NorthWest Copper Reports Positive Metallurgical Recoveries of 94% Copper, 71% Gold and 92% Silver at the Lorraine Deposit

NorthWest Copper (TSX-V: NWST) is pleased to report that positive metallurgical results have been achieved from the first modern metallurgical work completed on samples from the Lorraine copper-gold-silver deposit, located in north-central British Columbia. Highlights of the test work include:

- High batch cleaner flotation recoveries of up to 94%, 71% and 92% for copper, gold and silver, respectively.

- High metal recoveries at a relatively coarse primary grind size of 80% passing 150 microns.

- Production of Cu concentrates with 31 to 54% Cu that contain 7.4 to 25.4 g/t Au and 152 to 405 g/t Ag, and also up to 1.64 g/t palladium and anomalous platinum.

- Low concentrations of potentially deleterious trace elements in the Cu concentrate.

“These metallurgical results demonstrate that mineralization in our Lorraine deposit can potentially produce high metal recoveries to a clean, high-grade salable copper concentrate”, stated Tyler Caswell, Vice President Exploration for NorthWest. “The results also highlight several opportunities for optimizing future metallurgical work, improving metal recoveries and evaluating other beneficial metal recovery-energy consumption trade-offs to positively impact future project evaluation.”

The test work program described below was designed by Base Metallurgical Laboratories Ltd. and BOMENCO Minerals Engineering Corp. The work was executed by Base Met in their facilities in Kamloops, BC. Both groups are independent of NorthWest. Samples for compositing were collected by the NorthWest Copper geology team.

Composite Samples

The metallurgical program tested five composite samples that ranged from 19.6 kg to 37.4 kg in size, and included one from the Bishop Zone (BZC) and four from the Lower Main Zone (LMC1-4; Table 1). Two composites were created from half-split historical drill core, which was deemed suitable for scoping test work because it was intact, had been well stored, and had very low pyrite concentration that minimized surface oxidation of sulphide minerals. The remaining three samples are from the Lower Main Zone and comprised assay coarse reject material from drill holes completed by Northwest in 2022. These crushed materials have a large surface area compared to intact core, and to prevent surface oxidation of the sulphide minerals these three samples were placed in frozen storage immediately after routine geochemical analyses. The samples contain disseminated copper mineralization hosted by pyroxenite and syenite, which are the predominant material types in the Lorraine deposit. The samples were selected to be reasonable geological and geochemical representations of the main styles of mineralization at Lorraine, as currently understood, and therefore are interpreted to be reasonable for use in the scoping metallurgical test work reported here. Copper concentrations in the five composites range from approximately average (0.61 % Cu) to higher grade (1.21% Cu), in comparison to the average grade of 0.55% Cu in the indicated mineral resources estimate at the Lorraine deposit.1

Table 1. Composite characteristics and head assay grades.

| Composite | Material Used | Rock Type | Mass (kg) |

Head Assay | |||||

| Cu% | Au g/t | Ag g/t | Pt g/t | Pd g/t | S% | ||||

| Bishop Zone (BZC) | Half core | pyroxenite | 36.5 | 1.15 | 0.14 | 9.60 | <0.01 | 0.03 | 0.51 |

| Lower Main Zone (LMZ1) | Half core | syenite | 31.5 | 1.21 | 0.86 | 8.80 | <0.01 | 0.01 | 0.64 |

| Lower Main Zone (LMZ2) | Coarse Rejects |

syenite | 26.7 | 0.79 | 0.31 | 4.80 | <0.01 | 0.01 | 1.16 |

| Lower Main Zone (LMZ3) | Coarse Rejects |

syenite & monzonite | 37.4 | 0.77 | 0.36 | 6.00 | <0.01 | 0.01 | 0.38 |

| Lower Main Zone (LMZ3) | Coarse Rejects |

pyroxenite | 19.6 | 0.61 | 0.30 | 3.40 | <0.01 | 0.03 | 0.46 |

Summary of Recovery Tests

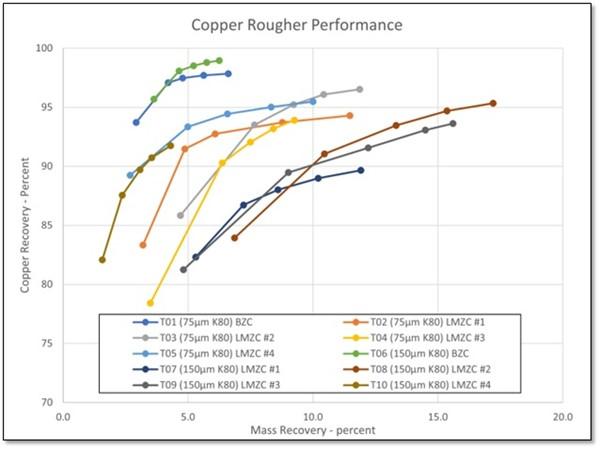

Two sets of five-stage rougher flotation tests compared results from typical porphyry (75 µm) and coarse (150 µm) primary K80 grind sizes (Table 2). Copper recoveries of 94-98% were achieved at the finer grind, whereas the coarse grind recovered 90-99% Cu (Figure 1). Overall recoveries at the two grind sizes ranged from 66-90% for Au, and from 86-97% for Ag. The results support potential to beneficiate Lorraine mineralization at a relatively coarse, possibly energy-saving grind size without a large impact on metal recovery, and this opportunity can be assessed by future grind size versus metal recovery trade off studies. A gravity test on 150 µm grind size material recovered 4-24% of gold to a gravity concentrate, and when the gravity tails were treated by rougher flotation there was a modest improvement in overall gold recovery, providing an additional possible avenue to further improve performance.

Table 2. Summary of rougher flotation recoveries.

| Comp | Primary Grind Size (µm K80) | Recovery (%) | ||||

| Cu | Au | Ag | Pt | Pd | ||

| BZC | 75 | 97.8 | 86.3 | 96.9 | 37.9 | 75.2 |

| 150 | 99.0 | 89.5 | 97.0 | 35.4 | 75.0 | |

| LMC1 | 75 | 94.3 | 80.4 | 92.9 | 20.9 | 37.8 |

| 150 | 89.7 | 70.5 | 85.6 | 31.8 | 38.3 | |

| LMC2 | 75 | 96.5 | 76.8 | 90.8 | 15.6 | 45.5 |

| 150 | 95.3 | 82.9 | 85.7 | 29.3 | 50.6 | |

| LMC3 | 75 | 93.9 | 81.5 | 93.2 | 19.7 | 41.9 |

| 150 | 93.6 | 85.7 | 88.3 | 20.5 | 47.1 | |

| LMC4 | 75 | 95.5 | 75.4 | 88.5 | 33.8 | 68.1 |

| 150 | 91.8 | 66.4 | 88.1 | 38.5 | 62.9 | |

_______________

1 See NI 43-101 technical report titled “Lorraine Copper-Gold Project NI 43-101 Report & Mineral Resource Estimate Omineca Mining Division, B.C”, dated September 12, 2022 with an effective date of June 30, 2022, filed under the Company’s SEDAR+ profile at www.sedarplus.com.

Figure 1. Copper recovery curves for rougher flotation tests at two primary grind sizes.

Cleaner flotation tests go an important step beyond rougher tests and more closely simulate concentrate production potential. Cleaner tests were completed on material ground to 150 µm for initial rougher flotation, followed by a regrind targeting a 25 µm size before progressing through three-stage open circuit cleaner flotation. The samples performed extremely well (Table 3). The Bishop Zone composite had Cu, Au and Ag recoveries of 94%, 71% and 92%, respectively, to a concentrate with 54% Cu, 7.4 g/t Au, and 405 g/t Ag. Samples from the Lower Main Zone had recoveries of 83-89% Cu, 57-70% Au, and 74-83% Ag to concentrates with 31-49% Cu, 11-25 g/t Au, and 152-360 g/t Ag. The high Cu concentrations in the concentrate (up to 54% Cu) reflect the hypogene (unweathered) copper sulphide mineralogy of the mineralization, which in addition to chalcopyrite (~34 wt % Cu) also includes bornite (~63 wt % Cu) and chalcocite (~80 wt % Cu). Intriguingly, two samples also returned 1.41 and 1.64 g/t Pd accompanied by significantly anomalous Pt. Analyses of the five copper concentrates produced by the cleaner flotation tests demonstrate that Lorraine can produce high quality concentrates with all trace elements below likely penalty threshold concentrations.

Table 3. Cleaner concentrate compositions and recoveries.

| Comp | Cleaner Concentrate Performance | |||||||||

| Assay % or g/t | Recovery% | |||||||||

| Cu | Au | Ag | Pt | Pd | Cu | Au | Ag | Pt | Pd | |

| BZC | 54.4 | 7.35 | 405 | 0.21 | 1.41 | 94.2 | 71.2 | 91.5 | 28.8 | 76.1 |

| LMC1 | 48.4 | 25.4 | 317 | 0.06 | 0.21 | 83.4 | 57.2 | 78.5 | 10.2 | 27.6 |

| LMC2 | 31.3 | 11.3 | 152 | 0.04 | 0.22 | 89.1 | 69.3 | 74.3 | 7.8 | 29.9 |

| LMC3 | 48.9 | 22.5 | 360 | 0.08 | 0.38 | 85.6 | 70.1 | 82.5 | 9.1 | 29.9 |

| LMC4 | 52.3 | 20.0 | 292 | 0.26 | 1.64 | 87.4 | 64.8 | 79.5 | 19.5 | 53.6 |

Comminution Tests

Bond Ball Mill work indices were measured on each of the five composites to assess grindability. Results range from 15.0 kWh/t (average hardness) to 20.3 kWh/t (very hard) and are in line with expectations that were based on core competency and rock mineralogy and texture.

Table 4. Glossary of Terms2

| Ball Mill | A mill in which tumbling steel balls grind larger particles to a smaller size. |

| Comminution | The breaking of large particles into smaller particles. The most common comminution processes are crushing and grinding. |

| Composite | A larger sample created by combining several smaller samples. |

| Concentrate | The valuable product from a flotation mineral processing plant. |

| Flotation | A common mineral recovery process whereby chemicals are added to water to cause target minerals (such as Cu minerals) to attach to rising air bubbles, which are then removed to recover the ore minerals into a concentrate. |

| Recovery | The percentage of the valuable metal present in the feed that reports to the concentrate. |

Lorraine

The Lorraine deposit is part of the Lorraine Project. The Lorraine Project covers 56,000 hectares and is located in north-central British Columbia, 280 km northwest of Prince George, BC and approximately 40 km from NorthWest’s Kwanika-Stardust Project. The Lorraine deposit is located near the centre of the Project tenure and is a silica-undersaturated alkalic copper-gold porphyry deposit, which is the same classification as the Galore Creek and Mount Polley deposits.3 Mineralization at the Lorraine deposit is hosted mostly by Early Jurassic syenite and pyroxenite intrusions that are part of the Duckling Creek Syenite Complex (“DCSC”). A modern, compliant mineral resource estimate (MRE) was completed in 2022 that includes indicated resources of 12.952 Mt grading 0.55% Cu and 0.16 g/t Au, and inferred resources of 45.252 Mt grading 0.43% Cu and 0.10 g/t Au. 4 As described in previous disclosures, however, gold concentration is likely understated and silver was not included in the estimation because many historical drill holes were inconsistently analyzed for the two metals. The MRE extends to surface and includes the Lower Main, Upper Main, and Bishop Zones and intervening rock. Copper sulphides manifest various combinations of chalcopyrite, bornite and hypogene chalcocite, and the concentration of pyrite is generally low. Gold and silver, where analyzed, are spatially related to the copper mineralization, and elevated concentrations of platinum and palladium have been reported in several published papers.

_______________

2 https://www.911metallurgist.com/blog/mineral-processing-glossary

3 Lang et al. (1995) Triassic-Jurassic silica-undersaturated and silica-saturated alkalic intrusions in the Cordillera of British Columbia: Implications for arc magmatism. Geology, v. 23, p. 451-454.

4 See NI 43-101 technical report titled “Lorraine Copper-Gold Project NI 43-101 Report & Mineral Resource Estimate Omineca Mining Division, B.C”, dated September 12, 2022 with an effective date of June 30, 2022, filed under the Company’s SEDAR+ profile at www.sedarplus.com.

Quality Assurance / Quality Control

Geochemical analyses reported by Base Met utilize a variety of analytical methods to optimize results for specific elements and elemental groups. All analyses were completed by Base Met, with exception of chlorine and fluorine analysis. Gold was analyzed by fire assay with AAS finish, whereas platinum-palladium is based on fire assay with ICP-OES finish. Sulphur and TOC were measured by LECO. Copper was determined by single element aqua regia digestion with AAS finish, whereas silver, arsenic and antimony used an ICP-OES finish. Other trace elements were measured by aqua regia digestion and ICP-OES analysis. Whole rock analyses use ICP-OES following total digestion by lithium metaborate fusion. Chlorine was analyzed by Short Lived INAA using method code 4F-Cl, and fluorine was determined by Fusion Specific Ion Electrode analysis (method code 4F-F) at Activation Laboratories in Ancaster, Ontario. All methods employed certified reference materials for analytical control.

Drilling completed at Lorraine in 2022 was supervised by on-site NorthWest personnel who collected and tracked samples and implemented a full QA/QC program using blanks, standards and duplicates to monitor analytical accuracy and precision. The samples were sealed on site and shipped to AGAT Laboratories in Calgary, Alberta. AGAT’s quality control system complies with global certifications for Quality ISO 9001:2015. Core samples were analyzed using a combination of AGAT’s 201-071 process for low-level concentrations (ICP-MS/4 Acid digestion) and higher-level concentrations were finalized with method 201-097 (Sodium Peroxide Fusion/ICP-OES). Gold assaying was completed with 202-055, a 30-gram fire assay with ICP finish.

Technical aspects of this news release have been reviewed, verified, and approved by Tyler Caswell, P.Geo., VP Exploration of NorthWest, and Matt Bolu, M.Sc., P.Eng., Principal Metallurgical Engineer, BOMENCO Minerals Engineering Corp, both of whom are qualified persons as defined by National Instrument 43-101 – Standards of Disclosure for Minerals Projects.

About NorthWest Copper:

NorthWest Copper is a copper-gold explorer with a pipeline of advanced and early-stage projects in British Columbia. With a robust portfolio in a tier one jurisdiction, NorthWest Copper is well positioned to participate fully in a strengthening global copper market. We are committed to responsible mineral exploration and are working collaboratively with First Nations to ensure future exploration and development incorporates stewardship best practices and traditional land use.

MORE or "UNCATEGORIZED"

Delta Reports New Gold Intercept at Nova Target in Wedge Area, 4 Kilometres West of Eureka; Follow-Up Drill Program Underway

Delta Reports New Gold Intercept at Nova Target in Wedge Area, 4 ... READ MORE

Silver One Announces Closing Of Final Tranche Of $32 Million Financing

Silver One Resources Inc. (TSX-V: SVE) (OTCQX: SLVRF) (FSE: BRK1)... READ MORE

SAGA Metals Achieves 100% Drilling Success in 2025—Reports Final Assays from Trapper South at Radar Critical Minerals Project in Labrador

Exceptional grades of Titanium, Vanadium and Iron in all 15 drill... READ MORE

Near Surface Intersection Yields 6.58 g/t gold over 10.35 metres

Intersection is within 33 metres from surface and contained in a ... READ MORE

Alamos Gold Provides Three-Year Operating Guidance Outlining 46% Production Growth by 2028 at Significantly Lower Costs

Further production growth to one million ounces annually expected... READ MORE