum, and US$24.00/oz silver; 3) estimated recoveries of 92%, 70%, and 70% for Cu, Mo, and Ag respectively; and 4) net smelter return value of metals as percentage of the price, estimated at 86.5%, 90.7%, and 75.0% for Cu, Mo, and Ag respectively.

Qualified Person

The scientific and technical content of this news release has been reviewed and approved by Mr. Bernard-Olivier Martel, P. Geo. (OGQ 492), an independent “qualified person” as defined by National Instrument 43-101 – Standards of Disclosure for Mineral Projects.

Quality Assurance / Quality Control

Mineralized intervals reported herein are calculated using an average 0.12% CuEq lower cut-off over contiguous 20-metre intersections (shorter intervals as the case may be at the upper and lower limits of reported intervals). Intervals of 20 metres or less are not reported unless indicating significantly higher grades. True widths are estimated at 90- 92% of the reported core length intervals.

Osisko Metals adheres to a strict QA/QC program for core handling, sampling, sample transportation and analyses, including insertion of blanks and standards in the sample stream. Drill core is drilled in HQ or NQ diameter and securely transported to its core processing facility on site, where it is logged, cut and sampled. Samples selected for assay are sealed and shipped to ALS Canada Ltd.’s preparation facility in Sudbury. Sample preparation details (code PREP-31DH) are available on the ALS Canada website. Pulps are analyzed at the ALS Canada Ltd. facility in North Vancouver, BC. All samples are analyzed by four acid digestion followed by both ICP-AES and ICP-MS for Cu, Mo and Ag.

About Osisko Metals

Osisko Metals Incorporated is a Canadian exploration and development company creating value in the critical metals sector, with a focus on copper and zinc. The Company acquired a 100% interest in the past-producing Gaspé Copper mine from Glencore Canada Corporation in July 2023. The Gaspé Copper mine is located near Murdochville in Québec’s Gaspé Peninsula. The Company is currently focused on resource expansion of the Gaspé Copper system, with current Indicated Mineral Resources of 824 Mt averaging 0.34% CuEq and Inferred Mineral Resources of 670 Mt averaging 0.38% CuEq (in compliance with NI 43-101). For more information, see Osisko Metals’ November 14, 2024 news release entitled “Osisko Metals Announces Significant Increase in Mineral Resource at Gaspé Copper”. Gaspé Copper hosts the largest undeveloped copper resource in eastern North America, strategically located near existing infrastructure in the mining-friendly province of Québec.

In addition to the Gaspé Copper project, the Company is working with Appian Capital Advisory LLP through the Pine Point Mining Limited joint venture to advance one of Canada’s largest past-producing zinc mining camps, the Pine Point project, located in the Northwest Territories. The current mineral resource estimate for the Pine Point project consists of Indicated Mineral Resources of 49.5 Mt averaging 5.52% ZnEq and Inferred Mineral Resources of 8.3 Mt averaging 5.64% ZnEq (in compliance with NI 43-101). For more information, see Osisko Metals’ June 25, 2024 news release entitled “Osisko Metals releases Pine Point mineral resource estimate: 49.5 million tonnes of indicated resources at 5.52% ZnEq”. The Pine Point project is located on the south shore of Great Slave Lake, NWT, close to infrastructure, with paved road access, an electrical substation and 100 kilometres of viable haul roads.

MORE or "UNCATEGORIZED"

Delta Reports New Gold Intercept at Nova Target in Wedge Area, 4 Kilometres West of Eureka; Follow-Up Drill Program Underway

Delta Reports New Gold Intercept at Nova Target in Wedge Area, 4 ... READ MORE

Silver One Announces Closing Of Final Tranche Of $32 Million Financing

Silver One Resources Inc. (TSX-V: SVE) (OTCQX: SLVRF) (FSE: BRK1)... READ MORE

SAGA Metals Achieves 100% Drilling Success in 2025—Reports Final Assays from Trapper South at Radar Critical Minerals Project in Labrador

Exceptional grades of Titanium, Vanadium and Iron in all 15 drill... READ MORE

Near Surface Intersection Yields 6.58 g/t gold over 10.35 metres

Intersection is within 33 metres from surface and contained in a ... READ MORE

Alamos Gold Provides Three-Year Operating Guidance Outlining 46% Production Growth by 2028 at Significantly Lower Costs

Further production growth to one million ounces annually expected... READ MORE