West Red Lake Gold Provides Madsen Mine Restart Activities Update

West Red Lake Gold Mines Ltd. (TSX-V: WRLG) (OTCQB: WRLGF) is pleased to provide an update on activities at the Madsen Mine as the Company advances towards its goal of a targeted restart in 2025.

Since acquiring the Madsen Mine project last year, the Company has completed a site-wide operational assessment to make informed decisions about what surface and underground upgrades would underpin a sustainable mining operation.

“I have led teams through many mine builds and each build reinforced the lesson that operational readiness is essential to a successful mine startup,” said Shane Williams, President and CEO. “Operational readiness spans the entirety of a mine, from infill drilling to stope and development planning to budgeting to maintenance and procurement systems to strong staffing and an active safety culture and much more.

“Since the Madsen mine was acquired with an abundance of infrastructure, our focus has been understanding what to add to increase efficiency and optionality. The team is doing impressive work on these key deliverables and I am pleased to provide this update on the work underway at site.”

Definition Drilling

The Company has been drilling definition holes in the Austin, South Austin, and McVeigh resource areas since October 2023. The definition drilling effort started with one rig and accelerated in April with a second drill. The program has run continuously and over 40,000 metres of drilling has been completed to date.

Definition drilling is fundamental to West Red Lake Gold’s restart plan. Gold mineralization is high grade and pervasive within the known alteration package at Madsen but requires a high level of definition drilling. This is common is high-grade gold systems.

Tightly spaced definition drill holes to inform an accurate geologic model is an essential step in mitigating continuity risk and enabling mine plans that target mineralization and identify waste. The Company views this feedback loop – definition drilling, resource model updating, stope planning, and mine engineering – as the foundation of a successful mine.

Tailing Storage Facility Dam Lift

A tailings dam lift project got underway in early August. Increasing the dam height by 4 metres will create enough additional tailings capacity for 10 years of operation, assuming a milling rate of 800 tonnes per day.

The tailings dam project is a critical part of the mine restart plan. Sigfusson Northern is the main construction contractor, with JDS Energy & Mining and Knight Piésold Consulting involved in construction management and QA QC/EOR (engineer on record). To date the progress has been excellent: 60% of the work has been completed and the project is tracking ahead of schedule and under budget. This has the project on track to be ready to receive material well before start of the winter period.

Figure 1: Aerial view of progress on the project to increase the height of the tailings dam by 4 metres.

Connection Drift

The Connection Drift is a 1,200-metre haulage way being driven to connect the East and West ramps of the underground mine at Madsen. These ramps, with independent portals, were not previously connected, resulting in substantial inefficiencies in moving mined material to the mill.

The Company raised $10 million via Canadian Development Expense flow-through funds (see May 16, 2024, news release) to finance this project. Dedicated project equipment has been brought on site, including an Epiroc Jumbo drill, and is active underground. The drift was initiated in August, is at 5% completion to date, and is targeted for completion in February 2025.

Figure 2: The Epiroc Jumbo drill brought on site for the Connection Drift project, heading to the portal.

Mine Dewatering and Evaporator Fans

There is opportunity to extend the limits of known mineralization at the Madsen mine to depth. The neighbouring mines operated by Evolution Mining currently mine down to 3000 metres; by contrast, resources at the Madsen Mine have been defined down to only 1200 metres. Multiple historic drill holes that returned notable mineralization from downplunge of the defined resource underscore this potential. And parts of the defined resource, including the 8 Zone that carries the highest grades of the resource areas at Madsen, are below the current water level.

Water dropped below the 13 level of the mine in early July. Mining areas in the first few years of the restart plan are all above the 12 level. However, dewatering of the Madsen Mine is a critical long-term objective because the Company wants to create the option to mine deeper, to access known and potential mineralization.

To this end, two evaporator fans were delivered and installed in August to create additional dewatering capacity. By helping water evaporate, the fans effectively increase the holding capacity of the polishing pond. This additional capacity will ease pressure on the water treatment system in the spring, when natural runoff adds volume to the polishing pond, and through the summer, when dry conditions can suspend the ability to discharge into Coin Creek.

Optimal performance from the water treatment plant throughout the summer, a season that has also seen enough rainfall to keep Coin Creek running and thus allow consistent discharge of treated water, has pulled the level in the polishing pond down 2 metres since March. The pond is on track to reach target minimum operating level by fall. Record daily volumes through the plant, averaging over 5,000 cubic metres of water a day, made this possible even as dewatering in the mine advanced another 46 metres.

Primary Crusher

The Company is pleased to report a procurement deal with Powerscreen of Canada, a dealer for Terex Corporation, for the purchase of a primary crusher. Delivery is expected in October.

The electric primary jaw crusher plant (model CRJ3042) reduces rock from 19.6-inch feed size to 4-inch or less. The crusher can process 145 tonnes of rock per hour. The mill at the Madsen Mine has a nameplate capacity of 800 tonnes per day.

Figure 3: An electric primary jaw crusher plant of the kind West Red Lake Gold procured for the Madsen Mine, loaded for transport from supplier Powerscreen of Canada

Test Mining

Test mining is now underway. The program has two goals: to inform safe and effective mine planning and to produce bulk samples for reconciliation calculations.

A result of Madsen Mine’s operational history is a range of mining environments, including resource areas with no nearby mining, areas adjacent to empty stopes, and areas adjacent to backfilled stopes. Test mining will assess how to operate in these environments safely and effectively.

A historically uncharted void and small discrepancies between mapped and actual stope locations slowed the program in its early days. After incorporating early learnings, the engineering and production teams have now developed a detailed plan for this test mining program, including a schedule of areas for bulk sampling. Bulk samples will be batch-processed to enable mine-to-mill reconciliation calculations. The Company looks forward to publishing updates on this plan.

Equipment

Mining equipment continues to arrive on site to support underground development, test mining, and the Connection Drift, and in anticipation of equipment needs upon a restart decision being made. Equipment additions of late include a CAT 730C Haul Truck, two Epiroc ST2G LHD (load-haul-dump), a Getman 4000 Anfo Loader, a Manitou MT1440 Telehandler, and a CAT R1700K LHD.

The Madsen mine was acquired with some mobile equipment, though many newer items were removed from site during the CCAA process that predated West Red Lake Gold. Equipment arriving now is thus improving and expanding an existing fleet.

Figure 4: Epiroc ST2G LHD and CAT 730 Haul Truck

Figure 5: Getman 4000 Anfo Loader and CAT 966M Wheeled Loader

Work Force Accommodations and Mine Site Facilities

West Red Lake Gold has placed a purchase order for mine site accommodations and a Mine Dry facility for the Madsen Mine. Permitting with local authorities is underway.

The Company understands the commitments of remote work and wants to ensure that workforce accommodations are of top quality and provide a home away from home for its employees. West Red Lake has partnered with Horizon North to provide 114-person accommodations and mine dry facilities for the Madsen mine site. These facilities are targeted for operation in February 2025.

Horizon North is an industry leader in providing accommodations and services to meet workforce requirements within the mining industry in Canada and serves major mines across Canada.

Figure 6: A drawing of the work force accommodations planned for the Madsen Mine, being built and operated by Horizon North.

Figure 7: A photo of a similar Horizon North facility, taken during an inspection by West Red Lake Gold employees

Site Team

The workforce at the Madsen mine continues to grow, with 48 new positions filled in the last three months. Many posted positions elicit multiple applications from qualified candidates, highlighting the advantage of operating in a well-established mining district such as Red Lake.

Recent hires include several leadership positions that the Company was pleased to fill with strong candidates.

David Towle joined as Mill Manager. Mr. Towle has over 35 years of experience in mill operations and production and has held the roles of Mill Manager and Mill Superintendent on multiple occasions. He recently worked as Commissioning Manager at Ascot Resources’ Premier project in British Columbia. Previous roles involved managing mill construction and start-up at Lion One Metals’ Tuvatu project in Fiji, Atlantic Gold’s (now St. Barbara’s) Touquay Mine, and Pretium Resources’ (now Newmont’s) Brucejack Mine.

Mr. Towle has a long history of success with the Madsen Mill. He worked in the facility in 1989 when it was a Placer Dome asset located in Pickle Lake, Ontario; he oversaw moving, rebuilding, and recommissioning the mill at the Madsen site under Pure Gold; and he will now guide the facility through another anticipated restart under West Red Lake Gold.

Gavin Clow joined as Chief Engineer. Mr. Clow is a professional mining engineer with a Bachelor of Applied Science from the University of Toronto and extensive industry experience. His recent role as Manager Mining Canada at Optimize Group involved overseeing a broad range of operations, from feasibility studies to pit design and project costing. His expertise includes managing open pit and underground mining projects and leading significant initiatives like mine scheduling system creation and feasibility studies. Previous roles at Dumas Contracting, Klondex Mines, and Rambler Metals & Mining grounded his skills in project estimation, production planning, and infrastructure design.

QUALIFIED PERSON

The technical information presented in this news release has been reviewed and approved by Maurice Mostert, P.Eng., Vice President of Technical Services for West Red Lake Gold and the Qualified Person for technical services at the West Red Lake Project, as defined by National Instrument 43-101 Standards of Disclosure for Mineral Projects.

ABOUT WEST RED LAKE GOLD MINES

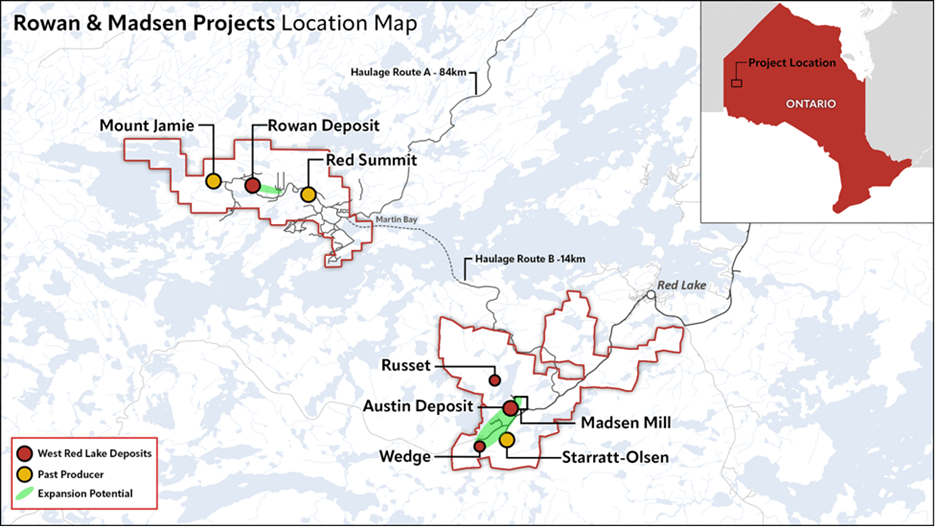

West Red Lake Gold Mines Ltd. is a mineral exploration company that is publicly traded and focused on advancing and developing its flagship Madsen Gold Mine and the associated 47 km2 highly prospective land package in the Red Lake district of Ontario. The highly productive Red Lake Gold District of Northwest Ontario, Canada has yielded over 30 million ounces of gold from high-grade zones and hosts some of the world’s richest gold deposits. WRLG also holds the wholly owned Rowan Property in Red Lake, with an expansive property position covering 31 km2 including three past producing gold mines – Rowan, Mount Jamie, and Red Summit.

MORE or "UNCATEGORIZED"

Delta Reports New Gold Intercept at Nova Target in Wedge Area, 4 Kilometres West of Eureka; Follow-Up Drill Program Underway

Delta Reports New Gold Intercept at Nova Target in Wedge Area, 4 ... READ MORE

Silver One Announces Closing Of Final Tranche Of $32 Million Financing

Silver One Resources Inc. (TSX-V: SVE) (OTCQX: SLVRF) (FSE: BRK1)... READ MORE

SAGA Metals Achieves 100% Drilling Success in 2025—Reports Final Assays from Trapper South at Radar Critical Minerals Project in Labrador

Exceptional grades of Titanium, Vanadium and Iron in all 15 drill... READ MORE

Near Surface Intersection Yields 6.58 g/t gold over 10.35 metres

Intersection is within 33 metres from surface and contained in a ... READ MORE

Alamos Gold Provides Three-Year Operating Guidance Outlining 46% Production Growth by 2028 at Significantly Lower Costs

Further production growth to one million ounces annually expected... READ MORE