Robex Extends Life of Mine for Nampala Gold Mine With Updated Technical Study

Robex Resources Inc. (TSX-V: RBX) is pleased to announce the results of an updated NI43-101 technical report for its Nampala Mine in Mali.

Highlights:

- Increased Reserves Life of Mine: Nampala mine life extended to December 2026 (from June 2026) with Mineral Reserves at 121Koz ounces @ 0.93g/t;

- Potential to grow Mineral Reserves: Indicated Mineral Resources (inclusive of Mineral Reserves) of 243Koz @ 0.94g/t Au;

- Economics: Consensus Case (Gold Price: US$2,490/oz):

- Pre-tax Net Present Value at discount rate of 5% (“NPV5%”) of US$106.1M, and

- Post-tax NPV5% of US$71.1M.

- Average annual gold production: Nampala is expected to produce 52,000 ounces gold per year over LoM

- Costs in line with budget: LoM All-In Sustaining Costs of US$1,106 /oz.

Robex Managing Director Matthew Wilcox commented: “Increasing the life of mine at Nampala is an important step for Robex to define the future for this asset. The team at Nampala has done a fantastic job of continuing to produce gold at low costs in a challenging environment.

Nampala is expected to continue to produce free cash on a monthly basis and continue to support our development of the Kiniero gold mine in Guinea, which we have demonstrated can produce 139,000oz gold per year over its 9.5-year mine life and is set to pour first gold later this year.”

The Report was prepared in accordance with Canadian Securities Administrators’ National Instrument 43-101 – Standards of Disclosure for Mineral Projects (“NI 43-101”). The independent NI 43-101 technical report supporting the Nampala Study will be published on SEDAR at www.sedar.com within the next 45 days.

Napala’s updated economic model was run at two gold prices;

- Scenario 1 with gold price of US$1,800/oz used for the Mineral Reserve, and

- Scenario 2 with the S&P consensus long-term gold price at end of October 2024, ranging from US$2,490/oz to US$2,314/oz.

The Study extends Nampala Life of Mine (“LoM”) to December 2026 (versus June 2026) with Mineral Reserves of 121Koz at 0.93 g/t Au. The post-tax NPV5% at consensus gold price is US$71.1m as shown in Table 1

Table 1: Summary of NPV Scenarios (as of 1 September 2024)

| Scenario | Unit | NPV 5% | |

| Pre-Tax | Post-Tax | ||

| Scenario 1: $1800/oz | US$m | 48.2 | 28.8 |

| Scenario 2: The S&P consensus gold price (at end October 2024) | US$m | 106.1 | 71.1 |

TECHNICAL STUDY DETAILS

Overview

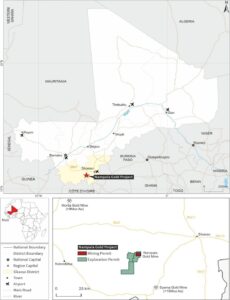

The Nampala Property is comprised of a contiguous block of one mining permit (Nampala Mine) and three adjoining exploration permits (Mininko, Gladie and Kamasso). The Property is located in the Sikasso and Kolondieba Circles of the Sikasso Region in southern Mali, and is approximately 255km southeast of Bamako, the capital of Mali, and ~60km southwest of Sikasso, the capital of the Sikasso Region as shown in Figure 1 . The Nampala Gold Mine is approximately 40km northwest of Resolute Mining’s 4.0Moz Syama Gold Mine.

Within the Property, the Nampala Gold Mine is a Production Project that involves ongoing mining and processing activities. The adjacent exploration permits are advanced exploration projects with detailed exploration work, including drilling and trenching.

Figure 1 Regional location of the Nampala Gold Project

Geology

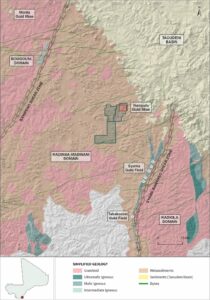

The Property is located within the Kadiana-Madinana Domain of the Birimian Supergroup in southern Mali (Figure 2). This Domain is located within the broader Baoulé-Mossi Domain, a significant greenstone belt of West Africa renowned for its gold mineralisation.

Figure 2 Simplified Regional Geology of the Bagoe Greenstone Belt

Source: Micon (2024) modified from Ballo, et al. (2015)

The Birimian Supergroup is a significant component of the West African Craton, formed around 2.2 Ga to 2.0 Ga. It comprises a sequence of intensely deformed and metamorphosed volcanic and sedimentary rocks. The Birimian is typically divided into two parts: a lower volcanic group with basalts and andesites and an upper sedimentary group with greywackes, sandstones, and shales. These turbiditic sedimentary rocks are significant, as they often host significant gold mineralisation.

The local geology of the Nampala Property and its surrounding permits are primarily based on the studies conducted by Baril et al. (2011), Boisse et al. (2020), the mapping and studies completed by BRGM and the geological interpretations made by Micon International Co Limited (Micon) who were responsible for the geological and resource modelling for this Report, and overall compilation thereof.

The Nampala Mine and the adjacent Mininko permit exhibit geological characteristics like those observed within the neighbouring Gladie and Kamasso permits. The primary lithological units, include significant marker horizons such as graphitic shales that extend southward from the Nampala Permit into these areas, continuing beyond the southwestern boundary of Kamasso.

The Nampala Mine and the Mininko permit are situated within the pelitic shale and arenite units of the Bagoe Formation, which belong to the Birimian Supergroup. This formation trends north-northeast, spanning several hundred kilometres into Côte d’Ivoire and dipping beneath the Taoudeni Basin to the north.

Gold mineralisation of the Nampala Property is like many other Palaeoproterozoic gold deposits in the Baoulé-Mossi domain of the West African Craton that formed during a craton-wide gold metallogenic event late in the Eburnean Orogeny (Lawrence, Treloar, Rankin, Harbidge, & Holliday, 2013).

Gold mineralisation is primarily hosted within competent, coarse-grained turbiditic units, specifically greywackes and siliceous sandstones. These lithologies, characterised by their brittle nature, facilitated the fracturing and subsequent vein formation. Gold occurs predominantly within structurally controlled tension quartz vein systems and stockworks that exploit these fractures and associated zones of enhanced porosity.

The tonalite intrusion, enveloped by lamprophyres, also contains mineralised quartz veins that share a similar orientation with those observed in the metasediments, suggesting a common structural control on mineralisation. Although the lamprophyre intrusions exhibit limited mineralisation, confined primarily to their margins, they appear to influence the spatial distribution of gold significantly. This is evidenced by the preferential concentration of gold mineralisation in the metasediments proximal to the lamprophyre contacts, supported by lithological competency contrasts and geochemical gradients.

Conversely, shear zones are predominantly developed within the more ductile, often graphitic, shales. These shear zones, however, are typically barren of significant gold mineralisation.

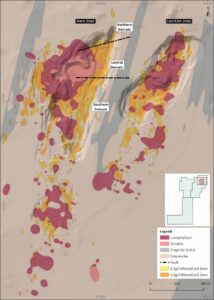

Figure 3 Geology of the Nampala Gold Mine

Source: Micon (2024) from the Robex Mapping Data and Micon 2024 interpretation

Mineral Resources and Reserves

The 2024 Mineral Resource Estimate (MRE) was prepared by Micon and has an effective date of 30th September 2024. It has been constrained by a topographic surface of the same date. The 2024 Mineral Resource statement is presented in Table 2

Table 2: Nampala Mineral Resource Statement, effective date 30th September 2024

| Regolith | Cut-Off (g/t Au) |

Tonnage (Mt) |

Gold Grade (g/t Au) |

Contained Gold (koz) |

| INDICATED | ||||

| Oxide | 0.35 | 5.85 | 0.84 | 158.33 |

| Transition | 0.43 | 2.09 | 1.13 | 76.03 |

| Fresh | 1.89 | 0.10 | 3.00 | 9.36 |

| TOTAL | – | 8.04 | 0.94 | 243.72 |

| INFERRED | ||||

| Oxide | 0.35 | 0.32 | 0.79 | 8.05 |

| Transition | 0.43 | 0.23 | 1.62 | 8.50 |

| Fresh | 1.89 | 0.01 | 2.53 | 0.41 |

| TOTAL | – | 0.56 | 0.95 | 16.97 |

Source: Micon (2024)

Notes:

- The Mineral Resource Estimate has been prepared in accordance with National Instrument 43-101 (NI 43-101) Standards of Disclosure for Mineral Projects with an effective date of 30 September 2024. Dr Ryan Langdon of Micon is the QP responsible for the MRE.

- The database was closed on 10 September 2024 and the Mineral Resources were constrained to a topographic survey dated 30 September 2024.

- To demonstrate Reasonable Prospects for Eventual Economic Extraction (RPEEE), open pit Mineral Resources were constrained by an optimised pit shell. All blocks above the cut-off and within the pit shell were included in the Mineral Resources. Robex created the optimised pit shell.

- Cut-off grades for Mineral Resource reporting were calculated using a gold price of US$2,200 oz and are: oxide (laterite, mottled zone, saprolite) 0.35 g/t Au; transition (upper saprock, lower saprock) 0.43 g/t Au; and fresh (fresh rock)1.89 g/t Au.

- Mineral Resources are not Mineral Reserves and have not demonstrated economic viability. There is no certainty that all or any part of the estimated Mineral Resources will be converted into Mineral Reserves.

- Average density values used are: laterite and mottled zone 1.56 t/m3 to 1.74 t/m3; saprolite 1.55 t/m3 to 1.68 t/m3; upper saprock 2.05 t/m3 to 2.24 t/m3; lower saprock 2.40 t/m3to 2.42 t/m3; and fresh rock 2.63 t/m3to 2.74 t/m3.

- Grade interpolation by ordinary kriging using a block model with a block size of 10 m (X) by 20 m (Y) by 5 m (Z). Outlier management used grade capping for extreme outliers and a restricted search neighbourhood for outliers on a domain-by-domain basis.

- Mineral Resources in volumes with a drill grid spacing of 40 m by 40 m were classified as Indicated Mineral Resources. All other volumes were classified as Inferred Mineral Resources. To limit extrapolation, a wireframe was used to constrain the interpolated blocks to approximately 10 m below the base of the drilling.

- Totals presented in this table reported from the Mineral Resource models, are subject to rounding, and may not total exactly.

The Mineral Reserves for Nampala were derived from the Mineral Resources using the modifying factors outlined in the Mining Plan. All Mineral Reserves are classified as Probable, as they are based on Indicated Mineral Resources. Inferred and Unclassified Mineral Resources were excluded from the resource-to-reserve conversion, ensuring compliance with reporting standards. The stockpiles are excluded from the Mineral Reserve estimate, as it is not classified as a Mineral Resource and therefore cannot be converted to Reserves. The Nampala Mineral Reserves with effective date 30th September 2024 is presented in Table 3.

Table 3: Nampala Mine Mineral Reserves, effective date 30th September 2024

| Nampala Mine Mineral Reserves | ||||||

| Ore Type | Proven | Probable | ||||

| Ore (Mt) |

Gold Grade (g/t Au) |

Total Gold (koz) |

Ore (Mt) |

Gold Grade (g/t Au) |

Total Gold (koz) |

|

| Oxide | – | – | – | 3.268 | 0.90 | 94.61 |

| Transition | – | – | – | 0.776 | 1.06 | 26.35 |

| Total | – | – | – | 4.044 | 0.93 | 120.96 |

Source: Robex (2024)

Notes:

- The Mineral Reserves have been depleted for mining up to the 30th September 2024.

- Figures have been rounded to the appropriate level of precision for reporting.

- Due to rounding, some columns or rows may not compute exactly as shown.

- Mineral Reserves are stated as in-situ dmt (dry metric tonnes).

- Mining recovery of 100% and waste dilution of 6% were applied to each pit.

- Mineral Reserves reporting were calculated at a cut-off grade of 0.4g/t for oxide (laterite, mottled zone, saprolite and transition).

- Probable Mineral Reserves were derived from Indicated Mineral Resources.

- There are no known legal, political, environmental, or other risks that could materially affect the Mineral Reserves.

Exploration

Non-invasive exploration completed by Robex on the Nampala Property has been extensive, and Property-wide. First commenced in 2005, the Property-wide exploration has included:

- Remote Sensing: a remote sensing assessment by GaiaPix in 2022 that included a photogeological interpretation of satellite-borne remote sensing data using Landsat 8 OLI, SPOT 7, Shuttle Radar Topography Mission (SRTM) and regional airborne geophysical data. The geological interpretation of the remote-sensing data used anaglyph images to generate 3D topographic relief renditions. GaiaPix concluded that the geological mapping delineated structural elements that represented targets for gold exploration and that surface soil geochemical sampling was the recommended follow-up prospecting tool.

- Geophysics: during the 2005 to 2008 exploration campaign, a 25 m-spaced IP survey was conducted over the Nampala geochemical anomaly. In 2021, Robex engaged Eureka Consulting (Pty) Ltd (Eureka) to merge two historical geophysical data sets comprising magnetics and resistivity. Geophysical data has proven valuable in correlating the known geology and structures against the bulk-leach-extractable-gold (BLEG) Au-in-soil geochemical fabric.

- Rock Chip Sampling: during 2009, Robex conducted fieldwork across its exploration permits. A total of 255 rock chip and grab samples were collected.

- Soil Sampling: In line with the recommendations from GaiaPix, Robex commenced a Property-wide BLEG soil sampling geochemistry campaign in December 2021. The BLEG sampling method was used to accurately measure fine-grade gold and sampling heterogeneity, reducing the inherent nugget effect in samples. There is a demonstrated strong relationship between the BLEG Au-in-soil, magnetics, intrusives, and structures.

Drilling

Since drilling first commenced at Nampala pre-1992, >342,000 m of drilling has been completed on the Property. This includes a combination of DD, RC, AC, Rotary Air Blast (RAB) and auger drilling. Current drilling by Robex commenced in 2005. Robex drilling accounts for >312,000 m of the drilling completed on the Property. Drilling has primarily focussed on drilling the Nampala deposit of the Nampala Mine, accounting for ~74% of all drilling. Drilling purposes has included exploration, verification, sterilisation, resource, and reserve delineation, mining geotechnical and water. Drilling completed on the Nampala Property can be summarised as:

- Historical drilling (pre-2005) accounts for 575 drill holes for 30,073 m – almost exclusively AC and RAB drilling.

- Robex drilling (2005 to present) accounts for 5,668 drill holes for 312,851 m (126 x DD drill holes for 21,640 m; 874 x RC drill holes for 88,044 m; 1,806 AC drill holes for 160,735 m; 352 RAB drill holes for 16,465 m; and 2,510 auger drill holes for 25,967 m).

Sample Preparation, Analysis and Security

The Robex procedures for geological sample preparation, analysis, and security are well documented and publicly available. They adhere to best practice procedures and protocols. Robex has utilised two independent commercial laboratories to analyse drilling samples – Bamako SGS Mineral Laboratory in Mali (SGS Bamako) with accreditation number T0652, and SGS Robex-Nampala laboratory at the Nampala mine site, which does not hold formal accreditation. The sample preparation methodology is standard comprising crushing and pulverising of samples to collect a subsample for fire assay using a lead collection fire assay technique with an Atomic Absorption Spectroscopy (AAS) finish. The Robex QA/QC protocol includes the insertion of standards, blanks and field duplicates. One standard, one blank and one field duplicate are inserted into every batch of samples, for 20 samples per batch.

Mining Methods

Mining at Nampala is conducted using a conventional open-pit method, involving contractor operated hydraulic excavators for loading and dump trucks for hauling. In areas of transitional lithology and laterites, drilling and blasting are employed, although most of the material is mined through free digging.

The mining sequence at Nampala is primarily influenced by the plant requirements and the tropical climate’s dry and wet seasons. Oxide and transitional materials differ in processing throughput, with transitional ore typically having a higher grade than oxide ore.

Ore from the Nampala and East Pits will be partially transported to the ROM pad near the crusher, while the remainder will be stockpiled at various locations around the pits to ensure a steady feed to the plant during the wet season. The ore will be segregated into stockpiles based on grade to facilitate optimal blending.

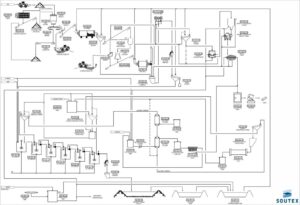

Processing Operations

Since 2017, the Nampala Mine has been in continuous operation, processing primarily oxide material (saprolite). The current processing flowsheet (Figure 4) for the Nampala Mine employs a design consisting of a scrubber, ball mill circuit, and cyclone classification. Gold recovery is achieved through a combination of gravity concentration followed by a carbon-in-leach (“CIL”) process and Zadra elution. Since the initial implementation of the flowsheet), enhancements have been made to improve processing efficiency. A mineral sizer was added to manage large ore blocks, ensuring smoother material handling, and a cone crusher was integrated into the grinding circuit to address critical-size particles, optimising overall grinding performance.

Continuous efforts have been made to reduce reagent consumption, while lime consumption remains high, as is typical for saprolite, cyanide consumption is notably low, with a set point of less than 140 NaCN ppm in the first leach tank and no further additions required.

The requirements associated with the current process are the following:

- Ore: 5,800 t/d of oxidised material with a minimal feed grade of 0.50 g/t Au.

- Water: 1 m3 of water per tonne of processed ore which 2/3 is recirculated.

- Energy: 8 kWh/t to 12 kWh/t for the mill including operation support infrastructures.

- Plant availability of 90%.

Figure 4 Nampala Mine Process Plant Flowsheet

The total gold produced since January 2017 is approximately 370 koz Au. Mill throughput has shown an increasing trend and attributable gold production has averaged 123.7 kg/month. The mine has achieved consistent increases in throughput since 2020. Table 4 shows the production performance from 2020 to 2023. However, in 2024, the introduction of harder transitional ore led to a slight reduction in throughput.

The gold recovery shows an increasing trend to early 2022, resulting from continuous plant optimisation. From early 2022, the gold recovery averaged 88.8% which matches that predicted by metallurgical testwork by Soutex in 2020 (88.8% to 88.9%). Plant availability has shown a constant trend and has averaged 90.3% which matches industry norms. Compared to the 2020 predictions made by Soutex, during the period 2020 to 2023 the mill throughputs were higher than predicted and mill feed gold grades were higher by more than 10%. Target gold recoveries were met, resulting overall in the total gold production being more than 25% higher than predicted.

Table 4: Comparison of Predicted and Actual Production and Recovery Data

| Period | Predicted Plant Feed (t) |

Actual Plant Feed (t) |

Predicted Feed Grade (g/t Au) |

Actual Feed Grade (g/t Au) |

Predicted Gold Rec. (Au %) |

Actual Gold Rec. (Au%) |

Predicted Gold Rec. (Au oz) |

Actual Gold Rec. (Au oz) |

| 2020 | 1,905,000 | 1,886,317 | 0.83 | 0.94 | 88.8 | 88.6 | 45,400 | 50,348 |

| 2021 | 1,905,000 | 1,948,284 | 0.69 | 0.81 | 88.9 | 91.4 | 37,400 | 46,555 |

| 2022 | 1,905,000 | 2,025,463 | 0.67 | 0.81 | 88.8 | 88.6 | 36,300 | 46,650 |

| 2023 | 1,911,000 | 2,224,888 | 0.65 | 0.81 | 88.8 | 89.6 | 35,600 | 51,826 |

| +6% | +19% | +1% | +26% | |||||

Source: Micon (2024) from Soutex (2024) and Robex (2024)

Infrastructure

The current Nampala mine boundary fence has a total length of 12,900 m, enclosing an area of 803 ha. This expansion ensures that the entire mining operation is within a secured boundary, enhancing operational safety and site management.

The Nampala Mine is supplied by two water sources: fresh water and potable water. Potable water is currently sourced from one of three available wells (Well No. 17). For fresh water, 23 wells have been constructed, with 15 currently in operation. These sources ensure a reliable water supply to support operational and domestic needs at the site. Additional water storage is maintained with a buffer water pond with a capacity of 32,734 m3 and a retention pond with a capacity of 32,474 m3.

The Nampala Mine relies on a hybrid power system consisting of two energy sources: a solar plant and a thermal (diesel) power plant. The solar plant includes 7,280 photovoltaic panels with a total installed capacity of 3.39 MW, of which 96% (3.25 MW) is utilised. The thermal power plant provides an additional 10 MW of installed capacity. The system is further supported by a 2.6 MWh battery storage unit, ensuring stability and optimising energy use.

There are two waste dumps near the pits: Waste Dump North, located north of both the East and West Pits, and Waste Dump East, situated east of the East Pit. Waste Dump North had an initial capacity of 3.8 Mm3 of waste, with a planned expansion to accommodate an additional 21.3 Mt. As of October 2023, the Waste Dump North is nearly full, and further expansion is not feasible. Consequently, a new waste dump area was designated east of the East Pit in November 2023 (East Waste Dump). An additional area south of the East Pit has been identified and sterilised for future expansions as a potential waste dump.

Construction of Tailings Pond Cell No. 5 commenced in October 2023. At its current level (340), the cell has a capacity of 591,419 m3, equating to approximately 4 to 5 months of storage at a consolidated density of 1.4 t/m3. Plans are underway to extend Cell No. 5 to Level 345, a process expected to take approximately two months. Once completed, the capacity will increase to 3.2 Mm3, equivalent to 4.48 Mt, providing more than two years of storage capacity. The expansion is permitted.

The principal stockpiles are located north of the pits, near the processing plant. The principal stockpiles have capacity of approximately 250 kt, categorised into high-grade, medium-grade, and low-grade materials.

The Nampala Mine is equipped with a four-bed medical clinic staffed by four nurses and a part-time medical doctor. The facility also includes a pharmacy and a laboratory, the latter currently under construction, to enhance on-site medical services.

There are offices for administration, plant, medical services, training, exploration, mining, geology, and contractors. Other infrastructure on site includes a rubbish treatment plant, warehouse, hangar and airstrip, plant nursery, and communications systems.

The accommodation and welfare facilities at Nampala include a lodging area for security personnel and a camp equipped with a gym, mini shop, and canteen. The total lodging capacity is 119 people. A kitchen dedicated to mill employees provides up to 480 meals per day.

Figure 5 shows layout of the Nampala mine infrastructure

Figure 5 Nampala Mine Infrastructure Layout

Capital and Operating Costs

The mine is currently in production so there is no development capital cost required.

The total capital and closure costs from 1st September 2024 until the end of the LOM are US$37.8m. This includes sustaining capital at US$2.2M and capitalised stripping costs at US$31.5 million and US$4.06M in Closure and contract termination costs. Sustaining Capex was calculated with the latest operating data updated as of December 2024.

The operating costs used in the economic analysis are summarised in Table 5.

Table 5 Operating Costs Summary

| Across the LOM, starting September 2024 | Total | Unit Cost | Costs |

| (US$ million) | (US$/t ore milled) | (per oz US$/oz) | |

| Mining | 47,902 | 11.8 | 414 |

| Processing | 50,237 | 11.2 | 434 |

| General and Administration | 21,221 | 4.7 | 184 |

| Transport, Insurance and Refining | 224 | 0 | 2 |

| Royalty and Statutory Cost | 36,078 | 8 | 312 |

| C1 Costs | 119,584 | 27.8 | 1,034 |

| C2 Costs | 125,885 | 29.2 | 1,089 |

| C3 Costs | 163,095 | 29.4 | 1,410 |

| AISC | 161,963 | 37.2 | 1,401 |

| Revenue | 230,846 | 66 | 2,308 |

Source: Robex December (2024)

Economic Analysis

An updated economic assessment of the Nampala Mine has been conducted, incorporating actual operational data and the new technical inputs outlined in this Report. The economic model was prepared by Australian based Infinity Corporate Finance Pty Ltd., with input data sourced from a variety of contributors, including consultants, current suppliers and contractors, and Robex’s internal technical and financial teams. Key financial parameters, such as the Project’s taxation regime and exchange rates, were also provided by Robex.

The economic model was run at two gold prices; Scenario 1 with gold price of US$1,800/oz used for the Mineral Reserve and Scenario 2 with the S&P consensus long term gold price at end of October 2024 as shown in Table 6.

Table 6: LoM Gold Price

| LOM Gold Price | Years | 2025 | 2026 | 2027 |

| Scenario 1 Mineral Reserve | US$/oz | 1,800 | 1,800 | 1,800 |

| Scenario 2 S&P consensus gold price (end of October 2024) | US$/oz | 2,490 | 2,431 | 2,320 |

The cashflow analysis excludes inflation and presents all financial data in real US dollars as of 30th September 2024. Only cashflows post 30th September 2024 are considered.

The mine has an expected LOM of 27 months (inclusive of stockpiles) from 30th September 2024. As of 30th September 2024, based on consensus forward gold prices and a 5% discount rate, the Project’s estimated NPV is US$71 million post-tax as show in in Table 7.

Table 7: Summary of NPV Scenario’s (as of 1 September 2024)

| Scenario | Unit | NPV 5% | |

| Pre-Tax | Post-Tax | ||

| Scenario 1: $1800/oz | US$m | 48.2 | 28.8 |

| Scenario 2: The S&P consensus gold price (at end October 2024) | US$m | 106.1 | 71.1 |

Source: Robex December (2024)

Post-tax annual cash flows are show in Table 8.

Table 8: Post-tax cashflow at consensus forward gold prices

| Production Summary | Unit | Total / Average | 2024 | 2025 | 2026 | 2027 |

| Ore & Waste Mined | ||||||

| Ore | kt | 4,044 | 554 | 1,934 | 1,556 | – |

| Waste | kt | 11,935 | 1,599 | 6,969 | 3,367 | – |

| Grade | g/t /Au | 0.93 | 0.85 | 0.88 | 1.02 | – |

| Ore Processed | ||||||

| Oxide | kt | 3,723 | 564 | 1,899 | 1,260 | – |

| Transitional | kt | 776 | 4 | 208 | 564 | – |

| Oxide | g/t Au | 0.90 | 0.81 | 0.84 | 0.93 | – |

| Transitional | g/t Au | 1.06 | 0.99 | 0.92 | 1.11 | – |

| Contained Metal | ||||||

| Processed | koz | 130 | 14.80 | 57.20 | 57.90 | – |

| Recovered | koz | 115.4 | 13.14 | 50.81 | 51.69 | – |

| Recovery | % | – | 89% | 89% | 89% | – |

| Project Cashflows After Tax | ||||||

| Net Revenue | US$ million | 230 | 24 | 100 | 106 | – |

| Opex | US$ million | (120) | (15) | (60) | (45) | – |

| Tax | US$ million | (30) | – | (11) | (16) | (3) |

| Change in Working Capital | US$ million | – | 7 | – | (3) | (4) |

| Capex | US$ million | – | – | – | – | – |

| Sustaining Capex | US$ million | (6) | (.5) | (2) | (4) | – |

| Annual Cash Flow | US$ million | 75 | 16 | 28 | 38 | (7) |

Note: the figures have been rounded

Source: Infinity and Robex (2024)

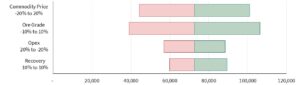

The Project value was evaluated through sensitivity (Figure 6) analyses examining the impact of changes in gold price and operating costs. The analysis indicates that the Project is most sensitive to fluctuations in the gold price, followed by changes in operating costs.

Figure 6 Post-tax NPV5% Sensitivity

Qualified Person

Scientific or technical information in this press release that relates to the geology and exploration history of the Nampala Property was prepared or supervised by Andrew de Klerk, B.Sc.(Hons.), Pr.Sci.Nat. (400030/11), SAIMM, GSSA Principal Geologist and Project Manager, is a full-time employee for Micon International Co Limited. Mr de Klerk is a professional Geoscientist with the South African Council for Natural Scientific Professions (Membership No. 400030/11). He is a member of the South African Institute of Mining and Metallurgy (SAIMM) and a Fellow of the Geological Society of Africa and has sufficient experience that is relevant to the project under consideration which he is undertaking to qualify as a Qualified Person under NI 43-101.

Scientific or technical information in this press release that relates to the geology and exploration history of the Nampala Property was prepared or supervised by André Bezuidenhout, a full-time employee for Micon International Co. Mr Bezuidenhout is a Fellow of The Geological Society of London (No. 1044812) and a registered Professional Natural Scientist (Pr.Sci.Nat. No. 008765) and has sufficient experience that is relevant to the project under consideration which he is undertaking to qualify as a QP under NI 43-101.

Scientific or technical information in this press release that relates to the geological modelling and Mineral Resources was prepared or supervised by Ryan Langdon, a full-time employee for Micon International Co Ltd. Dr Langdon is a Fellow of The Geological Society of London and a registered Chartered Geologist (No. 1022491) and has sufficient experience that is relevant to the project under consideration which he is undertaking to qualify as a QP under NI 43-101.

Scientific or technical information in this press release that relates to the Mineral Reserves was reviewed and prepared by Michiel Frederik Breed, an associate of for Micon International Co Ltd. Mr Breed is a fellow of the South African Institute of Mining and Metallurgy (SAIMM), Member No. 702556 and a Professional Engineer with Engineering Council of South Africa, Registration No. 20130531) and has sufficient experience that is relevant to the project under consideration which he is undertaking to qualify as a QP under NI 43-101.

Scientific or technical information in this press release that relates to the metallurgy and mineral processing of the Nampala Mine was prepared or supervised by Nigel Smalley, a full-time employee for Micon International Co Ltd. Mr Smalley is a Member of the Institute of Materials, Minerals & Mining, MIMMM (No. 459181) and an Associate Member of the Australasian Institute of Mining and Metallurgy (AAusIMM (No. 322114) and has sufficient experience that is relevant to the project under consideration which he is undertaking to qualify as a QP under NI 43-101.

Scientific or technical information in this press release that relates to Environmental Studies, Permitting and Social or Community Impacts was prepared or supervised by Becky Humphrey, an associate of for Micon International Co Ltd. Ms Humphrey is a Full Member of the Chartered Institute of Environmental Management and Assessment (MIEMA), a Professional Member of the Institute of Materials, Minerals and Mining (MIMMM) and a Chartered Environmentalist (CEnv) registered with the Society for the Environment (Registration No. 10664) and has sufficient experience that is relevant to the project under consideration which she is undertaking to qualify as a QP under NI 43-101.

Further details on the scientific and technical information relating to Nampala will be provided in the technical report for the Independent Technical Report on the Nampala, Mininko, Gladie and Kamasso Permits and a Mineral Resource and Reserve Estimate of the Nampala Gold Mine, Mali, West Africa which will be filed on SEDAR at www.sedar.com within the next 45 days.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this press release.

About Robex Resources Inc.

Robex is a multi-jurisdictional West African gold production and development company with near-term exploration potential. The Company is dedicated to safe, diverse and responsible operations in the countries in which it operates with a goal to foster sustainable growth. The Company has been operating the Nampala mine in Mali since 2017 and is advancing the Kiniero Gold Project in Guinea.

Robex is supported by two strategic shareholders and has the ambition to become one of the most important mid-tier gold producers in West Africa.

MORE or "UNCATEGORIZED"

Eloro Resources Announces Closing of Bought Deal LIFE Private Placement for Gross Proceeds of C$17 Million

Eloro Resources Ltd. (TSX: ELO) (FSE: P2QM) is pleased to announce the closing of its previously an... READ MORE

Minera Alamos Updates Resources and Reserves for the Pan Gold Mine in Nevada

Minera Alamos Inc. (TSX-V: MAI) (OTCQX: MAIFF) is pleased to announce updated Mineral Resource and M... READ MORE

Ero Copper Reports Fourth Quarter and Full Year 2025 Operating and Financial Results

Ero Copper Corp. (TSX: ERO) (NYSE: ERO) is pleased to announce its operating and financial results f... READ MORE

Rare Element Resources Announces Results of Oversubscribed Rights Offering of Common Shares

Rare Element Resources Ltd. (OTCQB: REEMF) is pleased to report that its previously announced... READ MORE

TRX Gold Reports Record Q2 2026 Production and Company Update

TRX Gold Corporation (TSX: TRX) (NYSE American: TRX) is pleased to announce preliminary resu... READ MORE