Rupert Resources Reports Preliminary Economic Assessment for Ikkari Outlining After-Tax NPV of US$1.6B

Rupert Resources Ltd (TSX-V:RUP) is pleased to announce results from its Preliminary Economic Assessment for the Company’s 100% owned Rupert Lapland Project, including our flagship Ikkari gold discovery and Pahtavaara mine and mill located in Northern Finland.

{All figures are in US$ unless otherwise noted}

PEA Highlights:

- High-confidence, de-risked resource: Flagship Ikkari deposit’s updated Mineral Resource Estimate upgrades 84% of ounces to the Indicated resource category, and defines a cohesive deposit with broad intervals of consistent high-grade gold.

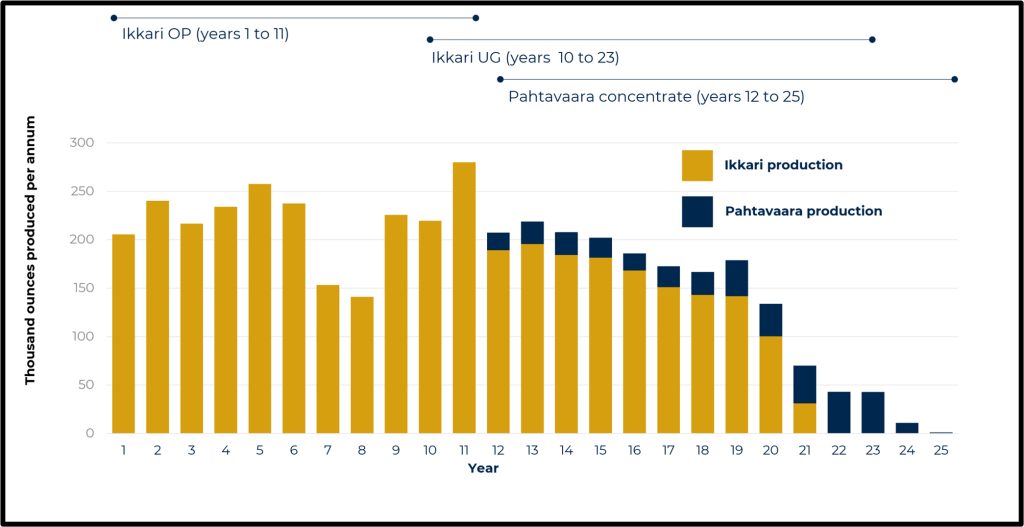

- Phased mine plan optimizing near-term cash flow: Open-pit operation at Ikkari in first 11 years, transitioning to Ikkari underground (years 10-23) and Pahtavaara concentrate (years 12 to 24).

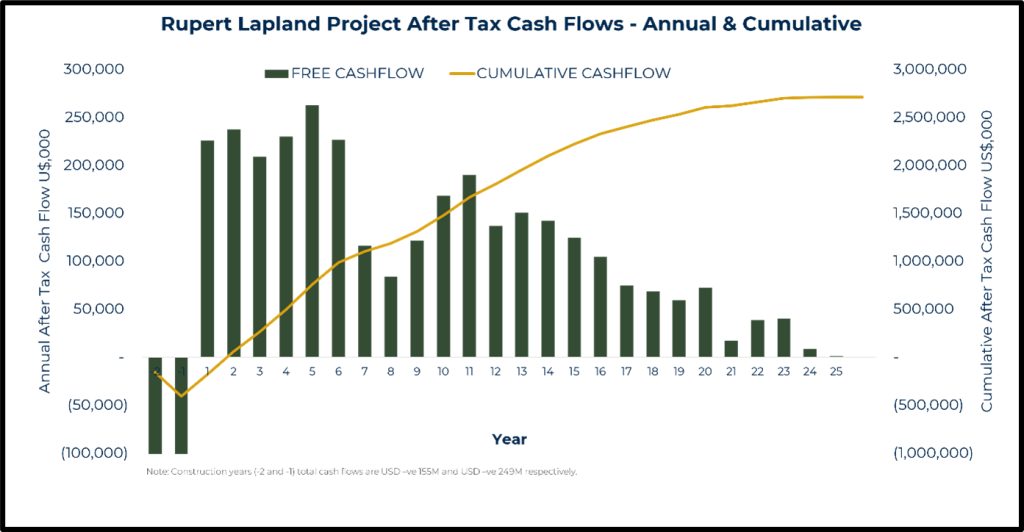

- Robust returns and fast-track to payback: After-tax Net Present Value (5% discount) of $1.6 billion with unlevered Internal Rate of Return of 46% and payback after only two years, assuming a gold price of $1,650 per troy ounce.

- Long life: 22-year life of mine includes recovered gold of 4.25 million ounces with average annual production of 200,000 ounces. Open pit operation is expected to support average annual production of 220,000 ounces in years one to 11.

- High margin production profile: Expected lowest quartile all-in sustaining cost of $759/oz over LOM, and $596/oz during open-pit operation. Low sensitivity to cut-off grade and low initial strip ratio.

James Withall, CEO of Rupert Resources, commented:

“This PEA study indicates exceptionally high-margin and meaningful returns on a robust project. The results are a testament to both the quality of the asset and our technical team. In only three years, we’ve gone from discovery hole to a preliminary study outlining an after-tax NPV of $1.6 billion, anchored by Ikkari. What excites us is that we still have room to grow at Ikkari and other satellite targets that we will be drill testing this winter. We have a real opportunity to not only advance Ikkari as outlined in our PEA, but systematically develop a cornerstone asset in a significant new gold camp over time.”

Study team and cautionary statement

The PEA study team was led by Tetra Tech, a global provider of consulting and engineering services for mining projects. Tetra Tech was supported by International Resource Solutions Pty Ltd (resource estimation), Axe Valley Mining Consultants Ltd (mining), SRK Ltd (geotechnical and hydrological studies), Grinding Solutions Ltd (metallurgy), Paterson & Cook (tailings) and Envineer Oy (environmental studies).

The Mineral Resource estimate included in the PEA is reported according to the classification criteria set out in the Canadian Institute of Mining, Metallurgy, and Petroleum Definition Standards for Mineral Resources and Reserves. These standards are internationally recognized and allow the reader to compare the Mineral Resource with that reported for similar projects.

The results of the PEA will be set forth in an independent technical report prepared in accordance with National Instrument 43-101 Standards of Disclosure for Mineral Projects which will be filed on SEDAR under the Company’s profile within 45 days of the date of this news release.

Readers are cautioned that the PEA summarized in this press release is intended to provide only an initial high-level review of the project potential and that the PEA is preliminary in nature and is intended to provide an initial assessment of the project’s economic potential and development options. The PEA mine schedule and economic assessment includes numerous assumptions and is based on both Indicated and Inferred mineral resources. Inferred resources are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves, and there is no certainty that the project economic assessments described herein will be achieved or that the PEA results will be realized. Mineral Resources are not Mineral Reserves and do not have demonstrated economic viability. Additional exploration will be required to potentially upgrade the classification of the Inferred Mineral Resources to be considered in future advanced studies.

Summary

Table 1. Project production summary

| Years 1 to 11 | LOM (22 years) | ||

| Milled tonnes | Million tonnes | 37.9 | 71.6 |

| Mill throughput | Million tonnes per annum | 3.5 | 3.5 |

| Strip ratio | Waste : Ore | 3.6 | 4.6 |

| Average processed grade | Grams per tonne (gold) | 2.1 | 1.9 |

| Average metallurgical recovery | % | 95 | 95 |

| Average annual gold production | 000 troy ounces | 220 | 200 |

| Recovered gold | Million troy ounces | 2.4 | 4.2 |

| Total Cash Cost | $ / troy ounce | 501 | 667 |

| Sustaining capital | $ / troy ounce | 95 | 93 |

| All in Sustaining Cost (AISC) | $ / troy ounce | 596 | 759 |

As per the World Gold guidance (Gold All in Sustaining Costs | Gold AISC | World Gold Council), the objective of the all-in sustaining costs metric is to provide key stakeholders (i.e. management, shareholders, governments, local communities, etc.) with comparable metrics that reflect as close as possible the full cost of producing and selling an ounce of gold, and which are fully and transparently reconcilable back to amounts reported under Generally Accepted Accounting Principles as published by the Financial Accounting Standards Board (“FASB” also referred to as “US GAAP”) or the International Accounting Standards Board (“IASB” also referred to as “IFRS”). AISC and AIC are non-GAAP metrics subject to regulatory and disclosure requirements of the various jurisdictions applicable to the reporting company.

Table 2. Project economics

| Life of mine | Years | 22 |

| Net Present Value (5% discount rate) | USD million | 1,600 |

| Internal rate of return (unlevered) | % | 46 |

| Payback | Years | 2.0 |

| Capital expenditure (Initial) | USD million | 405 |

| Capital expenditure (Sustaining) | USD million | 395 |

| Revenue | USD million | 6,955 |

| Operating cost | USD million | 2,775 |

| Free cash (after tax) | USD million | 2,710 |

Table 3. Project operating cost

| Life of mine operating cost | USD / tonne milled | USD / oz |

| Mining | 18.1 | 333 |

| Water treatment | 1.4 | 26 |

| Concentrate freight | 0.1 | 2 |

| Processing | 10.9 | 204 |

| Tailings | 1.6 | 28 |

| Closure fund | 0.8 | 15 |

| G&A | 2.4 | 44 |

| Freight/Refining | 0.1 | 3 |

| Royalty | 0.7 | 12 |

| Total Cash Costs | 36.1 | 667 |

Table 4. Project capital costs

| Initial capex | USD millions |

| Mining o/p pre-production | 16.6 |

| Process Plant | 131.0 |

| Civils and infrastructure | 29.5 |

| Water treatment | 96.4 |

| Tailings | 20.4 |

| First fills & spares | 10.0 |

| Owner’s Costs | 20.0 |

| Closure bond | 37.2 |

| Contingency | 43.5 |

| Total initial capex | 404.6 |

| Sustaining capex | USD millions |

| Pahtavaara initial capex | 41.0 |

| Underground mining | 178.8 |

| Water treatment | 34.0 |

| Tailings & waste dump | 34.9 |

| Plant sustaining | 101.0 |

| Pahtavaara closure bond | 5.0 |

| Total | 394.7 |

Table 5. Model inputs

| Assumption | Unit | Value |

| Gold price | USD / troy ounce | 1650 |

| Exchange rate | EUR / USD | 1:1 |

| Corporate tax rate | % | 20 |

Mining

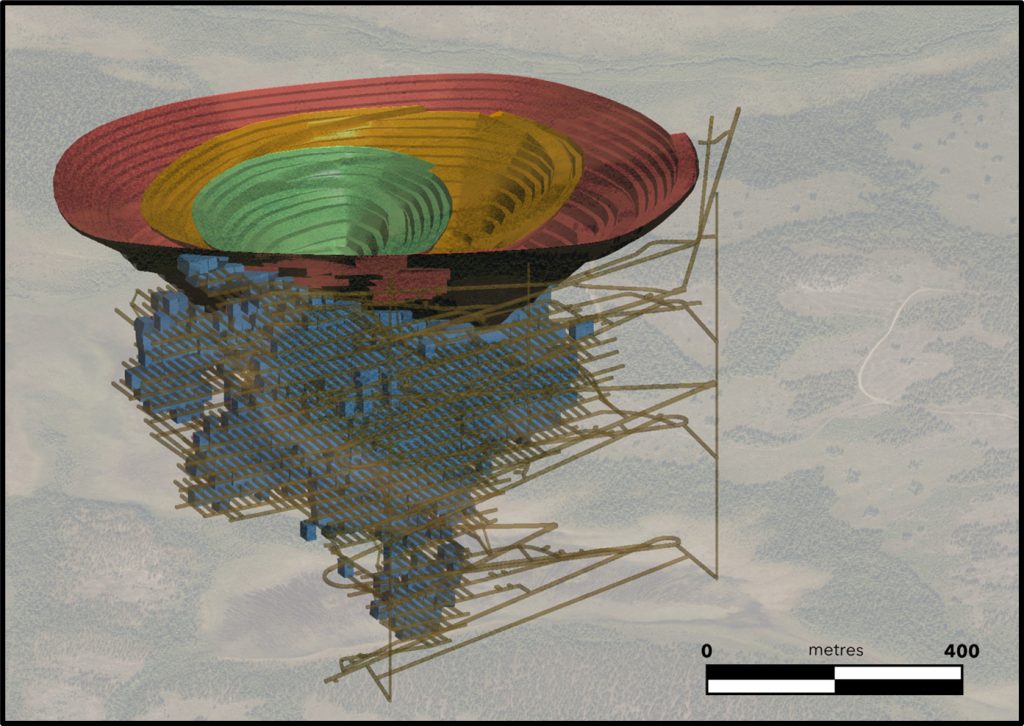

- 11 year open pit operation at Ikkari, followed by an 11 year underground operation

- ROM feed supplemented by Pahtavaara 11g/t Au concentrate from year 12

- Low initial strip ratio of 1.6, 3.6 average over life of Ikkari open pit.

The PEA considers that Ikkari will be initially developed as an open pit with a target production rate of 3.5 Mtpa of plant feed. As the open pit reaches the end of its life (after 11 years) the underground development will be completed so that the underground operation can continue as the open pit is depleted. The transition point between open pit and underground operations was determined by operating costs as well as the limitation of the current exploration permit boundary. Open pit mining at Ikkari is expected to utilise a conventional shovel and truck configuration (140 tonne medium sized haul trucks matched with 300 tonne hydraulic excavators). Underground mining at Ikkari was modelled assuming the sub-level caving method. The mine at Pahtavaara will be re-developed as an open pit and underground mine (employing the long hole open stoping method) to produce a high-grade concentrate which will then be hauled by road to the Ikkari plant for final processing.

Table 6. PEA Ikkari open pit strip ratios

| OP stage | Strip ratio (waste : ore) |

| 1 | 1.6 |

| 2 | 2.7 |

| 3a | 5 |

| 3b | 5.5 |

| Total | 3.6 |

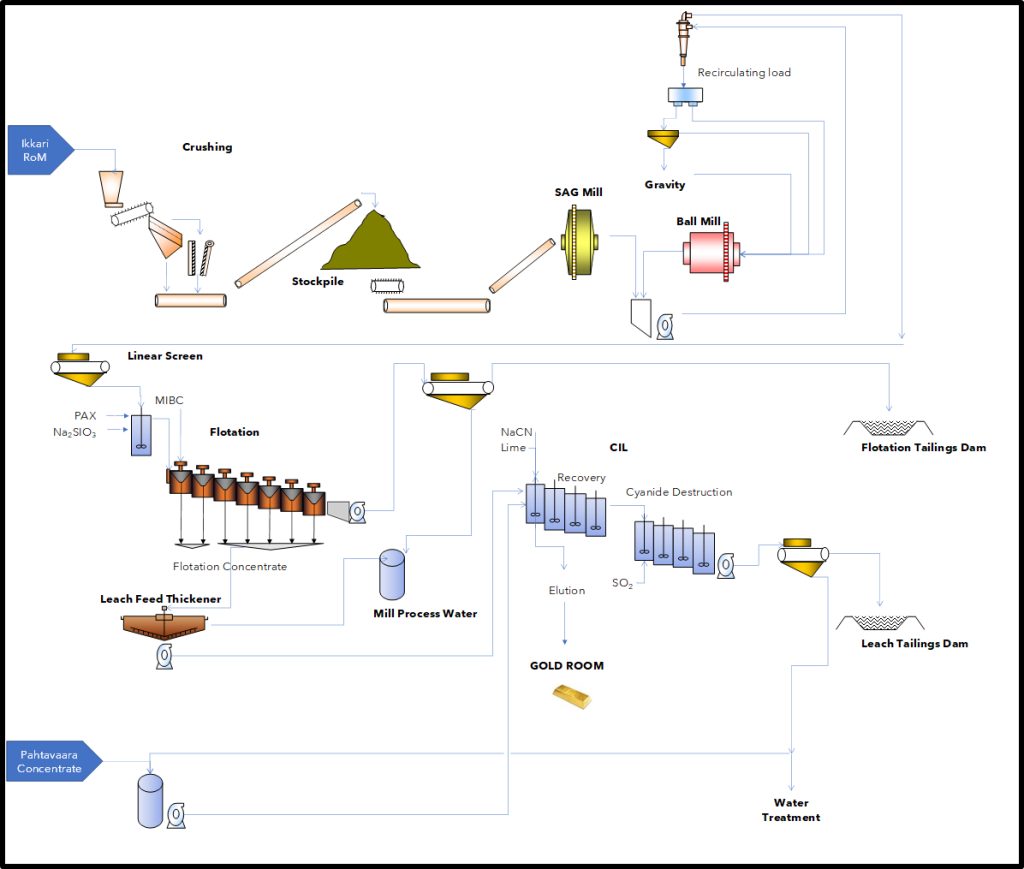

Metallurgy and processing

- 3.5Mtpa mill capacity with conventional flow sheet

- Testwork supports overall recovery of 95%

- P80 grind size of 175 micron and grinding energy of 15.5kwh/t indicating ore is moderately hard

A new plant was envisaged by the study to process 3.5Mtpa of run-of-mine (ROM) ore from the Ikkari open pit and underground at an average grade of 1.82g/t Au (including processing low grade stockpiles towards the end of life of mine). Testwork showed the gold at Ikkari is non-refractory and occurs in the native form or associated with pyrite. The process considered comprises crushing and grinding to reduce the RoM material to a characteristic grind (P80) of 175 microns (µ), and a gravity circuit to recover the native gold. The pyrite associated gold will be recovered by flotation and fed, with the re-pulped concentrate from Pahtavaara, into the leach circuit where lime and cyanide are added in the presence of air to extract the gold. The gold will be then recovered in an adsorption, desorption, and recovery (ADR) circuit. The leach tails will be treated to remove cyanide and filtered for co-disposal with waste rock. The liquor recovered from the filtration is treated prior to re-use. See flowsheet (Figure 4).

The Pahtavaara ROM ore would be processed through a 0.5Mtpa gravity and flotation concentration facility that is envisaged to be expanded to 0.75Mtpa after 7 years of operation. The resulting high-grade concentrate product would be fed in to the Ikkari CIL circuit for gold recovery to dore.

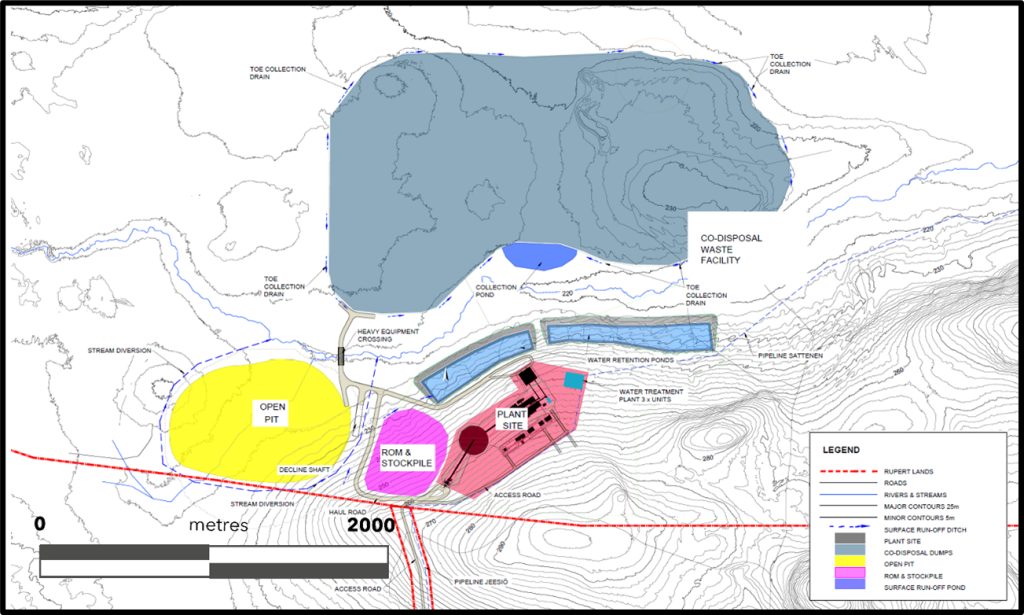

Access and infrastructure

- All infrastructure located on 100% Rupert held property

- Co-disposal of waste rock and tailings

- Access to renewable power

Access

Ikkari is well supported by existing infrastructure and is accessed by tarmac and a 5km gravel road from the towns of Kittilä (50km west) and Sodankylä (40km east) both of which provide support services and labour to two existing mines in the area.

Co-disposal of mine waste and tailings

Mine waste and tailings are planned to be combined and disposed of together to increase physical and chemical stability of the waste. Initial studies suggest that the potential for acid generation could be significantly reduced by the buffering effect on acid solutions by carbonates present in the Ikkari rock and lime in the leach tails. Detailed waste material characterisation studies are underway for optimization of the long-term storage facility design parameters for construction, operation and eventual closure.

Hydrogeology & Water treatment

Initial hydrogeological studies have been undertaken at the Ikkari project site to formulate a management plan. To reduce contact water, surface water flows will be diverted where possible to avoid the open pit, plant site and waste facilities and a series of dewatering bores would be installed to reduce water flows into the mining operation. All water that comes in contact with the operation will be collected in lined storage dam structures and treated in a water treatment facility to remove potential contaminants before discharge via pipelines to nearby water courses. Further hydrogeological studies are being undertaken as part of data collection for future studies.

The plant design envisages water to be recirculated within the plant to minimize water consumption with water recovered from the cyanide destruction filtration to be treated in the water treatment area. Treated water is to be used for the re-pulping of the Pahtavaara concentrate and for reagent make-up. Brine produced by the water treatment plant will be added to the cyanide destruction tailings.

Power

A 220kV power transformer substation is located 9km from Ikkari that can be used as a connection point to the national grid for a 110 kV power line to the Ikkari minesite. A power surplus is envisaged in Lapland towards the end of the decade, with a significant contribution expected from renewables.

Permitting & Stakeholder Engagement

Rupert Resources has been pro-actively engaged in baseline data collection and stakeholder engagement since 2018. The base case PEA presented here is one of three potential development options that will be the subject of the environmental impact assessment program (“EIA Program”) that will be presented to all relevant authorities in the next month and presented for feedback at public meetings expected to occur in early 2023. On completion of the EIA Program work and the planned project Pre-Feasibility Study, the results will be presented in the project Environmental Impact Assessment document that will form the basis on which an environmental permit application is submitted. Rupert has also begun a parallel program of land use planning with the local and regional authorities and has also set up a stakeholder co-operation group that will have the opportunity to comment and give opinions and feedback during the EIA process.

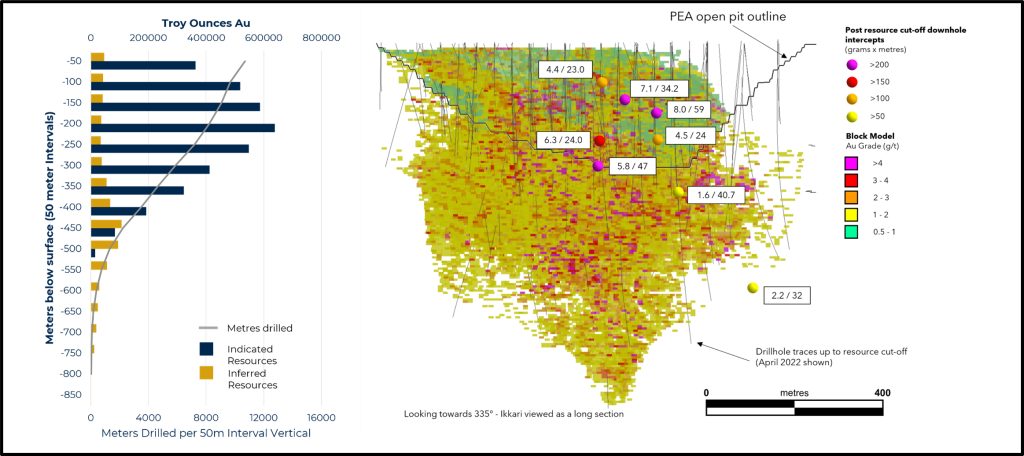

Resource

The updated Ikkari Mineral Resource Estimate is based on 73,000 metres of drilling to April 2022. The Mineral Resource Estimate maintains the 2.5g/t average grade initially reported in the September 2021 maiden Mineral Resource Estimate and upgrades 84% of the resource to the Indicated category. Ikkari’s 100%-owned, mineral resource is now reported to include 46.4 million tonnes (Mt”) at 2.5 grams per tonne gold (“g/t Au”) for 3.68 million Indicated ounces and 11.8 Mt at 1.9 g/t Au for 710,000 Inferred ounces.

The consolidated global resource includes Ikkari, Pahtavaara and a maiden gold Mineral Resource Estimate from Heinä Central. The Heinä Central resource is not included in the PEA mining inventory. Our global consolidated resource now comprises 48.3 Mt at 2.5g/t Au for 3.86 million ounces in the Indicated category and 20Mt at 1.9g/t Au for 1.26 million Inferred ounces (see table 7).

Upside and optimisation

The PEA results provide a high-level initial estimate of the potential economic value of the mineral resources discovered to date. As per the press release dated 19 September, 2022, Rupert’s extensive exploration programmes continue with 72,800m of drilling planned for 2022/23 drill season. 70% of the drilling is allocated for Ikkari and nearby satellites and 30% to regional programmes. The near-term aim is to identify potential mineralisation that should be considered in the next level of engineering study and any future development scenario planning.

Work programmes either already underway or to be completed over the coming year also include condemnation drilling, auger drilling to better define the bedrock-till interface, soil testing, expanded geotechnical data collection for pit slope and underground mine optimisation, waste characterisation testwork, stage 4 metallurgical testwork, stage 2 hydrogeological studies and completion of our third continuous year of extensive environmental surveys.

Table 7. Rupert Lapland Project consolidated resources

| Classification | Target Area | Mining Method |

Cut-off Au (g/t) |

Tonnage (Mt) |

Gold grade | Gold contained | |

| Au (g/t) | Kg | Ounces | |||||

| Indicated | Open Pit | 0.5 | 30,000,000 | 2.5 | 75,000 | 2,400,000 | |

| Ikkari | Underground | 1.0 | 16,500,000 | 2.4 | 40,000 | 1,280,000 | |

| Total | 46,400,000 | 2.5 | 110,000 | 3,680,000 | |||

| Open Pit | 0.5 | 900,000 | 2.2 | 1,900 | 60,000 | ||

| Pahtavaara | Underground | 1.5 | 1,000,000 | 3.7 | 3,700 | 120,000 | |

| Total | 1,900,000 | 3.0 | 5,600 | 180,000 | |||

| Indicated Total | 48,300,000 | 2.5 | 120,000 | 3,860,000 | |||

| Inferred | Open Pit | 0.5 | 3,100,000 | 1.5 | 4,800 | 150,000 | |

| Ikkari | Underground | 1.0 | 8,700,000 | 2.0 | 17,000 | 550,000 | |

| Total | 11,800,000 | 1.9 | 22,000 | 710,000 | |||

| Pahtavaara | Open Pit | 0.5 | 3,700,000 | 1.6 | 5,900 | 190,000 | |

| Underground | 1.5 | 2,200,000 | 3.1 | 6,800 | 220,000 | ||

| Total | 5,900,000 | 2.1 | 13,000 | 410,000 | |||

| Heinä Central (not included in mining inventory) |

Open Pit | 0.5 | 2,200,000 | 1.7 | 3,800 | 120,000 | |

| Underground | 1.2 | 400,000 | 2.1 | 900 | 30,000 | ||

| Total | 2,700,000 | 1.8 | 4,700 | 150,000 | |||

| Inferred Total | 20,400,000 | 1.9 | 39,000 | 1,260,000 | |||

November 2022 Preliminary Economic Assessment and resource estimate for the Ikkari and Pahtavaara Projects.

The Mineral Resource estimate included in the Preliminary Economic Assessment (“Study” or “PEA” is reported according to the classification criteria set out in the Canadian Institute of Mining, Metallurgy, and Petroleum Definition Standards for Mineral Resources and Reserves). These standards are internationally recognized and allow the reader to compare the Mineral Resource with that reported for similar projects. The results of the PEA will be set forth in an independent technical report prepared in accordance with National Instrument 43-101 Standards of Disclosure for Mineral Projects which will be filed on SEDAR under the Company’s profile within 45 days of the date of this news release. Readers are cautioned that the PEA is preliminary in nature and is intended to provide an initial assessment of the project’s economic potential and development options. The PEA mine schedule and economic assessment includes numerous assumptions and is based on both Indicated and Inferred mineral resources. Inferred resources are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves, and there is no certainty that the PEA results will be realized. Mineral resources are not mineral reserves and do not have demonstrated economic viability. Additional exploration will be required to potentially upgrade the classification of the inferred mineral resources to be considered in future advanced studies. The Mineral Resource estimate for the Project is reported in accordance with National Instrument 43-101 and has been estimated using the Canadian Institute of Mining, Metallurgy and Petroleum “Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines”. The Mineral Resource estimates for Ikkari and Pahtavaara were calculated using the multiple indicator kriging method (MIK) and are classified as a combination of Indicated and Inferred as defined by the CIM. The Mineral Resource Estimate for Heinä Central was calculated using ordinary kriging method, and is classified as Inferred as defined by the CIM, and has not been included in the mining inventory. Numbers are affected by rounding. For Pahtavaara, the estimate was reported using cut-offs of 0.5g/t Au for mineralisation potentially mineable by open pit methods and 1.5g/t Au for that portion that is potentially extractable by underground methods, using recoveries of 89%. For Ikkari, the estimate was reported using cut-offs of 0.5g/t Au for mineralisation potentially mineable by open pit methods and 1.0g/t Au for that portion that is potentially extractable by underground methods, using recoveries of 95%. For Heinä Central, the estimate is reported using cut-offs of 0.5g/t Au for mineralisation potentially mineable by open pit methods and 1.2g/t Au for that portion that is potentially extractable by underground methods, using recoveries of 78%. All estimations use a gold price of EUR1650/oz to generate cut-off grades, recoveries as stated and costs derived from PEA estimates. Please see Table 8 for Mineral Resources sensitivity to cut off grade for Ikkari and Pahtavaara.

Table 8a. Ikkari Mineral Resource Estimate Sensitivity Tables

| Classification | Mining Method | Cut-off | Tonnage | Grade | Gold | |

| Au (g/t) | (Mt) | Au (g/t) | Kg | Ounces | ||

| Indicated | Open Pit | 0.3 | 33 300 000 | 2.3 | 75 900 | 2 440 000 |

| 0.4 | 31 700 000 | 2.4 | 75 300 | 2 420 000 | ||

| 0.5 | 30 000 000 | 2.5 | 74 500 | 2 400 000 | ||

| 0.6 | 28 100 000 | 2.6 | 73 500 | 2 360 000 | ||

| 0.7 | 26 400 000 | 2.7 | 72 400 | 2 330 000 | ||

| Underground | 0.6 | 24 700 000 | 1.9 | 46 200 | 1 490 000 | |

| 0.8 | 19 900 000 | 2.2 | 42 900 | 1 380 000 | ||

| 1 | 16 500 000 | 2.4 | 39 800 | 1 280 000 | ||

| 1.2 | 13 900 000 | 2.7 | 37 000 | 1 190 000 | ||

| Inferred | Open Pit | 0.3 | 3 900 000 | 1.3 | 5 100 | 160 000 |

| 0.4 | 3 500 000 | 1.4 | 5 000 | 160 000 | ||

| 0.5 | 3 100 000 | 1.5 | 4 800 | 150 000 | ||

| 0.6 | 2 700 000 | 1.7 | 4 600 | 150 000 | ||

| 0.7 | 2 400 000 | 1.8 | 4 300 | 140 000 | ||

| Underground | 0.6 | 14 900 000 | 1.5 | 22 000 | 710 000 | |

| 0.8 | 11 100 000 | 1.7 | 19 300 | 620 000 | ||

| 1 | 8 700 000 | 2 | 17 200 | 550 000 | ||

| 1.2 | 6 800 000 | 2.2 | 15 100 | 490 000 | ||

Table 8b. Pahtavaara Mineral Resource Estimate Sensitivity Table

| Classification | Mining Method | Cut-off | Tonnage | Grade | Gold | |

| Au (g/t) | (Mt) | Au (g/t) | Kg | Ounces | ||

| Indicated | Open Pit | 0.3 | 1 100 000 | 1.8 | 2 000 | 64 000 |

| 0.4 | 1 000 000 | 2 | 2 000 | 63 000 | ||

| 0.5 | 900 000 | 2.2 | 1 900 | 62 000 | ||

| 0.6 | 800 000 | 2.3 | 1 900 | 60 000 | ||

| 0.7 | 700 000 | 2.5 | 1 800 | 59 000 | ||

| Underground | 1 | 1 500 000 | 2.8 | 4 400 | 140 000 | |

| 1.5 | 1 000 000 | 3.7 | 3 700 | 120 000 | ||

| 2 | 700 000 | 4.6 | 3 200 | 100 000 | ||

| 2.5 | 500 000 | 5.5 | 2 800 | 90 000 | ||

| Inferred | Open Pit | 0.3 | 4 700 000 | 1.3 | 6 300 | 200 000 |

| 0.4 | 4 200 000 | 1.5 | 6 100 | 200 000 | ||

| 0.5 | 3 700 000 | 1.6 | 5 900 | 190 000 | ||

| 0.6 | 3 300 000 | 1.7 | 5 700 | 180 000 | ||

| 0.7 | 3 000 000 | 1.8 | 5 500 | 180 000 | ||

| Underground | 1 | 3 900 000 | 2.3 | 8 900 | 290 000 | |

| 1.5 | 2 200 000 | 3.1 | 6 800 | 220 000 | ||

| 2 | 1 400 000 | 3.9 | 5 400 | 170 000 | ||

| 2.5 | 900 000 | 4.8 | 4 400 | 140 000 | ||

Qualified Person Statement

The PEA was prepared by Tetra Tech for Rupert Resources. The study was managed by EUR ING Andrew Carter BSc, CEng, MIMMM, MSAIMM, SME Technical Director Coffey Geotechnics Ltd – A Tetra Tech Company, who is a Qualified Person under National Instrument 43-101 and has reviewed and approved the scientific and technical information in this press release. TetraTech have prepared the PEA according to AACE International Recommended Practice No. 18R-97 to a Class 4 cost estimate classification. The Mineral Resource estimates used as a basis for the PEA were prepared by Brian Wolfe, Principal Consultant, International Resource Solutions Pty Ltd., an independent qualified person under NI 43-101. Dr Matthew Randall, BSc, PhD, CEng, MIMMM, Director and Principal Mining Engineer for Axe Valley Mining Consultants Ltd is the qualified person for the mining components of the report. Dr Charlie Seabrook, MAIG, RPGeo. Exploration Manager, is the Qualified Person who supervised the preparation of the scientific and technical disclosure in this news release on behalf of Rupert Resources.

About Rupert Resources

Rupert Resources is a gold exploration and development company listed on the TSX Venture Exchange. The Company is focused on making and advancing discoveries of scale and quality with high margin and low environmental impact potential. The Company’s principal focus is Ikkari, a new high quality gold discovery in Northern Finland. Ikkari is part of the Company’s “Rupert Lapland Project,” which also includes the Pahtavaara gold mine, mill, and exploration permits and concessions located in the Central Lapland Greenstone Belt of Northern Finland. The Company also holds a 100% interest in the Surf Inlet Property in British Columbia, a 100% interest in properties in Central Finland and a 20% carried participating interest in the Gold Centre property located adjacent to the Red Lake mine in Ontario.

About Tetra Tech

Tetra Tech is a leading provider of high-end consulting and engineering services for projects globally. With 21,000 associates and 450 offices worldwide, Tetra Tech provides clear solutions to complex problems in water, environment, infrastructure, resource management, energy, and international development. For more information about Tetra Tech, please visit www.tetratech.com

Figure 1. Project production profile (Graphic: Business Wire)

Figure 2. Project model after tax cash flow (Graphic: Business Wire)

Figure 3. Ikkari mine – open pit stages and underground mining infrastructure (Graphic: Business Wire)

Figure 4. Ikkari flowsheet (Graphic: Business Wire)

Figure 5. Ikkari site layout (Graphic: Business Wire)

Figure 6. Ikkari block model, gold yield and drill density (Graphic: Business Wire)

MORE or "UNCATEGORIZED"

Delta Reports New Gold Intercept at Nova Target in Wedge Area, 4 Kilometres West of Eureka; Follow-Up Drill Program Underway

Delta Reports New Gold Intercept at Nova Target in Wedge Area, 4 ... READ MORE

Silver One Announces Closing Of Final Tranche Of $32 Million Financing

Silver One Resources Inc. (TSX-V: SVE) (OTCQX: SLVRF) (FSE: BRK1)... READ MORE

SAGA Metals Achieves 100% Drilling Success in 2025—Reports Final Assays from Trapper South at Radar Critical Minerals Project in Labrador

Exceptional grades of Titanium, Vanadium and Iron in all 15 drill... READ MORE

Near Surface Intersection Yields 6.58 g/t gold over 10.35 metres

Intersection is within 33 metres from surface and contained in a ... READ MORE

Alamos Gold Provides Three-Year Operating Guidance Outlining 46% Production Growth by 2028 at Significantly Lower Costs

Further production growth to one million ounces annually expected... READ MORE